Beruflich Dokumente

Kultur Dokumente

Biofilm Case Study

Hochgeladen von

South Santee AquacultureCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Biofilm Case Study

Hochgeladen von

South Santee AquacultureCopyright:

Verfügbare Formate

George Hutchinson is vice president,

Technology Algae Control US (www.algaecontrol.us),

Charleston County, S.C.

Sound Water Practices

Ultrasonic Technology Controls

Algae and Biofilm

Ultrasound waves are a natural way to minimize algae-related

problems by reducing THM levels, maintenance cycles, and taste

and odor problems. BY GEORGE HUTCHINSON

I

mplementing ultrasound, a pressure, or expel waste products through an environment in which algae attach and

new “green” technology, is helping its contractile vacuole. thrive. Biofilm consists of layers of bac-

utilities improve water quality and Controlling biofilm growth on equip- teria that form on host surfaces, creating

decrease operating costs by control- ment surfaces inside the plant eliminates attachment points for algae. Ultrasound

ling algae growth in ponds, lakes,

and reservoirs and eliminating biofilm Before and After Ultrasonic Treatment

growth inside water treatment plants. Ultrasonic vibrations pose no threat to people, animals, or fish, but devastate algae.

Before APHANOCHAETE After

Ultrasound Zaps Algae

When algae propagation in a water source

is controlled, fewer algae are brought into

a plant at the intake. Ultrasonic technol-

ogy controls algae growth by matching

the resonance frequency of the algae cells

with just enough power to influence cell

ARCELLA

structure.

For example, blue-green algae

(cyanobacteria) have a gas vesicle system

of hundreds to thousands of tiny organ-

elles per cell that’s easily broken by ultra-

sonic sound waves. As a result, the algae

lose buoyancy and sink, their life cycle

processes are disrupted, and their ability OEDOGONIUM

to guard against bacteria is weakened.

Roaming algae (green, brown, black,

filamentous, etc.) don’t have gas ves-

icles, but the ultrasonic unit affects the

algal inner cell membrane, causing it to

separate from the outer sheath. When

separation is complete, the cell can no

longer obtain nutrients, control internal

18 Opflow April 2008 www.awwa.org/communications/opflow

2008 © American Water Works Association

No Ultrasound—December 2006 With Ultrasound—July 2007

The city of Union discovered its basin-cleaning

process was quicker in basins where ultrasound

was present, as the biofilm was attached more

loosely than in basins without ultrasound.

waves prevent formation of the biofilm base layer by prevent- A TESTING GROUND

ing most free-swimming planktonic bacteria from becoming After learning about the use of ultrasonic technology for algae

strongly attached sessile bacteria, which grow on a surface. control at the SC Rural Water Association annual show, Arnold

Biofilm typically starts forming as quickly as 20 min to 3 hr Franklin, Union’s lead water treatment plant operator, arranged

after cleaning. Recent US Department of Agriculture aquacul- for the technology to be tested at the city’s plant. The basins

ture studies conclude that as much as 60 percent of coccoid and weirs were cleaned thoroughly, and two ultrasonic units—

bacteria—critical to biofilm formation—are killed by ultrasound one in a sedimentation basin and another aimed at the v-notch

waves in a 4-day period, though many types of bacteria are weirs—were installed.

unharmed. The ultrasonic sound waves vibrate the bacteria, Almost immediately, plant personnel observed that bio-

and the bacterial pili retract as if they are in turbulent water. film and algae weren’t accumulating in basins or on weirs that

The bacteria don’t excrete the polysaccharide glue necessary to were under the influence of the ultrasound waves. Without bio-

attach to a surface, so biofilm growth is hindered. film, the algae didn’t have an environment in which to adhere

and propagate. When biofilm did form, the basins and weirs

A case in point were easier to clean because the biofilm was more loosely

The city of Union, S.C., pumps water 7 mi from the Broad attached.

River into its potable water plant and processes 3.2–5.4 mgd, The city subsequently implemented the ultrasound technol-

depending on the season. To reduce THM disinfection by- ogy plantwide and has continued to reduce THMs and haloacetic

products in potable water, the city stopped chlorinating at acid (HAA) levels. Once again, cleaning can be conducted every

the river intake in the summer of 2006, which resulted in a 6 weeks, a welcome improvement during the area’s summer heat

50 percent reduction in sodium hypochlorite use. However, by and drought conditions, which necessitate reduced cleaning.

