Beruflich Dokumente

Kultur Dokumente

Chapter 1. Ferrous Metals 1.1: Contributors Preface

Hochgeladen von

savicivanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chapter 1. Ferrous Metals 1.1: Contributors Preface

Hochgeladen von

savicivanCopyright:

Verfügbare Formate

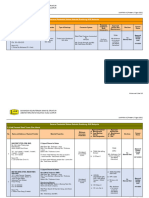

CONTENTS

Contributors Preface xi

xiii

Chapter 1. Ferrous Metals 1.1 Introduction 1.2 The Structure of Iron 1.3 Steelmaking 1.4 Carbon and Alloy Steels 1.5 Selection of Alloy Steels 1.6 Selection and Specification 1.7 Welding Ferrous Metals 1.8 Summary References Chapter 2. Aluminum and Its Alloys 2.1 Introduction 2.2 Alloy and Temper Designation System 2.3 Physical Properties 2.4 Mechanical Properties 2.5 Corrosion Resistance 2.6 Product Forms 2.7 Fabrication 2.8 Joining 2.9 Finishes 2.10 Glossary References Chapter 3. Titanium 3.1 Introduction 3.2 Basic Metallurgy 3.3 Alloy Classification and Overview 3.4 Properties 3.5 Corrosion and Corrosion Resistance 3.6 Alloys for Cryogenic Applications 3.7 Titanium Alloys for High-Temperature Applications 3.8 Casting Alloys 3.9 Precipitate and Dispersoid Strengthened Alloys Wrought Alloy Processing References v

1.1 1.1 1.2 1.6 1.11 1.29 1.43 1.61 1.91 1.92 2.1 2.1 2.5 2.27 2.41 2.92 2.107 2.129 2.138 2.162 2.174 2.177 3.1 3.1 3.4 3.12 3.16 3.27 3.33 3.34 3.41 3.43 3.44 3.60

vi

HANDBOOK OF MATERIALS FOR PRODUCT DESIGN

Chapter 4. Plastics 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 Introduction The Nature of Plastics Polymer Structures and Polymerization Reactions Plastic-Processing Methods and Design Guidelines Thermosetting Plastics Thermoplastics Glass-Fiber-Reinforced Thermoplastics Plastic Films and Tapes Plastic Surface Finishing Material Selection References

4.1 4.1 4.6 4.8 4.10 4.18 4.34 4.75 4.76 4.78 4.80 4.106 5.1 5.1 5.5 5.25 5.31 5.32 5.35 5.40 5.76 5.78 5.85 5.88 5.91 5.96 5.98 5.103 5.105 6.1 6.1 6.3 6.5 6.7 6.9 6.10 6.15 6.28 6.31 6.31

Chapter 5. Composite Materials and Processes 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 5.9 5.10 5.11 5.12 5.13 5.14 5.15 Introduction Material Systems Ply Orientations, Symmetry, and Balance Quasi-isotropic Laminate Analysis Composite Failure and Design Allowables Composite Fabrication Techniques Analysis Design of Composite Structures Damage Tolerance Composite Repairs Adhesive Bonding and Mechanical Fastening Environmental Effects Composite Testing Safety Issues with Composite Materials References

Chapter 6. Part 1: Natural and Synthetic Rubbers 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 Historical Properties of Polymers General-Purpose Rubbers Specialty Rubbers Thermoplastic Elastomers Characterizing Heat and Oil Resistance Other Properties Compounding Rubber References Suggested Readings

