Beruflich Dokumente

Kultur Dokumente

Spur Gear Design1

Hochgeladen von

simalaraviCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Spur Gear Design1

Hochgeladen von

simalaraviCopyright:

Verfügbare Formate

Module 2 - GEARS Lecture 1 - INTRODUCTION Contents 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.

9 History of gears Definition of gears Types of gears and their applications. Spur Gear Helical Gear Double helical or Herringbone Gear Internal Gear Rack and pinion Bevel Gear (a) Straight (b) Spiral (c) hypoid 1.10 Crossed helical gear 1.11 Law of gearing 1.12 Gear profiles 1.13 Meshing of gears 1.1 HISTORY OF GEARS Indian history as per our mythological stories is more than 12,000 years old. Since then people living here have been striving to improve the living conditions. We also know that earlier people were living in the caves and the doors of the caves were made of granite. How were these heavy doors opened and closed? They were opened and closed by none other than a system with gear mechanism, wheel, lever and rope drives. However, the documented evidence has been lost due to destruction by the invaders and improper storing of palm leaf literature. The guru Kula method of teaching and passing of the information from mouth to ear procedure and keeping some of the advances as closely guarded secret have resulted in poor dissemination of the knowledge and documentation. But, the knowledge of gears has gone from India to east through some of the globe trotters from China as back as 2600 years BC. They have used the gears then ingeniously in chariots for measuring the speed and other mechanisms. Primitive gears shown in Fig. 1 were first used in door drive mechanism in temples and caves, and water lifting mechanisms 2600 B.C. in India and elsewhere.

Aristotle in the fourth century B.C. mentions in his writings that gears were being used very commonly in many applications. Classical origin of worm gearing was made by Archimedes 287-212 B.C. Vitruvius a military engineer in his writing in 28 B.C. has described a number of gear applications, typical ones are shown in Figs. 1.2 and 1.3.

Fig.1.1 Primitive gears made of wood

Fig.1.2 Water wheel and grain mill described by Vitruvius 40 B.C

Fig.1.3 Schematic diagram of an odometer for a carriage described by Vitruvius 28 BC Leonard da Vinci used multitudes of gears in various mechanisms developed by him 500 A.D. Greek and Roman literatures show extensive usage of gears for forward motion. Toothed gears used for the clocks of Cathedrals and other ecclesiastical buildings during the middle ages are still preserved in many places. Salisbury cathedral still possesses the oldest clock in England made in 1386. The Wells Cathedral clock made in 1392 is preserved in Science museum, South Kensington. Though the iron gears have worn out to some extent, they still keep good timings. German artist Albrecht Durers engravings show a vehicle designed for the Emperor Maximilian I during 15th century which is shown in Fig.1.4. That vehicle was driven by worm gears on all four wheels. This clearly shows that he knew the concept of gearing which helped him in sketching them accurately. In 18th century, Industrial Revolution in England led to usage of cycloidal gears for clocks, irrigation devices, water mills and Fig.1.4 Chariot using worm gears

powered machines. Fig. 1.5 gives the glimpses of their contribution to engine application. The industrialization of west made a big impact on gear technology which is the key to the modern development and the gear technology is advancing rapidly. It is most unlikely that gears are going to be replaced by any other component for their function in the near future.

Fig.1.5 Schematic diagram of Watts rotating Engine, 1784, first engine to produce power directly on a shaft 1.2 DEFINITION OF GEARS Gears are toothed members which transmit power / motion between two shafts by meshing without any slip. Hence, gear drives are also called positive drives. In any pair of gears, the smaller one is called pinion and the larger one is called gear immaterial of which is driving the other. When pinion is the driver, it results in step down drive in which the output speed decreases and the torque increases. On the other hand, when the gear is the driver, it results in step up drive in which the output speed increases and the torque decreases.

1.3 CLASSIFICATION OF GEARS Gears are classified according to the shape of the tooth pair and disposition into spur, helical, double helical, straight bevel, spiral bevel and hypoid bevel, worm and spiral gears and this is shown in Fig. 1.6

(i)

(j)

Fig. 1.6 (a) Spur gear, (b) helical gear, (c) Double helical gear or herringbone gear, (d) Internal gear , (e) Rack and pinion, (f) Straight bevel gear, (g) Spiral bevel gear, (h) Hypoid bevel gear ,

(i) worm gear and (j) Spiral gear

1.4 SPUR GEARS

Fig.1.7 Spur Gear

Fig.1.8 Gearbox of a motor cycle using spur gears

Spur gears have their teeth parallel to the axis Fig.1.7 and are used for transmitting power between two parallel shafts. They are simple in construction, easy to manufacture and cost less. They have highest efficiency and excellent precision rating. They are used in high speed and high load application in all types of trains and a wide range of velocity ratios. Hence, they find wide applications right from clocks, household gadgets, motor cycles, automobiles, and railways to aircrafts. One such application is shown in Fig.1.8. 1.5 HELICAL GEARS

Fig.1.9 Helical Gear

Fig.1.10 Automatic transmission of an automobile

Helical gears are used for parallel shaft drives. They have teeth inclined to the axis as shown in Fig. 1.9. Hence for the same width, their teeth are longer than spur gears and have higher load carrying capacity. Their contact ratio is higher than spur gears and they operate smoother and quieter than spur gears. Their precision rating is good. They are recommended for very high speeds and loads. Thus, these gears find wide applications in automotive gearboxes as illustrated in Fig. 1.10. Their efficiency is slightly lower than spur gears. The helix angle also introduces axial thrust on the shaft.

