Beruflich Dokumente

Kultur Dokumente

Dodge Jeep 4.7L V8

Hochgeladen von

pipedown456Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dodge Jeep 4.7L V8

Hochgeladen von

pipedown456Copyright:

Verfügbare Formate

The 4.

7 Liter Next Generation and semi-Hemi V8 Engine (Dodge - Jeep)

Chryslers first truly new V-8 since the 1960s, the Corsair 4.7 had better power, gas mileage, and emissions than the 5.2 liter engine it replaced; a new truck V6, the 3.7, was based on it, replacing the 3.9 liter V6 based on the 5.2. The engine was reportedly designed as a replacement for the venerable 4-liter AMC I-6, with the 3.7 to replace the AMC 2.5. EGR and knock sensors were added in 2005. In 2007 (model year 2008), Chrysler replaced the 4.7 liter V8 with a new version. Power went from 230 hp to 290 hp (and up to 320 lb-feet of torque) with that move; gas mileage went up, and noise and vibration went down. The new 4.7-liter V-8 features 5.7-Hemi features such as two spark plugs per cylinder, with a high 9.8:1 compression ratio, and better port flow; but it has a new slant/squish combustion system design.

Refinements included significant revisions to the induction system, reduced reciprocating mass via a lightweight piston/rod assembly, and reduced accessory drive speed. A new normally open valve lash adjuster system smooths the engine at idle, while electronic throttle control is needed for new stability systems. The engine will be manufactured at the Mack Avenue Engine Complex in Detroit.

Chrysler's New Cammer: Mopars first all-new production V8 in 41 years

By RICK EHRENBERG. Copyright 1999 by Rick Ehrenberg. Used by permission. This article covers the 1999-2007 version.

The new 287 is just that, new, sharing almost nothing but a heritage with the ol'reliables. For starters, it's the first true production Mopar V8 mill to incorporate aluminum cylinder heads ( okay, we know about the 1965 A-990 Hemi ) a plastic intake manifold, and magnesium valve covers. Nothing is re-hashed here, and the combustion chambers are almost hemispherical ! And, although it might take a year or two, we'll bet that variants of this powerplant - the "C" engine? - with more or less cylinders, and varying internal dimensions will replace virtually all RWD gasoline powerplants now in the Chrysler stable. In other words, this is a real milestone. So let's take a detailed tour of what's what, what fits what, and start some good rumors about where DC will take this engine in the future. We'll begin at the lower extremities. Bottom end of the Corsair 4.7 Virtually all dimensions of the cast-iron block are new. The bore spacing is reduced from the 1955-1998 small block's 4.46 to 4.09" - this an indicator of how large the new engine eventually could (or could not) be enlarged to. Basic bore size is 3.66," larger yes, than a 273 (by a mere 0.030) but smaller than all the other A-engines - the 318, even going back to the 1950s, was always 3.9." Why ? Small bores are easier to clean up for emissions. Speaking of bores, the roundness is held to a maximum of 0.00015", and taper to 0.0006" - virtually race engine specs.

Deck height is 9.09," compared to 9.60 for the ol LA mill. As a even more profound indicator of jest how new the new design really is, even the offset of the LH cylinder bank is reduced. Like the current LA-based V10, the 287 doesn't use individual main-bearing caps. Instead, what Chrysler calls a 'bedplate' (girdle to us old hotrodders) clamps all five mains at once, adding rigidity while reducing noise and vibration. The bedplate is high-tech even to the material - compacted graphite iron. It is sealed to the block with the old standby: RTV silicone sealer. Incidentally, this bedplate is such a beefy piece that disassembly is almost like 'splitting the cases' on a motorcycle engine. The crankshaft is nodular cast iron, hardened and microfinished. A one piece rear main seal, similar to the 2.2L design, seals to the outside of the 100 mm o.d. rear flange, which is an 8 bolt, one-offset pattern, in Chrysler performance tradition. Main journals are 2.5" diameter, identical to the 318/340 (the 360 is 2.81"), and are crossdrilled. Rod journals are 2.0", 1/8" smaller than the 318's 2.125. All journals have rolled fillets, a significant step taken, in the best racing engines, to prevent stress cracks from forming. Balance is better than 18 gm/cm, and torsional vibrations are looked after by a modern 3 spoke-style snout dampener, with most of the weight placed where it will do the most good - at the outer diameter. The stroke is 3.405", a shade longer than the 273-340 was at 3.31, but shorter than the 360's 3.58. Still we'd call it a 'short stroke' engine. Looking briefly at the block, there is room for some stroke increase. Having the cam out of the way helps a lot.

