Beruflich Dokumente

Kultur Dokumente

Allegro Elastic Attachment Nozzles

Hochgeladen von

Nordson Adhesive Dispensing SystemsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Allegro Elastic Attachment Nozzles

Hochgeladen von

Nordson Adhesive Dispensing SystemsCopyright:

Verfügbare Formate

Allegro Elastic Attachment Nozzles

Advanced nozzle technology delivers precise adhesive fiber deposition for high-speed elastic attachment.

Allegro elastic attachment nozzles:

n n n n

Use novel air-assisted contact coating technology Facilitate increased production speeds Support close centers Offer improved durability with easier maintenance and inspection Stabilize elastic strand position with integral guides Optimize adhesive placement Improve creep resistance Reduce adhesive variance Offer durability through all-steel construction for extended service life the elastic strand and, while still molten, manipulation of the adhesive by the process air flow to form the adhesive around the entire strand for consistent, repeatable coating with exceptionally low variability. The process air also assists in cleanliness of cutoff of adhesive flow and in nozzle maintenance. Allegro nozzles in most common configurations are maintained in inventory for rapid delivery and may be made to order for other specific elastic configuration requirements. The nozzles are made of all-steel construction and use a proprietary coating to enhance durability and wear resistance. Allegro nozzles are compatible with UM22 and UM25 modules for mid-speed intermittent adhesive applications; Speed-Coat modules for the most demanding highspeed intermittent lines; UM50 modules for continuous operation; high-speed, electric E-400U modules and UM3 modules for metering applications. Common Universal parts minimize inventory and simplify service. Special nozzle lengths up to 175 mm are available to support many-strand applications.

n n n n n

Nordson Allegro nozzles consistently apply a hot melt adhesive coating on the elastic strands used for elasticized features on baby diapers, training pants, and adult incontinence products. The patent-pending Allegro nozzle supports high-speed production lines, up to 650 meters per minute, while maintaining elastic centers as close as two millimeters. Production efficiency is enhanced with a robust design for nozzle durability and simplified cleaning and inspection. The Allegro nozzle uses an integral-strand guide to stabilize the elastic strand just prior to adhesive application and process air just after adhesive application to maintain performance at demanding production speeds. The process entails contact adhesive application to the top of

Allegro Elastic Attachment Nozzles

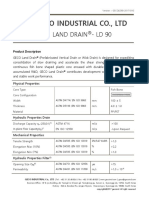

Specifications1

Module Compatibility Materials of Construction Nozzle Orifice Sizes Nozzle to Substrate Distance Adhesive Flow Add-on Weight Production Speed Capability Adhesive Viscosity Operating Temperature Air Consumption Air Pressure2 Working Hydraulic Pressure Maximum Hydraulic Pressure

1. 2.

All Universal modules All-steel construction with proprietary coating 0.51 mm (0.020 in.) Contact 2.5 to 25 grams per minute per orifice 25 to 100 milligrams/strand/meter 100 to 650 m/min (330 to 2,132 ft/min) 4,500 to 8,000 centipoise 70 to 205 C (160 to 400 F) 0.08 scfm per strand 0.3 to 0.7 bar (4.4 to 10.3 psi) 6.8 to 40.1 bar (100 to 600 psi) 89.6 bar (1300 psi)

For more information, speak with your Nordson representative or contact your Nordson regional office.

United States Duluth, Georgia (800) 683-2314 Phone (866) 667-3329 Fax Europe Luneburg, Germany (49) 4131-894-0 Phone (49) 4131-894-149 Fax Japan Tokyo, Japan (81) 3-5762-2700 Phone (81) 3-5762-2701 Fax Asia/Australia/ Latin America Amherst, Ohio (440) 985-4496 Phone (440) 985-1096 Fax Find us on:

Values are typical and may vary based on specific adhesive and application. Process air (pressure regulation supplied by customer).

Patented integral strand guide.

Learn more about Allegro nozzles

Nozzles detach easily without removing modules.

NWL-12-5758 Issued 6/12 2012 Nordson Corporation All Rights Reserved. Printed in U.S.A. Nordson reserves the right to make design changes between printings.