1.6 DOUBLE HELICAL GEAR OR HERRINGBONE GEAR Double helical or Herringbone gears used for transmitting power between two parallel shafts. They have opposing helical teeth with or without a gap depending on the manufacturing method adopted, Fig. 1.11. Two axial thrusts oppose each other and nullify. Hence the shaft is free from any axial force. Though their load capacity is very high, manufacturing difficulty makes them costlier than single helical gear. Their applications are limited to high capacity reduction drives like that of cement mills and crushers, one such application is exhibited in Fig. 1.12.

Fig. 1.11 Double Helical Gear or Herringbone Gear

Fig. 1.12 Reduction gearbox of cement mill

1.7. INTERNAL GEAR Internal gears are used for transmitting power between two parallel shafts. In these gears, annular wheels are having teeth on the inner periphery. This makes the drive very compact Fig.1.13. In these drives, the meshing pinion and annular gear are running in the same direction

Fig.1.13.Internal Gear

A. flywheel B. torque divider C. torque converter D. rear transmission brakes a. input shaft

b. intermediate shaft c. output brake d. divider brake e. rear transmission f. free wheel

Fig. 1.14 Diwabus transmission (Voith) with internal gears Their precision rating is fair. They are useful for high load and high speed application with high reduction ratio. Applications of these gears can be seen in planetary gear drives of automobile automatic transmissions-Fig.1.14, reduction gearboxes of cement mills, step-up drives of wind mills. They are not recommended for precision meshes because of design, fabrication, and inspection limitations. They should only be used when internal feature is necessary. However, today precision machining capability has led to their usage even in position devices like antenna drives. 1.8 Rack and Pinion Rack is a segment of a gear of infinite diameter. The tooth can be spur as in Fig. 1.15 or helical as in Fig.1.16. This type of gearing is used for converting rotary motion into translatory motion or visa versa. Typical example of rack and pinion applications are shown in Figs. 1.17 and 1.18.

Fig .1.15 Spur tooth rack and pinion

Fig. 1.16 Helical tooth rack and pinion

Fig.1.17 Lathe carriage drive mechanism showing rack and pinion arrangement.

Fig.1.18 Radial drilling machine spindle movement with rack and pinion arrangement

1.9a STRAIGHT BEVEL GEAR Straight bevel gears are used for transmitting power between intersecting shafts, Fig. 1.19. They can operate under high speeds and high loads. Their precision rating is fair to good. They are suitable for 1:1 and higher velocity ratios and for right-angle meshes to any other angles. Their good choice is for right angle drive of particularly low ratios. However, complicated both form and fabrication limits achievement of precision. They should be located at one of the less critical meshes of the train. Wide application of the straight bevel drives is in automotive differentials, right angle drives of blenders and conveyors. A typical application of straight bevel used in differential application is shown in Fig.1.20.

Fig.1.19 Straight Bevel Gear

Fig. 1.20 Differential of an automobile

1.9b SPIRAL BEVEL GEAR Spiral bevel gears shown in Fig. 1.21 are also used for transmitting power between intersecting shafts. Because of the spiral tooth, the contact length is more and contact ratio is more. They operate smoother than straight bevel gears and have higher load capacity. But, their efficiency is slightly lower than straight bevel gear. Usage of spiral bevel gears in an automobile differential is shown Fig.1.22.

Fig.1.21 Spiral Bevel Gear

Fig.1.22 Crown and Pinion of final drive of an automobile

1.9c HYPOID BEVEL GEAR

Fig.1.23 Hypoid Bevel Gear

Fig.1.24 Crown and Pinion of final drive of an automobile

These gears are also used for right angle drive in which the axes do not intersect. This permits the lowering of the pinion axis which is an added advantage in automobile in avoiding hump inside the automobile drive line power transmission. However, the non intersection introduces a considerable amount of sliding and the drive requires good lubrication to reduce the friction and wear. Their efficiency is lower than other two types of bevel gears. These gears are widely used in current day automobile drive line power transmission. 1.9. WORM GEAR Worm and worm gear pair consists of a worm, which is very similar to a screw and a worm gear, which is a helical gear as shown in Fig. 1.25. They are used in right-angle skew shafts. In these gears, the engagement occurs without any shock. The sliding action prevalent in the system while resulting in quieter operation produces considerable frictional heat. High reduction ratios 8 to 400 are possible.