Carrying on a performance small-block tradition begun with the 1968 340, all bearings are bi-metal Federal Mogul aluminum alloy. As in all production small blocks, only the upper half of the mains are grooved. Unlike the previous smallblock, however, thrust isn't taken by a lip on #3 main. Instead, two (front and rear) separate 180-degree thrust bearing/washers float on the top half of the usual (for Mopar) #3 main journal. Connecting rods. Yes! The long-rod Mopar tradition continues. The 6.12" length, same as all LA engines have always been, puts rod/stroke ratio at a very favorable 1.80, better than the current 360, and only a shade worse than the 273-340. But the traditional forged steel rod is gone. Now you'll find powder-forged metal cracked rods [until model year 2008, when they switched to 36MnVS4 forged steel thanks, Chris). In this process, first used by Chrysler in the 2.0L SOHC Neon engine, the rods are produced and machined in one piece. Then the caps are literally cracked off, guillotined if you will, resulting in an absolutely perfect mating surface that almost lock together, preventing cap walk. Fasteners are hardened M9 capscrews threaded directly into the rod,

no nuts are used. Rod weight is 556 grams, compared to 726 to 758 grams for various production LAengine rods. 0.945" wrist pins, weighing in at 143 grams, are press-fit in the rods. Compression ratio is "blueprint" (and advertised) at 9.5:1, and typically measures 9.0:1. Regular (87) fuel is recommended. But the design allows for high-compression domed pistons in the future. [Webmaster note: these are used on the high output version, though this is a single-vehicle engine: Grand Cherokee only.] Pistons are cast aluminum, have moly coated skirts for break-in scuff resistance, and weigh 366 grams. They are fitted at 0.0008-0.0020" skirt clearance - rather snug but nothing unusual for a street engine. The usual 3-groove ring pack is used (.062/.062/.120") but in addition to the common plasma-moly-filled top rings, the second ring is chrome. Oil rings are chrome as well, with a stainless expander. Bucking the current trend, the oil ring tension is rather high (12 lbs) allowing good oil control even in high-mileage engines. In fact, the spec for the 95th percentile customer is 150,000 mile useful life. In the never ending quest to reduce emissions, the distance from the top ring groove to the top of the piston has been reduced to only 1/8th of an inch, making these areas susceptible to excess wear and heat. To combat this, the top ring land, and the area from the land to the head, are hard anodized. No oversized pistons are available, and the replacement pistons/rods are supplied only as an assembly. Can you say aftermarket? The oiling system isn't radical, using a clever design first seen on the AMC V8s: the georotor-type pump is mounted in the timing cover, and is driven off the crank snout. Direct drive, unlike the current LA engine, which, if you think about it, is a nightmare. The oil pump drive torque comes off the crank nose, through the chain, to the cam, back through the full length of the cam, through a bevel gearset to the intermediate shaft, and then through a hexagonal drive to the pump itself. Whew ! Can you say, simplified ? The new, block mounted pump has a 75 psi relief valve, and a displacement of approx 1 cubic inch per revolution. The oil pan is stamped steel, includes a windage tray (integral with the pan gasket) and has a capacity of 5 quarts plus one in the filter. Pump clearances are designed for the recommended 5W30 oil. Topside - 4.7 liter Next Generation Heads They are Chrysler's first real production light-alloy V8 cylinder heads. Semi-permanent mold aluminum castings, the heads break no new ground but are nonetheless state-of-the-art. Head bolts are 11mm, but the meat is there for a future upgrade to a performance version 12mm. The head bolt pattern is the same for each cylinder (and almost perfectly square at 4.00 x 4.10"), and retains the traditional LA 10 bolt per head arrangement. A super quality 3 layer laminated stainless steel gasket seals the deal. The heads are 'handed' - ie. not interchangeable side to side, mostly because the ports are in a different order left to right.

