Beruflich Dokumente

Kultur Dokumente

Seismic Response of Wood-Frame Construction: Part B: The Role of Wood-Framed Diaphragms

Hochgeladen von

rmm99rmm99Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Seismic Response of Wood-Frame Construction: Part B: The Role of Wood-Framed Diaphragms

Hochgeladen von

rmm99rmm99Copyright:

Verfügbare Formate

Built to Resist Earthquakes

The Path to Quality Seismic Design and Construction

Briefing Paper 3

Seismic Response of Wood-Frame Construction

Part B: The Role of Wood-Framed Diaphragms

Introduction This Briefing Paper 3, Seismic Response of Wood-Frame Construction, consists of three parts that discuss how earthquakes affect woodframed construction, including specifics regarding their earthquake-resisting elements, and identifies construction features required for good seismic performance. Part A provides a brief overview of how earthquakes affect woodframe construction and explains the load path in wood construction. This Part B describes diaphragm chords and collector elements, lateral-force transfer within diaphragms, and lateral-force transfer from diaphragms to shear walls or frames. Part C discusses woodframed, shear-wall construction including stiffness issues and hold-downs. Diaphragms, Chords, and Collectors Wood-frame buildings use wood construction for the roof and floors, and many low-rise concrete and masonry wall buildings use a wood-framed roof. These elements, called horizontal diaphragms, are constructed in modern buildings using wood structural panels (e.g., plywood, or oriented strand board) fastened with nails or staples to the various vertical-load-carrying wood framing members (e.g., sawn lumber joists and purlins, truss-type joists, or glulam or paralam beams) spanning between supporting walls or frames. A diaphragm transfers lateral forces by acting like a horizontal beam (Figure 1). It spans between shear walls or frames located in the story below the diaphragm. During an earthquake, the diaphragm is subjected to horizontal forces that are based on its own mass and the tributary mass of the walls attached along its edges (for information on calculating tributary mass, see Briefing Paper 1, Part B). The exact amount of the force depends on the design ground acceleration and the type of resisting system being used. Wood-frame shear wall systems will generally produce smaller diaphragm design loads than buildings with heavier concrete or masonry walls. Just like a vertical-load-carrying beam, the ends of the diaphragm must transfer the lateral forces

Boundary Chord in Compression

Shear Forces Lateral Force

Boundary Collector

Boundary Chord in Tension Shear Wall

Deflected Shape of Diaphragm

Figure 1. Plan view of diaphragm showing elements and deflected shape under lateral loading.

Briefing Paper 3, Part B ATC/SEAOC Joint Venture Training Curriculum

to the resisting shear walls or frames. The connection between the diaphragm edge or boundary and the walls or frames must transmit the shear forces. As described in Briefing Paper 1, Part D, this connection is provided by a load path member called a collector, which collects forces from along the diaphragm edge and carries Wood Ledger them to the adjacent shear wall or frame (Figure 1). The specific type of collector member used will vary, Figure 2. Collector element--wood ledger connecting depending on the construcroof/floor diaphragm to wall tion of the walls below the diaphragm edges. In a building with a woodplates or supplemental blocking installed between framed diaphragm and concrete or masonry studs and immediately below the top plates may walls, the collector is normally a wood ledger also be necessary. that is bolted to the wall. When the walls below are wood-stud framing, the collector is usually In wood stud wall buildings, the double top plate the double top plate of the stud wall. At interior normally serves as both a boundary collector and shear walls, the collector is most often a wood a chord. This is because diaphragm forces beam located in the plane of the roof or floor. In acting parallel to the wall use the plate as a each of these cases, the collector transmits collector, and forces acting perpendicular to the earthquake forces along its length and also wall use it as a chord. This dual purpose makes carries vertical dead and live loads. Accounting the wall top plate a critical element in the load for both the lateral and vertical loads is necespath of wood-frame construction. sary when designing the connections and determining the size of the collector. Force Transfer within a Wood Diaphragm As the diaphragm bends due to lateral forces (Figure 1), it creates either a tension or compression force in the chord member. This force is greatest at the middle of the appropriate span between the walls or frames. In wood-frame stud-wall construction, the double top plates of the wall perform the chord function. Because tension occurs in the chord, any splices in a top plate must be specifically designed to resist tension, or the chord will pull apart. If the top plate is cut to accommodate piping or other penetrating items, the portion removed can seriously reduce the plates ability to function as a chord. Holes, large notches and other interruptions of the top plate should be properly reinforced to maintain the capacity to resist chord forces. Steel straps are often used to provide replacement capacity. However, straps often do not work well in compression, so that thicker top The sheathing fastened to the top surface of a wood-framed floor or roof diaphragm is a membrane that provides the diaphragm with the shear capacity to transmit lateral forces to the walls and frame elements (Figure 3). The shear capacity is primarily determined by the thickness of the sheathing and the size and spacing of the fasteners attaching the edges of each individual piece of sheathing to the framing below. However, the sheathing layout pattern and the use of wood blocking below the edges also affects the capacity. The layout of the short side of the sheathing edges is usually staggered between adjacent rows to provide greater capacity. When all edges occur over framing, the diaphragm is called fully blocked. A blocked diaphragm contains more fasteners, thereby increasing its resisting capacity. Unblocked

