Beruflich Dokumente

Kultur Dokumente

Technical Information No. 1: Grey Lamellar Graphite Cast Iron

Hochgeladen von

MOHAMMAD ASIFOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Technical Information No. 1: Grey Lamellar Graphite Cast Iron

Hochgeladen von

MOHAMMAD ASIFCopyright:

Verfügbare Formate

Technical information No.

CLAAS GUSS GmbH Am Stadtholz 52, D-33609 Bielefeld Postfach 10 0845, D-33508 Bielefeld Telefon (05 21) 93 15-0 Telefax (05 21) 93 15-2 88 Internet: http://www.claasguss.de E-mail: info@claasguss.de

Grey lamellar graphite cast iron

Definition

Grey (lamellar graphite) cast iron is a cast material, iron and carbon based, carbon being present mainly in the form of lamellar graphite particle (flake graphite). Its properties mainly depend on the amount of graphite, the graphite shape and graphite distribution in the metallic matrix. The European norm classifies grey (lamellar graphite) cast iron according to its mechanical properties. The material grades are either specified by tensile strength or by Brinell hardness.

Relevant standards

Material designation and material properties: DIN EN 1561 Grey lamellar graphite iron General Tolerances and machining allowance: DIN ISO 8062 valid for all designs made since August 1998 (DIN 1686, valid for designs created before August 1998) Metallic materials Brinell hardness test: DIN EN ISO 6506. Metallic Material Tensile testing at ambient temperature: DIN EN 10002-1

Influence of the chemical composition a) Basic Elements

Cast iron is an alloy consisting of iron and 5 main attendant elements C, Si, Mn, P and S. The element C and Si have got the most important influence on the ultimate tensile strength and Brinell hardness (HB). The higher the C and Si content, the higher are the values of Rm and HB. Mn, P and S have got a minor influence.

Mechanical properties of lamellar graphite cast iron

The cooling rate during solidification and during the following phase transformations has a significant influence on the materials strength as well as on its hardness. The values, given in the table below, refer to separately cast samples with a diameter of 30 mm, which correspond to a wall thickness of 15 mm. Nowadays significantly thinner walls can be cast. Generally higher values of strength than those values that are listed in the table below are found in these thin walls. By adding alloying elements special properties can be realised. These alloyed material grades are not included in the presented scheme.

b) Alloying elements

If special properties are required, these may be achieved by adding certain alloying elements. These specific properties can not be integrated in the systematic approach given below.

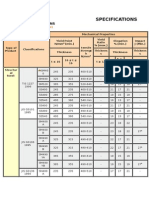

Mechanical properties of separately cast samples (30 mm diameter)

Material designation Material No. Out-dated designation DIN 1693 Microstructure Tensile strength Rm 0,1%-proof stress Rp0,1 Elongation at fracture A Compression strength dB 0,1% compression yield point d 0,1 Bending strength bB Shear strength aB Torsional strength T tB Modulus of Elasticity 3) E Poisson ratio Bending fatigue strength 4) bW Fatigue limit under reversed tension-compression stresses5) zdW Fracture toughness KIC

Rev. 01/04. 2006

[N/mm2] [N/mm2] [%] [N/mm2] [N/mm2] [N/mm2] [N/mm2] [N/mm2] [kN/mm2] [N/mm2] [N/mm2] [N/mm3/2]

EN-GJL-150 EN-JL 1020 GG 15 ferr./pearl. 1502)250 98 165 0,8 0,3 600 195 250 170 170 78 103 0,260 70 40 320

EN-GJL-200 EN-GJL-250 EN-GJL-300 EN-JL 1030 EN-JL 1040 EN-JL 1050 GG 20 GG 25 GG 30 pearlitic 200300 250 350 300 400 130 195 165 228 195 260 0,8 0,3 0,8 0,3 0,8 0,3 720 840 960 260 325 390 290 340 390 230 290 345 230 290 345 88 113 103 118 108 137 0,260 0,260 0,260 90 120 140 50 400 60 480 75 560

EN-GJL-350 EN-JL 1060 GG 35 350450 228 285 0,8 0,3 1080 455 490 400 400 123 143 0,260 145 85 650

1) When there are special requirements relation to machinability or magnetic properties, the grade ENGJL-100 may be used. The required properties can be obtained by means of a structure changing heat treatment process. This grade is not referred to in this table. 2) The bold printed numbers are the required minimum values for ultimate tensile strength. They are referred to in the designation of the respective material grade. 3) Depending on the quantity and form of the graphite as well as on the stress level and the testing method 4) The following approximately applies: bW 0.35 to 0.5 * Rm 5) The following approximately 0.53* bW=0.26 applies: bW Rm

torsional fatigue strength:

TtW

0,42 Rm

Relationship between hardness and tensile strength of grey (lamellar graphite) cast iron:

Brinell hardness (HB)

Tensile strength Rm (N/mm2)

Brinell hardness of castings made of grey (lamellar graphite) iron, mandatory and anticipated values at the agreed test position

Materialdesignation 1) EN-GJL-HB 155 out-dated designation GG-150 HB Material No. EN-JL 2010 Wall thickness [mm] > 2,5 5 10 20 40 2,5 5 10 20 40 4 5 10 20 40 5 10 20 40 10 20 40 20 40 Up to 5 10 20 40 80 5 10 20 40 80 5 10 20 40 80 10 20 40 80 20 40 80 40 80 Brinell hardness 2) HB 30 Min. 170 140 125 110 100 190 170 150 135 120 200 180 160 145 200 180 165 200 185 Max. 210 185 170 160 155 260 225 205 185 175 275 260 230 210 195 275 255 235 215 275 255 235 275 255

EN-GJL-HB 175 out-dated designation GG-170 HB

EN-JL 2020

EN-GJL-HB 195 out-dated designation GG-190 HB

EN-JL 2030

EN-GJL-HB 215 out-dated designation GG-220 HB

EN-JL 2040

EN-GJL-HB 235 out-dated designation GG-240 HB EN-GJL-HB 255 out-dated designation GG-260 HB

1)

EN-JL 2050

EN-JL 2060

The values in the material designation refer to the anticipated values of Brinell hardness at a wall thickness of 15 mm. The grades EN-GJL-HB 175 up to EN-GJL-HB 255 approximately correspond to the grades EN-GJL-150 to EN-GJL-350. On agreement between the manufacturer and the purchaser a narrower hardness range may be adopted at the position on the casting, provided that this is not less than 40 Brinell hardness units.

2)

Das könnte Ihnen auch gefallen

- HOT-ROLLED STEEL PRODUCTSDokument8 SeitenHOT-ROLLED STEEL PRODUCTS25091972Noch keine Bewertungen

- Din en 1563Dokument2 SeitenDin en 1563Tayfun Tezanlar78% (9)

- CR StandardsDokument6 SeitenCR Standardsalpha_beta48Noch keine Bewertungen

- 3coated SteelDokument20 Seiten3coated Steelalifakash1605Noch keine Bewertungen

- COLD FORMED STEEL MEMBERS AND DESIGNDokument14 SeitenCOLD FORMED STEEL MEMBERS AND DESIGNMihai MariusNoch keine Bewertungen

- GGG40 50 60Dokument10 SeitenGGG40 50 60fklicekNoch keine Bewertungen

- Reliable partner for welding cast iron materialsDokument8 SeitenReliable partner for welding cast iron materialshrk100Noch keine Bewertungen

- Cold Rolling MillDokument4 SeitenCold Rolling MillArslan BohioNoch keine Bewertungen

- Malleable Iron Property Casting QualityDokument1 SeiteMalleable Iron Property Casting QualityMetal deptNoch keine Bewertungen

- SG Iron and Cast Iron Material SpecificationsDokument9 SeitenSG Iron and Cast Iron Material Specificationsvtsusr fvNoch keine Bewertungen

- Tubular Products From Special MetalsDokument26 SeitenTubular Products From Special Metalskaveh-bahiraeeNoch keine Bewertungen

- SpecificationsDokument9 SeitenSpecificationsmahi1437Noch keine Bewertungen

- Cold Rolled Steel StripDokument40 SeitenCold Rolled Steel StripshelarsanjayNoch keine Bewertungen

- En GJL 250Dokument2 SeitenEn GJL 250Jitendra BhosaleNoch keine Bewertungen

- Structural SteelsDokument1 SeiteStructural SteelsrjueiNoch keine Bewertungen

- Ductile Iron, Gray Cast Iron, and Malleable Cast Iron Technical ParametersDokument1 SeiteDuctile Iron, Gray Cast Iron, and Malleable Cast Iron Technical ParametersprasadgayuNoch keine Bewertungen

- Techical Delivery Conditions PDFDokument31 SeitenTechical Delivery Conditions PDFGoran DjuricNoch keine Bewertungen