The intake valves are 1.89", and the exhausts are 1.46," in keeping with the latest Detroit theories regarding Intake:Exhaust valve diameter ratio. With the intake splayed at 13 degrees, the 64cc combustion chamber is approximately hemispherical in shape. Typical Mopar 3-groove, flash-chromed stems, hardened tips, and a length of 4.45" gives you an idea of the valve package - nothing radical, but a generous intake size for the displacement. Guides are press-in, and the stem diameter is approximately 9/32" - even smaller than the 5/16" used on Hemis and Magnum V8s. This is obviously to improve flow and reduce friction. Springs are moderate, but adequate, given the 6,000 RPM fuel shutoff point. But the valve actuation - that is something else again. Gone are the pushrods forever [editors note: they came back on the Hemi...!]. A head mounted camshaft on each cylinder head operates the valves through a set of needle bearing roller rocker arms, with opposite-end hydraulic lash adjusters acting as the fulcrum, a system not unfamiliar to anyone who's ever played with an 1988 or newer Trenton I-4 (2.2 or 2.5L). But looky here, the Intake and Exhaust rockers are opposite each other. Yup, it's almost a Hemi. The cams are each driven by a separate chain, each of which are driven off an idler, in the approximate location of the ol'LA's cam sprocket. This idler sprocket, in turn, is driven from the crank in typical pushrod practice timing set fashion. The camshafts themselves are radical - although not in lift or duration. These are truck engines, after all: 0.443" lift on the intake, and 0.429" on the exhaust, duration is 244 degrees intake, 254 on the exhaust, partially compensating for the smallish exhaust valves. Overlap is only 18 degrees. This is an emissions, and torquer motor, remember. What makes the cams radical isn't the timing, but the construction. They are hollow steel tubes with the individual lobes, of powdered metal, sinter-bonded in place. In fact, the cams, being hollow, are used to bring oil to the intake lobes, which have oiling holes. Cam (valve) covers are cast magnesium. The ports are 1.86 square inches at the port face, and the injectors are mounted to the port in the head, not the intake manifold, which as we shall see, is made of polymer. Speaking of intakes, this is another cool deal - literally. Following in the footsteps of 'little cousin 2.0 SOHC,' the manifold is a one piece glass filled nylon thingie. With a lengthwise plenum and 8 cross-over ram-type ports, it's quite a shock, especially if you are used to LD-340s and M-1s. Runner length (in manifold only) is 20 inches, and there's quite a bit of port length in the heads, so the mill clearly isn't designed for 8,500 RPM passes. But the all-plastic construction should go a long way toward keeping charge-air temperatures down, aiding HP production. Up top, a single bore, side draft throttle body measures 2.56" diameter. If that sounds small, remember that a medium sized Holley 4-barrel has typically bores of 1.625." Doing the math, that computes to 8.3 square inches for the carb, and 5.1 square inches for the EFI throttle body. But remember that the carb has to pass

the air around not only the throttle blades, but through the much smaller - and more restrictive - venturis. We're willing to bet that this throttle assembly passes about as much air as a 600 CFM carburetor ! Not bad for a 287-inch powerplant, eh ? Exhaust manifolds appear to be logs, especially in the initial Jeep version (We expect the Dodge truck ones to be better.) But they are, in reality, individually ported, and not nearly as bad as they look. Heat shield over them is super high-tech - aluminum core with stainless on each side. Electronics There are two interesting electronics-related details worth noting. First, this engine has coil-on-plug ignition. No plug wires, a separate ignition coil mounts to each plug. This something all us guys with headers and toasted plug wires can really appreciate. Even wilder is the absence of a throttle cable - it's fly by wire, dudes. All you're doing when you mash the 'gas' is sending a signal to the computer, which will, hopefully, respond faster than "All ahead full....aye, aye, captain." The Future Will the 287 replace the 318 in Dodge trucks, SUV's and vans? Definitely, by the fall of 1999 for sure. But here's where our engineering analysis ends and sheer speculation begins, guys. There's no secret mad of the fact that a V6 version will be available soon. Will it replace the LA-based V6? Absolutely. Will it replace the current Jeep I6? Probably. Will the 287 power the Prowler? Sure, makes sense to us. But will there be larger versions built to replace the 360, and the 488 inch V10 in the trucks and Viper? Hmm. Surely logical, but with the smallish bore spacing, don't look for this engine in V8 form to go much over 330 inches. Would say, a 325 incher be able to take over from the 360? Why the heck not? The 287 makes virtually the same torque and a tad more HP as the 318 Magnum (albeit at a greater RPM) so why couldn't a larger version do as well? And a 400 inch V10, in a SOHC (forked rocker arm)/ 4 valve arrangement, could, with a bit more radical valve timing, a bit more squeeze (say 11.0:1) bigger ports, and shorter intake runners, should have no trouble making 475-500 HP. Historical perspective: Rick was right about replacing the LA V6 and even the Jeep I6, but the Prowler was cut loose and, while a high-output 4.7 temporarily replaced the 360 in the Grand Cherokee, the Hemi would take the 360s place. The 4.7 would not be made larger, though it did get a substantial makeover. Hot Rodding

