Beruflich Dokumente

Kultur Dokumente

Adam Caruso - Shell Cladding Lining

Hochgeladen von

Iuliana LarisaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Adam Caruso - Shell Cladding Lining

Hochgeladen von

Iuliana LarisaCopyright:

Verfügbare Formate

Shell, Cladding, Lining Adam Caruso

OASE (Amsterdam, Netherlands: January 1997) Issue 47, pp.54-55

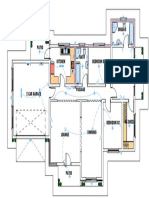

The Walsall Art Gallery has an insitu concrete structure whose walls form the primary structure and define the main interior spaces of the building. Pre-cast floors span between interior and perimeter walls, the depth of the joist element of the floor construction is sized according to the space being spanned rather than to the structural span. The structure of the building establishes the external profile of the gallery and a collection of differently sized interior spaces gathered together in close proximity. The whole of the exterior of the shell is clad. The interior is selectively lined to affect the character and scale of the different rooms of the gallery. The distance between the internal surface of the lining and the external surface of the cladding (approximately 600) allows for slack within which the requirements of the interior and the exterior can be subtly adjusted. The external face of the 300 mm thick external concrete wall is the waterproof layer of the building. Onto this surface is placed a layer of 100mm thick insulation and is hung a rain screen. The base of the building and the inward looking faces of the high level restaurant tower are clad in a rain screen of mill finished stainless steel. Three panels of the 2 mm thick steel are cut from a 1500 mm wide coil, the resulting 444 mm wide panels have vertical butt joints and are up to 6 meters long. Ground level glazing is flush with the stainless steel panels and is vertically subdivided to give an even number of glazed panels within each opening. The stainless steel screen is the inner layer. Onto the body of the tower is hung the outer layer of the rain screen, a more coarsely textured cloak of terracotta tiles whose scale reduces towards the top of the building. The tiles have a similar vertical proportion and the vertical joints shift in order to accommodate the internally determined window positions. The lapped bottom edge of the tiles and the corners of the building expose the 30mm thickness of the extruded terracotta units. The 600mm depth of the external wall is breached by windows formed with a welded stainless steel cage. The exterior of the cage is clad in mill finished stainless steel and flush structural glazing. The window cladding reinforces the impression of the stainless steel as an underlayer running beneath the terracotta overcloak of the building. The largest and most public interiors of the gallery are formed directly by the shell of the building. The internal surfaces of the insitu concrete walls are made with vertical boarded shuttering of 75mm wide, planed douglas fir boards. Onto the poured walls is placed the pre-cast joists and planks of the floor construction. The frequency and scale of the joist members are spatially analogous to the timber ceiling of a medieval hall. In some locations a 75 mm thick lining of vertical douglas fir boards are placed onto the concrete. The scale and grain of this lining is the same as the surface of the concrete. The floor of the shell is a 125mm thick power floated concrete whose surface is pigmented with a black titanium hardener. In the hall of the two storey suite the permanent collection galleries (the Garman Ryan Collection), the Douglas fir lining envelops the space, forming the floor, walls and ceiling surface. The 3m high galleries that are grouped about this hall have a douglas fir floor and ceiling and white plastered walls. The grain and scale of the timber ceiling can better hold the mechanical, electrical and security devices that are accommodated within the ceiling void. Timber skirtings, door reveals and window linings consistently project 30mm from the plaster surface. The scale and articulation of these galleries is designed to accommodate the small, residential scale of the Garman Ryan Collection, which will have a permanent hang. The four 6m high contemporary exhibition galleries are formed by thick plenum walls finished in white painted 18mm thick medium density fibreboard (MDF) on steel studwork. These walls hold the supply air ductwork and are clearly sitting on the power floated concrete floor, stopping just short of the pre-

Caruso St John Architects

cast concrete soffit. A 120mm high continuous gap accommodates supply air diffusers, which provide general lighting. Spot lights and security equipment can be housed within the 600mm depth of the precast concrete joists.

