Beruflich Dokumente

Kultur Dokumente

WM 710 Dispensing Gun Data Sheet

Hochgeladen von

Nordson Adhesive Dispensing SystemsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

WM 710 Dispensing Gun Data Sheet

Hochgeladen von

Nordson Adhesive Dispensing SystemsCopyright:

Verfügbare Formate

WM 710 Adhesive Dispensing Pneumatic Gun

High-flow cold adhesive gun provides sharp cutoff for intermittent and continuous production.

The Nordson WM 710 pneumatic bead gun features an innovative reverse-needle stroke function to produce excellent adhesive cutoff. The integrated needle and seat closes against the direction of material flow. This causes excess material to be pulled back into the gun significantly reducing nozzle dripping. The WM 710 pneumatic gun is ideal for slot nozzle applications and low- to medium-speed intermittent packaging, corrugated, and bag-and-sack manufacturing. Fast air-open, air-close gun operation complements clean cutoff to provide reliable pattern uniformity. Gun cycle times of 10.5 milliseconds (12.7 W) or 12 milliseconds (5.4 W) and a minimum service life of 30 million cycles deliver reliable response and long service life.

Efficient operation improves pattern and product quality.

Compact vertical gun-mount bracket simplifies installation and service. Vertical micro-adjust control facilitates critical gun positioning. Efficient control piston handles a wide range of adhesive types and viscosities. Removable gun cartridge expedites servicing without bracket disassembly and time-consuming repositioning. Quick-disconnect air fitting and pre-mounted solenoid speed installation. Corrosion-resistant materials on all wetted components and a stainless-steel needle help prolong gun life.

Reverse-needle stroke action delivers accurate cutoff and retards adhesive build-up on the nozzle. Integrated needle-and-seat design improves adhesive flow. Narrow body profile fits easily on most parent machinery and slot nozzles.

WM 710 Adhesive Dispensing Pneumatic Gun

Compact body size fits easily on most parent machinery and slot nozzles.

Efficient gun-mount bracket provides vertical micro-adjustment for critical positioning.

A wide selection of nozzle orifice diameters and pattern plates meets diverse pattern requirements.

Specifications Working Hydraulic Pressure Maximum Hydraulic Pressure Operating Air Pressure

36 bar (529 psi) 100 bar (1470 psi) 0.5 to 6 bar (7 to 88 psi), 4 bar (59 psi) recommended 10.5 ms (12.7 W), 12.0 ms (5.4 W) 0.3 to 1.5 mm (0.012 to 0.059 in.)

1/2-20 UNF 25 mm 14 mm (0.98 in.) (0.55 in.)

90.5 mm (3.56 in.)

5.5 mm (0.22 in.)

65 mm (2.56 in.) M6(2x)

Minimum Cycle Time* Nozzle Diameter Range Pattern Coating Width Connection Fitting Electrical Service

129 mm (5.08 in.)

Up to 100 mm (3.94 in.) 1/2-20 UNF 230 VAC, 50/60 Hz, 24 VDC or 110 VAC solenoid 0.45 kg (1.0 lb)

19 mm (0.75 in.) 6/4 mm (0.24/0.16 in.) 14.5 mm (0.57 in.) 18.5 mm (0.73 in.) 47 mm (1.85 in.)

Weight

* Cycle times based on an adhesive viscosity of 900 centipoise. Actual cycle time will vary depending on adhesive viscosity and characteristics.

For more information, talk with your Nordson representative or contact your Nordson regional office.

United States Duluth, Georgia Telephone: (800) 683-2314 Toll-free Facsimile: (866) 667-3329 www.nordson.com/packaging Canada Markham, Ontario Telephone:(800) 463-3200 Facsimile: (905) 475-8821 Europe Udenhout, The Netherlands Telephone:(31) 13-511-8777 Facsimile: (31) 13-511-3995 Japan Tokyo, Japan Telephone:(81) 3-5762-2700 Facsimile: (81) 3-5762-2701 Asia/Australia/ Latin America Amherst, Ohio Telephone: (440) 985-4797 Facsimile: (440) 985-1096

When you expect more.

2000, 2003 Nordson Corporation All Rights Reserved. Nordson reserves the right to make design changes between printings.

Nordson Corporation 11475 Lakefield Drive Duluth, Georgia 30097-1511

PKL-03-3013 Issued 4/03 Printed in U.S.A.