Where will the aftermarket - and Mopar Performance - take the 287? There's already a supercharger setup from Performance West, and available through any Jeep dealer. But less radical upgrades would seem to be quite easy. Revised, premium fuel calibration - more spark advance, and a tad more fuel in the form of a computer chip flash would seem to be almost a must. There's room for larger valves, the Mopar machine shops are probably already plotting how they'll re-contour and flow the heads; headers are almost guaranteed, along with a less restrictive air intake setup, and Crane or Comp Cams will surely have cams for it. In other words, we see no reason why this engine can't respond to all the usual hot rodding techniques, and then some. In fact, with such a bountiful set of basic ingredients, hot rodding this engine seems a natural. This is roughly what Chrysler told us about the first generation On the Jeep, it is mated with an all-new, electronically-controlled transmission with five forward ratios. An alternate second gear ratio will provide improved performance. A 3.7 liter version of the 4.7 is used on the 2002 and up Jeep Liberty (known as the Cherokee outside North America). The 4.7 has, on the Jeep, 235 horsepower (over 172 kW) and 295 lb.-ft. (400 Nm) of torque, slightly more power than the 318. It produces 30% less pollution, noise, vibration, and harshness. Fuel economy is 7% better with the new four-speed automatic. The engine has more pulling power, faster initial acceleration, and three miles per gallon better economy. Buddy Revell pointed out that the new engine is "almost" a Hemi - "the only reason it isn't called a hemi is because the combustion chambers have a wall on one side that makes it look kind of like a flat tire. Other than that everything is in the same arangment. The valve springs are across from each other and the spark plug goes right down the middle." The 4.7 has a cast iron block and two cast aluminum cylinder heads with a single overhead camshaft per bank and two valves per cylinder. It displaces 4701 cm3 (287 cu in.). A relatively small bore of 3.66 inches (93 mm) helped reduce overall length of the engine, packaging it for the compact engine bay of the Grand Cherokee. The stroke is 3.4 inches (86.5 mm). Breathing features include a new tuned-length runner intake manifold, free-flowing intake and exhaust ports and fast-burn combustion chambers. Operating with a high 9.3:1 compression ratio, the engine still only requires regular-grade fuel. Lightweight material applications and more efficient engine accessories such as the alternator, power steering pump and air conditioning compressor further bolster performance and economy. Aluminum cylinder heads, a hollow camshaft with sintered steel lobes, magnesium valve covers and a molded composite intake manifold contribute to an overall weight reduction of 54 pounds (24 kg) compared to the previous 5.2-liter engine.

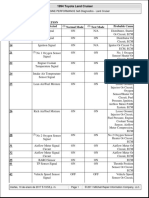

Driveability is enhanced by variable fuel injection timing, sequential multi-port injection, a quick-sensing inlet-side positioned thermostat and coil-on-plug ignition, in which each individual spark plug has its own secondary ignition coil. To improve fuel economy, the new engine features a patented hybrid cooling fan system that combines inline electric and engine-driven fans. This system allows the engine fan to idle at a very low speed (250-300 rpm. vs. the typical 650-700 rpm.), decreasing noise and vibration at idle and low speeds. The newly designed cooling system, with a high efficiency water pump and a secondary thermostat control, reduces power consumption by 12 percent (6 bhp/4.5 kW). The new coil-on-plug ignition system, two-stage chain cam drive with automatic tensioners, premium gaskets and cylinder head mounted fuel injectors are a few of the basic design features that provide for a greatly increased engine life. The engine is designed to operate 150,000 miles (240,000 km) under normal conditions without part replacement other than normal maintenance items. A new automatic serpentine belt tensioner increases the average accessory belt life to 100,000 miles (160,000 km). Specifications: first and second generations 4.7 liter Chrysler V8 engine 2005 Compression Ratio Max engine speed Horsepower Torque Gas mileage 9.5:1 2008 9.8:1

6,000 rpm 6,000 rpm 230@4,600* 290@3,600* 14/18** 290 320 ?

* High performance version: 250 hp, 300 lb-ft. ** Measurement system became stricter for 2008; new generation truck. According to oh20, the 2008-model-year 4.7 was rated at: Dakota Aspen / Durango 302 hp @ 5,650 rpm 329 lb-ft @ 3,950 rpm 303 hp @ 5,650 rpm 330 lb-ft @ 3,950 rpm

Grand Cherokee / Commander 305 hp @ 5,650 rpm 334 lb-ft @ 3,950 rpm Ram Common to both generations:

310 hp @ 5,650 rpm 329 lb-ft 3,950 rpm

Type and Description: V-type, liquid-cooled Displacement: 287 cu. in. (4701 cu. cm) Bore x Stroke: 3.66 x 3.40 (93.0 x 86.5) Valve System: Chain driven, SOHC, 16 valves, hydraulic end-pivot roller rockers

