Beruflich Dokumente

Kultur Dokumente

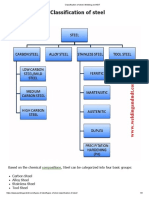

Classification of Carbon and Low Alloy Steels

Hochgeladen von

momoitachiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Classification of Carbon and Low Alloy Steels

Hochgeladen von

momoitachiCopyright:

Verfügbare Formate

Classification of Carbon and low alloy steels

The definition of the carbon steels by American Iron and Steel Institute (AISI) is as follows: Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, columbium [niobium], molybdenum, nickel, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 0.40 per cent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60. Steels can be classified based on different systems depending upon:

The composition: Carbon, micro alloy, low alloy, high alloy or stainless steel. The manufacturing processes: Open hearth furnace, basic oxygen process, energy optimizing furnace or electric arc furnace. The finishing methods: Hot rolling, cold rolling or forging etc. The type of product: Flat such as plate, sheet, strip, long such as wire rods, reinforcement bars, rounds and shapes, pipes and tubes or forged products. The de oxidation method: Killed, semi-killed, rimmed or capped steel. The microstructure: Ferritic, austenitic, pearlitic, bainitic or martensitic. The strength levels: HSS, HSLA or normal strength to meet standard requirement heat. The treatment process: Annealing, normalizing, thermo mechanical treatment, quenching and tempering etc. Quality defining designations: Forging quality, Commercial quality, drawing quality or welding quality etc. Steels

Carbon

As a group carbon steels are the most frequently produced and used steels. More than 85% of the steels produced are carbon steels. Variations in carbon have the greatest effect on the mechanical properties of steels. Increase in the carbon content results into increase in the hardness as well as increase in the strength of the steel. Hence carbon steels are generally defined according to their carbon content. Generally speaking, carbon steels contain up to 2% total alloying elements and can be subdivided into ultra low carbon, low carbon, medium carbon, high carbon, and ultra high carbon steels. These are described below: Ultra low carbon steels These steels contain very low carbon usually less than 0.10%. These steels also contain very low manganese and very low silicon. These steels are having extra deep drawing properties and usually produced in the form of flat and wire rod products.

Low carbon steels These steels contain up to 0.30% C. This category includes mild steel with carbon content usually in the range of 0.15-0.30%. The largest category of this class of steel is flat rolled products in the form of sheet or strip usually in the cold rolled and annealed condition. The carbon content for these deep drawing quality steels is around 0.10% C, with up to 0.5% manganese. For structural use produced in the form of plates and sections, the carbon content may be increased up to 0.30%, with higher manganese content up to 1.6%. Medium-carbon steels These steels are similar to low carbon steels except that the carbon content in these steels are higher and normally in the range of 0.31 to 0.60% and the manganese from 0.60 to 1.65%. Due to Increased carbon content, the medium carbon steels can be used in the quenched and tempered condition. The medium carbon steels are used as shafts, axles, gears, crankshafts, couplings and forgings. Steels in the 0.40 to 0.60% C range are also used for rails, railway wheels and rail axles. High carbon steels These steels have carbon content ranging from 0.60 to 1.00% with manganese content ranging from 0.30 to 0.90%. The use of high carbon steels includes springs, pre stressed concrete wires and high strength wires etc. Ultrahigh carbon steels These steels contains carbon in the range of 1.25 to 2.0%. These steels are normally thermo-mechanically processed to produce microstructures consisting of ultra-fine, equi-axed grains of spherical, discontinuous pro-eutectoid carbide particles. High Strength Low Alloy Steels

High strength low alloy (HSLA) steels, or micro-alloyed steels are designed to meet the specific requirement of mechanical properties rather than a chemical composition. These steels are designed to provide better mechanical properties and/or greater resistance to atmospheric corrosion than conventional carbon steels. The carbon content in HSLA steels may range from 0.05-0.25% and manganese content up to 2.0% in order to provide adequate deep drawing and welding properties. In these steels small quantities of chromium, nickel, molybdenum, copper, nitrogen, vanadium, niobium, titanium and zirconium are also used in various combinations. The HSLA steels may also have small additions of calcium, rare earth elements, or zirconium for sulfide inclusion shape control. HSLA are classified as below:

Weathering steels or atmospheric corrosion resistant steels These steels exhibit better atmospheric corrosion resistance due to an adherent oxide layer formed on it. These steels normally contain copper around 0.3%.