Nordson Corporation 11475 Lakefield Drive Duluth, GA 30097-1511

(800) 683-2314 nordson.com/hotmelt

Das könnte Ihnen auch gefallen

- Universal Continuous Signature Nozzles Data SheetDokument2 SeitenUniversal Continuous Signature Nozzles Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Easy PW Series Profile Wrapping ApplicatorDokument2 SeitenEasy PW Series Profile Wrapping ApplicatorNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Spot Welding Interview Success: An Introduction to Spot WeldingVon EverandSpot Welding Interview Success: An Introduction to Spot WeldingNoch keine Bewertungen

- RediFlex Hoses Data SheetDokument2 SeitenRediFlex Hoses Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Steel Structures Design Based on Eurocode 3Von EverandSteel Structures Design Based on Eurocode 3Bewertung: 3 von 5 Sternen3/5 (1)

- DP490Dokument6 SeitenDP490transervuk2013Noch keine Bewertungen

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationVon EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNoch keine Bewertungen

- APEX Adhesive Slot Die ApplicatorDokument2 SeitenAPEX Adhesive Slot Die ApplicatorITWDynatecNoch keine Bewertungen

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Covalence WPC100M Shrink Sleeves PDFDokument2 SeitenCovalence WPC100M Shrink Sleeves PDFJMROMANTNoch keine Bewertungen

- UFD Equity Fiberized Spray Adhesive ApplicatorDokument2 SeitenUFD Equity Fiberized Spray Adhesive ApplicatorITWDynatecNoch keine Bewertungen

- UFD High-Speed Fiberized Spray Adehsive ApplicatorDokument2 SeitenUFD High-Speed Fiberized Spray Adehsive ApplicatorITWDynatecNoch keine Bewertungen

- W7 304E Plating Lines MontageDokument9 SeitenW7 304E Plating Lines MontageAnonymous wtK1AZBi100% (1)

- Gulf-O-Flex Insulation Tube & Coil: Dimensions of Box: 50x50x20 CmsDokument6 SeitenGulf-O-Flex Insulation Tube & Coil: Dimensions of Box: 50x50x20 CmsRiyas UdheenNoch keine Bewertungen

- Olex Nexan HandbookDokument112 SeitenOlex Nexan Handbook322399mk7086Noch keine Bewertungen

- CNL 3952Dokument2 SeitenCNL 3952Zaroio OreiaNoch keine Bewertungen

- Jain PE Gas Piping SystemDokument4 SeitenJain PE Gas Piping Systemkishore@scribdNoch keine Bewertungen

- Equity Continuous Slot Die - Adhesive ApplicatorDokument2 SeitenEquity Continuous Slot Die - Adhesive ApplicatorITWDynatecNoch keine Bewertungen

- Silenta Premium BrochureDokument32 SeitenSilenta Premium Brochurejagadeeshkumar116Noch keine Bewertungen

- Cable Tray 27Dokument37 SeitenCable Tray 27Sri Ravindra Yadav PattapogulaNoch keine Bewertungen

- Polyken 932 TapeDokument2 SeitenPolyken 932 TapeKyaw Kyaw AungNoch keine Bewertungen

- PURBlue 4 Adhesive Melters Product LiteratureDokument2 SeitenPURBlue 4 Adhesive Melters Product LiteratureNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- LA 825 RC Liquid Adhesive Dispensing Electric ApplicatorsDokument2 SeitenLA 825 RC Liquid Adhesive Dispensing Electric ApplicatorsNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Eurob 600Dokument6 SeitenEurob 600CEERIAATE MEDKONNoch keine Bewertungen

- Enquiry Data in MailDokument20 SeitenEnquiry Data in MailNITINNoch keine Bewertungen

- Loaia Star Linger MachineryDokument30 SeitenLoaia Star Linger MachinerySaif MastoiNoch keine Bewertungen

- Logging Head PsDokument2 SeitenLogging Head PsBonviNoch keine Bewertungen

- Global Transmission Sleeve: Product Data SheetDokument2 SeitenGlobal Transmission Sleeve: Product Data SheetgoumrisalimaNoch keine Bewertungen

- Ficha Tecnica Cinta de Juntas 930-35-50Dokument3 SeitenFicha Tecnica Cinta de Juntas 930-35-50Carlos TarquinoNoch keine Bewertungen

- AdvancedTechHose WhyNordson HRDokument2 SeitenAdvancedTechHose WhyNordson HRpopmart21Noch keine Bewertungen

- Welding Solutions SensorsDokument124 SeitenWelding Solutions SensorsСања БанковићNoch keine Bewertungen

- Ex Platform Scale - PFA589Dokument5 SeitenEx Platform Scale - PFA589xinying liuNoch keine Bewertungen