Fuel Injection: Sequential, multi-port, electronic, returnless Construction: Compacted Graphite Iron bedplate, cast-iron block, aluminum alloy heads Fuel Requirement: E85 (Ethanol) or Unleaded regular, 87 octane (R+M)/2 Oil Capacity: 6 qt. (5.7L) Emission Controls: Dual three-way catalytic converters, heated oxygen sensors, and internal engine features

Das könnte Ihnen auch gefallen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesVon EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesBewertung: 5 von 5 Sternen5/5 (1)

- Jeep Engine and Cam SpecsDokument6 SeitenJeep Engine and Cam Specsmnlwood25580% (1)

- How to Build Max-Performance Chevy LT1/LT4 EnginesVon EverandHow to Build Max-Performance Chevy LT1/LT4 EnginesBewertung: 3 von 5 Sternen3/5 (1)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsVon EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsBewertung: 5 von 5 Sternen5/5 (2)

- JEEP WJ 2000 Service ManualDokument117 SeitenJEEP WJ 2000 Service Manualdoniluz0% (4)

- Catalogo GM PerformanceDokument167 SeitenCatalogo GM PerformancewagnerNoch keine Bewertungen

- For Other Uses, See .: Jeep (Disambiguation)Dokument6 SeitenFor Other Uses, See .: Jeep (Disambiguation)Marlin ZamoraNoch keine Bewertungen

- Borgeson Steering JointsDokument29 SeitenBorgeson Steering JointsKerry Murray100% (1)

- Corvette Central Part Catalog For 1979 CorvetteDokument204 SeitenCorvette Central Part Catalog For 1979 Corvettereltih18Noch keine Bewertungen

- Alphabetical Index of Auto Repair Manual SectionsDokument13 SeitenAlphabetical Index of Auto Repair Manual SectionsAnonymous DR7W37SeqNoch keine Bewertungen

- OME Guide CurrentDokument136 SeitenOME Guide CurrentTomas Reyes50% (2)

- LMC Trucks Catalogue CompleteDokument132 SeitenLMC Trucks Catalogue CompletedgibNoch keine Bewertungen

- 350/290 HP Engine (19355658 Base) Long Block Specifications: I-Sheet Part Number 19172591Dokument21 Seiten350/290 HP Engine (19355658 Base) Long Block Specifications: I-Sheet Part Number 19172591Bladimir Luna campagneNoch keine Bewertungen

- Jeep Dana AxleDokument3 SeitenJeep Dana AxleDeddy Rimawan100% (1)

- Xgi DanaDokument158 SeitenXgi Dana08088338Noch keine Bewertungen

- Lubrication and Maintenance: General InformationDokument12 SeitenLubrication and Maintenance: General InformationfontapNoch keine Bewertungen

- Hitch Install Manual 031511Dokument208 SeitenHitch Install Manual 031511jwarnock62Noch keine Bewertungen

- 1999 Jeep TJ Wrangler Service Manual - 23. BodyDokument84 Seiten1999 Jeep TJ Wrangler Service Manual - 23. Bodybfranklin33Noch keine Bewertungen

- Nolathane Catalogue Ed9.0Dokument224 SeitenNolathane Catalogue Ed9.0Brett Stewart75% (4)

- Flowtech CatalogDokument52 SeitenFlowtech CatalogFernando Meneses100% (1)

- Yukon Gear Catalog PDFDokument108 SeitenYukon Gear Catalog PDFJUANNI55Noch keine Bewertungen

- LS Catalog 2015 Lo Res PDFDokument72 SeitenLS Catalog 2015 Lo Res PDFJorgeNoch keine Bewertungen

- Identifying Jeeps: Serial Number LocationsDokument26 SeitenIdentifying Jeeps: Serial Number Locationsjean talusNoch keine Bewertungen

- This Is TestDokument20 SeitenThis Is TestramapeddintiNoch keine Bewertungen

- Xfer Case IdentificationDokument9 SeitenXfer Case IdentificationErickMaki0% (1)

- 1999-2004 JGC Engine Service ManualDokument154 Seiten1999-2004 JGC Engine Service ManualMike RileyNoch keine Bewertungen

- Jeep Grand Cherokee WJ - Transmission Service and MaintenaceDokument7 SeitenJeep Grand Cherokee WJ - Transmission Service and MaintenaceYan Armana100% (1)

- Dodge Journey 2017 - Owner's ManualDokument510 SeitenDodge Journey 2017 - Owner's Manualandres camachin100% (1)

- Group 242 - NP242 Transfer CaseDokument26 SeitenGroup 242 - NP242 Transfer CaseretulikNoch keine Bewertungen