Control rolled steel These steels are hot rolled as per predetermined rolling schedule designed to develop a highly deformed austenite structure that will transform to a very fine equi-axed ferrite structure on cooling.

Pearlite reduced steels - The strength of these steels is obtained by very fine grain ferrite and by precipitation hardening. These steels are having very low carbon content and hence little or no pearlite in the microstructure.

Micro-alloyed steels These steels contain small content of niobium, vanadium, and/or titanium for refinement of grain size as well as for precipitation hardening.

Acicular ferrite steels These are very low carbon steels with sufficient level of hardenability. The structure of these steels transform on cooling to a very fine high strength acicular ferrite structure instead of the usual polygonal ferrite structure.

Dual-phase steels These steels are processed to a micro-structure of ferrite containing small uniformly distributed regions of high carbon martensite. These steels have low yield strength and a high rate of work hardening. These steels are of high strength with superior formability.

Low alloy Steels Low alloy steels are steels that exhibit mechanical properties superior to the properties of plain carbon steels due to the additions of alloying elements like nickel, chromium, and molybdenum. Total alloy content in these steels may from 2.01% up to the levels just below those of stainless steels which contain a minimum of 10% of Chromium. In most of the low alloy steels, the primary function of the alloying elements is to increase hardenability so as to optimize the mechanical properties and toughness after heat treatment. However in some cases the addition of alloying elements is done to reduce environmental degradation for specified service conditions. Low alloy steels are generally classified as per:

Chemical composition This classification is based on the alloying element such as tungsten steels, nickel steels, nickel chromium steels, molybdenum steels, chromium molybdenum steels etc.

Heat treatment low alloy steels can be classified based on heat treatment such as quenched and tempered steels, normalized and tempered steels or annealed steels.

Since there is a wide variety of chemical compositions possible in low alloy steels and also due to the fact that some steels can be used in more than one heat treated condition It is rather difficult to classify low alloy steels and there exists some overlap. However below there are given four major groups of alloy steels which are in common use. i. Low-carbon quenched and tempered steels These steels combine high yield strength (from 350 to 1035 N/mm) and high tensile strength with good notch toughness, ductility, corrosion resistance and weldability. These steels have various combinations of these characteristics based on their intended applications. Some of these steels are produced as forgings or castings. ii. Medium-carbon ultra-high strength steels These are structural steels which are having yield strengths that can exceed 1380 N/mm. Some of these steels are covered by designations given in various standards while some other are having proprietary compositions. Product forms for these steels include billets, bars, rods, forgings, sheets, pipes and welding wires. iii. Bearing steels These steels are used for ball and roller bearing applications. These steels consist of low carbon (0.10 to 0.20% C) case hardened steels and high carbon (less than 1.0% C) through hardened steels. Some of these steels are covered by designations given in different standards. iv. Chromium-molybdenum heat-resistant steels These steels contain 0.5 to 9% Cr and 0.5 to 1.0% Mo. The carbon content is usually below 0.2%. The chromium provides improved oxidation and corrosion resistance while the molybdenum increases strength at elevated temperatures. These steels are normally supplied in the normalized and tempered, quenched and tempered or annealed conditions.

Das könnte Ihnen auch gefallen

- Metallurgy of MaterialsDokument15 SeitenMetallurgy of Materialscal2_uniNoch keine Bewertungen

- Classification of Steel - Welding and NDTDokument3 SeitenClassification of Steel - Welding and NDTAshif Iqubal100% (1)

- Metallurgical Achievements: Selection of Papers Presented at the Birmingham Metallurgical Society's Diamond Jubilee Session, 1963-1964Von EverandMetallurgical Achievements: Selection of Papers Presented at the Birmingham Metallurgical Society's Diamond Jubilee Session, 1963-1964W. O. AlexanderNoch keine Bewertungen

- Materials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985Von EverandMaterials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985J. V. BeeNoch keine Bewertungen

- Carbon and Alloy Steel PDFDokument52 SeitenCarbon and Alloy Steel PDFmaz234100% (3)

- 1006 Casting ProblemsDokument113 Seiten1006 Casting ProblemsParam SaxenaNoch keine Bewertungen