eliminating the chlorination at the intake, bacteria and algae

quickly began to adhere to the sedimentation basin walls and LOOKING AHEAD

Photographs: south santee aquaculture

v-notch weirs, forming biofilm. The city was concerned that November 2007 THM levels measured 34.4 μg/L, well below

algae growing inside the plant would soon cause taste and the regulated threshold of 80 μg/L. In January 2008, THM levels

odor problems. dropped again to 18 μg/L, and HAAs, for which the maximum

To eliminate the biofilm, plant personnel stepped up main- contaminant level is 60 μg/L, dropped from the November 2007

tenance by cleaning the basin walls and v-notch weirs every level of 22 μg/L to 12 μg/L in January 2008. Wastewater Super-

2 weeks instead of every 6 weeks. The biofilm and algae for- visor Donnie Johnson is so pleased with the results that he is

mation made the task difficult and increased maintenance time planning to install ultrasound technology in the wastewater

and costs. Keeping the plant compliant had turned into a main- clarifiers to eliminate biofilm formation and reduce the main-

tenance nightmare. tenance cycle from weekly to monthly.

www.awwa.org/communications/opflow April 2008 Opflow 19

2008 © American Water Works Association

Das könnte Ihnen auch gefallen

- Research: Wisconsin Department of Natural ResourcesDokument20 SeitenResearch: Wisconsin Department of Natural ResourcesFrancoGarbarinoRiffoNoch keine Bewertungen

- Applications of New Concepts of Physical-Chemical Wastewater Treatment: Vanderbilt University, Nashville, Tennessee September 18-22, 1972Von EverandApplications of New Concepts of Physical-Chemical Wastewater Treatment: Vanderbilt University, Nashville, Tennessee September 18-22, 1972Bewertung: 5 von 5 Sternen5/5 (1)

- Application of Biofilm Technology in Wastewater Treatment: A Critique PaperDokument3 SeitenApplication of Biofilm Technology in Wastewater Treatment: A Critique PaperShishii LeeNoch keine Bewertungen

- Biofilm ProcessDokument34 SeitenBiofilm Processfaridkhan100% (2)

- Bacterial PhysiologyVon EverandBacterial PhysiologyC. H. WerkmanBewertung: 1 von 5 Sternen1/5 (1)

- Supercritical Fluid Cleaning: Fundamentals, Technology and ApplicationsVon EverandSupercritical Fluid Cleaning: Fundamentals, Technology and ApplicationsSamuel P. SawanNoch keine Bewertungen

- Liquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentVon EverandLiquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentNoch keine Bewertungen

- Microbial Analysis of Water SampleDokument9 SeitenMicrobial Analysis of Water SamplePalaysma AmrahsNoch keine Bewertungen

- Sanitary Engineer II: Passbooks Study GuideVon EverandSanitary Engineer II: Passbooks Study GuideNoch keine Bewertungen

- Municipal Wastewater Treatment: Evaluating Improvements in National Water QualityVon EverandMunicipal Wastewater Treatment: Evaluating Improvements in National Water QualityNoch keine Bewertungen

- Cyanobacteria: Architects of Earth's AtmosphereDokument5 SeitenCyanobacteria: Architects of Earth's Atmospherekha_yenNoch keine Bewertungen

- Chimie VerdeDokument10 SeitenChimie VerdeSorin MiuNoch keine Bewertungen

- Percolation Behaviour of A Cane DiffuserDokument47 SeitenPercolation Behaviour of A Cane Diffuserarnieuni100% (1)

- Modeling of Activated Sludge With ASM1 Model, Case Study On Wastewater Treatment Plant of South of IsfahanDokument10 SeitenModeling of Activated Sludge With ASM1 Model, Case Study On Wastewater Treatment Plant of South of IsfahanAnish GhimireNoch keine Bewertungen

- Fundamentals of Water Treatment Unit Processes (Feb 2013)Dokument9 SeitenFundamentals of Water Treatment Unit Processes (Feb 2013)lalo2385100% (1)

- CM1205 Chromogenic Coliform Agar ISODokument2 SeitenCM1205 Chromogenic Coliform Agar ISOMaria AspriNoch keine Bewertungen

- Domestic Water Treatment Guide Volume 4Dokument99 SeitenDomestic Water Treatment Guide Volume 4nermeen ahmedNoch keine Bewertungen

- Advanced Math HandbookDokument88 SeitenAdvanced Math HandbookNikka LopezNoch keine Bewertungen

- Counting BacteriaDokument30 SeitenCounting Bacteriayuppie_raj2175100% (1)

- Bacterial GrowthDokument37 SeitenBacterial GrowthJCKARL100% (1)