- Transfer Case Catalog 2007Dokument51 SeitenTransfer Case Catalog 2007davidNoch keine Bewertungen

- 2011 Ford Mustang GT 5.0 Coyote EngineDokument41 Seiten2011 Ford Mustang GT 5.0 Coyote EngineclevercogNoch keine Bewertungen

- OtroDokument216 SeitenOtrobj42Noch keine Bewertungen

- Accel Catalog 2011 74488gDokument212 SeitenAccel Catalog 2011 74488gCarlos GudiñoNoch keine Bewertungen

- Engine Crankshaft Reluctor Wheel and Camshaft Gear Tooth Count InformationDokument3 SeitenEngine Crankshaft Reluctor Wheel and Camshaft Gear Tooth Count InformationCarlos Arturo de DiosNoch keine Bewertungen

- Jeep WJ 2001 Grand Cherokee MOPAR Parts CatalogDokument413 SeitenJeep WJ 2001 Grand Cherokee MOPAR Parts Catalogdrwolcot75% (4)

- Nismo Motorsports Catalog 2010Dokument108 SeitenNismo Motorsports Catalog 2010wisrianti100% (1)

- GM Chassis Application 1986-2004view PDFDokument376 SeitenGM Chassis Application 1986-2004view PDFMotonetas de Antes100% (1)

- Engine 3.0 v6Dokument130 SeitenEngine 3.0 v6Wlises GonzalezNoch keine Bewertungen

- Painless Wiring Harness Install InstructionsDokument60 SeitenPainless Wiring Harness Install InstructionsNick MarinoNoch keine Bewertungen

- 2011 WK Parts PDFDokument563 Seiten2011 WK Parts PDFHugo GoNoch keine Bewertungen

- TJ Diagnostic CodesDokument3 SeitenTJ Diagnostic Codeschristopheserv100% (1)

- 97 Parts ListDokument352 Seiten97 Parts ListSPLINGEY2114Noch keine Bewertungen

- Dodge RAM Truck 2002 Workshop Repair Manual - EngineDokument192 SeitenDodge RAM Truck 2002 Workshop Repair Manual - EngineLuis Ramon Arguello Real100% (1)

- 2011 Jeep Grand Cherokee wiring diagramsDokument108 Seiten2011 Jeep Grand Cherokee wiring diagramssimon_someone217Noch keine Bewertungen

- 2014 JP GrandCherokee SPDokument9 Seiten2014 JP GrandCherokee SPSteve RugeNoch keine Bewertungen

- 2005 Chevrolet Tahoe/Suburban Owner ManualDokument530 Seiten2005 Chevrolet Tahoe/Suburban Owner ManualClaudio Hernández PobleteNoch keine Bewertungen

- Jeep XJ Fuse Box DiagramDokument16 SeitenJeep XJ Fuse Box Diagramandrei.verehaNoch keine Bewertungen

- WK JK Remote StartDokument37 SeitenWK JK Remote StartArnold Torres100% (1)

- 2006 Cadillac Escalade BrochureDokument35 Seiten2006 Cadillac Escalade Brochureruizar28Noch keine Bewertungen

- FordShopManual1970 PDFDokument84 SeitenFordShopManual1970 PDFpenguindevourer100% (1)

- 2003 Chevrolet Tahoe OwnersDokument516 Seiten2003 Chevrolet Tahoe OwnersAaron AdamsNoch keine Bewertungen

- Silverado2002 4.3 Lts. MecanicaDokument519 SeitenSilverado2002 4.3 Lts. MecanicaKevinNavarro100% (1)

- 2009 Mopar Perfomance PDFDokument351 Seiten2009 Mopar Perfomance PDFmacNoch keine Bewertungen

- 5th Wheel InstallationsDokument45 Seiten5th Wheel InstallationsTracey HiggsNoch keine Bewertungen

- Model 30 Ring and Pinion SpecsDokument4 SeitenModel 30 Ring and Pinion SpecsVuela BajoNoch keine Bewertungen

- Jeep Parts List 2004 KJDokument527 SeitenJeep Parts List 2004 KJlilfrogerNoch keine Bewertungen

- Acom06 - 2 Oxidation of S35315 in Water Vapor Containing Atmospheres Under Cyclic & Isothermal ConditionsDokument19 SeitenAcom06 - 2 Oxidation of S35315 in Water Vapor Containing Atmospheres Under Cyclic & Isothermal Conditionspipedown456Noch keine Bewertungen

- Sandvik SS GradesDokument3 SeitenSandvik SS Gradespipedown456Noch keine Bewertungen