- Manufacturing Process - Module2.0Dokument33 SeitenManufacturing Process - Module2.0Fiza KamaNoch keine Bewertungen

- Non Ferrous AlloysDokument18 SeitenNon Ferrous Alloysamele25100% (1)

- Ferrous Alloys Properties and ApplicationDokument21 SeitenFerrous Alloys Properties and ApplicationMohan RaiNoch keine Bewertungen

- New 4140 Alloy SteelDokument3 SeitenNew 4140 Alloy SteelShariq KhanNoch keine Bewertungen

- Materials For Engineering 16 - AluminumDokument15 SeitenMaterials For Engineering 16 - AluminumKris WilochNoch keine Bewertungen

- Show Brazing AluminiumDokument6 SeitenShow Brazing Aluminiumneptuno97Noch keine Bewertungen

- Ingot CastingDokument5 SeitenIngot CastingalacalleNoch keine Bewertungen

- 10-Low Alloy Steel PDFDokument32 Seiten10-Low Alloy Steel PDFIdes Trian100% (1)

- Advanced Material SelectionDokument8 SeitenAdvanced Material SelectionAdewoyin ErnestNoch keine Bewertungen

- Powder MetallurgyDokument44 SeitenPowder MetallurgyjrvinodNoch keine Bewertungen

- Ferrous Metal & AlloysDokument30 SeitenFerrous Metal & AlloysRed ReidNoch keine Bewertungen

- Porosity in Castings AFS Transactions 2005Dokument28 SeitenPorosity in Castings AFS Transactions 2005jlplazaolaNoch keine Bewertungen

- Heat Exchanger With Helical BafflesDokument8 SeitenHeat Exchanger With Helical BaffleshuangjlNoch keine Bewertungen

- Heat Transfer FundamentalsDokument6 SeitenHeat Transfer FundamentalsMuhammad FahadNoch keine Bewertungen

- ASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceDokument4 SeitenASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceSumedh ParadkarNoch keine Bewertungen

- Thermal Analysis of Continuous Casting Process (Maryeling)Dokument10 SeitenThermal Analysis of Continuous Casting Process (Maryeling)Marko's Brazon'Noch keine Bewertungen

- Application of Cold Rolled Grain Oriented Electrical SteelDokument3 SeitenApplication of Cold Rolled Grain Oriented Electrical SteelALIKHANI2000Noch keine Bewertungen

- Steel ManufacturingDokument29 SeitenSteel ManufacturingNDTInstructor100% (3)

- SAE Steel Grades - WikipediaDokument30 SeitenSAE Steel Grades - Wikipediamanoj ranathiive100% (1)

- Basic Information About Metals and AlloysDokument7 SeitenBasic Information About Metals and AlloysMahesh JingarwarNoch keine Bewertungen

- Physics Ii: Technological University of The Philippines-Taguig Electrical Engineering DepartmentDokument34 SeitenPhysics Ii: Technological University of The Philippines-Taguig Electrical Engineering DepartmentEsmeralda TapizNoch keine Bewertungen

- Review of Creep Resistant SteelsDokument4 SeitenReview of Creep Resistant SteelsAleš NagodeNoch keine Bewertungen

- Heat Loss Calculations and Heater Selection Radiant Infrared Heating PDFDokument8 SeitenHeat Loss Calculations and Heater Selection Radiant Infrared Heating PDFSeptian HarryNoch keine Bewertungen

- Task2.2 Melting EfficiencyDokument47 SeitenTask2.2 Melting EfficiencyemregnesNoch keine Bewertungen

- Martensite and The Control of Retained AusteniteDokument6 SeitenMartensite and The Control of Retained AusteniteMarcoTulioFonsecaNoch keine Bewertungen

- C 533 Calcium SilicateDokument4 SeitenC 533 Calcium SilicatereneeNoch keine Bewertungen

- 21 Chemical Elements and Effects On Steel Mechanical PropertiesDokument12 Seiten21 Chemical Elements and Effects On Steel Mechanical Propertieshaidv254100% (1)

- Heat TreatmentDokument24 SeitenHeat TreatmentOlanrewaju Slyman Damilola100% (1)

- Austempered Ductile Iron (Adi) 1Dokument20 SeitenAustempered Ductile Iron (Adi) 1Ashutosh GuptaNoch keine Bewertungen

