Beruflich Dokumente

Kultur Dokumente

Saic Q 1049

Hochgeladen von

Gian CarloOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Saic Q 1049

Hochgeladen von

Gian CarloCopyright:

Verfügbare Formate

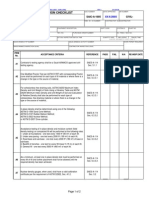

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Cement Based Non-Shrink Grout Mixing, Placement, Sampling, and Testing Inspection

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-Q-1049

WBS / BI / JO NUMBER

18-May-05

CIVIL-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

Grout Mixing Inspection Grout shall be mixed per the Grout Manufacturer's instructions. (PIP STS03600, Sec. 6.3.1) The quantity of mixing water added shall be that recommended by the Grout Manufacturer's instructions. (PIP STS03600, Sec. 6.3.1) The total dissolved solids in the mixing water to be used for mixing prepackaged grouts shall not exceed 500ppm. Grout Placement Inspection Joints in grout shall be located as shown on the IFC Drawings or as recommended by the grout manufacturer. (PIP STS03600, Sec. 6.2.6) The minimum thickness of the grout shall be the space between the bottom of the base plate and the top of the concrete foundation; The minimum thickness of grout shall be 25mm's. When type of grout is not specified by the equipment Manufacturer, cementitious grout shall be used for any of the following situations: 1. For Rotating equipment that satisfies all of these requirements: a) Equipment with driver horsepower less than 500 (373 kW). b) Equipment with speeds 3600 RPM or less. c) Equipment that has a total weight of up to 2,270 kg (5,000 lbs) 2. Grouting of structural base plates, anchor bolts, columns and precast members, i.e: wall panels, beams, etc. Grout shall be dry packed, flowed or pumped into place per the manufacturer's written instructions for the type of grout being installed; The grout manufacturer's written instructions shall be strictly followed. (PIP STS03600, Sec. 6.3.2) Grout shall be placed in only one direction to prevent trapping air; Grouting shall be quick and continuous to avoid segregation, bleeding or premature initial set. (PIP STS03600, Sec. 6.3.3) Grout Sampling Inspection Two sets of 3 grout test cubes shall be cast in the field for each day grout is mixed and placed in the field. (PIP STS03600, Sec. 4.2.1) Curing shall be the same method as the field grout is cured and test cubes for compressive strength at 7 and 28 days of age. (PIP STS03600, Sec. 4.2.1) The temperature of the grout when placed shall be 230C + 30C. (ASTM C 1107, Sec. 9.1.2) SAES-Q-010 Sec. 3.2 SAES-Q-010 Sec. 3.2 SAES-Q-010 Sec. 3.2 SAES-Q-010 Sec. 3.2 SAES-Q-005 Sec. 4.3.2.c SAES-Q-010 Sec. 3.2 SAES-Q-010 Sec. 3.2 SAES-Q-010 Sec. 5.2

A1

A2

A3

B1

B2

B3

SAES-Q-010 Sec. 6.1

B4

SAES-Q-010 Sec. 3.2

B5

SAES-Q-010 Sec. 3.2

C1

C2

C3

Page 1 of 2

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Cement Based Non-Shrink Grout Mixing, Placement, Sampling, and Testing Inspection

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-Q-1049

WBS / BI / JO NUMBER

18-May-05

Civil

CONTRACTOR / SUBCONTRACTOR

ITEM No. D

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

Grout Testing Inspection The compressive strength of the grout shall be a minimum of 24MPa (3500psi) at 7 days of age. (ASTM C 1107, Sec. 7.2, Table 1) The compressive strength of the grout shall be a minimum of 35MPa (5000psi) at 28 days of age. (ASTM C 1107, Sec. 7.2, Table 1) SAES-Q-010 Sec. 3.2 SAES-Q-010 Sec. 3.2

D1

D2

REMARKS:

REFERENCE DOCUMENTS: 1- SAES-Q-010 -- Cement Based, Non-Shrink Grout for Structural and Equipment Grouting, 29 February 2004 2- SAES-Q-005 -- Concrete Foundations, 30 June 2004

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 2 of 2

Das könnte Ihnen auch gefallen

- Saudi Aramco Inspection ChecklistDokument2 SeitenSaudi Aramco Inspection ChecklistAbdul Hannan100% (1)

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CDokument3 SeitenSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CAbdul HannanNoch keine Bewertungen