Das könnte Ihnen auch gefallen

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosVon EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNoch keine Bewertungen

- NuFlo Liquid Turbine FlowmetersDokument6 SeitenNuFlo Liquid Turbine FlowmetersphostyNoch keine Bewertungen

- Ооо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RDokument53 SeitenОоо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RSiva baalan50% (2)

- A320 GACA ORAL TEST Updated 14/09/2013 Emergency EquipmentDokument20 SeitenA320 GACA ORAL TEST Updated 14/09/2013 Emergency EquipmentMustafa ElbazNoch keine Bewertungen

- Compile of Lab Thin CylinderDokument13 SeitenCompile of Lab Thin CylinderKhairi Azri100% (4)

- Pilot Boat PO - Sea Trial ReportDokument16 SeitenPilot Boat PO - Sea Trial ReportKyaw Oo100% (2)

- Powerdrive x6Dokument7 SeitenPowerdrive x6ice_PLNoch keine Bewertungen

- Rig Inspection - ModuspecDokument536 SeitenRig Inspection - Moduspecwideawake.wa91Noch keine Bewertungen

- IR ECM590 Track Drill SpecDokument8 SeitenIR ECM590 Track Drill Specjean565100% (2)

- ASTM E23-12c PDFDokument25 SeitenASTM E23-12c PDFSantiago Oliva100% (2)

- Working Tables For Compressible FlowDokument30 SeitenWorking Tables For Compressible FlowJeremy GorospeNoch keine Bewertungen

- ValvesDokument8 SeitenValvespravin_2011Noch keine Bewertungen

- Standard AltaBlue Touch Adhesive Melters Data SheetDokument2 SeitenStandard AltaBlue Touch Adhesive Melters Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- BN-G-Y017 Welding Inspection GuideDokument5 SeitenBN-G-Y017 Welding Inspection GuidePugalNoch keine Bewertungen

- Unbrako Catalog FastenerDokument26 SeitenUnbrako Catalog Fastenerdesign_rajeev100% (1)

- Failure of Secondary Reformer RefractoryDokument27 SeitenFailure of Secondary Reformer RefractoryZeshanNoch keine Bewertungen

- Weld Overlay Procedure For InconelDokument3 SeitenWeld Overlay Procedure For InconelArash Mohamadi100% (2)

- Universal Nozzles and Modules BrochureDokument4 SeitenUniversal Nozzles and Modules BrochureNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Pump Sizing CalculationDokument12 SeitenPump Sizing Calculationionutlaur86Noch keine Bewertungen

- QSSDokument48 SeitenQSSArvind KhapleNoch keine Bewertungen

- 332-355 Metabo en 01Dokument24 Seiten332-355 Metabo en 01Rajko SjeklocaNoch keine Bewertungen

- Durable Design For Survivability in Harsh Environments: Qualitrol 050Dokument2 SeitenDurable Design For Survivability in Harsh Environments: Qualitrol 050Rafael Cruz VazquezNoch keine Bewertungen

- Economical, Miniature Limit Switch Boasting Rigid ConstructionDokument5 SeitenEconomical, Miniature Limit Switch Boasting Rigid ConstructionRajeev Saini100% (1)

- Chapter 10 Mechanical FeedthroughsDokument50 SeitenChapter 10 Mechanical FeedthroughsPardhu YellaNoch keine Bewertungen

- Bore Gage: Inside Diameter MeasurementDokument12 SeitenBore Gage: Inside Diameter MeasurementBhaveshBalasNoch keine Bewertungen

- Transducers, Cables, Couplants and Test Blocks For Ultrasonic Precision Thickness GagesDokument6 SeitenTransducers, Cables, Couplants and Test Blocks For Ultrasonic Precision Thickness GagesALP69Noch keine Bewertungen

- Miller Spectrum 875 XtremeDokument4 SeitenMiller Spectrum 875 XtremeomaralihasNoch keine Bewertungen

- The IK-54D: Economical Gas Shape Cutter for High ProductionDokument4 SeitenThe IK-54D: Economical Gas Shape Cutter for High ProductionJose BustosNoch keine Bewertungen

- DPDT Basic Switch For Two Independent Circuit ControlDokument5 SeitenDPDT Basic Switch For Two Independent Circuit ControlShubham GuptaNoch keine Bewertungen