Briefing Paper 3, Part B ATC/SEAOC Joint Venture Training Curriculum

diaphragm are large, and if inadequate connections are provided, the walls may pull away from the roof or floor. As shown in Figure 4, this can result in a collapse of the roof or floor in that region, and the wall itself may also fall. To prevent this type of failure, additional load path connections are needed to secure the diaphragm to the walls. Diaphragm beams and purlins perpendicular to the wall must be anchored directly to the concrete or masonry wall. In addition, the anchor connection to the wood members must be symmetrical. Therefore, if the Figure 3. Sheathing in typical wood diaphragms. anchor is mounted to the side face of a beam, an identical diaphragms do not have a nailing surface below anchor should be placed on the opposite beam the long edges of the sheathing and consequently face. Where beams perpendicular to the wall they have less capacity. The minimum thickness (width) of the framing below sheathing edges with closely spaced nails is also important. These framing members receive fasteners from two abutting panel edges, and the framing must be wide enough to prevent its splitting when two rows of fasteners are used. Openings through diaphragms occur where duct shafts, stairs, and skylights are located. These openings interrupt the flow of forces through the diaphragm. If the openings are large enough, special straps along their edges are required to complete the load path and transfer forces around the opening. A stair or other opening along a diaphragm boundary edge can sometimes interrupt a collector or chord member, so special attention must be given to the load path when openings occur along edges. Wood diaphragms also provide bracing for outof-plane forces on walls. The out-of-plane earthquake forces are a result of the diaphragm pushing or pulling on the walls in response to building drift and also from the bending of the diaphragm itself. Adequate resistance for outof-plane forces is important in every building. It is particularly critical when the walls are concrete or masonry, and the diaphragm is wood construction. The out-of-plane loads caused by concrete or masonry walls attached to the

Figure 4. Concrete Tilt-Up Wall Building with Failure at the Wall-to-Roof Connection

Briefing Paper 3, Part B ATC/SEAOC Joint Venture Training Curriculum

are widely spaced, additional lines of blocking may be needed to provide a load path for the out-ofplane wall anchorage.