Caruso St John Architects

Das könnte Ihnen auch gefallen

- Fire Resistant Materials and Construction PDFDokument44 SeitenFire Resistant Materials and Construction PDFAnonymous ePcnZoBENoch keine Bewertungen

- Women's Health - September 2018 AUDokument140 SeitenWomen's Health - September 2018 AUIuliana LarisaNoch keine Bewertungen

- Color, Space, and Style - All The DetailsDokument289 SeitenColor, Space, and Style - All The DetailsConstantinescu I. Valentin92% (51)

- Homebuilding - Renovating-UltimateDesignBuildGuideDokument60 SeitenHomebuilding - Renovating-UltimateDesignBuildGuideverivtudawNoch keine Bewertungen

- Civil Work Power Block AreaDokument370 SeitenCivil Work Power Block AreaapsNoch keine Bewertungen

- Floor Tile Market SurveyDokument12 SeitenFloor Tile Market SurveyJhanviNoch keine Bewertungen

- Duragal Flooring Systems Technical Brochureduragal Flooring Systems Technical Brochure PDFDokument36 SeitenDuragal Flooring Systems Technical Brochureduragal Flooring Systems Technical Brochure PDFLin SieNoch keine Bewertungen

- Herzog & de Meuron Birdsnest Movie (Presskit)Dokument16 SeitenHerzog & de Meuron Birdsnest Movie (Presskit)jusdefruitNoch keine Bewertungen

- FS21 Design Studio - Textile, ReaderDokument92 SeitenFS21 Design Studio - Textile, ReaderEdgarBritoNoch keine Bewertungen

- Adam Caruso - The Tyranny of The NewDokument2 SeitenAdam Caruso - The Tyranny of The Newoa.carlosNoch keine Bewertungen

- The Feeling of Things in Art and ArchitectureDokument2 SeitenThe Feeling of Things in Art and ArchitectureIuliana LarisaNoch keine Bewertungen

- Timber DesignDokument17 SeitenTimber Designshaina mae omandacNoch keine Bewertungen

- I4.8 Information Sheet Glass in Stand Construction Inside Trade Fair Halls 2019 PDFDokument12 SeitenI4.8 Information Sheet Glass in Stand Construction Inside Trade Fair Halls 2019 PDFatalayyNoch keine Bewertungen

- Precast Concrete For Low-RiseDokument62 SeitenPrecast Concrete For Low-RiseJune Suriyawanakul100% (4)

- The Brochure Series of Architectural Illustration, Volume 01, No. 01, January 1895 The Gothic Palaces of VeniceVon EverandThe Brochure Series of Architectural Illustration, Volume 01, No. 01, January 1895 The Gothic Palaces of VeniceNoch keine Bewertungen

- Oris.51 Zumthor - LeisDokument6 SeitenOris.51 Zumthor - Leisconrad100% (1)

- Bison Hollow Core FloorsDokument16 SeitenBison Hollow Core FloorsJohn WoodsNoch keine Bewertungen

- Scripting Cultures: Architectural Design and ProgrammingVon EverandScripting Cultures: Architectural Design and ProgrammingBewertung: 5 von 5 Sternen5/5 (1)

- Meaning Building Aldo Rossi and The Practice of Memory PDFDokument124 SeitenMeaning Building Aldo Rossi and The Practice of Memory PDFMarina PasarinNoch keine Bewertungen

- Al Bahr Towers: The Abu Dhabi Investment Council HeadquartersVon EverandAl Bahr Towers: The Abu Dhabi Investment Council HeadquartersNoch keine Bewertungen

- 11 Alnatura+Arena-InzellDokument42 Seiten11 Alnatura+Arena-InzellAida Domingo Losa100% (1)

- Sample Issue USADokument48 SeitenSample Issue USAThiago EvangelistaNoch keine Bewertungen

- Method of Statement For Tile Laying Work-Qc-RvlDokument9 SeitenMethod of Statement For Tile Laying Work-Qc-Rvljohn paul100% (1)

- Archiguide 2009Dokument75 SeitenArchiguide 2009Constantin Dodon100% (1)

- Michael Maltzan ResumeDokument1 SeiteMichael Maltzan ResumeStephen UrgoNoch keine Bewertungen

- San Rocco Pure Beauty CallDokument8 SeitenSan Rocco Pure Beauty Callrod57Noch keine Bewertungen

- Bread Is Gold Preview PDFDokument21 SeitenBread Is Gold Preview PDFAndrea Ko100% (1)