CONTENTS

vii

Chapter 6. Part 2: Elastomeric Materials and Processes 6.9 Introduction 6.10 Thermoplastic Elastomers (TPEs) 6.11 Polyurethane Thermoplastic Elastomers (TPUs) 6.12 Polyamides 6.13 Melt Processable Rubber (MPR) 6.14 Thermoplastic Vulcanizate (TPV) 6.15 Synthetic Rubbers (SRs) 6.16 Natural Rubber (NR) 6.17 Conclusion References Chapter 7. Ceramics and Ceramic Composites 7.1 Introduction 7.2 Ceramic Fabrication 7.3 Surface Properties of Ceramics 7.4 Thermal Properties of Ceramic Materials 7.5 Mechanical Properties of Ceramic Substrates 7.6 Electrical Properties of Ceramics 7.7 Metallization of Ceramic Substrates 7.8 Ceramic Materials 7.9 Composite Materials 7.10 Forming Ceramics and Composites to Shape References Chapter 8. Inorganic Glasses 8.1 Commercial Glass Families 8.2 Special Glasses 8.3 Glass Making IGlass Melting 8.4 Glass Making IIGlass Forming 8.5 Annealing and Tempering 8.6 Glass Fiber 8.7 Optical Communications Fiber 8.8 Notes and Acknowledgments References Bibliography Chapter 9. Coatings and Finishes 9.1 Introduction 9.2 Environment and Safety 9.3 Surface Preparation 9.4 Coating Selection 9.5 Coating Materials 9.6 Application Methods

6.35 6.35 6.35 6.45 6.56 6.58 6.60 6.67 6.83 6.85 6.85 7.1 7.1 7.3 7.6 7.9 7.14 7.22 7.29 7.40 7.49 7.57 7.60 8.1 8.1 8.37 8.82 8.102 8.119 8.145 8.163 8.170 8.170 8.172 9.1 9.1 9.5 9.6 9.12 9.22 9.41

viii

HANDBOOK OF MATERIALS FOR PRODUCT DESIGN

9.7 9.8

Curing Summary References

9.55 9.58 9.59 10.1 10.1 10.2 10.5 10.27 10.35 10.44 10.50 10.54 10.63 10.66 11.1 11.1 11.2 11.4 11.5 11.20 11.25 11.37 11.40 11.50 11.61 11.62 12.1 12.1 12.15 12.32 12.60 12.82 12.95 12.107 12.119 13.1 13.1 13.6 13.14

Chapter 10. Metallic Finishes and Processes 10.1 Fundamentals 10.2 Metallic Finishes and Processes 10.3 Aluminum Coatings 10.4 Cadmium Coatings 10.5 Chromium Coatings 10.6 Copper Coatings 10.7 Copper Alloy Coatings 10.8 Tin and Tin Alloy Coatings 10.9 Silver Coatings References Chapter 11. Plastics Joining Materials and Processes 11.1 Introduction 11.2 General Types of Plastic Materials 11.3 Types of Plastic Joining Processes 11.4 Direct Heat Welding 11.5 Indirect Heating Methods 11.6 Friction Welding 11.7 Solvent Cementing 11.8 Methods of Mechanical Joining 11.9 Recommended Assembly Processes for Common Plastics 11.10 More Information on Joining Plastics References Chapter 12. Plastics and Elastomers as Adhesives 12.1 Introduction to Adhesives 12.2 Design and Test of Adhesive Joints 12.3 Surface Preparation 12.4 Types of Adhesives 12.5 Selecting an Adhesive 12.6 Effect of the Environment 12.7 Processing and Quality Control of Adhesive Joints References Chapter 13. Testing of Materials 13.1 Introduction Typical Paint and Coating Test Program 13.2 Chemical Characterization

CONTENTS

ix

13.3 13.4 13.5 13.6

Thermal Analysis Thermal Testing Mechanical Testing Miscellaneous Testing Recommended Readings References

13.24 13.32 13.36 13.44 13.54 13.54 14.1 14.1 14.18 14.22 14.26 14.29 14.29 14.32 14.50 14.97 14.98 14.99 14.100

I.1

Chapter 14. Materials Recycling 14.1 Introduction 14.2 Collection of Materials for Recycling 14.3 Ferrous Metal Recycling 14.4 Aluminum Recycling 14.5 Recycling of Other Nonferrous Metals 14.6 Glass Recycling 14.7 Paper Recycling 14.8 Plastics Recycling 14.9 Recycling of Rubber 14.10 Recycling of Textiles 14.11 Recycling of Wood References