Floor diaphragm

Wall anchors produce additional stress within the diaphragm Clip angle is because the out-of-plane anchorneeded when age force must be resisted by the shear wall nailing of diaphragm sheathing sheathing stops along the line of the anchored at floor framing beams. An unblocked diaphragm normally requires extra fasteners along panel edges occurring over those anchored beams. The code also requires continuous cross ties Shear wall between walls on opposite sides of the building to resist out-ofplane loads. Where beams are not a single continuous piece Figure 5. Connection of Floor Rim Joist or Blocking to Top Plate of across the entire diaphragm, the Wall Below individual beams must be spliced to provide this continuous tie. These splices may of the specific details used, this part of the load be constructed using steel plates with bolts path must be provided. through the beams and may also require welded connections where beams intersect interior steel Resources for Additional Reading columns. ATC, 1995, Guidelines for the Design of Transfer of Diaphragm Forces to Horizontal Wood Diaphragms, Applied TechWalls or Frames nology Council, Report ATC-7, Redwood City, California. The sheathing fasteners along the diaphragm boundary edges transfer forces out of the diaphragm to the collectors or directly to shear walls or frames. This makes those locations particularly important for providing a complete load path. However, this is only one piece of the load path between the horizontal diaphragm and the vertical resisting elements below. The boundary edge framing member (edge beam, rim joist, or blocking) below the sheathing must also be attached to a shear wall top plate, or a wood nailer attached to the top of a frame beam to complete the transfer of forces. Several methods can be used for this connection, depending on how the designer details the shear transfer. Rim joists and edge blocking can be connected to wall plates using sheet metal angles and nails, as shown in Figure 53. Alternatively, the wall sheathing can be fastened to both the diaphragm edge member and the wall top plate. Regardless

About this Briefing Paper Series

Briefing papers in this series are concise, easy-to-read summary overviews of important issues and topics that facilitate the improvement of earthquake-resistant building design and construction quality. This briefing paper was prepared by the ATC/SEAOC Joint Venture, a partnership of the Applied Technology Council (ATC) and the Structural Engineers Association of California (SEAOC). Funding for the series was provided by the California Seismic Safety Commission, Proposition 122 Retrofit Practices Improvement Program. Copies of Briefing Papers can be downloaded from ATCs World Wide Web site (www.atcouncil.org), or are available from: ATC/SEAOC Joint Venture c/o Applied Technology Council 555 Twin Dolphin Drive, Suite 550 Redwood City, California 94065

Briefing Paper 3, Part B ATC/SEAOC Joint Venture Training Curriculum

Das könnte Ihnen auch gefallen

- Fig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyDokument3 SeitenFig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyAmer GonzalesNoch keine Bewertungen

- Shear Walls - An OverviewDokument6 SeitenShear Walls - An OverviewTabish IslamNoch keine Bewertungen

- Technical Bulletin - Timber Frame StructuresDokument24 SeitenTechnical Bulletin - Timber Frame Structuresrexo100% (1)

- Chalmers - Unintended InclinationDokument358 SeitenChalmers - Unintended InclinationPomijaNoch keine Bewertungen

- CLT ConnectionDokument25 SeitenCLT ConnectionthusiNoch keine Bewertungen

- 38f-Ply Web Box Beam Type 03.PngDokument5 Seiten38f-Ply Web Box Beam Type 03.PngParthiban ArivazhaganNoch keine Bewertungen

- Wall TiesDokument32 SeitenWall TiesBandula PrasadNoch keine Bewertungen

- Diaphragms For Timber Framed Buildings Vol 17 No1 2004Dokument8 SeitenDiaphragms For Timber Framed Buildings Vol 17 No1 2004Tiago Lamy SilvaNoch keine Bewertungen

- Cavity Walls: Presented by - Aishwarya Deshmukh Aniket Late Tejas Joshi Dhananjay Marda Priti PawarDokument30 SeitenCavity Walls: Presented by - Aishwarya Deshmukh Aniket Late Tejas Joshi Dhananjay Marda Priti PawarTejas JoshiNoch keine Bewertungen

- Eb1 PDFDokument6 SeitenEb1 PDFAndyPalmerNoch keine Bewertungen

- 23-2 Design of Floor Diaphragms MoroderDokument9 Seiten23-2 Design of Floor Diaphragms Morodersbarwal9Noch keine Bewertungen