- Invested 00 BL IsDokument556 SeitenInvested 00 BL IsDLM7Noch keine Bewertungen

- Catalogos de Arquitectura Contemporanea - Christian HauvetteDokument95 SeitenCatalogos de Arquitectura Contemporanea - Christian HauvetteAnn Gutierrez QuinteroNoch keine Bewertungen

- Auditorium Congress Center Kursaal Rafael MoneoDokument18 SeitenAuditorium Congress Center Kursaal Rafael Moneoyduarch100% (2)

- Adam Caruso - Sigurd Lewerentz and A Material Basis For FormDokument2 SeitenAdam Caruso - Sigurd Lewerentz and A Material Basis For FormIuliana LarisaNoch keine Bewertungen

- Adam Caruso - Sigurd Lewerentz and A Material Basis For FormDokument2 SeitenAdam Caruso - Sigurd Lewerentz and A Material Basis For FormIuliana LarisaNoch keine Bewertungen

- ETH Zürich Professor Adam Caruso HS 2011 Trabeation WorkbookDokument74 SeitenETH Zürich Professor Adam Caruso HS 2011 Trabeation WorkbookЕрнест ЛукачNoch keine Bewertungen

- Alvaro SizaDokument25 SeitenAlvaro SizaLekshmi TNoch keine Bewertungen

- Betts Project-Caruso ST John-Diorama - CatalogueDokument33 SeitenBetts Project-Caruso ST John-Diorama - CataloguericardoNoch keine Bewertungen

- Columns - Walls - Floors 2013Dokument176 SeitenColumns - Walls - Floors 2013700spymaster007Noch keine Bewertungen

- EXPO'98 - de LISBOA Projeto e LegadoDokument12 SeitenEXPO'98 - de LISBOA Projeto e Legadofrancisco33Noch keine Bewertungen

- The Feeling of Things: Towards an Architecture of EmotionsDokument2 SeitenThe Feeling of Things: Towards an Architecture of EmotionsSandra SamirNoch keine Bewertungen

- Wolfgang Huß - Matthias Kaufmann - Konrad Merz - Building in Timber - Room Modules-DeTAIL (2019)Dokument113 SeitenWolfgang Huß - Matthias Kaufmann - Konrad Merz - Building in Timber - Room Modules-DeTAIL (2019)merveozgurNoch keine Bewertungen

- Spatial Infrastructure: Essays on Architectural Thinking as a Form of KnowledgeVon EverandSpatial Infrastructure: Essays on Architectural Thinking as a Form of KnowledgeNoch keine Bewertungen

- HS 2012 Denkmal - Waldhaus: A century of additions to a historic Swiss chaletDokument77 SeitenHS 2012 Denkmal - Waldhaus: A century of additions to a historic Swiss chaletЕрнест ЛукачNoch keine Bewertungen

- Rossi, Ungers and KoolhaasDokument28 SeitenRossi, Ungers and Koolhaasweareyoung5833100% (1)

- Inflection 04: Permanence: Journal of the Melbourne School of DesignVon EverandInflection 04: Permanence: Journal of the Melbourne School of DesignNoch keine Bewertungen

- Pure Space: Expanding the Public Sphere through Public Space Transformations in Latin American Spontaneous SettlementsVon EverandPure Space: Expanding the Public Sphere through Public Space Transformations in Latin American Spontaneous SettlementsNoch keine Bewertungen

- Malmö Konsthall Designed for Art InstallationsDokument2 SeitenMalmö Konsthall Designed for Art InstallationsIuliana LarisaNoch keine Bewertungen

- Prize. .Herzog.&.de - Meuron. (2001) .1Dokument29 SeitenPrize. .Herzog.&.de - Meuron. (2001) .1MassaCoNoch keine Bewertungen

- aDVVT-EVERY DAY THEATRE-BETTS PROJECT-LRDokument35 SeitenaDVVT-EVERY DAY THEATRE-BETTS PROJECT-LRAndrew DeerNoch keine Bewertungen

- Alberto Campo Baeza Olnick Spanu Glass BoxDokument5 SeitenAlberto Campo Baeza Olnick Spanu Glass BoxStoian CristianNoch keine Bewertungen

- Aureli Tattara Barbarism Begins at Home PariDokument5 SeitenAureli Tattara Barbarism Begins at Home PariFrancisco PereiraNoch keine Bewertungen