- Chicago Pneumatic Breakers Brochure (US)Dokument12 SeitenChicago Pneumatic Breakers Brochure (US)Sumit BhasinNoch keine Bewertungen

- "Go Lean, Think Green": Manufacturers Alliance Group, IncDokument12 Seiten"Go Lean, Think Green": Manufacturers Alliance Group, IncmoonstarNoch keine Bewertungen

- Special Purpose Basic SwitchDokument5 SeitenSpecial Purpose Basic Switchng_viet_cuong_groupNoch keine Bewertungen

- KR Mini Mill SeriesDokument31 SeitenKR Mini Mill SeriesShani KhanNoch keine Bewertungen

- Display BrochureDokument8 SeitenDisplay BrochurevanNoch keine Bewertungen

- 9851 3286 01 - L-Cop1132Dokument4 Seiten9851 3286 01 - L-Cop1132NeilNoch keine Bewertungen

- HP Bypass Valves Type ARS: ApplicationDokument2 SeitenHP Bypass Valves Type ARS: Applicationbb84sharmaNoch keine Bewertungen

- Super Air Knife Installation & Maintenance: Compressed Air Line SizesDokument0 SeitenSuper Air Knife Installation & Maintenance: Compressed Air Line Sizeskresimir.mikoc9765Noch keine Bewertungen

- Accu CutterDokument4 SeitenAccu CuttermehranNoch keine Bewertungen

- SeamerweldersDokument4 SeitenSeamerweldersstefan.e.bathoryNoch keine Bewertungen

- Tool Steel Ring - Product Data Sheet - EnglishDokument2 SeitenTool Steel Ring - Product Data Sheet - EnglishVishal ChudasamaNoch keine Bewertungen

- KGE1000Ti Service ManualDokument41 SeitenKGE1000Ti Service Manualmarksmods100% (1)

- SV97Dokument2 SeitenSV97nclogesh_1981Noch keine Bewertungen

- Nu SS 1044svd&afsDokument2 SeitenNu SS 1044svd&afshhjkhNoch keine Bewertungen

- Sidewinder Pneumatic Pump Series Sales Brochure 2016 Web 053017Dokument6 SeitenSidewinder Pneumatic Pump Series Sales Brochure 2016 Web 053017Prihartono Danan WingusNoch keine Bewertungen

- Well HandyDokument6 SeitenWell HandymtonellyNoch keine Bewertungen

- Cilindros e Servo CilindrosDokument16 SeitenCilindros e Servo CilindrosluisbottonNoch keine Bewertungen

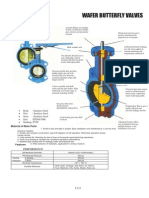

- Wafer Butterfly ValvesDokument2 SeitenWafer Butterfly ValvesSandi AslanNoch keine Bewertungen

- Tech BellowsDokument12 SeitenTech Bellowshaider100% (2)

- Re 10223Dokument26 SeitenRe 10223medi38Noch keine Bewertungen

- Honeywell SZL WL Series SpecificationDokument22 SeitenHoneywell SZL WL Series SpecificationR NandakumarNoch keine Bewertungen

- Moog ServoValves G761 761series Catalog enDokument20 SeitenMoog ServoValves G761 761series Catalog enDhiraj ShrivastavNoch keine Bewertungen

- H 04437Dokument4 SeitenH 04437E_Amr_SorourNoch keine Bewertungen

- Hydraulic Breakers BrochureDokument8 SeitenHydraulic Breakers BrochureEndraNoch keine Bewertungen

- Torque WrenchesDokument12 SeitenTorque WrenchesjleonosNoch keine Bewertungen

- Honeywell Sensing Micro Switch 14CE Limit Product Sheet 002387 1 enDokument13 SeitenHoneywell Sensing Micro Switch 14CE Limit Product Sheet 002387 1 enJason GuerreroNoch keine Bewertungen

- Machining Strenx and HardoxDokument32 SeitenMachining Strenx and HardoxKohilan NahivNoch keine Bewertungen

- Guth VSR Modulating ValvesDokument8 SeitenGuth VSR Modulating ValvesRaul Guevara TorresNoch keine Bewertungen

- E Gasspring PDFDokument148 SeitenE Gasspring PDFSing Industrial Gas VietnamNoch keine Bewertungen