- Acom85 - 2 Oxidation Kinetics of Heat Resistant Alloys Part I+IIDokument12 SeitenAcom85 - 2 Oxidation Kinetics of Heat Resistant Alloys Part I+IIpipedown456Noch keine Bewertungen

- AL 316 - 317dataDokument14 SeitenAL 316 - 317dataClaudia MmsNoch keine Bewertungen

- Acom86 - 1+2 Engineering Properties of Duplex SS (2205, 2307) PDFDokument24 SeitenAcom86 - 1+2 Engineering Properties of Duplex SS (2205, 2307) PDFpipedown456Noch keine Bewertungen

- Ra SS2205Dokument16 SeitenRa SS2205pipedown456Noch keine Bewertungen

- Acom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFDokument16 SeitenAcom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFpipedown456Noch keine Bewertungen

- Families of Stainless SteelDokument8 SeitenFamilies of Stainless Steelpipedown456Noch keine Bewertungen

- AVESTA CORROSION MANAGMENT: Corrosion Engineering of High Pressure Piping in RO-PlantsDokument8 SeitenAVESTA CORROSION MANAGMENT: Corrosion Engineering of High Pressure Piping in RO-Plantspipedown456Noch keine Bewertungen

- Acom85 - 3 Optimization of High-Pressure Piping in Reverse Osmosis Plants (254 SMO)Dokument8 SeitenAcom85 - 3 Optimization of High-Pressure Piping in Reverse Osmosis Plants (254 SMO)pipedown456Noch keine Bewertungen

- 316 TiDokument4 Seiten316 Tithomas_v501925Noch keine Bewertungen

- Acom85 - 1 Weight Optimization in Offshore Construction PDFDokument8 SeitenAcom85 - 1 Weight Optimization in Offshore Construction PDFpipedown456Noch keine Bewertungen

- Avesta 10030 - Type2205Dokument11 SeitenAvesta 10030 - Type2205pipedown456Noch keine Bewertungen

- Technical Data: Blue SheetDokument10 SeitenTechnical Data: Blue Sheetpipedown456Noch keine Bewertungen

- Avesta 2205 AC DCDokument1 SeiteAvesta 2205 AC DCpipedown456Noch keine Bewertungen

- Avesta 2205-Hx Ac/Dc: Covered ElectrodesDokument1 SeiteAvesta 2205-Hx Ac/Dc: Covered Electrodespipedown456Noch keine Bewertungen

- SANDVIK What Is Stainless SteelDokument7 SeitenSANDVIK What Is Stainless Steelpipedown456Noch keine Bewertungen

- Avesta 2205 VDX Ac DCDokument1 SeiteAvesta 2205 VDX Ac DCpipedown456Noch keine Bewertungen

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDokument36 SeitenRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456Noch keine Bewertungen

- RA151 28pgDokument31 SeitenRA151 28pgpipedown456Noch keine Bewertungen

- All Outokumpu SS GradesDokument1 SeiteAll Outokumpu SS Gradespipedown456Noch keine Bewertungen

- Allegheny High Perf AlloysDokument8 SeitenAllegheny High Perf Alloyspipedown456Noch keine Bewertungen

- Introduction To The Family of Stainless SteelsDokument29 SeitenIntroduction To The Family of Stainless Steelspipedown456Noch keine Bewertungen

- Stainless Steel 304 Product InfoDokument1 SeiteStainless Steel 304 Product Infoarunava001Noch keine Bewertungen

- Ferritic Grade 1.4509Dokument1 SeiteFerritic Grade 1.4509pipedown456Noch keine Bewertungen

- The Development of Stainless Steel: by An Unknown WriterDokument2 SeitenThe Development of Stainless Steel: by An Unknown Writerpipedown456Noch keine Bewertungen

- Austenitic ST - St. 1.4372 (AISI 201)Dokument1 SeiteAustenitic ST - St. 1.4372 (AISI 201)pipedown456Noch keine Bewertungen

- EN 1.4521 Ferritic Stainless Steel Product InformationDokument1 SeiteEN 1.4521 Ferritic Stainless Steel Product Informationpipedown456Noch keine Bewertungen

- Nitrogen Bearing Steels & SSDokument7 SeitenNitrogen Bearing Steels & SSpipedown456Noch keine Bewertungen

- CSI SS GuideDokument22 SeitenCSI SS Guidepipedown456Noch keine Bewertungen

- Not For Reproduction: Illustrated Parts List 356400Dokument28 SeitenNot For Reproduction: Illustrated Parts List 356400moisesNoch keine Bewertungen