Efficiency of these gears is low anywhere from 90% to 40 %. Higher speed ratio gears are non-reversible. Their precision rating is fair to good. They need good lubrication for heat dissipation and for improving the efficiency. The drives are very compact.

Fig.1.25 Worm Gear

Fig. 1.26 Worm gearbox of a crane drive

Worm gearing finds wide application in material handling and transportation machinery, machine tools, automobiles etc. An industrial worm gear box used for converting horizontal to vertical drive is shown in Fig. 1.26.

1.10 Spiral Gear

Spiral gears are also known as crossed helical gears, Fig. 1.27. They have high helix angle and transmit power between two non-intersecting non-parallel shafts. They have initially point contact under the conditions of considerable sliding velocities finally gears will have line contact. Hence, they are used for light load and low speed application such as instruments, sewing machine etc. Their precision rating is poor. An application of spiral gear used in textile machinery is shown in Fig. 1.28.

Fig 1.27 Spiral Gear

Fig. 1.28 Application of spiral gear in a textile machinery

TABLE 1 SUMMARY AND EVALUATION OF GEAR TYPES

Type Spur Features and Precision Rating Parallel Shafting. High speeds and loads highest efficiency Precision Rating is excellent Applications Applicable to all types of trains and a wide range of velocity ratios. Comments Regarding Precision Simplest tooth elements offering maximum precision. First choice, recommended for all the gear meshes, except where very high speeds and loads or special features of other types, such as right angle drive, cannot be avoided. Equivalent quality to spurs, except for complication of helix angle. Recommended for all high-speed and high-load meshes. Axial thrust component must be accommodated. To be avoided for precision meshes. Point contact limits capacity and precision. Suitable for right angle drives, if light load. A less expensive substitute for bevel gears. Good lubrication essential because of point of contact and high sliding action. Not recommended for precision meshes because of design, fabrication, and inspection limitations. Should only be used when internal feature is necessary.

Helical

Parallel Shafting. Very high Most applicable to speeds and loads. Efficiency high speeds and slightly less than spur mesh. loads; also used whenever spurs are Precision Rating is good used. Relatively low velocity ratio; low speeds and light loads only. Any angle skew shafts.

Crossed Skewed shafting. Point Helical contact. High sliding Low speeds Light loads Precision Rating is poor Internal Parallel shafts spur High speeds High loads Precision Rating is fair

Bevel

Intersecting shafts, High speeds, High loads. Precision Rating is fair to good Right-angle skew shafts, High velocity ratio, High speeds and loads, Low efficiency, Most designs nonreversible. Precision rating is fair to good

Internal drives requiring high speeds and high loads; offers low sliding and high stress loading; good for high capacity, long life. Used in planetary gears to produce large reduction ratios. Suitable for 1:1 and higher velocity ratios and for rightangle meshes (and other angles) High velocity ratio Angular meshes High loads

Worm mesh

Good choice for right angle drive, particularly low ratios. However complicated both form and fabrication limits achievement of precision. Should be located at one of the less critical meshes of the train. Worm can be made to high precision, but worm gear has inherent limitations. To be considered for average precision meshes, but can be of high precision with care. Best choice for combination high velocity ratio and right-angle drive. High sliding requires excellent lubrication.

Table is continued in the next page

(Continued) TABLE 1 SUMMARY AND EVALUATION OF GEAR TYPES

Type Specials - Face, Spiroid, Helicon, Beveloid Features and Precision Rating Intersecting and skew shafts. Modest speeds and loads. Precision Rating is fair to good Applications Special cases Comments Regarding Precision To be avoided as precision meshes. Significant non-conjugate action with departure from nominal center distance and shaft angles. Fabrication needs special equipment and inspection is limited.

1.11 LAW OF GEARING The fundamental law of gearing states that the angular velocity ratio between the gears of a gear set must remain constant throughout the mesh. This amounts to the following relationship:

1 n d Z 1 2 2 n 2 d1 Z1 2

(1.1)

where the terminology for the above is as follows:

Fig.1.29 Two spur gears in mesh

In order to maintain constant angular velocity ratio between two meshing gears, the common normal of the tooth profiles, at all contact points with in mesh, must always pass through a fixed point on the line of centers, called pitch point. 1.12 PROFILES SATISFYING LAW OF GEARS Profiles which can satisfy the law of gearing are shown in Fig. 1.22 a to c. These are (a) involute (b) cycloidal and (c) circular arc or Novikov. Among these, cycloidal was the first to be evolved. This is followed by the invention of involute profile which replaced many of the other profiles due to several technological advantages. Circular arc or Novikov

profile has some advantages over the other profiles. But due to manufacturing difficulties, it did not become popular. However with powder metallurgy process it is slowly getting into industry now for specific application.