- Mechanical Seals in AgitatorsDokument6 SeitenMechanical Seals in AgitatorsLy Ca TieuNoch keine Bewertungen

- Cilindros e Servo CilindrosDokument16 SeitenCilindros e Servo CilindrosluisbottonNoch keine Bewertungen

- ISC2 Series Broch A4Dokument6 SeitenISC2 Series Broch A4isosicaNoch keine Bewertungen

- Gasket Jointing FullDokument48 SeitenGasket Jointing FullManishBoyNoch keine Bewertungen

- Turbine Meter NufloDokument8 SeitenTurbine Meter NufloJaime SeguraNoch keine Bewertungen

- Leaflet SpeedStar Diamond - enDokument2 SeitenLeaflet SpeedStar Diamond - enA JunedNoch keine Bewertungen

- 3M-EMD High Voltage CableAss PBDokument8 Seiten3M-EMD High Voltage CableAss PBLiz Vilela ArízagaNoch keine Bewertungen

- Universal UM22 Modules Data SheetDokument2 SeitenUniversal UM22 Modules Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Qual CrimpDokument38 SeitenQual CrimpAlmendra GCNoch keine Bewertungen

- The Definitive O Ring Design GuideDokument31 SeitenThe Definitive O Ring Design GuideChezNoch keine Bewertungen

- Longitudinal Seam Welders BrochureDokument8 SeitenLongitudinal Seam Welders Brochuregrincheu70Noch keine Bewertungen

- FRP Cable Tray 1Dokument37 SeitenFRP Cable Tray 1Vikas TanejaNoch keine Bewertungen

- Hot oil resistant 150°C automotive engine wireDokument2 SeitenHot oil resistant 150°C automotive engine wireanna_malai078351Noch keine Bewertungen

- Rosemount 8705 Flanged SensorsDokument3 SeitenRosemount 8705 Flanged SensorsJorge' VillanuevaNoch keine Bewertungen

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDokument8 SeitenAD01166M NUFLO Liquid Turbine Flow Meters Data SheetsarkaftNoch keine Bewertungen

- E.dot+ Electric Guns Data SheetDokument2 SeitenE.dot+ Electric Guns Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Geco Industrial Co., LTD: Land Drain - LD 90Dokument2 SeitenGeco Industrial Co., LTD: Land Drain - LD 90Gisella Mariel RubilarNoch keine Bewertungen

- Adhesive Film & TapeDokument6 SeitenAdhesive Film & TapeJothi Vel MuruganNoch keine Bewertungen

- SigmaCover 280Dokument5 SeitenSigmaCover 280ajuhaseenNoch keine Bewertungen

- FRS Electrical Panel Spec EOIDokument20 SeitenFRS Electrical Panel Spec EOITravis WoodNoch keine Bewertungen

- Parker TechSeal ParFab Design Guide TSD 5420Dokument44 SeitenParker TechSeal ParFab Design Guide TSD 5420Christopher GarciaNoch keine Bewertungen

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDokument8 SeitenAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosNoch keine Bewertungen

- M50 enDokument338 SeitenM50 entomwilkinsNoch keine Bewertungen

- Guntner MANDokument28 SeitenGuntner MANJosé Luis Boncún Carnero100% (2)

- Installation Guide For GRE PipingDokument32 SeitenInstallation Guide For GRE PipingAnh Võ100% (5)