- Engineered Wood Products and An Introduction To Timber Structural SystemsDokument7 SeitenEngineered Wood Products and An Introduction To Timber Structural SystemsSang Keun YooNoch keine Bewertungen

- WoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 2 PDFDokument4 SeitenWoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 2 PDFtdegrobertNoch keine Bewertungen

- Diaphragm Action and Design - SpringerDokument3 SeitenDiaphragm Action and Design - SpringerGuillermo Agustín Yáñez QuezadaNoch keine Bewertungen

- Compliance Document For NZ Building Code, Clause B1Dokument88 SeitenCompliance Document For NZ Building Code, Clause B1Matthew BishopNoch keine Bewertungen

- Engineered TimberDokument14 SeitenEngineered TimberNaar Muhendislik100% (1)

- Eb9 PDFDokument7 SeitenEb9 PDFAndyPalmerNoch keine Bewertungen

- Reporters: Clemente, John Andrei de Pedro, John Paul Fajardo, Xandra Ale Soriano, AlgernonDokument19 SeitenReporters: Clemente, John Andrei de Pedro, John Paul Fajardo, Xandra Ale Soriano, AlgernonJogz de PedroNoch keine Bewertungen

- How To Calculate Deformations in Timber Structures Using Eurocode 1Dokument8 SeitenHow To Calculate Deformations in Timber Structures Using Eurocode 1dhanya1995Noch keine Bewertungen

- I. Bejtka - Cross (CLT) and Diagonal (DLT) Laminated Timber As InnovativeDokument144 SeitenI. Bejtka - Cross (CLT) and Diagonal (DLT) Laminated Timber As InnovativeFredNoch keine Bewertungen

- Woodbased Panels SelectionDokument16 SeitenWoodbased Panels SelectionEbisugawaNoch keine Bewertungen

- Eb 6Dokument7 SeitenEb 6AndyPalmerNoch keine Bewertungen

- Eb 8Dokument7 SeitenEb 8SyedjamelNoch keine Bewertungen

- American Institute of Timber Construction: AITC 104-2003 Typical Construction DetailsDokument32 SeitenAmerican Institute of Timber Construction: AITC 104-2003 Typical Construction DetailsMohammad Humayun KabirNoch keine Bewertungen

- Details For Structural SampleDokument1 SeiteDetails For Structural SampleCarolyn LopioNoch keine Bewertungen

- Weep Hole Part Elevation Section: Drawn: Checked: Approved: Date: CAW 5/9/2011Dokument1 SeiteWeep Hole Part Elevation Section: Drawn: Checked: Approved: Date: CAW 5/9/2011Peter Jean-jacquesNoch keine Bewertungen

- Masonry DesignDokument21 SeitenMasonry DesignkevinblacheNoch keine Bewertungen

- Timber TechnologyDokument6 SeitenTimber TechnologyShailendra PatilNoch keine Bewertungen

- Full Text 01Dokument122 SeitenFull Text 01giuruc23100% (1)

- Design of Reinforced Concrete Slab With Regard To ExplosionsDokument133 SeitenDesign of Reinforced Concrete Slab With Regard To ExplosionsNameNoch keine Bewertungen

- L9b - Timber StructuresDokument12 SeitenL9b - Timber StructuresalexrodriguezabcNoch keine Bewertungen

- As1684 Split Level c2 House BracingDokument43 SeitenAs1684 Split Level c2 House BracingUday PratapNoch keine Bewertungen

- WoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 1 PDFDokument4 SeitenWoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 1 PDFtdegrobertNoch keine Bewertungen

- VET Timber Decay CH 7 Ws 9Dokument5 SeitenVET Timber Decay CH 7 Ws 9RoOhi MugHalNoch keine Bewertungen

- Traditional Timber Turkish Houses and Structural DetailsDokument8 SeitenTraditional Timber Turkish Houses and Structural DetailsEszter SzokeNoch keine Bewertungen

- Evolution of EtfeDokument4 SeitenEvolution of EtfeMonika SadhaNoch keine Bewertungen