- ESP PRP: EngineDokument7 SeitenESP PRP: EngineLebahMaduNoch keine Bewertungen

- Lean BurnDokument7 SeitenLean BurnnirwalamitNoch keine Bewertungen

- CauhoiontapDokument7 SeitenCauhoiontapÁNH NGỌC NGUYỄN THỊNoch keine Bewertungen

- CP Instructionsheet V4262012Dokument2 SeitenCP Instructionsheet V4262012Jean Paul BésNoch keine Bewertungen

- b2-1 Marine Auxiliary EngineDokument684 Seitenb2-1 Marine Auxiliary EngineManish Alexander MohanNoch keine Bewertungen

- ECU Codes ExplainedDokument12 SeitenECU Codes ExplainedIsrael GerardoNoch keine Bewertungen

- Tabla 1 Engine ControlDokument2 SeitenTabla 1 Engine Controljulio montenegroNoch keine Bewertungen

- Tuning Valve ClearanceDokument3 SeitenTuning Valve ClearanceShimmer Crossbones100% (1)

- Hitachi genuine engine parts catalog guideDokument158 SeitenHitachi genuine engine parts catalog guidepeter chenNoch keine Bewertungen

- Wiseco Harley 2019 UpdateDokument2 SeitenWiseco Harley 2019 UpdateRuud BakkerNoch keine Bewertungen

- Internship Report on Manufacturing Processes at Perfect Alloy Components Pvt. LtdDokument4 SeitenInternship Report on Manufacturing Processes at Perfect Alloy Components Pvt. LtdJayanth MurthyNoch keine Bewertungen

- G3512 Gas Engine Technical Data SheetDokument3 SeitenG3512 Gas Engine Technical Data SheetNimNoch keine Bewertungen

- Engine PDFDokument254 SeitenEngine PDFtipo333194% (18)

- Hyundai 35-40-45DS 50da-7e PDFDokument1.042 SeitenHyundai 35-40-45DS 50da-7e PDFMichał LicznerskiNoch keine Bewertungen

- Fiat 127 PDFDokument34 SeitenFiat 127 PDFLuis Gaspar100% (2)

- Aircraft Ignition SystemsDokument17 SeitenAircraft Ignition Systemsvinithakrishnan100% (1)

- دليل مختبر محركاتDokument69 Seitenدليل مختبر محركاتabood mohammadNoch keine Bewertungen

- S. No Stages of Power Car During D-Check Power Car Make/DIV. in Date SS2 Due Remarks/PDCDokument12 SeitenS. No Stages of Power Car During D-Check Power Car Make/DIV. in Date SS2 Due Remarks/PDCshakeel alamNoch keine Bewertungen

- Manual Suzuki Celerio (2015) (201 Páginas)Dokument2 SeitenManual Suzuki Celerio (2015) (201 Páginas)robinson rodriguezNoch keine Bewertungen

- Test Engine E Specificatio NS: Iveco F1C Ceuro4Dokument3 SeitenTest Engine E Specificatio NS: Iveco F1C Ceuro4Rafael FernandesNoch keine Bewertungen

- Service Manual Picanto Ion G3HGDokument12 SeitenService Manual Picanto Ion G3HGrectificamosNoch keine Bewertungen

- Allison v-1710 Aircraft EngineDokument10 SeitenAllison v-1710 Aircraft EngineWilliamNoch keine Bewertungen

- Izuzu Motor x22 SeDokument102 SeitenIzuzu Motor x22 SeGerardo FloresNoch keine Bewertungen

- NS Elida Checklist for ME 3 Engine OverhaulDokument5 SeitenNS Elida Checklist for ME 3 Engine OverhaulnickNoch keine Bewertungen

- Crankshaft Position Sensor Circuit MalfunctionDokument2 SeitenCrankshaft Position Sensor Circuit MalfunctionpepeladazoNoch keine Bewertungen

- RCEXL Ignition Installation and Timing GuideDokument3 SeitenRCEXL Ignition Installation and Timing GuideradmuttNoch keine Bewertungen

- C565001 E04Dokument714 SeitenC565001 E04MIGUEL POSSO100% (2)

- 2007 Toyota Prius 1.5L MFI HEV DOHC 4cyl - Repair Guides - Components & Systems - Idle Air Control ValveDokument11 Seiten2007 Toyota Prius 1.5L MFI HEV DOHC 4cyl - Repair Guides - Components & Systems - Idle Air Control ValvePrivate LaneNoch keine Bewertungen

- Camshaft Timing: Testing and AdjustingDokument8 SeitenCamshaft Timing: Testing and AdjustingsxturboNoch keine Bewertungen