- Meen 360 Cheat SheetDokument1 SeiteMeen 360 Cheat SheetSaniya SohailNoch keine Bewertungen

- Carpenteria Corsi SRL BrochureDokument20 SeitenCarpenteria Corsi SRL BrochureubagweNoch keine Bewertungen

- Casting Steel Alloys PDFDokument6 SeitenCasting Steel Alloys PDFIAmaeyNoch keine Bewertungen

- Casting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesDokument11 SeitenCasting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesIOSRjournalNoch keine Bewertungen

- Aluminium AssignmentDokument12 SeitenAluminium AssignmentAnonymous hVkq1jQvNoch keine Bewertungen

- JIS G 3116 SG255 Materaial Properties For LPG Tank 50 KGDokument2 SeitenJIS G 3116 SG255 Materaial Properties For LPG Tank 50 KGRahmad DesmanNoch keine Bewertungen

- Heat TreatmentDokument44 SeitenHeat Treatmentmurari100% (2)

- HP40 NBDokument13 SeitenHP40 NBTarun ChandraNoch keine Bewertungen

- Design Data Book PDFDokument73 SeitenDesign Data Book PDFDheeraj Shukla0% (1)

- IIT Karokpur VacuumDokument6 SeitenIIT Karokpur Vacuumnarayananx5Noch keine Bewertungen

- Brazing and Soldering - Learn Refrigeration PDFDokument2 SeitenBrazing and Soldering - Learn Refrigeration PDFAblePraxisNoch keine Bewertungen

- Steel GradesDokument12 SeitenSteel GradesDidar Singh Thethi100% (1)

- Harris Brazing MaterialsDokument3 SeitenHarris Brazing MaterialsfontyflockNoch keine Bewertungen

- Presentation On Heat TreatmentDokument43 SeitenPresentation On Heat Treatmentgosaye desalegnNoch keine Bewertungen

- Flame Cutting: BY B.Lakshman 2017109025Dokument46 SeitenFlame Cutting: BY B.Lakshman 2017109025Aswath BalajiNoch keine Bewertungen

- Galvanic and Corrosion Compatibility Dissimilar Metal Corrosion GuideDokument21 SeitenGalvanic and Corrosion Compatibility Dissimilar Metal Corrosion Guidehitesh_tilalaNoch keine Bewertungen

- The Use of Titanium in Family Automobiles: Current Trends: K. Faller and F.H. (Sam) FroesDokument2 SeitenThe Use of Titanium in Family Automobiles: Current Trends: K. Faller and F.H. (Sam) FroesAmol HawaldarNoch keine Bewertungen

- Aluminum Extrusion Process OverviewDokument4 SeitenAluminum Extrusion Process Overviewken_desNoch keine Bewertungen

- Lecture Chapter 4 Phase Transformation and Metal AlloysDokument79 SeitenLecture Chapter 4 Phase Transformation and Metal AlloysWinni TanNoch keine Bewertungen

- CASTING Design GuideDokument54 SeitenCASTING Design GuideXin Yu75% (4)

- Material EngineeringDokument46 SeitenMaterial EngineeringBoaquin KhenNoch keine Bewertungen

- M 1.2.8 Carbon, Lowalloyed, Fine Grained, and ThermomechanicalyDokument17 SeitenM 1.2.8 Carbon, Lowalloyed, Fine Grained, and Thermomechanicalydokumen qcNoch keine Bewertungen

- Classification of Carbon and Low-Alloy Steels: AbstractDokument23 SeitenClassification of Carbon and Low-Alloy Steels: AbstractharieduidNoch keine Bewertungen

- AISI Designation: Stainless Tool Steels Killed Carbon SteelsDokument14 SeitenAISI Designation: Stainless Tool Steels Killed Carbon SteelsShankar JhaNoch keine Bewertungen

- AlloysDokument91 SeitenAlloysNiccoloNoch keine Bewertungen

- Training Evaluation Sample FormDokument2 SeitenTraining Evaluation Sample FormmomoitachiNoch keine Bewertungen

- Idc Routing Sheet Sample Part 1Dokument1 SeiteIdc Routing Sheet Sample Part 1momoitachiNoch keine Bewertungen