(a)

(b)

(c)

Fig. 1.22 Profiles satisfying the law of gearing, (a) involute (b) cycloidal and (c) Circular arc

1.12a Involute Gear Tooth Profile Involute is the path generated by the end of a thread as it unwinds from a reel. In order to understand what is involute, imagine a reel with thread wound in the clockwise direction as in Fig.1.2. Tie a knot at the end of the thread. In the initial position, the thread is at B0 with knot on the reel at C0. Keeping the reel stationary, pull the thread and unwind it to position B1. The knot now moves from C0 to C1. If the thread is unwound to position B2 the knot moves to C2 position. In repeated unwinding, the taut thread occupies position B3, B4 while the knot moves to C3, C4 positions. Connect these points C0 to C4 by a smooth curve, the profile obtained is nothing but an involute, the illustration of which is given below.

This forms the left side part of the tooth profile. If similar process is repeated with thread wound on the reel in anticlockwise direction in the same position, it forms the right side part of the same tooth. The completely formed involute tooth is shown in Fig.1.25.

Fig.1.23 The generation of involute Fig.1.24 The generation of involute profile on left side profile on right side

Involute profiles have special properties. Imagine two involute teeth in contact as shown in Fig.1.26. If a normal is drawn at the contact point to the involute profile, it will be tangent to the generating circles. This can be visualized better from Fig. 1.23 where the taut thread is normal to the profile as well as tangent to the reel which forms the generating or the base circle. The profile will be involute above the base circle only. Below the base circle the profile will not be involute.

The common normal to the profile at the contact point will be tangent to the base circles. It passes through a fixed point lying at the intersection of the tangent to the rolling/pitch circles and the line connecting the centres of the gear wheels. This point is known as the pitch point. As the gears rotate the contact point travels along the common tangent to the base circle. Hence this line is also known as the line of action. The movement of the contact point along the line of action can be seen in the gear meshing later on.

Fig.1.25 Involute gear tooth profile appearance after generation

Fig. 1.26 Gear meshing

Advantages of Involute Gears 1. Variation in centre distance does not affect the velocity ratio. 2. Pressure angle remains constant throughout the engagements which results in smooth running. 3. Straight teeth of basic rack for involute admit simple tools. Hence, manufacturing becomes simple and cheap.

1.12b Cycloidal Gear Tooth Profile Cycloid is the locus of a point on the circumference of a circle when it rolls on a straight line without slipping. If the circle rolls on the outside of another circle or inside of another circle gives rise to epicycloid and hypocycloid respectively. This is illustrated in Fig. 1.27. The profile of a cycloidal tooth consists of two separate curves or double curvature. This tooth form also satisfies the law of gearing or conjugate action similar to an involute gear.

Fig.1.27 Figure illustrating the generation of cycloidal tooth

Fig.1.28 Cycloidal tooth form

Fig.1.29 Cycloidal gear of a clock.

Advantages of Cycloidal Gears 1. Cycloidal gears do not have interference. 2. Cycloidal tooth is generally stronger than an involute tooth owing to spreading flanks in contrast to the radial flanks of an involute tooth. 3. Because of the spreading flanks, they have high strength and compact drives are achievable. 4. Cycloidal teeth have longer life since the contact is mostly rolling which results in low wear. Disadvantages of Cycloidal Gears 1. For a pair of Cycloidal gears, there is only one theoretically correct center distance for which a constant angular-velocity ratio is possible. 2. The hob of Cycloidal gear has curved teeth unlike involute rack teeth. Hence hob manufacture is difficult and costly. 3. Cycloidal gear will cost more. Applications of Cycloidal Gears 1. Cycloidal gears are extensively used in watches, Clocks - Fig.1.30, and instruments where strength and interference are prime considerations. 2. Cast bull gears of paper mill machinery. 3. Crusher drives in sugar mills.

Fig. 1.30 Application of cycloidal tooth gear in a clock mechanism

1.12c Novikov, Wildhaber or Circular Arc Tooth Profile

Fig.1.31 Transverse section of Novikov gear

Fig.1.32 Novikov gears in mesh

The Novikov gears are having circular tooth surfaces in the transverse section Fig. 1.31. Normally pinion has a convex tooth profile and the gear tooth has a concave tooth profile. They can also have concave profile for pinion and convex profile for the gear or convex profiles for both. The teeth of Novikov gears have point contact in mesh. Hence to increase the contact ratio the teeth are made helical and appearance of Novikov gear is shown in Fig.1.32. The height of a Novikov gear tooth is about half that of the corresponding an involute tooth of the same module. Hence these teeth can with stand high load with weight of the gears approximately half the size of involute gears. Since these gears are having pure rolling action at the contact, their efficiency is as high as 99.5%. Novikov gear also satisfies the law of gearing since the common normal to the gears at the point of contact will always be passing through a fixed point, viz., pitch point as illustrated in Fig. 1.31 and in more detail in Fig. 1.33. Hence these profiles are conjugate to each other and pressure angle remains constant