Index

Das könnte Ihnen auch gefallen

- Introduction To Microelectronic Fabrication PDFDokument332 SeitenIntroduction To Microelectronic Fabrication PDFChristy Moore92% (13)

- Welding of Metallic Materials: Methods, Metallurgy, and PerformanceVon EverandWelding of Metallic Materials: Methods, Metallurgy, and PerformanceFuad KhoshnawNoch keine Bewertungen

- Nace-Test MethodsDokument22 SeitenNace-Test MethodsmartinNoch keine Bewertungen

- Product Design and Manufacturing (2013)Dokument540 SeitenProduct Design and Manufacturing (2013)bhat9388% (40)

- Leseprobe 01Dokument72 SeitenLeseprobe 01trường phạmNoch keine Bewertungen

- Manufacturing Processes For Engineering MaterialsDokument10 SeitenManufacturing Processes For Engineering Materialsrmsamy125% (37)

- Mechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsVon EverandMechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsNoch keine Bewertungen

- Pipe FabricationDokument42 SeitenPipe FabricationJanani M Janani67% (6)

- Astm F 1110Dokument4 SeitenAstm F 1110eliasNoch keine Bewertungen

- Design of Cold Formed Steel Members 2003 LibroDokument246 SeitenDesign of Cold Formed Steel Members 2003 LibroFelipeNoch keine Bewertungen

- GooglepreviewDokument37 SeitenGooglepreviewJhundel Factor PajarillagaNoch keine Bewertungen

- BS 5493-Protective CoatingDokument113 SeitenBS 5493-Protective Coatingget5rajesh92% (13)

- Electronic Packaging ToCDokument10 SeitenElectronic Packaging ToCjaya007suryaNoch keine Bewertungen

- Condition Assessment and Cathodic Protection of Reinforced Concrete Cooling TowerDokument20 SeitenCondition Assessment and Cathodic Protection of Reinforced Concrete Cooling TowerPhilip Albert HutapeaNoch keine Bewertungen

- Engineering Materials PDFDokument24 SeitenEngineering Materials PDFPradeepkumarKatgiNoch keine Bewertungen

- Metallizing FilmDokument229 SeitenMetallizing Filmdinhtupy16Noch keine Bewertungen

- An Introduction To Failure Analysis For Metallurgical EngineersDokument20 SeitenAn Introduction To Failure Analysis For Metallurgical EngineersbluecreteNoch keine Bewertungen

- Ebook PDF Civil Engineering Materials by Peter A Claisse PDFDokument41 SeitenEbook PDF Civil Engineering Materials by Peter A Claisse PDFelizabeth.mcmillion447100% (33)

- API 653 Study GuideDokument19 SeitenAPI 653 Study GuideSubramaniam Ramasamy86% (7)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesVon EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesBewertung: 5 von 5 Sternen5/5 (5)

- Physical Metallurgy: Principles and PracticeDokument11 SeitenPhysical Metallurgy: Principles and PracticeAkhil KumarNoch keine Bewertungen

- Corrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesVon EverandCorrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesNoch keine Bewertungen

- The Handbook of Biomass Combustion and Co-Firing (2008)Dokument465 SeitenThe Handbook of Biomass Combustion and Co-Firing (2008)Frederico Peiro75% (20)

- Understanding Impurities in Copper ElectrometallurgyDokument61 SeitenUnderstanding Impurities in Copper ElectrometallurgyJoselinn LoaezaNoch keine Bewertungen

- Temenoff BiomaterialsDokument0 SeitenTemenoff BiomaterialsJason Chou0% (9)

- Ceramic MaterialsDokument215 SeitenCeramic MaterialsAndreea NilăNoch keine Bewertungen