- Trends: Wetness Indicator Market AdvisoryDokument7 SeitenTrends: Wetness Indicator Market AdvisoryNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Private Label Water Bottler Realizes Pure Savings With Intermittent Adhesive DispensingDokument4 SeitenPrivate Label Water Bottler Realizes Pure Savings With Intermittent Adhesive DispensingNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- ProBlue Fulfill Integrated Melter and Fill SystemDokument2 SeitenProBlue Fulfill Integrated Melter and Fill SystemNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- E.dot+ Electric Guns Data SheetDokument2 SeitenE.dot+ Electric Guns Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Nitrogen Generation System and Booster Data SheetDokument2 SeitenNitrogen Generation System and Booster Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- PB Melters 15-30-50 Data SheetDokument2 SeitenPB Melters 15-30-50 Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Freedom Integrated Hot Melt Packaging SolutionDokument4 SeitenFreedom Integrated Hot Melt Packaging SolutionNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- SureBead Applicators Data SheetDokument2 SeitenSureBead Applicators Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- PB Melters 4-7-10 Data SheetDokument2 SeitenPB Melters 4-7-10 Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- EcoBead Data SheetDokument2 SeitenEcoBead Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- MiniBlue II Data SheetDokument2 SeitenMiniBlue II Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- LogiComm Sensors & Barcode Readers BrochureDokument4 SeitenLogiComm Sensors & Barcode Readers BrochureNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Advanced Technology Hoses Data SheetDokument2 SeitenAdvanced Technology Hoses Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Large AltaBlue Touch Adhesive Melters Data SheetDokument2 SeitenLarge AltaBlue Touch Adhesive Melters Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Standard AltaBlue Touch Adhesive Melters Data SheetDokument2 SeitenStandard AltaBlue Touch Adhesive Melters Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal TruFlow Applicators Data SheetDokument2 SeitenUniversal TruFlow Applicators Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal TruFlow Systems BrochureDokument4 SeitenUniversal TruFlow Systems BrochureNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal Slice Applicators Data SheetDokument2 SeitenUniversal Slice Applicators Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- GP200 Remote Metering Station Data SheetDokument2 SeitenGP200 Remote Metering Station Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal Spray Nozzles Product ComparisonDokument3 SeitenUniversal Spray Nozzles Product ComparisonNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- VersaBlue XN Series 50-100-150 Data SheetDokument2 SeitenVersaBlue XN Series 50-100-150 Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal UM25 Modules Data SheetDokument2 SeitenUniversal UM25 Modules Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- VersaBlue XC Series Data SheetDokument2 SeitenVersaBlue XC Series Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Nordson Universal Modules ComparisonDokument1 SeiteNordson Universal Modules ComparisonNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal Intermittent Signature Nozzles Data SheetDokument2 SeitenUniversal Intermittent Signature Nozzles Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal Nozzles and Modules BrochureDokument4 SeitenUniversal Nozzles and Modules BrochureNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal UM50 Modules Data SheetDokument2 SeitenUniversal UM50 Modules Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- Universal UM22 Modules Data SheetDokument2 SeitenUniversal UM22 Modules Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- UM3 Universal Modules Data SheetDokument2 SeitenUM3 Universal Modules Data SheetNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- NVH Analysis in AutomobilesDokument30 SeitenNVH Analysis in AutomobilesTrishti RastogiNoch keine Bewertungen

- DX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Dokument6 SeitenDX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Welissa ChicanequissoNoch keine Bewertungen

- Bid Document PDFDokument125 SeitenBid Document PDFAzharudin ZoechnyNoch keine Bewertungen

- 63db2cf62042802 Budget Eco SurveyDokument125 Seiten63db2cf62042802 Budget Eco SurveyNehaNoch keine Bewertungen

- Green Solvents For Chemistry - William M NelsonDokument401 SeitenGreen Solvents For Chemistry - William M NelsonPhuong Tran100% (4)

- Vitamin D3 5GDokument7 SeitenVitamin D3 5GLuis SuescumNoch keine Bewertungen

- Successful Organizational Change FactorsDokument13 SeitenSuccessful Organizational Change FactorsKenneth WhitfieldNoch keine Bewertungen

- Farmers InterviewDokument5 SeitenFarmers Interviewjay jariwalaNoch keine Bewertungen

- Recommended lubricants and refill capacitiesDokument2 SeitenRecommended lubricants and refill capacitiestele123Noch keine Bewertungen

- A Dream Takes FlightDokument3 SeitenA Dream Takes FlightHafiq AmsyarNoch keine Bewertungen

- Current Affairs Q&A PDF June 9 2023 by Affairscloud 1Dokument21 SeitenCurrent Affairs Q&A PDF June 9 2023 by Affairscloud 1Yashika GuptaNoch keine Bewertungen

- The Study of Accounting Information SystemsDokument44 SeitenThe Study of Accounting Information SystemsCelso Jr. AleyaNoch keine Bewertungen

- Courier - Capstone WebApp - Round 3 ReportDokument23 SeitenCourier - Capstone WebApp - Round 3 Reportmarmounette26Noch keine Bewertungen

- Sample Contract Rates MerchantDokument2 SeitenSample Contract Rates MerchantAlan BimantaraNoch keine Bewertungen

- Tambunting Pawnshop Vs CIR Re VATDokument7 SeitenTambunting Pawnshop Vs CIR Re VATMark Lester Lee AureNoch keine Bewertungen

- HetNet Solution Helps Telcos Improve User Experience & RevenueDokument60 SeitenHetNet Solution Helps Telcos Improve User Experience & RevenuefarrukhmohammedNoch keine Bewertungen