Fig.1.33 Enlarged view of Novikov gears in mesh in transverse section

Advantages of Novikov Gears 1. A convex surface is always in contact with another concave surface. 2. The beam strength is much higher for the pinion than for the gear when the gear is much larger than the pinion. 3. The contacting teeth have rolling action and hence wear is less. 4. If the convex profile is on the pinion teeth, and within the practical limits, the radii are close to the same value to provide the maximum possible wear strength. Disadvantages of Novikov Gears 1. The circular-arc profiles are not conjugate and consequently, in a plane each tooth can make contact at only one point in each revolution. 2. The circular-arc gears are very sensitive to variations in center distances and are hence best suited for slow-speed operation. 3. For the circular-arc gears in a plane, the contact ratio is zero. Hence, the circular-arc teeth cannot be used on spur gears but must be used on helical gears, where the contact ratio for the gear can be made greater than 1.0 by providing overlap ratio.

Applications of Novikov or Circular Arc Gears

Fig 1.34 Slow speed Gear boxes

1.13 MESHING OF GEARS In order to have a more understanding of the conjugate action in gears and how the point of contact moves during the mesh, an illustration is provided in flash

----------------

Das könnte Ihnen auch gefallen

- History of GearsDokument12 SeitenHistory of GearsmorolosusNoch keine Bewertungen

- Gear Notes 1Dokument14 SeitenGear Notes 1Viswatej ChoudaryNoch keine Bewertungen

- Introduction To GearsDokument30 SeitenIntroduction To GearsPrakash Joshi100% (5)

- Mass College ProjectDokument68 SeitenMass College ProjectGLOBAL INFO-TECH KUMBAKONAMNoch keine Bewertungen

- Power Transmitting ElementsDokument20 SeitenPower Transmitting ElementsAsma Khan100% (1)

- Gearbox 210509074427Dokument59 SeitenGearbox 210509074427mussietilahungessesseNoch keine Bewertungen

- Chain Drives and V BeltsDokument6 SeitenChain Drives and V BeltsNiño PerezNoch keine Bewertungen

- Gear Technology Term Paper BreakdownDokument25 SeitenGear Technology Term Paper BreakdownRoopak GoyalNoch keine Bewertungen

- Pour Principles of Mechanics. Belt, Chain, Rope, Foot Treadle andDokument5 SeitenPour Principles of Mechanics. Belt, Chain, Rope, Foot Treadle andPrasanna GopalrathinamNoch keine Bewertungen

- Mechanical principles and drivesDokument5 SeitenMechanical principles and drivesRobinson GarciaNoch keine Bewertungen

- Gear Chikuku 1Dokument37 SeitenGear Chikuku 1Kelvin Kindice MapurisaNoch keine Bewertungen

- YDf M.design ProjectDokument16 SeitenYDf M.design ProjectyamdebrihanNoch keine Bewertungen

- Tutorial 3 Josephine Bakewa IDDokument10 SeitenTutorial 3 Josephine Bakewa IDJosephine BakewaNoch keine Bewertungen

- Different Types of Gears: Mr. Krunal M. More Mr. Glen J. Dixon Mr. Sujal K. Ingale Mr. Atharva TamoreDokument11 SeitenDifferent Types of Gears: Mr. Krunal M. More Mr. Glen J. Dixon Mr. Sujal K. Ingale Mr. Atharva Tamorerajeshrimore67Noch keine Bewertungen

- Bevel Gear Project ReportDokument22 SeitenBevel Gear Project ReportAnkit BurnwalNoch keine Bewertungen

- Main Shaft of Two Wheerls Modelling and AnalysisDokument42 SeitenMain Shaft of Two Wheerls Modelling and AnalysisAVINASHNoch keine Bewertungen

- Abdul Bari (Dome)Dokument83 SeitenAbdul Bari (Dome)A.F. MominNoch keine Bewertungen

- Chapter 2-Gear SystemDokument26 SeitenChapter 2-Gear SystemNui Yuhu KuwNoch keine Bewertungen

- Design Project Spur GearDokument5 SeitenDesign Project Spur GearAbel BatuNoch keine Bewertungen

- GEARSDokument39 SeitenGEARSGrezy MagnoNoch keine Bewertungen

- Gear Guide1Dokument57 SeitenGear Guide1dedemuamariskandar88Noch keine Bewertungen

- A Mini Project Report ON Study and Sectional Working Model of Deferential Gear BoxDokument17 SeitenA Mini Project Report ON Study and Sectional Working Model of Deferential Gear BoxRitesh YadavNoch keine Bewertungen

- Kassahun Tadess GeerboxDokument16 SeitenKassahun Tadess Geerboxabubekery61Noch keine Bewertungen

- Other Mechanisms: Looking For GATE Preparation Material? Join & Get Here Now!Dokument7 SeitenOther Mechanisms: Looking For GATE Preparation Material? Join & Get Here Now!Akash SoniNoch keine Bewertungen