- Applied Electrostatic PrecipitationDokument536 SeitenApplied Electrostatic PrecipitationtcbbssNoch keine Bewertungen

- Contents Structural Use of Glass in Buildings Second EditionDokument2 SeitenContents Structural Use of Glass in Buildings Second EditiongohtsNoch keine Bewertungen

- Curriculum: 1. Introduction To CompositesDokument2 SeitenCurriculum: 1. Introduction To CompositesasderbvaNoch keine Bewertungen

- Chap. 0 - SyllabusDokument10 SeitenChap. 0 - Syllabusalikhalil3177Noch keine Bewertungen

- Tehnička Keramika PDFDokument215 SeitenTehnička Keramika PDFRafija SoftićNoch keine Bewertungen

- Handbook of Polymeric Foams and Foam Technology: HanserDokument10 SeitenHandbook of Polymeric Foams and Foam Technology: Hanserfreidor0% (2)

- L S Xxiii: References 13Dokument8 SeitenL S Xxiii: References 13AchmadhanaPutratamaArdiantoroNoch keine Bewertungen

- Foundations of Materials Science and Engineering 7Th Edition William Fortune Smith Full ChapterDokument67 SeitenFoundations of Materials Science and Engineering 7Th Edition William Fortune Smith Full Chapterbrandy.zelkind660100% (7)

- Fundamentals of Materials Engineering - A Basic GuideVon EverandFundamentals of Materials Engineering - A Basic GuideNoch keine Bewertungen

- Table of Content Contents PagenoDokument3 SeitenTable of Content Contents PagenoShailendra KashyapNoch keine Bewertungen

- Engineered Ceramics: Current Status and Future ProspectsVon EverandEngineered Ceramics: Current Status and Future ProspectsTatsuki OhjiNoch keine Bewertungen

- Acid Base CementsDokument420 SeitenAcid Base Cementskka2000100% (1)

- Full Download Book Manufacturing Engineering and Technology PDFDokument41 SeitenFull Download Book Manufacturing Engineering and Technology PDFmelinda.wilson841100% (16)

- Callister AskelandDokument20 SeitenCallister AskelandRobert EshwerNoch keine Bewertungen

- Civl284 Lecture Notes 2015Dokument150 SeitenCivl284 Lecture Notes 2015Debendra Dev KhanalNoch keine Bewertungen

- Aluminium Redmud MMCDokument74 SeitenAluminium Redmud MMCRaghunath Krishnan100% (1)

- مفردات الزجاجDokument3 Seitenمفردات الزجاجمحمد المعموريNoch keine Bewertungen

- Masonry Design and Detailing Sixth Edition 6th Edition Ebook PDFDokument61 SeitenMasonry Design and Detailing Sixth Edition 6th Edition Ebook PDFkaryn.corman836100% (42)

- Detailed Table of ContentsDokument5 SeitenDetailed Table of ContentsWahyu HidayatNoch keine Bewertungen

- Ehe EngDokument551 SeitenEhe EngMohamed OumlkhirNoch keine Bewertungen

- Code On Structural Concrete (EHE-08) : Articles and AnnexesDokument31 SeitenCode On Structural Concrete (EHE-08) : Articles and AnnexesSimoo AkrNoch keine Bewertungen

- Piping Codes, Standards, and Specifications 1Dokument5 SeitenPiping Codes, Standards, and Specifications 1Manish KumarNoch keine Bewertungen

- FEM UE2bDokument2 SeitenFEM UE2bsavicivanNoch keine Bewertungen

- Fem Ue1Dokument2 SeitenFem Ue1savicivanNoch keine Bewertungen

- Front ViewDokument1 SeiteFront ViewsavicivanNoch keine Bewertungen

- Oglas Za Direktora Kvaliteta (Eng)Dokument2 SeitenOglas Za Direktora Kvaliteta (Eng)savicivanNoch keine Bewertungen

- Post & Disc Insulator and Hardware FittingsDokument14 SeitenPost & Disc Insulator and Hardware FittingsPritam SinghNoch keine Bewertungen