- Saic Q 1048Dokument1 SeiteSaic Q 1048Gian Carlo100% (1)

- Saic Q 1016Dokument2 SeitenSaic Q 1016Hussain Nasser Al- NowiesserNoch keine Bewertungen

- Saic A 1005Dokument2 SeitenSaic A 1005Hussain Nasser Al- Nowiesser0% (1)

- Satr M 1063Dokument3 SeitenSatr M 1063jerin100% (1)

- SAIC-A-1005 Rev 3 Compaction TestingDokument2 SeitenSAIC-A-1005 Rev 3 Compaction Testingimrankhan22Noch keine Bewertungen

- Saic Q 1012Dokument2 SeitenSaic Q 1012Hussain Nasser Al- Nowiesser100% (2)

- SAUDI ARAMCO UPGRADE WATER SYSTEMDokument3 SeitenSAUDI ARAMCO UPGRADE WATER SYSTEMLeopoldo TalandatoNoch keine Bewertungen

- Saic M 1014Dokument3 SeitenSaic M 1014Hussain Nasser Al- NowiesserNoch keine Bewertungen

- SAIC-Q-1043 Asphalt Core Density Testing InspectionDokument3 SeitenSAIC-Q-1043 Asphalt Core Density Testing InspectionAbdul HannanNoch keine Bewertungen

- Saic A 1003Dokument2 SeitenSaic A 1003Hussain Nasser Al- NowiesserNoch keine Bewertungen

- Saic Q 1014Dokument2 SeitenSaic Q 1014Hussain Nasser Al- NowiesserNoch keine Bewertungen

- Satip Q-012-01Dokument10 SeitenSatip Q-012-01Tayyab Achakzai100% (1)

- SAIC-Q-1044 Asphalt Paving Final InspectionDokument3 SeitenSAIC-Q-1044 Asphalt Paving Final InspectionAbdul HannanNoch keine Bewertungen

- SAIC-Q-1013 Rev 7 (Final)Dokument7 SeitenSAIC-Q-1013 Rev 7 (Final)Prince JoseNoch keine Bewertungen

- 09 Samss 088Dokument5 Seiten09 Samss 088Sohail TisekarNoch keine Bewertungen

- Saic Q 1004Dokument2 SeitenSaic Q 1004Hussain Nasser Al- Nowiesser100% (1)

- Satip Q 001 02Dokument1 SeiteSatip Q 001 02Abdul HannanNoch keine Bewertungen

- Saic A 1005.Dokument5 SeitenSaic A 1005.Fazal HaqNoch keine Bewertungen

- Saep 1152Dokument12 SeitenSaep 1152Shazab Nawaz0% (1)

- SAUDI ARAMCO CAST-IN-PLACE CONCRETE FORMWORK INSPECTION CHECKLISTDokument5 SeitenSAUDI ARAMCO CAST-IN-PLACE CONCRETE FORMWORK INSPECTION CHECKLISTNaushad AlamNoch keine Bewertungen

- SAIC-Q-1040 Placement and Compaction of Sub-Base and Aggregate Base Course Materials InspectioDokument3 SeitenSAIC-Q-1040 Placement and Compaction of Sub-Base and Aggregate Base Course Materials InspectioAbdul Hannan0% (1)

- Satip M 100 07Dokument10 SeitenSatip M 100 07munnaNoch keine Bewertungen

- Saic Q 1011Dokument2 SeitenSaic Q 1011Hussain Nasser Al- NowiesserNoch keine Bewertungen

- SAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionDokument8 SeitenSAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionAbdul HannanNoch keine Bewertungen

- SATIP Q 006 02 (Recovered)Dokument10 SeitenSATIP Q 006 02 (Recovered)Abdul HannanNoch keine Bewertungen

- SAIC-Q-1061 Conventional Asphalt & Sulfur Extended Asphalt Concrete Receiving, Placement and Testing InspectionDokument7 SeitenSAIC-Q-1061 Conventional Asphalt & Sulfur Extended Asphalt Concrete Receiving, Placement and Testing InspectionAbdul HannanNoch keine Bewertungen

- Saic Q 1015Dokument2 SeitenSaic Q 1015Hussain Nasser Al- Nowiesser100% (1)

- Handling and Storage of FBE Coated BarsDokument2 SeitenHandling and Storage of FBE Coated BarsMo'tasem SerdanehNoch keine Bewertungen