- Fabrication of A Bicycle Without A ChainDokument6 SeitenFabrication of A Bicycle Without A ChainFranklin Delano JuniorNoch keine Bewertungen

- GearDokument30 SeitenGearsai babuNoch keine Bewertungen

- GEARS: AN OVERVIEW OF COMMON GEAR TYPESDokument18 SeitenGEARS: AN OVERVIEW OF COMMON GEAR TYPESVasudev GuptaNoch keine Bewertungen

- Lab 1Dokument8 SeitenLab 1Mansoob BukhariNoch keine Bewertungen

- Mechanical ActuatorsDokument39 SeitenMechanical ActuatorsKashif UsmanNoch keine Bewertungen

- R.M. Van Druten, P.G. Van Tilborg, P.C.J.N. Rosielle, M.J.W. SchoutenDokument6 SeitenR.M. Van Druten, P.G. Van Tilborg, P.C.J.N. Rosielle, M.J.W. SchoutenAjay ChandranNoch keine Bewertungen

- Mechanisms Notes 2012Dokument12 SeitenMechanisms Notes 2012kookwfNoch keine Bewertungen

- Unit No. 1 Toothed Gearing: MR - KHARAGE A.B. (Asst. Prof.)Dokument37 SeitenUnit No. 1 Toothed Gearing: MR - KHARAGE A.B. (Asst. Prof.)Viraj BabarNoch keine Bewertungen

- Rocker Arm-Final ReportDokument48 SeitenRocker Arm-Final ReportKarthi Keyan0% (1)

- Chapter 4. Gear Train: Engr. Jonathan S. RodolfoDokument15 SeitenChapter 4. Gear Train: Engr. Jonathan S. Rodolfojoshua alhambraNoch keine Bewertungen

- Design of a Two-Stage GearboxDokument131 SeitenDesign of a Two-Stage Gearboxnigusu sisayNoch keine Bewertungen

- A On Selection of Gearbox For Epicycle Gear Train: PresentationDokument15 SeitenA On Selection of Gearbox For Epicycle Gear Train: PresentationPavs PavaniNoch keine Bewertungen

- Bme - Part 2Dokument44 SeitenBme - Part 2Sumanth ChallaNoch keine Bewertungen

- Gear MechanismsDokument4 SeitenGear MechanismsNaftali OmuhandeNoch keine Bewertungen

- Gearless Transmission: College of Engineering &technology Ghatikia, Bhubaneswar, Odisha - 751003, IndiaDokument32 SeitenGearless Transmission: College of Engineering &technology Ghatikia, Bhubaneswar, Odisha - 751003, IndiahiteshNoch keine Bewertungen

- Everything You Need to Know About GearsDokument55 SeitenEverything You Need to Know About GearsSumit SumanNoch keine Bewertungen

- Chapter 2: W/R Contact Geometry: 1. Fundamentals of Rail Vehicle Dynamics, by A.H. Wickens, Loughborough UniversityDokument50 SeitenChapter 2: W/R Contact Geometry: 1. Fundamentals of Rail Vehicle Dynamics, by A.H. Wickens, Loughborough UniversityAbel TeclayNoch keine Bewertungen

- Gearless Power Transmission For Skew Shafts (A SRRS Mechanism)Dokument12 SeitenGearless Power Transmission For Skew Shafts (A SRRS Mechanism)चन्दनप्रसादNoch keine Bewertungen

- Design Calculation of Propeller Shaft (Landcruiser) : Abstract - The Power Transmission System Is The GreatestDokument5 SeitenDesign Calculation of Propeller Shaft (Landcruiser) : Abstract - The Power Transmission System Is The GreatestDr. Aung Ko Latt100% (1)

- Study of Power Transmission DevicesDokument11 SeitenStudy of Power Transmission Devices01parthNoch keine Bewertungen

- Ars and CamsDokument85 SeitenArs and CamsHariharan MNoch keine Bewertungen

- Chapter - 1Dokument34 SeitenChapter - 1Yuva RajNoch keine Bewertungen

- Gear TypeDokument7 SeitenGear Typetajju_121Noch keine Bewertungen

- Machine Design & CAD Lecture on GearsDokument30 SeitenMachine Design & CAD Lecture on GearsAhmed zia tahirNoch keine Bewertungen

- Basics of Automobile 2Dokument51 SeitenBasics of Automobile 2Amit SinghNoch keine Bewertungen

- MD E-Note 22092018 125841PM PDFDokument175 SeitenMD E-Note 22092018 125841PM PDFPramod DhaigudeNoch keine Bewertungen

- Spur gear types and applicationsDokument4 SeitenSpur gear types and applicationsMarnelNoch keine Bewertungen

- Me III II DMM II LnotesDokument33 SeitenMe III II DMM II LnotesChandu MallamNoch keine Bewertungen

- 1.introduction To Carriage Workshop LallagudaDokument28 Seiten1.introduction To Carriage Workshop Lallagudavenkatesh naniNoch keine Bewertungen

