Beruflich Dokumente

Kultur Dokumente

CEB1100

Hochgeladen von

oscar horacio floresOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CEB1100

Hochgeladen von

oscar horacio floresCopyright:

Verfügbare Formate

COMPRESSOR,

1. PLANNING A. Effectivitv:

FRONT BEARING

HOUSING

ASSY - REWORK

INFORMATION: --__ and -B17B Series engines and compressor

All the followrng Model 250-CZO. -CZOB. -617, assemblies are affected by this bulletin. b&&k! c20 C2OB 817 B17B B. Reason: Enaine Serial No. CAE 820000 through CAE 823345 CAE 830000 through CAE 830416 CAE 870003 through CAE 870059 CAE 880001 through CAE 880186

Comoressor

Serial No.

CAC 30000 thmugh CAC 32999 CAC 38001 thmugh CAC 39016 CAC 33000 thmugh CAC 60003 thwugh CAC 33419 CAC 60061

CAC 80001 through CAC 80189

The retention configuration for the compressor front bearing oil seal is modified in all Series II engines. The two roll pins currently used in the compressor front bearing housing to position and retain the oil seal body are replaced with a retainer ring. This change will provide improved squareness control on the installed seal and will reduce the potential for damage to the seal carbon face during assembly. C. Descriotion: The new P/N 6893617 Bearing Housing is the same as the superseded housing except two 0.064 - 0.067 in. (1.63-l .70 mm) diameter roll pin holes are deleted and an internal groove, one slot and chamfer are added for retainer ring installation. Superseded PIN 6853505 Bearing Housings may be reworked and reidentified for use with the added retainer ring. The retainer ring is installed in the rear (narrower) groove of the No. 1 bearing oil seal and the O-ring is installed in the front (wider) groove. The spring and spring cup installation remains unchanged. The cup sleeve fits over the spring on the end which ccntacts the bearing. The retaining ring is compressed in the seal groove; then the bearing housing is installed over the spring, oil seal and bearing until the ring is seated fully inside the bearing housng groove. Although the bearing housing has a chamfered bore and a rear edge slot for access to the retainer ring lugs, always exercise care to prevent damage to the seal carbon face while engaging the retainer ring in the housing. D. Approval: Technical aspects are FAA approved E. Compliance: Compliance F. Code 6. It is recommended that this bulletin be accomplished following parts availabilify at next overhaul

Interchanoeabilitv: All changes in this bulletin must be incorporated stmultaneously.

January 31, 1977 Revision No. 4 August 31,1996

250-C20, 250-B17,

-C2OB -B17B

CEB-1100 TP CEB-1069 Page 1 of 4

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

Allison Engine Company COMMERCIAL ENGINE BULLETIN PLANNING G. INFORMATION: (Continued)

Material Availabilitv: New PIN 23059593 Nomenclature Ring, Retainer QY 1

H.

Tooling: The following special tools are required: New PIN 6893535 Nomenclature Compressor-Removal, Retainer Ring, Carbon Seal Qt!i 1

I.

Weight and Balance: Not affected.

J.

Electrical Load Data: Not affected.

K.

References: AlV-2047 and CW-2007. Affected: Manual, Turboshaft Manual, Turboshafl Models 25sC20, Manual, Turboprop Models 250-817. Models 250-C20, -CZOB, -CZOF. ATL-4174, CW-2336. CW-5618

L.

Other Publications (1) (2) (3) (4) (5) (6)

lOW2 Operation and Maintenance -C2OJ lOW2S Operation and Maintenance

Models 250-CZOS -C2OB. -CZOF, -C2OJ Models 250-817, -617B. -817C.

lOW3 Overhaul Manual, Turboshaft llW2 Operation and Maintenance -8170. -B17E llW3 llW4 Overhaul Manual, Turboprop

-8178.

-617C,

-B17D. -817E

Parts Catalog, Turboprop Models 250-817, INSTRUCTIONS:

-8178.