- Pressure Gauge TeklandDokument11 SeitenPressure Gauge Teklandพสธร สอนทองNoch keine Bewertungen

- 2 4CRDokument4 Seiten2 4CRNestramiNoch keine Bewertungen

- CS310ADokument4 SeitenCS310Arabacet2923Noch keine Bewertungen

- FRAME RIVETS REPLACEMENT WITH BOLTS SERVICE TIPS - Article No. 97-4-7Dokument2 SeitenFRAME RIVETS REPLACEMENT WITH BOLTS SERVICE TIPS - Article No. 97-4-7FlogamagNoch keine Bewertungen

- Application Example: Pneumatic 2-Finger Parallel GripperDokument35 SeitenApplication Example: Pneumatic 2-Finger Parallel GripperBaltazar EspinosaNoch keine Bewertungen

- Catlogo Mangueiras Hidrulicas ManuliDokument3 SeitenCatlogo Mangueiras Hidrulicas ManuliDomingos BarrosNoch keine Bewertungen

- Brochure Complete Instrument Valve Solution Tescom Anderson Greenwood Instrumentation en 6272716Dokument8 SeitenBrochure Complete Instrument Valve Solution Tescom Anderson Greenwood Instrumentation en 6272716Joshua Garcia CarrilloNoch keine Bewertungen

- Tyco Drenchers - TFP807 - 07 - 2014Dokument14 SeitenTyco Drenchers - TFP807 - 07 - 2014Sanitaristu100% (1)

- Brochure Isolation Valves Product Overview en en 5253576Dokument36 SeitenBrochure Isolation Valves Product Overview en en 5253576Muthu Kumar RNoch keine Bewertungen

- Doosan Control Valve (708) (Union)Dokument14 SeitenDoosan Control Valve (708) (Union)Ahsan HaseebNoch keine Bewertungen

- Enz Nozzle Catalog 2012Dokument97 SeitenEnz Nozzle Catalog 2012ryanvlopezNoch keine Bewertungen

- Saunders S360 Presentation - A4Dokument31 SeitenSaunders S360 Presentation - A4MeanRatNoch keine Bewertungen

- FLUJO POR DIAMETRO TURBINA NuFlo - Liquid - Turbine PDFDokument6 SeitenFLUJO POR DIAMETRO TURBINA NuFlo - Liquid - Turbine PDFOctavio CharryNoch keine Bewertungen

- Freedom Integrated Hot Melt Packaging SolutionDokument4 SeitenFreedom Integrated Hot Melt Packaging SolutionNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Private Label Water Bottler Realizes Pure Savings With Intermittent Adhesive DispensingDokument4 SeitenPrivate Label Water Bottler Realizes Pure Savings With Intermittent Adhesive DispensingNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- SureBead Applicators Data SheetDokument2 SeitenSureBead Applicators Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Trends: Wetness Indicator Market AdvisoryDokument7 SeitenTrends: Wetness Indicator Market AdvisoryNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- PB Melters 15-30-50 Data SheetDokument2 SeitenPB Melters 15-30-50 Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- E.dot+ Electric Guns Data SheetDokument2 SeitenE.dot+ Electric Guns Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- ProBlue Fulfill Integrated Melter and Fill SystemDokument2 SeitenProBlue Fulfill Integrated Melter and Fill SystemNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- PB Melters 4-7-10 Data SheetDokument2 SeitenPB Melters 4-7-10 Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Advanced Technology Hoses Data SheetDokument2 SeitenAdvanced Technology Hoses Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- RediFlex Hoses Data SheetDokument2 SeitenRediFlex Hoses Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- EcoBead Data SheetDokument2 SeitenEcoBead Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- MiniBlue II Data SheetDokument2 SeitenMiniBlue II Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Nitrogen Generation System and Booster Data SheetDokument2 SeitenNitrogen Generation System and Booster Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Large AltaBlue Touch Adhesive Melters Data SheetDokument2 SeitenLarge AltaBlue Touch Adhesive Melters Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal TruFlow Systems BrochureDokument4 SeitenUniversal TruFlow Systems BrochureNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal UM50 Modules Data SheetDokument2 SeitenUniversal UM50 Modules Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- LogiComm Sensors & Barcode Readers BrochureDokument4 SeitenLogiComm Sensors & Barcode Readers BrochureNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- VersaBlue XN Series 50-100-150 Data SheetDokument2 SeitenVersaBlue XN Series 50-100-150 Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal Slice Applicators Data SheetDokument2 SeitenUniversal Slice Applicators Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal TruFlow Applicators Data SheetDokument2 SeitenUniversal TruFlow Applicators Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Nordson Universal Modules ComparisonDokument1 SeiteNordson Universal Modules ComparisonNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal UM25 Modules Data SheetDokument2 SeitenUniversal UM25 Modules Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- GP200 Remote Metering Station Data SheetDokument2 SeitenGP200 Remote Metering Station Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- VersaBlue XC Series Data SheetDokument2 SeitenVersaBlue XC Series Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal Spray Nozzles Product ComparisonDokument3 SeitenUniversal Spray Nozzles Product ComparisonNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal UM22 Modules Data SheetDokument2 SeitenUniversal UM22 Modules Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal Intermittent Signature Nozzles Data SheetDokument2 SeitenUniversal Intermittent Signature Nozzles Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- UM3 Universal Modules Data SheetDokument2 SeitenUM3 Universal Modules Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Schapery RA 1962 (PHD Dissertation)Dokument182 SeitenSchapery RA 1962 (PHD Dissertation)Marcelo MedeirosNoch keine Bewertungen