- Nexus Undercarriage Cross Reference GuideDokument185 SeitenNexus Undercarriage Cross Reference GuideRomanNoch keine Bewertungen

- Funded African Tech Startups 2020Dokument13 SeitenFunded African Tech Startups 2020LoNoch keine Bewertungen

- City Gas Distribution ReportDokument22 SeitenCity Gas Distribution Reportdimple1101100% (9)

- Uniform Bonding Code (Part 2)Dokument18 SeitenUniform Bonding Code (Part 2)Paschal James BloiseNoch keine Bewertungen

- FC Bayern Munich Marketing PlanDokument12 SeitenFC Bayern Munich Marketing PlanMateo Herrera VanegasNoch keine Bewertungen

- TicketDokument2 SeitenTicketbikram kumarNoch keine Bewertungen

- 2010 Yoshimura Book of SpeedDokument83 Seiten2010 Yoshimura Book of Speedacornwoods_brentNoch keine Bewertungen

- CMTD42M FDokument3 SeitenCMTD42M FagengfirstyanNoch keine Bewertungen

- SINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORDokument3 SeitenSINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORElias EliasNoch keine Bewertungen

- Jodi Ridgeway vs. Horry County Police DepartmentDokument17 SeitenJodi Ridgeway vs. Horry County Police DepartmentWMBF NewsNoch keine Bewertungen

- Harry Styles: The Rise of a Pop StarDokument9 SeitenHarry Styles: The Rise of a Pop StarBilqis LaudyaNoch keine Bewertungen

- Whats The Average 100 M Time For An Olympics - Google SearchDokument1 SeiteWhats The Average 100 M Time For An Olympics - Google SearchMalaya KnightonNoch keine Bewertungen

- Iso 4624Dokument15 SeitenIso 4624klkopopoonetdrghjktl100% (2)

- Top Machine Learning ToolsDokument9 SeitenTop Machine Learning ToolsMaria LavanyaNoch keine Bewertungen

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableVon EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNoch keine Bewertungen

- Guidelines for Implementing Process Safety ManagementVon EverandGuidelines for Implementing Process Safety ManagementNoch keine Bewertungen

- The User's Journey: Storymapping Products That People LoveVon EverandThe User's Journey: Storymapping Products That People LoveBewertung: 3.5 von 5 Sternen3.5/5 (8)

- Introduction to Petroleum Process SafetyVon EverandIntroduction to Petroleum Process SafetyBewertung: 3 von 5 Sternen3/5 (2)

- Design for How People Think: Using Brain Science to Build Better ProductsVon EverandDesign for How People Think: Using Brain Science to Build Better ProductsBewertung: 4 von 5 Sternen4/5 (8)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesVon EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesBewertung: 5 von 5 Sternen5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationVon EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNoch keine Bewertungen

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeVon EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNoch keine Bewertungen

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryVon EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryBewertung: 4 von 5 Sternen4/5 (5)

- Rules of Thumb for Maintenance and Reliability EngineersVon EverandRules of Thumb for Maintenance and Reliability EngineersBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Understanding Automotive Electronics: An Engineering PerspectiveVon EverandUnderstanding Automotive Electronics: An Engineering PerspectiveBewertung: 3.5 von 5 Sternen3.5/5 (16)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsVon EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNoch keine Bewertungen

- Guidelines for Auditing Process Safety Management SystemsVon EverandGuidelines for Auditing Process Safety Management SystemsNoch keine Bewertungen

- Safety Fundamentals and Best Practices in Construction IndustryVon EverandSafety Fundamentals and Best Practices in Construction IndustryNoch keine Bewertungen

- Incidents That Define Process SafetyVon EverandIncidents That Define Process SafetyNoch keine Bewertungen

- 507 Mechanical Movements: Mechanisms and DevicesVon Everand507 Mechanical Movements: Mechanisms and DevicesBewertung: 4 von 5 Sternen4/5 (28)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisVon EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsVon EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNoch keine Bewertungen

- Inherently Safer Chemical Processes: A Life Cycle ApproachVon EverandInherently Safer Chemical Processes: A Life Cycle ApproachBewertung: 5 von 5 Sternen5/5 (1)

- LNG Risk Based Safety: Modeling and Consequence AnalysisVon EverandLNG Risk Based Safety: Modeling and Consequence AnalysisNoch keine Bewertungen

- Operational Amplifier Circuits: Analysis and DesignVon EverandOperational Amplifier Circuits: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (2)