- VILLAS On A LAKE, Alessandro ScandurraDokument38 SeitenVILLAS On A LAKE, Alessandro ScandurraLNoch keine Bewertungen

- PeoplesPalacesDEF PDFDokument296 SeitenPeoplesPalacesDEF PDFolgapintoduarteNoch keine Bewertungen

- Material Gesture Site: Mount EtnaDokument32 SeitenMaterial Gesture Site: Mount EtnaApriani Kurnia SarashayuNoch keine Bewertungen

- Mat Urbanism: Growth and Change: Jaime J. Ferrer Forés Universitat Politècnica de CatalunyaDokument11 SeitenMat Urbanism: Growth and Change: Jaime J. Ferrer Forés Universitat Politècnica de Catalunyacattaculvirtual100% (2)

- 2018 049 Elliott Enonce Elliott EnonceDokument85 Seiten2018 049 Elliott Enonce Elliott EnonceDenisa BalajNoch keine Bewertungen

- Rebuilding Japan: Ishigami's Design PhilosophyDokument10 SeitenRebuilding Japan: Ishigami's Design PhilosophyarrgggNoch keine Bewertungen

- WorkshopDokument17 SeitenWorkshopbacksuNoch keine Bewertungen

- Anyone Corporation - Any PublicationsDokument7 SeitenAnyone Corporation - Any Publicationsangykju2Noch keine Bewertungen

- Wittkower 5 Palladio and The Problem of Harmonic Proportions1Dokument44 SeitenWittkower 5 Palladio and The Problem of Harmonic Proportions1justnewbieNoch keine Bewertungen

- CHIPERFIELDDokument5 SeitenCHIPERFIELDXtremeevilNoch keine Bewertungen

- Documenting 60 Years of Living ArchitectureDokument40 SeitenDocumenting 60 Years of Living Architecturedemullu reddiNoch keine Bewertungen

- Boc02 Job-Floris Circular-Buildings PDFDokument82 SeitenBoc02 Job-Floris Circular-Buildings PDFCristina ConstantinNoch keine Bewertungen

- David ChipperfieldDokument8 SeitenDavid ChipperfieldIvana Patricia 黒蘭 DilasNoch keine Bewertungen

- A Simple Heart Pier Vittorio Aureli PDFDokument10 SeitenA Simple Heart Pier Vittorio Aureli PDFAndrew DeerNoch keine Bewertungen

- Valerio Olgiati WorksDokument14 SeitenValerio Olgiati Worksweareyoung5833Noch keine Bewertungen

- 3 4 From Bauhaus To KoolhaasDokument6 Seiten3 4 From Bauhaus To KoolhaasmorphologicsNoch keine Bewertungen

- Architecture (1) .Ebook .Peter - EisenmanDokument66 SeitenArchitecture (1) .Ebook .Peter - EisenmanCecilia DumbskyNoch keine Bewertungen

- Catalogos de Arquitectura Contemporanea - Francesco VeneziaDokument96 SeitenCatalogos de Arquitectura Contemporanea - Francesco VeneziaOana PorimeNoch keine Bewertungen

- For the Record: The First Women in Canadian ArchitectureVon EverandFor the Record: The First Women in Canadian ArchitectureNoch keine Bewertungen

- The senses in interior design: Sensorial expressions and experiencesVon EverandThe senses in interior design: Sensorial expressions and experiencesNoch keine Bewertungen

- Resisting Postmodern Architecture: Critical regionalism before globalisationVon EverandResisting Postmodern Architecture: Critical regionalism before globalisationNoch keine Bewertungen

- 566 A10041 PDFDokument6 Seiten566 A10041 PDFIuliana LarisaNoch keine Bewertungen

- Motherland Presentation 14PIMDokument10 SeitenMotherland Presentation 14PIMIuliana LarisaNoch keine Bewertungen

- Motherland Presentation 14PIMDokument10 SeitenMotherland Presentation 14PIMIuliana LarisaNoch keine Bewertungen

- 508 MSDS en 04-24-2013Dokument8 Seiten508 MSDS en 04-24-2013Iuliana LarisaNoch keine Bewertungen