- Co-Treatment of Landfill Leachate and Settled Domestic Wastewater Using Composite Adsorbent in Sequencing Batch ReactorDokument232 SeitenCo-Treatment of Landfill Leachate and Settled Domestic Wastewater Using Composite Adsorbent in Sequencing Batch ReactorAmin Mojiri100% (1)

- Coagulants and Natural Polymers: Perspectives For The Treatment of WaterDokument8 SeitenCoagulants and Natural Polymers: Perspectives For The Treatment of Waterhuonggiangnguyen3011Noch keine Bewertungen

- Algal Origin and DiversityDokument18 SeitenAlgal Origin and DiversityArunchand RayarothNoch keine Bewertungen

- CalculationDokument28 SeitenCalculationManish Kumar Ghora100% (1)

- Ionic Liquids in Lipid Processing and Analysis: Opportunities and ChallengesVon EverandIonic Liquids in Lipid Processing and Analysis: Opportunities and ChallengesXuebing XuNoch keine Bewertungen

- 2 Polymer Optimization For Centrifuge Dewatering PDFDokument48 Seiten2 Polymer Optimization For Centrifuge Dewatering PDFAnonymous Hy5Ir9QXNoch keine Bewertungen

- Water For Injection-By AnamDokument20 SeitenWater For Injection-By AnamMuhammad Bilal TahirNoch keine Bewertungen

- Ozonation in Organic Chemistry V2: Nonolefinic CompoundsVon EverandOzonation in Organic Chemistry V2: Nonolefinic CompoundsBewertung: 5 von 5 Sternen5/5 (1)

- Chief Water Treatment Plant Operator: Passbooks Study GuideVon EverandChief Water Treatment Plant Operator: Passbooks Study GuideNoch keine Bewertungen

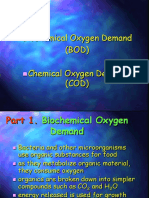

- Biochemical Oxygen Demand (BOD) Chemical Oxygen Demand (COD)Dokument35 SeitenBiochemical Oxygen Demand (BOD) Chemical Oxygen Demand (COD)wahyu hidayatNoch keine Bewertungen

- Lab 12 - MPNDokument10 SeitenLab 12 - MPNMariana LacerdaNoch keine Bewertungen

- Research 2 Duplex Pump: GradeDokument10 SeitenResearch 2 Duplex Pump: GradeAli Requiso MahmudNoch keine Bewertungen

- How Wastewater Treatment Protects the EnvironmentDokument11 SeitenHow Wastewater Treatment Protects the EnvironmentAkinola PreciousNoch keine Bewertungen

- Aerobic Granular Sludge. Cultivation Parameters and Remoal MechanismsDokument53 SeitenAerobic Granular Sludge. Cultivation Parameters and Remoal MechanismsBárbara VianaNoch keine Bewertungen

- Activated Sludge - Troubleshooting GuideDokument5 SeitenActivated Sludge - Troubleshooting Guidekuthappady0% (1)

- Aquaponic Equipment - The Carifier. Nelson, Rebecca. Pade, JohnDokument2 SeitenAquaponic Equipment - The Carifier. Nelson, Rebecca. Pade, JohnSelbor951Noch keine Bewertungen

- Chemistry ProjectDokument7 SeitenChemistry ProjectdanielaNoch keine Bewertungen

- Ozonation of Drinking Water - Part I. Oxidation Kinetics and Product FormationDokument25 SeitenOzonation of Drinking Water - Part I. Oxidation Kinetics and Product FormationArif HidayatNoch keine Bewertungen

- Bubble Coalescence Inhibition Depends on Electrolyte Concentration and Bubble SizeDokument8 SeitenBubble Coalescence Inhibition Depends on Electrolyte Concentration and Bubble SizeJose Luis Barrientos RiosNoch keine Bewertungen

- Desalting Water Treatment Membrane Manual PDFDokument172 SeitenDesalting Water Treatment Membrane Manual PDFCelenia BejaranoNoch keine Bewertungen

- Book SummaryDokument73 SeitenBook SummaryOlivier ManiraguhaNoch keine Bewertungen

- Aerobic Digestion PDFDokument74 SeitenAerobic Digestion PDFvalkiria112Noch keine Bewertungen

- Removal of Methylene BlueDokument26 SeitenRemoval of Methylene BlueAjay KrishnanvNoch keine Bewertungen

- Aeration System in BioreactorDokument9 SeitenAeration System in BioreactorlovleshrubyNoch keine Bewertungen

- Wastewater Math FormulasDokument17 SeitenWastewater Math FormulasPratiwi Natsir PutriNoch keine Bewertungen