- How To Protect Hollow-Core Slabs in Parking Structures From Deicing SaltsDokument5 SeitenHow To Protect Hollow-Core Slabs in Parking Structures From Deicing SaltsShamim Ahsan ZuberyNoch keine Bewertungen

- ADDMIX 109 PCCI-v1Dokument2 SeitenADDMIX 109 PCCI-v1Ankita Baban GavadeNoch keine Bewertungen

- Basic CorrosionDokument11 SeitenBasic CorrosionmohdluthfiNoch keine Bewertungen

- Design of Steel Earthing Grids in IndiaDokument9 SeitenDesign of Steel Earthing Grids in Indiacamono2000Noch keine Bewertungen

- Credentials - Liquipoxy CTE PDFDokument20 SeitenCredentials - Liquipoxy CTE PDFabhijit shindeNoch keine Bewertungen

- Cera System Catalogue 2011Dokument36 SeitenCera System Catalogue 2011prihartono_diasNoch keine Bewertungen

- Material Testing RequirementsDokument23 SeitenMaterial Testing RequirementsbinhNoch keine Bewertungen

- PIS Hempadur Quattro 17820Dokument2 SeitenPIS Hempadur Quattro 17820Freddy Carl FredricksenNoch keine Bewertungen

- 9 Corrosion Prevention Design Material SelectDokument58 Seiten9 Corrosion Prevention Design Material SelectJesus De la RosaNoch keine Bewertungen

- Checklist For Inspection of Bridges by Bridge Line UnitsDokument3 SeitenChecklist For Inspection of Bridges by Bridge Line UnitsSSE Bridge SSBNoch keine Bewertungen

- 52 - ApprovedTrussSystem List Ogos 2022Dokument18 Seiten52 - ApprovedTrussSystem List Ogos 2022siti nabilahNoch keine Bewertungen

- Answers Chapter 8Dokument3 SeitenAnswers Chapter 8Zoe SiewNoch keine Bewertungen

- Appendix A - Illovo Paint SpecificationDokument36 SeitenAppendix A - Illovo Paint Specificationmunshimbwe munshimbweNoch keine Bewertungen

- Radial Gate Cylinder Technology: First Selection Civil Engineering First Selection Civil EngineeringDokument16 SeitenRadial Gate Cylinder Technology: First Selection Civil Engineering First Selection Civil Engineerings_waqarNoch keine Bewertungen

- ProceedingsofNCAMMM 2018interiorDokument422 SeitenProceedingsofNCAMMM 2018interiorIbrahim HaddouchNoch keine Bewertungen

- Is 10221Dokument31 SeitenIs 10221Vinoth P50% (2)

- Corrosion Study Unit: Engineering and Technical Teaching EquipmentDokument5 SeitenCorrosion Study Unit: Engineering and Technical Teaching EquipmentEmmanuelNoch keine Bewertungen

- JM Eagle Blue Brute C900 Onesheet Rev21Dokument2 SeitenJM Eagle Blue Brute C900 Onesheet Rev21james.sakaiNoch keine Bewertungen

- Grassini, S. Et Al. Plasma Treatment For Cleaning and Protecting Metal Artefacts. 2007Dokument6 SeitenGrassini, S. Et Al. Plasma Treatment For Cleaning and Protecting Metal Artefacts. 2007Trinidad Pasíes Arqueología-ConservaciónNoch keine Bewertungen

- Material Selection For AlloyDokument8 SeitenMaterial Selection For AlloyOscarNoch keine Bewertungen

- Trends in Corrosion Management - FinalDokument11 SeitenTrends in Corrosion Management - FinalLuís PiresNoch keine Bewertungen

- GTAW Liquid Pool Convections and The Weld Shape Variations UnderDokument73 SeitenGTAW Liquid Pool Convections and The Weld Shape Variations UnderMariliaFrancoNoch keine Bewertungen