- "Hybrid" Light Steel Panel and Modular Systems PDFDokument11 Seiten"Hybrid" Light Steel Panel and Modular Systems PDFTito MuñozNoch keine Bewertungen

- Analysis of Shear Walls For Multi-Storey Timber Buildings PDFDokument54 SeitenAnalysis of Shear Walls For Multi-Storey Timber Buildings PDFRive NetNoch keine Bewertungen

- Trusses III Kingpost TrussesDokument12 SeitenTrusses III Kingpost TrussesCristian Morar-BolbaNoch keine Bewertungen

- Structural Glued-Laminated Timber (40pag)Dokument40 SeitenStructural Glued-Laminated Timber (40pag)pawkom100% (1)

- PRYDA - Connectors & Tie-Down Guide February 2013Dokument24 SeitenPRYDA - Connectors & Tie-Down Guide February 2013Joshua GibbingsNoch keine Bewertungen

- Tied Foundations-Portal FrameDokument3 SeitenTied Foundations-Portal FrameJaime Manalili LandinginNoch keine Bewertungen

- Glulam - Service Class 1Dokument3 SeitenGlulam - Service Class 1ikanyu79Noch keine Bewertungen

- Shear Problem in Timber StructureDokument6 SeitenShear Problem in Timber StructureIvan LiewNoch keine Bewertungen

- Design in Brickwork Non Load BearingDokument4 SeitenDesign in Brickwork Non Load Bearingharicv019Noch keine Bewertungen

- GluamDokument13 SeitenGluamMadelline Joy RitaritaNoch keine Bewertungen

- Residential Bearing Wall Removal: What Is A Bearing Wall and What Does It Do?Dokument7 SeitenResidential Bearing Wall Removal: What Is A Bearing Wall and What Does It Do?Hussein JaberNoch keine Bewertungen

- JJI-Joists Technical Manual Fourth EditionDokument44 SeitenJJI-Joists Technical Manual Fourth Editionneel123210% (1)

- Analysis of Glulam TimberDokument7 SeitenAnalysis of Glulam TimberaturutaNoch keine Bewertungen

- Ss Designprestressedconcrete enDokument8 SeitenSs Designprestressedconcrete enMarko ŠimićNoch keine Bewertungen

- LVL Handbook - Europe PDFDokument228 SeitenLVL Handbook - Europe PDFbenNoch keine Bewertungen

- Floor System in Multistory BuildingDokument25 SeitenFloor System in Multistory Buildingمحمد. إخوانNoch keine Bewertungen

- Hybrid Concrete Masonry Design: TEK 14-9ADokument8 SeitenHybrid Concrete Masonry Design: TEK 14-9AMega EstructurasNoch keine Bewertungen

- Structural Steel Beam Calculations For Loft Conversion ExampleDokument4 SeitenStructural Steel Beam Calculations For Loft Conversion ExamplePetar ValevNoch keine Bewertungen

- Basement 2 PDFDokument4 SeitenBasement 2 PDFDaniel FaizNoch keine Bewertungen

- A Five Story Precast Concrete Test Building For Seismic Conditions - Design DetailsDokument8 SeitenA Five Story Precast Concrete Test Building For Seismic Conditions - Design Detailswrite2eddyNoch keine Bewertungen

- 1 - Intro To RC Detailing - KDokument23 Seiten1 - Intro To RC Detailing - KAnonymous dlSmlsymHNoch keine Bewertungen

- PDMS Vs SmartPlantDokument24 SeitenPDMS Vs SmartPlantrmm99rmm990% (1)

- Slope Deflection MethodDokument87 SeitenSlope Deflection MethodFian ArdiyanaNoch keine Bewertungen

- OpenFX TutorialsDokument59 SeitenOpenFX Tutorialsrmm99rmm99Noch keine Bewertungen