-B17C, -B17D. -B17E

ACCOMPLISHMENT

Rework P/N 6853505 Compressor Front Bearing Housing to incorporate retention configuration for the bearing oil seal as follows:

the improved ,241 in. (31.73-31.52

(1)

(2) (3)

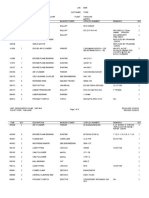

Machine 0.068-0.063 in. (1.73-l .60 mm) wide groove to 1.247-l mm) diameter inside the houslng (see Figure 1).

Add a 0.5674.557 in. (14.4s14.14 mm) wide retainer ring access slot. Remove burrs but do not break sharp edges on both sides of slot. Chamfer edge of housing to 1.248-l ,238 in. (31.7s31.45 mm) diameter x 30 degrees.

Obliterate the existing part number and reidentify as 6893617 Housing, Fri. Compr. Brg., per AS478-2Dl. Replace two MS16562-197 Pins with new P/N 23059593 Retainer Ring.

Record compliance with X0-C2O/C2OB CEB-1100 or250-B17/B176 TP CEB-1069 in the Compressor Assembly (blue pages) Modification Record, Part Ill of the Engine Log Book.

January 31,1977 Revision No. 4 August 31,1996

250-C20, 250-817.

-C20B -8178

CEB-1100 TP CEB-1069 Page 2 of 4

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

Allison COMMERCIAL 2. ACCOMPLISHMENT INSTRUCTIONS:

Engine Company ENGINE BULLETIN (Continued)

MARK 6893617 PER AS476~2Dl \

R 0.005

M&z

CIO?: A-A * REMOVE BURRS BUT DO NOT BREAK SHARP EDGES ON BOTH SIDES OF SLOT.

TOLERANCES OTHERWISE ENLARGED OF GROOVE DIMENSIONS ARE VIEW AXGLES 3 PLACE

UNLESS SPECIFIED

il DECIMALS

kO.010

IX INCHES

Compressor

Front Bearing Housing Figure No. 1 250-C20, 2.50-B17. -C20B -B 178

Rework

January 31,1977 Revision No. 4 August 31,1996

TP

CEB-1100 CEB-1069 Page 3 Of 4

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

Allison Engine Company COMMERCIAL ENGINE BULLETIN 3. MATERIAL A. B. New PIN 6893617 INFORMATION: is per compressor assembly. Instructions/ Disoosition 1

Basis for quantities Bill of material: Q!l 1

Nomenclature Housing, Bearing, Compressor Front Pin, l/16 Dia x ii/16 in.

@&p& 6853505

QY 1

MS16562-197

1 23059593

Ring. Retainer NOTES:

iNSTRUCTlONS/DlSPOSlTlON 1. 2. 3. Rework and reidentify Scrap removed part Added

CUSTOMER SUPPORT ALLISON ENGINE COMPANY

January 31.1977 Revision No. 4 August 31,1996

250-C20. 250-817.

-C2OB -8178

CEB-1100 TP CEB-1069 Page 4 of 4

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Introduction To Aircraft Performance, Selection and Design PDFDokument168 SeitenIntroduction To Aircraft Performance, Selection and Design PDFAnres Anres DictadorNoch keine Bewertungen

- QRH Rev 43DDokument294 SeitenQRH Rev 43Doscar horacio floresNoch keine Bewertungen

- DR6000 MK2 Diversity Receiver Manual, Installation & OperationDokument39 SeitenDR6000 MK2 Diversity Receiver Manual, Installation & Operationoscar horacio floresNoch keine Bewertungen

- Sketch A320Dokument33 SeitenSketch A320oscar horacio floresNoch keine Bewertungen

- TM-9-2320-280-20-2 HMMWV Unit Maintnance Vol 2Dokument945 SeitenTM-9-2320-280-20-2 HMMWV Unit Maintnance Vol 2AUGieDogie1100% (4)