- Saic M 1012Dokument2 SeitenSaic M 1012Hussain Nasser Al- NowiesserNoch keine Bewertungen

- Saic Q 1001Dokument2 SeitenSaic Q 1001Hussain Nasser Al- NowiesserNoch keine Bewertungen

- 09 Samss 088Dokument4 Seiten09 Samss 088Moustafa BayoumiNoch keine Bewertungen

- Saic L 1004Dokument2 SeitenSaic L 1004Hussain Nasser Al- NowiesserNoch keine Bewertungen

- Saes Q 006Dokument28 SeitenSaes Q 006Noor Alam JanNoch keine Bewertungen

- SATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsDokument2 SeitenSATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsAbdul HannanNoch keine Bewertungen

- Saic M 1009Dokument3 SeitenSaic M 1009Hussain Nasser Al- NowiesserNoch keine Bewertungen

- Satip Q 001 03Dokument10 SeitenSatip Q 001 03munnaNoch keine Bewertungen

- Saic M 1037Dokument3 SeitenSaic M 1037Hussain Nasser Al- Nowiesser100% (1)

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Dokument3 SeitenSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNoch keine Bewertungen

- Saic-Q-1035 Sub-Base & Base CourseDokument4 SeitenSaic-Q-1035 Sub-Base & Base CourseAbdul HannanNoch keine Bewertungen

- SAES-Q-012 (Criteria For Dessign & Construction of Precast & Prestressed Concrete)Dokument3 SeitenSAES-Q-012 (Criteria For Dessign & Construction of Precast & Prestressed Concrete)Nino Celso AstilleroNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument5 SeitenSaudi Aramco Inspection ChecklistAbdul HannanNoch keine Bewertungen

- Saic H 1003Dokument2 SeitenSaic H 1003Hussain Nasser Al- NowiesserNoch keine Bewertungen

- Saic M 1049Dokument3 SeitenSaic M 1049Hussain Nasser Al- NowiesserNoch keine Bewertungen

- Saic Q 1007Dokument2 SeitenSaic Q 1007Hussain Nasser Al- NowiesserNoch keine Bewertungen

- Satip M 100 10Dokument10 SeitenSatip M 100 10munnaNoch keine Bewertungen

- Saudi Aramco waterproofing inspectionDokument3 SeitenSaudi Aramco waterproofing inspectionSatheesh Rama SamyNoch keine Bewertungen

- SAES-Q-005 (Concrete Foundations)Dokument1 SeiteSAES-Q-005 (Concrete Foundations)Nino Celso AstilleroNoch keine Bewertungen

- Saic-Q-1035 Sub-Base & Base CourseDokument5 SeitenSaic-Q-1035 Sub-Base & Base CourseAbdul HannanNoch keine Bewertungen

- Saes A 204Dokument22 SeitenSaes A 204محمد العيسوى100% (2)

- Saudi Aramco Soil Sampling ChecklistDokument3 SeitenSaudi Aramco Soil Sampling ChecklistTayyab KhanNoch keine Bewertungen

- SAES-Q-001 - Criteria For Design and Construction of Concrete StructuresDokument24 SeitenSAES-Q-001 - Criteria For Design and Construction of Concrete Structures1.202056100% (2)

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 CivilDokument3 SeitenSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 Civilkarthi51289Noch keine Bewertungen

- SATIP-Q-006-01rev4 (Asphalt Paving - Batch Plant & 3rd Party Lab) PDFDokument3 SeitenSATIP-Q-006-01rev4 (Asphalt Paving - Batch Plant & 3rd Party Lab) PDFRamziAhmedNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection ChecklistWaleed MedhatNoch keine Bewertungen

- Saic Q 1045Dokument2 SeitenSaic Q 1045Gian Carlo0% (1)

- SAIC-D-2023 Rev 2Dokument2 SeitenSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-D-2006 Rev 2Dokument2 SeitenSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Saic N 2036Dokument6 SeitenSaic N 2036aamirapiNoch keine Bewertungen

- Tiling Onto Plaster and RenderDokument6 SeitenTiling Onto Plaster and RenderGian CarloNoch keine Bewertungen

- Angle DesignDokument245 SeitenAngle DesignGian CarloNoch keine Bewertungen

- Saic Q 1046Dokument1 SeiteSaic Q 1046Gian CarloNoch keine Bewertungen

- Saic Q 1045Dokument2 SeitenSaic Q 1045Gian Carlo0% (1)