- En GJL 300Dokument2 SeitenEn GJL 300Xantos YulianNoch keine Bewertungen

- Bar STDDokument8 SeitenBar STDtushk20100% (1)

- Guide To Structural Steel Selection - G-SpecificationsDokument56 SeitenGuide To Structural Steel Selection - G-SpecificationsFelix RanillaNoch keine Bewertungen

- Next Generation: Ultragrip Reducing CouplingsDokument1 SeiteNext Generation: Ultragrip Reducing CouplingsblindjaxxNoch keine Bewertungen

- NPA205 Black Rush TaeguTecDokument6 SeitenNPA205 Black Rush TaeguTecpchakkrapaniNoch keine Bewertungen

- Steel Supply Sub-Grades To EC3Dokument22 SeitenSteel Supply Sub-Grades To EC3Anonymous iS33V5Noch keine Bewertungen

- Die Casting Heat Treatment Process To Increase Strength Part 1Dokument4 SeitenDie Casting Heat Treatment Process To Increase Strength Part 1itslowNoch keine Bewertungen

- En GJL 300Dokument2 SeitenEn GJL 300Xantos YulianNoch keine Bewertungen

- The Modulus of Elasticity of Steel - Is It 200 GPaDokument9 SeitenThe Modulus of Elasticity of Steel - Is It 200 GPaRevanth KumarNoch keine Bewertungen

- Table of Material Properties For Structural Steel S235, S275, S355, S420Dokument4 SeitenTable of Material Properties For Structural Steel S235, S275, S355, S420Arjun Soman100% (1)

- Table of Material Properties For Structural Steel S235, S275, S355, S420Dokument4 SeitenTable of Material Properties For Structural Steel S235, S275, S355, S420vodounnou0% (1)

- CRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiaDokument4 SeitenCRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiarajfabNoch keine Bewertungen

- 37 - Weldability and Performance of AHSSDokument27 Seiten37 - Weldability and Performance of AHSSsivaNoch keine Bewertungen

- Salzgitter S275J2 steel sheet mechanical propertiesDokument1 SeiteSalzgitter S275J2 steel sheet mechanical propertiesPalani KarthiNoch keine Bewertungen

- Grey Cast Iron CompareDokument4 SeitenGrey Cast Iron CompareagustingrtNoch keine Bewertungen

- Cast Iron StandardsDokument2 SeitenCast Iron StandardsBao Duy NguyenNoch keine Bewertungen

- Hot Dip Galvan Neal EdDokument6 SeitenHot Dip Galvan Neal EdEstuardoANoch keine Bewertungen

- Trelleborg Bollard GuideDokument9 SeitenTrelleborg Bollard Guidenmh43Noch keine Bewertungen

- Spring Materials: Sizes & Strength ValuesDokument37 SeitenSpring Materials: Sizes & Strength ValuesAntonio PerezNoch keine Bewertungen

- En-485-4 AlMg3 H22Dokument20 SeitenEn-485-4 AlMg3 H22Atul FalduNoch keine Bewertungen

- Non-Alloy Structural Steels: Mechanical Properties Available DimensionsDokument1 SeiteNon-Alloy Structural Steels: Mechanical Properties Available DimensionsOM PRAKASH PALNoch keine Bewertungen

- Katalog Gunung Garuda NewDokument36 SeitenKatalog Gunung Garuda Newabduh81Noch keine Bewertungen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryVon EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesVon EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNoch keine Bewertungen

- Metal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryVon EverandMetal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyVon EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNoch keine Bewertungen

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryVon EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsVon EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsNoch keine Bewertungen

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantVon EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsVon EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNoch keine Bewertungen

- F M TableDokument2 SeitenF M TableMOHAMMAD ASIFNoch keine Bewertungen

- 2Dokument1 Seite2MOHAMMAD ASIFNoch keine Bewertungen

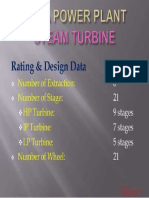

- Steam Turbine 2 638Dokument1 SeiteSteam Turbine 2 638MOHAMMAD ASIFNoch keine Bewertungen

- Size Width X Height (MM) Width X Height (In)Dokument1 SeiteSize Width X Height (MM) Width X Height (In)MOHAMMAD ASIFNoch keine Bewertungen

- Steam Turbine 5 638Dokument1 SeiteSteam Turbine 5 638MOHAMMAD ASIFNoch keine Bewertungen