- 3223some Issues of Optimizing The Schemes of Pneumatic Ash Removal Systems of Thermal Power PlantsDokument6 Seiten3223some Issues of Optimizing The Schemes of Pneumatic Ash Removal Systems of Thermal Power Plantsrmm99rmm99Noch keine Bewertungen

- 3224contact Free Measuring of The Level in Liquids and Bulk Mediums in Industrial Tanks Using Short Range Radar MethodsDokument3 Seiten3224contact Free Measuring of The Level in Liquids and Bulk Mediums in Industrial Tanks Using Short Range Radar Methodsrmm99rmm99Noch keine Bewertungen

- 3228estimation of Erosion in Pipelines at Pneumatic Conveying of Fine Bulk MaterialsDokument4 Seiten3228estimation of Erosion in Pipelines at Pneumatic Conveying of Fine Bulk Materialsrmm99rmm99Noch keine Bewertungen

- 3227internal Ash Conveying PlantsDokument3 Seiten3227internal Ash Conveying Plantsrmm99rmm99Noch keine Bewertungen

- 1223electrostatic PrecipitatorsDokument6 Seiten1223electrostatic Precipitatorsrmm99rmm99Noch keine Bewertungen

- 3222experience of Implementing Clyde Bergemann Technologies of Ash RemovalDokument3 Seiten3222experience of Implementing Clyde Bergemann Technologies of Ash Removalrmm99rmm99Noch keine Bewertungen

- 1224fabric Dust CollectorsDokument2 Seiten1224fabric Dust Collectorsrmm99rmm99Noch keine Bewertungen

- 842hydroturbine EquipmentDokument1 Seite842hydroturbine Equipmentrmm99rmm99Noch keine Bewertungen

- 3221technological Options For Removal of Fly Ash at TPPs in IndiaDokument4 Seiten3221technological Options For Removal of Fly Ash at TPPs in Indiarmm99rmm99100% (1)

- 1222fly Ash ScrubbersDokument1 Seite1222fly Ash Scrubbersrmm99rmm99Noch keine Bewertungen

- 311list of Coal-Fired TPPs and Boiler-HousesDokument6 Seiten311list of Coal-Fired TPPs and Boiler-Housesrmm99rmm99Noch keine Bewertungen

- Appendix 2CDokument159 SeitenAppendix 2Crmm99rmm99Noch keine Bewertungen

- Pressure Part Replacement In-Kind, Upgrade, Redesign: "What Are Your Options and How Do You Make The Right Decision?"Dokument18 SeitenPressure Part Replacement In-Kind, Upgrade, Redesign: "What Are Your Options and How Do You Make The Right Decision?"rmm99rmm99100% (1)

- APPENDIX D - Civil Design Criteria 021007Dokument9 SeitenAPPENDIX D - Civil Design Criteria 021007rmm99rmm99Noch keine Bewertungen

- RPI TP 0200 v1 2007Dokument17 SeitenRPI TP 0200 v1 2007rmm99rmm99100% (1)

- Appendix C Engineering Design CriteriaDokument37 SeitenAppendix C Engineering Design Criteriarmm99rmm99Noch keine Bewertungen

- Ds-Module 5 Lecture NotesDokument12 SeitenDs-Module 5 Lecture NotesLeela Krishna MNoch keine Bewertungen

- HU - Century Station - PAL517PDokument232 SeitenHU - Century Station - PAL517PTony Monaghan100% (3)

- En 50124 1 2001Dokument62 SeitenEn 50124 1 2001Vivek Kumar BhandariNoch keine Bewertungen

- Freshers Jobs 26 Aug 2022Dokument15 SeitenFreshers Jobs 26 Aug 2022Manoj DhageNoch keine Bewertungen

- Powerwin EngDokument24 SeitenPowerwin Engbillwillis66Noch keine Bewertungen

- 2 AcknowledgementDokument8 Seiten2 AcknowledgementPadil KonamiNoch keine Bewertungen

- Terminal Blocks: Assembled Terminal Block and SeriesDokument2 SeitenTerminal Blocks: Assembled Terminal Block and SeriesQuan Nguyen TheNoch keine Bewertungen