- Apu B 767Dokument103 SeitenApu B 767gm&oNoch keine Bewertungen

- TM-9-2320-280-20-3 HMMWV Unit Maintnance Vol 3Dokument1.151 SeitenTM-9-2320-280-20-3 HMMWV Unit Maintnance Vol 3AUGieDogie1100% (5)

- CEB1113Dokument1 SeiteCEB1113oscar horacio floresNoch keine Bewertungen

- CEB1106Dokument4 SeitenCEB1106oscar horacio floresNoch keine Bewertungen

- TM-9-2320-280-20-1 HMMWV Unit Maintnance Vol 1Dokument883 SeitenTM-9-2320-280-20-1 HMMWV Unit Maintnance Vol 1AUGieDogie1100% (6)

- MCDP Remote Panel WireDokument6 SeitenMCDP Remote Panel Wireoscar horacio floresNoch keine Bewertungen

- CEB1115Dokument6 SeitenCEB1115oscar horacio floresNoch keine Bewertungen

- LeitholdDokument1.383 SeitenLeitholdsethokiba67% (3)

- TM 9 2320 280 10 Operators Manual HMMWVDokument407 SeitenTM 9 2320 280 10 Operators Manual HMMWVAUGieDogie1100% (16)

- Detroit Diesel AllisonDokument1 SeiteDetroit Diesel Allisonoscar horacio floresNoch keine Bewertungen

- CEB1111Dokument5 SeitenCEB1111oscar horacio floresNoch keine Bewertungen

- CEB1112Dokument5 SeitenCEB1112oscar horacio floresNoch keine Bewertungen

- CEB1108Dokument5 SeitenCEB1108oscar horacio floresNoch keine Bewertungen

- CEB1110Dokument4 SeitenCEB1110oscar horacio floresNoch keine Bewertungen

- CEB1104Dokument8 SeitenCEB1104oscar horacio floresNoch keine Bewertungen

- CEB1107Dokument5 SeitenCEB1107oscar horacio floresNoch keine Bewertungen

- CEB1109Dokument6 SeitenCEB1109oscar horacio floresNoch keine Bewertungen

- HKMN Gas Turbine Division: Rolls-Royce Proprietary Data - Uncontrolled PrintedDokument10 SeitenHKMN Gas Turbine Division: Rolls-Royce Proprietary Data - Uncontrolled Printedoscar horacio floresNoch keine Bewertungen

- CEB1099Dokument6 SeitenCEB1099oscar horacio floresNoch keine Bewertungen

- CEB1097Dokument5 SeitenCEB1097oscar horacio floresNoch keine Bewertungen

- CEB1103Dokument31 SeitenCEB1103oscar horacio floresNoch keine Bewertungen

- CEB1102Dokument1 SeiteCEB1102oscar horacio floresNoch keine Bewertungen

- CEB1101Dokument5 SeitenCEB1101oscar horacio floresNoch keine Bewertungen

- CEB1098Dokument8 SeitenCEB1098oscar horacio floresNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Tesys D Lc1d09m7Dokument3 SeitenTesys D Lc1d09m7Awalaizal Suman JayaNoch keine Bewertungen

- 7 Steps To Publishing in A Scientific JournalDokument53 Seiten7 Steps To Publishing in A Scientific JournalZAHID HUSSAIN AMEERNoch keine Bewertungen

- Report - HARI GDokument73 SeitenReport - HARI GHari GNoch keine Bewertungen

- MidTerm Topic's MarPowerDokument18 SeitenMidTerm Topic's MarPowerBerbaño, Jan JoshuaNoch keine Bewertungen

- Vol3Dokument854 SeitenVol3Giapy Phuc Tran100% (66)

- WRT9261 8Dokument22 SeitenWRT9261 8Carmen Cecilia Larez SanchezNoch keine Bewertungen