- AVEVA OutfittingDokument8 SeitenAVEVA OutfittingMOHAMMAD ASIFNoch keine Bewertungen

- Steam Turbine 4 638Dokument1 SeiteSteam Turbine 4 638MOHAMMAD ASIFNoch keine Bewertungen

- EnglishDokument96 SeitenEnglishMOHAMMAD ASIFNoch keine Bewertungen

- School Development PlanDokument55 SeitenSchool Development PlanMOHAMMAD ASIFNoch keine Bewertungen

- Steam Turbine 3 638Dokument1 SeiteSteam Turbine 3 638MOHAMMAD ASIFNoch keine Bewertungen

- Emerson Control Valve HB Ed 3Dokument295 SeitenEmerson Control Valve HB Ed 3Ahmed SeliemNoch keine Bewertungen

- SheetMetal CalculationDokument7 SeitenSheetMetal CalculationVadivelu DhanakotiNoch keine Bewertungen

- AVEVA Hull StructuralDokument4 SeitenAVEVA Hull StructuralMOHAMMAD ASIF100% (1)

- Disclosure To Promote The Right To InformationDokument18 SeitenDisclosure To Promote The Right To InformationRatnakumarChittoorNoch keine Bewertungen

- IsometricDokument29 SeitenIsometricMOHAMMAD ASIFNoch keine Bewertungen

- Piping Elements: Pipes, Fittings, Flanges & ValvesDokument6 SeitenPiping Elements: Pipes, Fittings, Flanges & ValvesMOHAMMAD ASIFNoch keine Bewertungen

- Preparation of Molds For Rubber Molding To Ensure Smooth Start-Up in Production en v1Dokument9 SeitenPreparation of Molds For Rubber Molding To Ensure Smooth Start-Up in Production en v1MOHAMMAD ASIFNoch keine Bewertungen

- III Structural/ Design: Analysis and Calculation CAD Design/ Modeling Drafting CAD SupportDokument10 SeitenIII Structural/ Design: Analysis and Calculation CAD Design/ Modeling Drafting CAD SupportMOHAMMAD ASIFNoch keine Bewertungen

- BIBLE v3Dokument155 SeitenBIBLE v3MOHAMMAD ASIFNoch keine Bewertungen

- Pdms Syntax Library v1.1 2012Dokument35 SeitenPdms Syntax Library v1.1 2012seenu189100% (1)

- Quick PDMS command line referenceDokument3 SeitenQuick PDMS command line referenceVenkatesan VijayakumarNoch keine Bewertungen

- Non-Destructive Testing (NDT) : Bangalore - 560 059, KarnatakaDokument3 SeitenNon-Destructive Testing (NDT) : Bangalore - 560 059, KarnatakaMOHAMMAD ASIFNoch keine Bewertungen

- PDMS Commands (Piping)Dokument2 SeitenPDMS Commands (Piping)MOHAMMAD ASIFNoch keine Bewertungen

- BP ASME Certs Nov 2014 ExpirationDokument2 SeitenBP ASME Certs Nov 2014 ExpirationMOHAMMAD ASIFNoch keine Bewertungen

- Structure, Equipment & Others Remaining Commands of PdmsDokument5 SeitenStructure, Equipment & Others Remaining Commands of PdmsMOHAMMAD ASIFNoch keine Bewertungen

- Kinder Butterfly CatalogueDokument12 SeitenKinder Butterfly CatalogueMOHAMMAD ASIFNoch keine Bewertungen

- Non-Destructive Testing (NDT) : Bangalore - 560 059, KarnatakaDokument3 SeitenNon-Destructive Testing (NDT) : Bangalore - 560 059, KarnatakaMOHAMMAD ASIFNoch keine Bewertungen

- PModelingDMS Commands PipingDokument3 SeitenPModelingDMS Commands PipingMOHAMMAD ASIFNoch keine Bewertungen

- PDMS COMMANDS: QUICK REFERENCE FOR STRUCTURAL COMMANDSDokument3 SeitenPDMS COMMANDS: QUICK REFERENCE FOR STRUCTURAL COMMANDSMOHAMMAD ASIFNoch keine Bewertungen

- Pdms CommandsDokument6 SeitenPdms CommandsMOHAMMAD ASIFNoch keine Bewertungen

- Microdyn BWRO-1Dokument2 SeitenMicrodyn BWRO-1Rogerio SilvaNoch keine Bewertungen