- InnovationDokument64 SeitenInnovationIuliana LarisaNoch keine Bewertungen

- New York City of Aspiration Middle Class ReportDokument52 SeitenNew York City of Aspiration Middle Class ReportLenard DatilesNoch keine Bewertungen

- Gril Intensive Extensive Publico PrivadoDokument1 SeiteGril Intensive Extensive Publico PrivadoIuliana LarisaNoch keine Bewertungen

- Abs ImagesDokument73 SeitenAbs ImagesIuliana LarisaNoch keine Bewertungen

- Context perceptions in the architecture of Herzog and de Meuron and Peter ZumthorDokument2 SeitenContext perceptions in the architecture of Herzog and de Meuron and Peter ZumthorIuliana LarisaNoch keine Bewertungen

- Tzara, Tristan - Dada Manifesto 1918Dokument5 SeitenTzara, Tristan - Dada Manifesto 1918Iuliana LarisaNoch keine Bewertungen

- Cartzi PT BiblioDokument3 SeitenCartzi PT BiblioIuliana LarisaNoch keine Bewertungen

- w0167 PreDokument1 Seitew0167 PreKandeke DaviesNoch keine Bewertungen

- Build 141 Bracing SupplementDokument36 SeitenBuild 141 Bracing SupplementRajeev SharanNoch keine Bewertungen

- Punch Points - Phase-1 Dated 11-Dec-19Dokument14 SeitenPunch Points - Phase-1 Dated 11-Dec-19Goutam HotaNoch keine Bewertungen

- Construction AgreementDokument5 SeitenConstruction AgreementThamotharan AnnamalaiNoch keine Bewertungen

- Building Inspection Report: SampleDokument11 SeitenBuilding Inspection Report: Samplekrish1979Noch keine Bewertungen

- DEA Report-Baridhara Dohs BuildingDokument145 SeitenDEA Report-Baridhara Dohs BuildingCEG BangladeshNoch keine Bewertungen

- Conference HallDokument13 SeitenConference HallPrerana ManjunathNoch keine Bewertungen

- Ik2-Bam - B2-SC-D-6503 - 02 PDFDokument1 SeiteIk2-Bam - B2-SC-D-6503 - 02 PDFkramlester1982Noch keine Bewertungen

- Reinforced Interlocking Brick Structure Technical RequirementsDokument17 SeitenReinforced Interlocking Brick Structure Technical RequirementserjuniorsanjipNoch keine Bewertungen

- 380 Melb Sales Manual 15march2019Dokument15 Seiten380 Melb Sales Manual 15march2019Tamara SisilNoch keine Bewertungen

- Build Your Own Sauna Step-by-Step GuideDokument20 SeitenBuild Your Own Sauna Step-by-Step GuideWilliam BuchananNoch keine Bewertungen

- Complete installation guide for EcofilmSet underfloor heatingDokument4 SeitenComplete installation guide for EcofilmSet underfloor heatingadyro12Noch keine Bewertungen

- B.o.Q of Baste Shelga BridgeDokument12 SeitenB.o.Q of Baste Shelga BridgeAhmed BakrNoch keine Bewertungen

- Sample Construction SpecificationsDokument12 SeitenSample Construction SpecificationsCreativity is meNoch keine Bewertungen

- Biomur Raditionnel 37: Performances Caractéristiques TechniquesDokument4 SeitenBiomur Raditionnel 37: Performances Caractéristiques TechniquesmilasanNoch keine Bewertungen

- Btec Higher National Diploma in Quantity Surveying Technology ADokument51 SeitenBtec Higher National Diploma in Quantity Surveying Technology AlashNoch keine Bewertungen

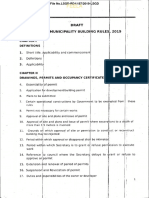

- KMBR 2019 PDFDokument229 SeitenKMBR 2019 PDFAtul JoseNoch keine Bewertungen

- CE 321 Design Project GuidelinesDokument6 SeitenCE 321 Design Project GuidelinesAlbasir Tiang Sedik REENoch keine Bewertungen

- Building collapse investigation in DelhiDokument4 SeitenBuilding collapse investigation in Delhifree birdNoch keine Bewertungen

- Lewis Leaflet PDFDokument2 SeitenLewis Leaflet PDFVengatesh NJNoch keine Bewertungen