- Dynamic Properties of RocksDokument5 SeitenDynamic Properties of RocksArnold John Laya100% (3)

- Chapter 6 Theory of Flexure PDFDokument88 SeitenChapter 6 Theory of Flexure PDFcoded coderNoch keine Bewertungen

- Doosan DX140W PDFDokument32 SeitenDoosan DX140W PDFjoseph anthony marca jacinto0% (1)

- Repair Parts Catalog: FOR Sunnen Vertical Honing MachineDokument48 SeitenRepair Parts Catalog: FOR Sunnen Vertical Honing MachineLucas Isaias da Silva100% (1)

- Choosing the Right Sanitary Rupture DiskDokument35 SeitenChoosing the Right Sanitary Rupture DiskAnonymous bHh1L1Noch keine Bewertungen

- Flange Face Types-RF、FF、RTJDokument8 SeitenFlange Face Types-RF、FF、RTJhervé louisNoch keine Bewertungen

- Introduction of Control Systems and Basic TerminologyDokument12 SeitenIntroduction of Control Systems and Basic TerminologyShivaji ThubeNoch keine Bewertungen

- Node List & SIFDokument2 SeitenNode List & SIFCandraNoch keine Bewertungen

- CHM 101 Lecture Note-Gas LawsDokument11 SeitenCHM 101 Lecture Note-Gas LawsMichael DanielsNoch keine Bewertungen

- Johan Aliff Bin Wan Ajhar 2017466056 Mohamad Aiman Bin Amer 2017466092 3. Muhammad Afnan Bin Che Zawawi 2017466082Dokument3 SeitenJohan Aliff Bin Wan Ajhar 2017466056 Mohamad Aiman Bin Amer 2017466092 3. Muhammad Afnan Bin Che Zawawi 2017466082Johan AliffNoch keine Bewertungen

- Assignment 5: Engineering Utilities IiDokument4 SeitenAssignment 5: Engineering Utilities IiRex SabersonNoch keine Bewertungen

- Eight: Beams: Bending and Shear StressDokument25 SeitenEight: Beams: Bending and Shear Stressparallax1957Noch keine Bewertungen

- Soil Deformation Pattern Around Laterally Loaded PilesDokument11 SeitenSoil Deformation Pattern Around Laterally Loaded PilesPEdro Omar Bengochea-StaufferNoch keine Bewertungen

- Paper On GravitationDokument8 SeitenPaper On GravitationShama tanveerNoch keine Bewertungen

- Chapter 4 Centroid - Distr. ForcesDokument33 SeitenChapter 4 Centroid - Distr. Forceskamal touilebNoch keine Bewertungen

- Key information on motor dataDokument8 SeitenKey information on motor dataRadj90Noch keine Bewertungen

- ESA Final Presentation Days: 30/03/2017 Alizee MalavartDokument13 SeitenESA Final Presentation Days: 30/03/2017 Alizee Malavartad.dabrowskiNoch keine Bewertungen

- Samsung EHS Selection - Split - Bratislava - AE090RXEDGG - EUDokument48 SeitenSamsung EHS Selection - Split - Bratislava - AE090RXEDGG - EUDusan NecasNoch keine Bewertungen