- Idc Routing Sheet Sample Part 2Dokument1 SeiteIdc Routing Sheet Sample Part 2momoitachiNoch keine Bewertungen

- Sample Audit Report FormDokument1 SeiteSample Audit Report FormmomoitachiNoch keine Bewertungen

- Pressure Test Report - SampleDokument1 SeitePressure Test Report - SamplemomoitachiNoch keine Bewertungen

- Approval Authority Matrix Sample Part - 2Dokument1 SeiteApproval Authority Matrix Sample Part - 2momoitachiNoch keine Bewertungen

- Approval Authority Matrix Sample Part - 1Dokument1 SeiteApproval Authority Matrix Sample Part - 1momoitachiNoch keine Bewertungen

- 2017 18 Fafsa Updates Students Parents PDFDokument2 Seiten2017 18 Fafsa Updates Students Parents PDFmomoitachiNoch keine Bewertungen

- 05 Chapt 5 PD Section 5.5 Process - ENG - FINAL - Oct 04Dokument14 Seiten05 Chapt 5 PD Section 5.5 Process - ENG - FINAL - Oct 04Sujith SekarNoch keine Bewertungen

- 2017 Disney Dining Plan PDFDokument6 Seiten2017 Disney Dining Plan PDFmomoitachiNoch keine Bewertungen

- MTS 2016 Final NoticeDokument38 SeitenMTS 2016 Final NoticeManprita BasumataryNoch keine Bewertungen

- Terms Conditions Scholarships 2017Dokument6 SeitenTerms Conditions Scholarships 2017Tabish IslamNoch keine Bewertungen

- 2017 Round Endeavour Applicant GuidelinesDokument24 Seiten2017 Round Endeavour Applicant Guidelinespkrsuresh2013Noch keine Bewertungen

- Schoolyearhcc2016 2017 ApprovedDokument2 SeitenSchoolyearhcc2016 2017 ApprovedmomoitachiNoch keine Bewertungen

- Macro Master 1032 CDokument1 SeiteMacro Master 1032 CmomoitachiNoch keine Bewertungen

- GMAW (Solid Wire) vs. FCAW (Flux-Cored Wire)Dokument3 SeitenGMAW (Solid Wire) vs. FCAW (Flux-Cored Wire)momoitachiNoch keine Bewertungen

- Macro Master 1034 CDokument1 SeiteMacro Master 1034 CmomoitachiNoch keine Bewertungen

- Job Knowledge 76 CtodDokument4 SeitenJob Knowledge 76 CtodmomoitachiNoch keine Bewertungen

- Macro Master 1033 CDokument1 SeiteMacro Master 1033 CmomoitachiNoch keine Bewertungen

- High Low High Low High Low High Low High Low Small Large Small Large Electrode Travel Speed Ampere/current Voltage Heat Input Cooling Rate Root GapDokument2 SeitenHigh Low High Low High Low High Low High Low Small Large Small Large Electrode Travel Speed Ampere/current Voltage Heat Input Cooling Rate Root GapmomoitachiNoch keine Bewertungen

- GMAW (Solid Wire) vs. FCAW (Flux-Cored Wire)Dokument3 SeitenGMAW (Solid Wire) vs. FCAW (Flux-Cored Wire)momoitachiNoch keine Bewertungen

- SymbolDokument48 SeitenSymbolmomoitachiNoch keine Bewertungen

- Welding SymbolDokument11 SeitenWelding SymbolmomoitachiNoch keine Bewertungen

- Wis 11Dokument25 SeitenWis 11momoitachiNoch keine Bewertungen

- WIS5 Duties N 3Dokument12 SeitenWIS5 Duties N 3momoitachiNoch keine Bewertungen

- Project Internal Audit NotificationDokument1 SeiteProject Internal Audit Notificationmomoitachi100% (1)

- Nokia 2690 RM-635 Service ManualDokument18 SeitenNokia 2690 RM-635 Service ManualEdgar Jose Aranguibel MorilloNoch keine Bewertungen

- Addressing Diversity Through The Years Special and Inclusive EducationDokument6 SeitenAddressing Diversity Through The Years Special and Inclusive EducationJiezel SurinNoch keine Bewertungen