- Flex I-O Terminal Base UnitsDokument16 SeitenFlex I-O Terminal Base UnitsFrancisco Mones RuizNoch keine Bewertungen

- Honeywell C554A Instruction (Eng)Dokument8 SeitenHoneywell C554A Instruction (Eng)Wahyudi andhika comNoch keine Bewertungen

- LOGIQ E9 R3.1.3 or Later Removable Trackball Cable Compatibility - IM - 5749846-100 - 2Dokument2 SeitenLOGIQ E9 R3.1.3 or Later Removable Trackball Cable Compatibility - IM - 5749846-100 - 2hakep112Noch keine Bewertungen

- Riparazione EcmDokument17 SeitenRiparazione Ecmjalvarez_385073Noch keine Bewertungen

- ASR X AP Racing Big Brake Kit 299mm - ASR PartsDokument1 SeiteASR X AP Racing Big Brake Kit 299mm - ASR PartsAnil dNoch keine Bewertungen

- Perkins 20 Kva (404D-22G)Dokument2 SeitenPerkins 20 Kva (404D-22G)RavaelNoch keine Bewertungen

- Adi Wijaya Project - Vc0-ReportDokument7 SeitenAdi Wijaya Project - Vc0-Reportryhz0410Noch keine Bewertungen

- Microcontrollers and Embedded Systems Unit 2:8051 ProgrammingDokument6 SeitenMicrocontrollers and Embedded Systems Unit 2:8051 ProgrammingKyly BlueNoch keine Bewertungen

- A New CMOS Charge Pump For Low Voltage ApplicationsDokument4 SeitenA New CMOS Charge Pump For Low Voltage Applicationskhausar1785Noch keine Bewertungen

- FSM Catologue 90-99Dokument99 SeitenFSM Catologue 90-99rotnegerNoch keine Bewertungen

- Yale GP080-120VX-BTGDokument28 SeitenYale GP080-120VX-BTGФедор СумовNoch keine Bewertungen

- Me Engines (The Computer Controlled Electronic Engines)Dokument5 SeitenMe Engines (The Computer Controlled Electronic Engines)Shekhar SharmaNoch keine Bewertungen

- Growatt 8000tl3 S ManualDokument30 SeitenGrowatt 8000tl3 S Manualletuananh122Noch keine Bewertungen

- Husqvarna 1992-2012 250 360 PartsDokument108 SeitenHusqvarna 1992-2012 250 360 Parts14583Noch keine Bewertungen

- DOMRAC Review QuestionsDokument2 SeitenDOMRAC Review Questionscalvin AliaNoch keine Bewertungen

- New NC Report FormatDokument24 SeitenNew NC Report FormatNitish SinghNoch keine Bewertungen

- STM32 Nucleo Boards ManualDokument63 SeitenSTM32 Nucleo Boards ManualMauro H. S. WencelewskiNoch keine Bewertungen

- 88-02 Cummins Exhaust BrakeDokument24 Seiten88-02 Cummins Exhaust Brakemark_dayNoch keine Bewertungen

- Explosionado de Partes: - Mini SplitDokument6 SeitenExplosionado de Partes: - Mini SplitAldair Contreras MataNoch keine Bewertungen

- For Information Only, Will Not Be Exchanged When Altered!: Spare Part ListDokument6 SeitenFor Information Only, Will Not Be Exchanged When Altered!: Spare Part ListPedro SuyenNoch keine Bewertungen

- 8038014P 2Dokument3 Seiten8038014P 2swarajNoch keine Bewertungen

- 33 KV SubstationDokument19 Seiten33 KV Substationraju chandanshiveNoch keine Bewertungen

- Isuzu Diesel EngineDokument43 SeitenIsuzu Diesel EngineKin Arvin PelagioNoch keine Bewertungen

- 30 Years of EL CID Use May 30 - J SuttonDokument14 Seiten30 Years of EL CID Use May 30 - J Suttonsarunagarajan7795Noch keine Bewertungen