- Gear Less Transmission System PDFDokument20 SeitenGear Less Transmission System PDFAbhijeet MoreNoch keine Bewertungen

- CHP 3 Power Transmission GEARSDokument18 SeitenCHP 3 Power Transmission GEARSabinmwangiNoch keine Bewertungen

- Epicyclic Gear Train and Worm Wheel Reducer (1) ..Dokument12 SeitenEpicyclic Gear Train and Worm Wheel Reducer (1) ..22r237Noch keine Bewertungen

- Bda20303 Chapter 1-Gear SystemDokument27 SeitenBda20303 Chapter 1-Gear SystemWan SamiraNoch keine Bewertungen

- Gearless Transmission Project ReportDokument32 SeitenGearless Transmission Project ReportHarish Kumar73% (22)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheVon EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsVon EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNoch keine Bewertungen

- Course Title Geometric Dimensioning and Tolerancing Course Code MD213Dokument3 SeitenCourse Title Geometric Dimensioning and Tolerancing Course Code MD213simalaraviNoch keine Bewertungen

- Dimensional Analysis GD&T Syllabus PDFDokument4 SeitenDimensional Analysis GD&T Syllabus PDFsimalaraviNoch keine Bewertungen

- GDandTfor 6sigma DesignDokument39 SeitenGDandTfor 6sigma DesignTommyCasillas-GerenaNoch keine Bewertungen

- BhagavatamDokument558 SeitenBhagavatamSarmaBvr100% (1)

- Fatigue Analysis PDFDokument6 SeitenFatigue Analysis PDFPallavit NigamNoch keine Bewertungen

- 1-1 R15 Syllabus PDFDokument22 Seiten1-1 R15 Syllabus PDFAshok ReddyNoch keine Bewertungen

- Design, Analysis and Manufacturing of Hydro-Pneumatic Press MachineDokument9 SeitenDesign, Analysis and Manufacturing of Hydro-Pneumatic Press MachineInternational Journal of computational Engineering research (IJCER)Noch keine Bewertungen

- 10 ForgingDokument51 Seiten10 ForgingsimalaraviNoch keine Bewertungen

- Composite Materials and Structures: First Announcement and Call For PapersDokument2 SeitenComposite Materials and Structures: First Announcement and Call For PapersJai SharmaNoch keine Bewertungen

- Carta Maestra de Soldadura y CortDokument7 SeitenCarta Maestra de Soldadura y CortAlejandro Del Valle TovarNoch keine Bewertungen

- 5 THDokument2 Seiten5 THsimalaraviNoch keine Bewertungen

- ME349 Engineering Design Projects: Introduction To Materials SelectionDokument6 SeitenME349 Engineering Design Projects: Introduction To Materials SelectionMehul KaklotarNoch keine Bewertungen

- Design For Adhesively Bonded AssembliesDokument6 SeitenDesign For Adhesively Bonded AssembliessimalaraviNoch keine Bewertungen

- Limits, Fits and TolerancesDokument4 SeitenLimits, Fits and Tolerancessimalaravi100% (1)

- Comparative Study of Wheel Rim Materials Ijariie1437Dokument4 SeitenComparative Study of Wheel Rim Materials Ijariie1437simalaraviNoch keine Bewertungen

- Sri Vishnu SahasranamamDokument31 SeitenSri Vishnu SahasranamamtheinfolabsNoch keine Bewertungen

- Engg Materials Lab Manual Kle UniveristyDokument42 SeitenEngg Materials Lab Manual Kle UniveristysimalaraviNoch keine Bewertungen

- Academic Calender For II, III and IV B.tech 2017-2018Dokument1 SeiteAcademic Calender For II, III and IV B.tech 2017-2018simalaraviNoch keine Bewertungen

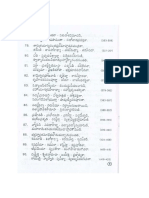

- LalithaSahasraNamam 2 PDFDokument11 SeitenLalithaSahasraNamam 2 PDFsimalaraviNoch keine Bewertungen

- DatesDokument7 SeitenDatessimalaraviNoch keine Bewertungen

- 1Dokument2 Seiten1jabbarNoch keine Bewertungen

- DFMDokument2 SeitenDFMkippcamNoch keine Bewertungen

- Assignment For Mid 2Dokument3 SeitenAssignment For Mid 2simalaraviNoch keine Bewertungen

- Lalitha SahasranamamDokument9 SeitenLalitha SahasranamamspinupolNoch keine Bewertungen

- Mechanical Technology - Comparators - Multiple Choice Questions and AnswersDokument4 SeitenMechanical Technology - Comparators - Multiple Choice Questions and Answerssimalaravi100% (1)

- PPC Unit 8Dokument15 SeitenPPC Unit 8simalaraviNoch keine Bewertungen

- IPE - 302 Sessional SheetDokument22 SeitenIPE - 302 Sessional SheetzahirrayhanNoch keine Bewertungen