- Human Resource Management (MGT 4320) : Kulliyyah of Economics and Management SciencesDokument9 SeitenHuman Resource Management (MGT 4320) : Kulliyyah of Economics and Management SciencesAbuzafar AbdullahNoch keine Bewertungen

- PMMC ExperimentDokument2 SeitenPMMC ExperimentShyam ShankarNoch keine Bewertungen

- Internal auditing multiple choice questionsDokument4 SeitenInternal auditing multiple choice questionsSantos Gigantoca Jr.Noch keine Bewertungen

- 1 CAT O&M Manual G3500 Engine 0Dokument126 Seiten1 CAT O&M Manual G3500 Engine 0Hassan100% (1)

- JA Ip42 Creating Maintenance PlansDokument8 SeitenJA Ip42 Creating Maintenance PlansvikasbumcaNoch keine Bewertungen

- Benedict - Ethnic Stereotypes and Colonized Peoples at World's Fairs - Fair RepresentationsDokument16 SeitenBenedict - Ethnic Stereotypes and Colonized Peoples at World's Fairs - Fair RepresentationsVeronica UribeNoch keine Bewertungen

- Open MPDokument30 SeitenOpen MPmacngocthanNoch keine Bewertungen

- Math 2 Curriculum GuideDokument19 SeitenMath 2 Curriculum GuideMichelle Villanueva Jalando-onNoch keine Bewertungen

- Painter CardDokument1 SeitePainter CardPraveen RANANoch keine Bewertungen

- Lorain Schools CEO Finalist Lloyd MartinDokument14 SeitenLorain Schools CEO Finalist Lloyd MartinThe Morning JournalNoch keine Bewertungen

- TiONA 592 PDS - ENDokument1 SeiteTiONA 592 PDS - ENQuang VANoch keine Bewertungen

- Family Preparedness PlanDokument6 SeitenFamily Preparedness PlanSabrinaelyza UyNoch keine Bewertungen

- My ResumeDokument4 SeitenMy Resumeapi-216740002Noch keine Bewertungen

- Sample ResumeDokument3 SeitenSample Resumeapi-380209683% (6)

- GEd 105 Midterm ReviewerDokument17 SeitenGEd 105 Midterm ReviewerAndryl MedallionNoch keine Bewertungen

- UntitledDokument21 SeitenUntitledRoberto RamosNoch keine Bewertungen

- PoiconverterDokument2 SeitenPoiconvertertaco6541Noch keine Bewertungen

- How To Use Hyper-V Snapshot Revert, Apply, and Delete OptionsDokument15 SeitenHow To Use Hyper-V Snapshot Revert, Apply, and Delete OptionsKaran MishraNoch keine Bewertungen

- SFA160Dokument5 SeitenSFA160scamalNoch keine Bewertungen

- RFID Receiver Antenna Project For 13.56 MHZ BandDokument5 SeitenRFID Receiver Antenna Project For 13.56 MHZ BandJay KhandharNoch keine Bewertungen

- Joy Difuntorum-Ramirez CVDokument2 SeitenJoy Difuntorum-Ramirez CVJojoi N JecahNoch keine Bewertungen

- British and American Culture Marking RubricDokument5 SeitenBritish and American Culture Marking RubricAn Ho LongNoch keine Bewertungen

- 4MB0 02R Que 20160609 PDFDokument32 Seiten4MB0 02R Que 20160609 PDFakashNoch keine Bewertungen

- Tender Evaluation Template GuideDokument15 SeitenTender Evaluation Template GuideKhalid NaeemNoch keine Bewertungen

- Ubc 2015 May Sharpe JillianDokument65 SeitenUbc 2015 May Sharpe JillianherzogNoch keine Bewertungen

- DOW™ HDPE 05962B: High Density Polyethylene ResinDokument3 SeitenDOW™ HDPE 05962B: High Density Polyethylene ResinFredo NLNoch keine Bewertungen

- Semi Detailed Lesson Plan ElementaryDokument3 SeitenSemi Detailed Lesson Plan ElementaryJinky JunioNoch keine Bewertungen

- Book 2 - Test 1Dokument2 SeitenBook 2 - Test 1Đức LongNoch keine Bewertungen

- Pump IntakeDokument6 SeitenPump IntakeAnonymous CMS3dL1T100% (1)

- CPS Layoffs BreakdownDokument21 SeitenCPS Layoffs BreakdownjroneillNoch keine Bewertungen