- Stainless Steel Molecular Etching PDFDokument6 SeitenStainless Steel Molecular Etching PDFp.designNoch keine Bewertungen

- A Practical Handbook of Seawater AnalysisDokument328 SeitenA Practical Handbook of Seawater Analysisfdlab100% (2)

- GHS - SDS Checklist (8-13, See 11)Dokument2 SeitenGHS - SDS Checklist (8-13, See 11)Thupten Gedun Kelvin OngNoch keine Bewertungen

- Separating Mixtures Summative TestDokument4 SeitenSeparating Mixtures Summative TestMisael GregorioNoch keine Bewertungen

- Diaphragm Pumps For AirDokument3 SeitenDiaphragm Pumps For Airapi-344897318Noch keine Bewertungen

- Postulates of Quantum Mechanics ExplainedDokument6 SeitenPostulates of Quantum Mechanics ExplainedShivank Mehra100% (1)

- New IffcoDokument48 SeitenNew IffcoDiliptiwariNoch keine Bewertungen

- Squeezing Ground ConditionDokument16 SeitenSqueezing Ground ConditionMourad HosniNoch keine Bewertungen

- ERIKS - High Purity Elastomer GuideDokument56 SeitenERIKS - High Purity Elastomer GuidejbertralNoch keine Bewertungen

- Galvanic and Corrosion Compatibility Dissimilar Metal Corrosion GuideDokument21 SeitenGalvanic and Corrosion Compatibility Dissimilar Metal Corrosion Guidehitesh_tilalaNoch keine Bewertungen

- JL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous BridgesDokument18 SeitenJL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous Bridgesjrobert123321Noch keine Bewertungen

- Centrifuge Moisture Equivalent of Soils: Standard Test Method ForDokument5 SeitenCentrifuge Moisture Equivalent of Soils: Standard Test Method ForCarlos CmbbNoch keine Bewertungen

- Analysis of Driven Pile Setup With Abaqus/Standard 2006Dokument1 SeiteAnalysis of Driven Pile Setup With Abaqus/Standard 2006SIMULIACorpNoch keine Bewertungen

- Introduction To Medical TechnologyDokument22 SeitenIntroduction To Medical TechnologyKaycee Gretz LorescaNoch keine Bewertungen

- Particle Physics: OutlineDokument57 SeitenParticle Physics: OutlineMadhukar RaoNoch keine Bewertungen

- Bilirubin-D Mindray bs-300Dokument1 SeiteBilirubin-D Mindray bs-300neofherNoch keine Bewertungen

- Development of Light Weight ConcreteDokument14 SeitenDevelopment of Light Weight ConcreteAmit ChouguleNoch keine Bewertungen

- TOA DKK Water Quality Sensor Xseries PreDokument12 SeitenTOA DKK Water Quality Sensor Xseries PrealdiniNoch keine Bewertungen

- 8 Mechanical VibrationsDokument10 Seiten8 Mechanical VibrationsTsihatesfaNoch keine Bewertungen

- Comet Assay: From Wikipedia, The Free EncyclopediaDokument11 SeitenComet Assay: From Wikipedia, The Free EncyclopediasuryasivNoch keine Bewertungen

- A985 A985m-2019Dokument12 SeitenA985 A985m-2019Kamal ThummarNoch keine Bewertungen

- TM Rev PDFDokument18 SeitenTM Rev PDFHarshavardhan KutalNoch keine Bewertungen

- Paper 2Dokument8 SeitenPaper 2Prateek MalhotraNoch keine Bewertungen

- IIT JEE Laws of Motion PhysicsDokument32 SeitenIIT JEE Laws of Motion PhysicsShakil Khan100% (1)

- Sasolwax SP30 TDSDokument2 SeitenSasolwax SP30 TDSLaboratorio Inkctech0% (1)

- Polymetron Model 9240 Multi-Channel Sodium AnalyzerDokument294 SeitenPolymetron Model 9240 Multi-Channel Sodium AnalyzersrinuvoodiNoch keine Bewertungen

- Con-011 Instruction For Painting Work Rev.0Dokument11 SeitenCon-011 Instruction For Painting Work Rev.0monchai_626Noch keine Bewertungen

- Scheme of Work Science Stage 4 - 2018 - tcm142-354171Dokument38 SeitenScheme of Work Science Stage 4 - 2018 - tcm142-354171R Raj Gurung100% (2)

- ActivityDokument1 SeiteActivityTomy GeorgeNoch keine Bewertungen