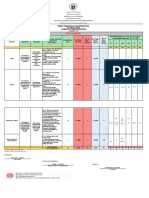

- Department of Education: Income Generating ProjectDokument5 SeitenDepartment of Education: Income Generating ProjectMary Ann CorpuzNoch keine Bewertungen

- LG Sigma+EscalatorDokument4 SeitenLG Sigma+Escalator강민호Noch keine Bewertungen

- Metalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520Dokument1 SeiteMetalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520NitinNoch keine Bewertungen

- IIM L: 111iiiiiiiDokument54 SeitenIIM L: 111iiiiiiiJavier GonzalezNoch keine Bewertungen

- Elastomeric Impression MaterialsDokument6 SeitenElastomeric Impression MaterialsMarlene CasayuranNoch keine Bewertungen

- Antibiotics MCQsDokument4 SeitenAntibiotics MCQsPh Israa KadhimNoch keine Bewertungen

- A Review of Mechanism Used in Laparoscopic Surgical InstrumentsDokument15 SeitenA Review of Mechanism Used in Laparoscopic Surgical InstrumentswafasahilahNoch keine Bewertungen

- Grade9 January Periodical ExamsDokument3 SeitenGrade9 January Periodical ExamsJose JeramieNoch keine Bewertungen

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Dokument6 SeitenRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoNoch keine Bewertungen

- Holiday AssignmentDokument18 SeitenHoliday AssignmentAadhitya PranavNoch keine Bewertungen

- Why File A Ucc1Dokument10 SeitenWhy File A Ucc1kbarn389100% (4)

- Frequency Response For Control System Analysis - GATE Study Material in PDFDokument7 SeitenFrequency Response For Control System Analysis - GATE Study Material in PDFNarendra AgrawalNoch keine Bewertungen

- Bushcraft Knife AnatomyDokument2 SeitenBushcraft Knife AnatomyCristian BotozisNoch keine Bewertungen

- Student Exploration: Digestive System: Food Inio Simple Nutrien/oDokument9 SeitenStudent Exploration: Digestive System: Food Inio Simple Nutrien/oAshantiNoch keine Bewertungen

- TRICARE Behavioral Health Care ServicesDokument4 SeitenTRICARE Behavioral Health Care ServicesMatthew X. HauserNoch keine Bewertungen

- Bài Tập Từ Loại Ta10Dokument52 SeitenBài Tập Từ Loại Ta10Trinh TrầnNoch keine Bewertungen

- Sample Cross-Complaint For Indemnity For CaliforniaDokument4 SeitenSample Cross-Complaint For Indemnity For CaliforniaStan Burman75% (8)

- Chapter Three: Tools For Exploring The World: Physical, Perceptual, and Motor DevelopmentDokument43 SeitenChapter Three: Tools For Exploring The World: Physical, Perceptual, and Motor DevelopmentHsieh Yun JuNoch keine Bewertungen

- CSEC SocStud CoverSheetForESBA Fillable Dec2019Dokument1 SeiteCSEC SocStud CoverSheetForESBA Fillable Dec2019chrissaineNoch keine Bewertungen

- CEN and CENELEC Position Paper On The Proposal For CPR RevisionDokument15 SeitenCEN and CENELEC Position Paper On The Proposal For CPR Revisionhalexing5957Noch keine Bewertungen

- BRAND AWARENESS Proposal DocumentDokument11 SeitenBRAND AWARENESS Proposal DocumentBuchi MadukaNoch keine Bewertungen

- Lateritic NickelDokument27 SeitenLateritic NickelRAVI1972100% (2)

- Discrete Mathematics and Its Applications: Basic Structures: Sets, Functions, Sequences, and SumsDokument61 SeitenDiscrete Mathematics and Its Applications: Basic Structures: Sets, Functions, Sequences, and SumsBijori khanNoch keine Bewertungen