- MMM Lab Manual 10mel47bDokument108 SeitenMMM Lab Manual 10mel47bsimalaraviNoch keine Bewertungen

- Surface Treatments, Coatings, and CleaningDokument13 SeitenSurface Treatments, Coatings, and CleaningsimalaraviNoch keine Bewertungen

- CadcamqbDokument6 SeitenCadcamqbMukesh KumarNoch keine Bewertungen

- Gear Train NewDokument108 SeitenGear Train NewArchana MaskeNoch keine Bewertungen

- Automatic Transmission BasicsDokument20 SeitenAutomatic Transmission BasicsDwy Bagus NNoch keine Bewertungen

- Subaru Impreza 2002Dokument3.366 SeitenSubaru Impreza 2002Tamás Nagy67% (3)

- Design of Bevel and Worm GearsDokument58 SeitenDesign of Bevel and Worm Gears60-Hafiz Muhammad AbdullahNoch keine Bewertungen

- Tooth Design: Forces Acting On Spur GearsDokument77 SeitenTooth Design: Forces Acting On Spur GearsJitendra KumarNoch keine Bewertungen

- Automobile Engg Lab ManualDokument49 SeitenAutomobile Engg Lab ManualDhanashriNoch keine Bewertungen

- Gearabc BDokument40 SeitenGearabc Bvadi100% (1)

- ME 1352 Design of Transmission SystemsDokument14 SeitenME 1352 Design of Transmission SystemsRameez FaroukNoch keine Bewertungen

- PDSDetail PageDokument3 SeitenPDSDetail PageEduleofNoch keine Bewertungen

- Aerospace Cng-SpecDokument5 SeitenAerospace Cng-SpecCristian ZapataNoch keine Bewertungen

- Design of Transmission System Unit IIIDokument57 SeitenDesign of Transmission System Unit IIIRaj MohanNoch keine Bewertungen

- Design and Fabrication of Shaft Driven BicycleDokument46 SeitenDesign and Fabrication of Shaft Driven BicycleNishanth Krishnan80% (10)

- GearDokument30 SeitenGearsai babuNoch keine Bewertungen

- Design and Analysis of 9 Speed GearboxDokument7 SeitenDesign and Analysis of 9 Speed GearboxHenok Ghiday0% (1)

- Sample Questions in Automobile EngineeringDokument4 SeitenSample Questions in Automobile EngineeringDipendra SenNoch keine Bewertungen

- GearDokument28 SeitenGeararavinth kNoch keine Bewertungen

- 2013 1357 Wang 02 WDokument15 Seiten2013 1357 Wang 02 WReinaldo Side JuniorNoch keine Bewertungen

- Metric Gear Equivalent PDFDokument1 SeiteMetric Gear Equivalent PDFkumaras1Noch keine Bewertungen

- 3 Power Transmission JJ615Dokument27 Seiten3 Power Transmission JJ615afiqzeroNoch keine Bewertungen

- Gears Engineering InformationDokument138 SeitenGears Engineering InformationxeyesightNoch keine Bewertungen

- DMS & MD 1&2 MCQ PDFDokument33 SeitenDMS & MD 1&2 MCQ PDFĀditya SonāvanéNoch keine Bewertungen

- Abdul Bari (Dome)Dokument83 SeitenAbdul Bari (Dome)A.F. MominNoch keine Bewertungen

- Specifications Models 37R116, 37R118 and 43R175: Carry Capacity: 18,200 To 47,200 Lbs (8250 To 21,400 KG.)Dokument7 SeitenSpecifications Models 37R116, 37R118 and 43R175: Carry Capacity: 18,200 To 47,200 Lbs (8250 To 21,400 KG.)Marek WyszatyckiNoch keine Bewertungen

- F15/F9.9BM (F15/F9.9W) : Parsun Outboard Engine Service ManualDokument106 SeitenF15/F9.9BM (F15/F9.9W) : Parsun Outboard Engine Service ManualElvis GulinNoch keine Bewertungen

- ME6601-Design of Transmission Systems PDFDokument27 SeitenME6601-Design of Transmission Systems PDFJeevitha RNoch keine Bewertungen

- BISON Integral Horsepower Product CatalogDokument52 SeitenBISON Integral Horsepower Product CatalogtorinomgNoch keine Bewertungen

- GEAR MANUFACTURING PROCESSESDokument35 SeitenGEAR MANUFACTURING PROCESSESMache Claros100% (1)

- A Method For Thermal Analysis of Spiral Bevel GearsDokument8 SeitenA Method For Thermal Analysis of Spiral Bevel Gearsvishal raiyaniNoch keine Bewertungen

- AXIP-0057 D46-170 D52-190 Parts List Before June 2013Dokument68 SeitenAXIP-0057 D46-170 D52-190 Parts List Before June 2013hidde bischoffNoch keine Bewertungen

- Hole DiggerDokument67 SeitenHole DiggerJeevan Landge PatilNoch keine Bewertungen