- I. You'll Hear A Conversation Between Two People. Listen and Fill in The Blanks (10 PTS) This Is The VOA Special English Agriculture ReportDokument7 SeitenI. You'll Hear A Conversation Between Two People. Listen and Fill in The Blanks (10 PTS) This Is The VOA Special English Agriculture ReportTHỌ NGUYỄN VĂNNoch keine Bewertungen

- Post War TheatreDokument11 SeitenPost War TheatrePaulPogba77Noch keine Bewertungen

- SCM 2011 PDFDokument4 SeitenSCM 2011 PDFAakash KumarNoch keine Bewertungen

- Evolis User ManualDokument28 SeitenEvolis User ManualIonmadalin1000Noch keine Bewertungen

- The First-Fourth Books of The HitopadésaDokument116 SeitenThe First-Fourth Books of The HitopadésaMiguel RosaNoch keine Bewertungen

- Wakit, Nico P.Dokument5 SeitenWakit, Nico P.yeng botzNoch keine Bewertungen

- Summative 1Dokument4 SeitenSummative 1Nean YsabelleNoch keine Bewertungen

- 2017 Reviving Tribal Tattoo TraditionsDokument3 Seiten2017 Reviving Tribal Tattoo Traditions高權梁Noch keine Bewertungen

- Q1 Practical Research 2 - Module 1bDokument15 SeitenQ1 Practical Research 2 - Module 1bRhea Mae MacabodbodNoch keine Bewertungen

- An Introduction To EFTDokument24 SeitenAn Introduction To EFTkunjammuNoch keine Bewertungen

- MHSS ItalyDokument9 SeitenMHSS Italyromedic36Noch keine Bewertungen

- FDokument102 SeitenFTop channelNoch keine Bewertungen

- NIELIT Recruitment For Scientist and Technical Assistants 2017 Official NotificationDokument6 SeitenNIELIT Recruitment For Scientist and Technical Assistants 2017 Official NotificationKshitija100% (1)

- Lubricants - McMaster-CarrDokument8 SeitenLubricants - McMaster-CarrjeanyoperNoch keine Bewertungen

- Solved Consider Again The Demand Function For Corn in Formula 1Dokument1 SeiteSolved Consider Again The Demand Function For Corn in Formula 1M Bilal SaleemNoch keine Bewertungen

- NeedScope On TechnologyDokument22 SeitenNeedScope On TechnologyNguyen Ngo Dinh PhuongNoch keine Bewertungen

- Introduction To Neutrino Physics: Paolo LipariDokument85 SeitenIntroduction To Neutrino Physics: Paolo LipariSubhankar HowladerNoch keine Bewertungen

- PUP 200 Quizzes 6Dokument47 SeitenPUP 200 Quizzes 6Nam TranNoch keine Bewertungen

- John Hopkins Evidence Table - Systematic ReviewDokument2 SeitenJohn Hopkins Evidence Table - Systematic Reviewsandy ThylsNoch keine Bewertungen

- Researchpaper Should Removable Media Be Encrypted - PDF - ReportDokument15 SeitenResearchpaper Should Removable Media Be Encrypted - PDF - ReportSakshi Dhananjay KambleNoch keine Bewertungen

- ResumeDokument3 SeitenResumeSaharsh MaheshwariNoch keine Bewertungen

- 1506a E88tag3 PDFDokument5 Seiten1506a E88tag3 PDFmohammad javad golNoch keine Bewertungen

- 1802SupplementaryNotes FullDokument235 Seiten1802SupplementaryNotes FullCourtney WilliamsNoch keine Bewertungen

- Conquering College The Most Fun You Can Have Learning The Things You Need To Know NodrmDokument144 SeitenConquering College The Most Fun You Can Have Learning The Things You Need To Know NodrmVithorNoch keine Bewertungen

- PienaDokument1 SeitePienaMika Flores PedroNoch keine Bewertungen

- Philosophical Thoughts On EducationDokument30 SeitenPhilosophical Thoughts On EducationCharyl Louise MonderondoNoch keine Bewertungen

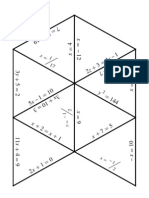

- Algebra1 Review PuzzleDokument3 SeitenAlgebra1 Review PuzzleNicholas Yates100% (1)

- One Wavelength To Loop SkywireDokument2 SeitenOne Wavelength To Loop SkywireRobert TurnerNoch keine Bewertungen