- Microbiology of Activated SludgeDokument5 SeitenMicrobiology of Activated SludgeSuresh Lakshmi Narasimhan100% (1)

- Softening: Water TreatmentDokument20 SeitenSoftening: Water Treatmentpkgarg_iitkgpNoch keine Bewertungen

- Removal of Pharmaceuticals From Wastewater by Fungal TreatmentDokument7 SeitenRemoval of Pharmaceuticals From Wastewater by Fungal TreatmentAmirahShaleha0% (1)

- Kinetic and Thermodynamic Study of Methanolysis of Poly (Ethylene Terephthalate) Waste PowderDokument6 SeitenKinetic and Thermodynamic Study of Methanolysis of Poly (Ethylene Terephthalate) Waste PowderMaria ElaineNoch keine Bewertungen

- DBDokument25 SeitenDBAbhijit MondalNoch keine Bewertungen

- Operations Problem in Suspended Growth 2021Dokument36 SeitenOperations Problem in Suspended Growth 2021Je Jed100% (1)

- Algae Article Fong 1503324Dokument63 SeitenAlgae Article Fong 1503324Alejandra AragónNoch keine Bewertungen

- FAQ's Potassium Dichromate Solutions in Sulphuric and Perchloric AcidDokument2 SeitenFAQ's Potassium Dichromate Solutions in Sulphuric and Perchloric AcidspsarathyNoch keine Bewertungen

- Activated Sludge, Respiration Inhibition Test (Carbon and Ammonium Oxidation)Dokument18 SeitenActivated Sludge, Respiration Inhibition Test (Carbon and Ammonium Oxidation)eikatopinenNoch keine Bewertungen

- 21810, Ultrapure Water Breakpoint CL andDokument5 Seiten21810, Ultrapure Water Breakpoint CL andWaleed EmaraNoch keine Bewertungen

- An Industrial Wastewater Contains 10 MG L ChlorophenolDokument5 SeitenAn Industrial Wastewater Contains 10 MG L ChlorophenolsumitNoch keine Bewertungen

- Pond Aerators, Water Circulators & De-Icers Lighting SolutionsDokument6 SeitenPond Aerators, Water Circulators & De-Icers Lighting SolutionsSouth Santee AquacultureNoch keine Bewertungen

- Pam 25 Co-Polymer Water Clarifier MsdsDokument2 SeitenPam 25 Co-Polymer Water Clarifier MsdsSouth Santee Aquaculture100% (1)

- Pond With Circulator Power Point SlideDokument10 SeitenPond With Circulator Power Point SlideSouth Santee AquacultureNoch keine Bewertungen

- Aerator Circulator Owners Manual KascoDokument20 SeitenAerator Circulator Owners Manual KascoSouth Santee AquacultureNoch keine Bewertungen

- Loch Ness Ss Pond Dye MsdsDokument1 SeiteLoch Ness Ss Pond Dye MsdsSouth Santee AquacultureNoch keine Bewertungen

- Sahara DG Herbicide MsdsDokument8 SeitenSahara DG Herbicide MsdsSouth Santee Aquaculture100% (1)

- South Santee OverviewDokument13 SeitenSouth Santee OverviewSouth Santee AquacultureNoch keine Bewertungen

- VitaStim Anaerobic SSADokument1 SeiteVitaStim Anaerobic SSASouth Santee AquacultureNoch keine Bewertungen

- Sonic Solutions Facts and SpecificationsDokument2 SeitenSonic Solutions Facts and SpecificationsSouth Santee Aquaculture100% (2)

- Rodeo Herbicide MsdsDokument3 SeitenRodeo Herbicide MsdsSouth Santee Aquaculture100% (1)

- Sonar Q Herbicide MsdsDokument4 SeitenSonar Q Herbicide MsdsSouth Santee Aquaculture100% (1)

- Karmex 80df Diuron MsdsDokument9 SeitenKarmex 80df Diuron MsdsSouth Santee Aquaculture100% (1)

- Sonar Q Herbicide MsdsDokument4 SeitenSonar Q Herbicide MsdsSouth Santee Aquaculture100% (1)

- Sonar As Herbicide MsdsDokument4 SeitenSonar As Herbicide MsdsSouth Santee Aquaculture100% (1)

- Reward Aquatic Herbicide MsdsDokument6 SeitenReward Aquatic Herbicide MsdsSouth Santee AquacultureNoch keine Bewertungen

- Renovate 3 Herbicide: Material Safety Data SheetDokument4 SeitenRenovate 3 Herbicide: Material Safety Data SheetSouth Santee AquacultureNoch keine Bewertungen

- Habitat Herbicide MsdsDokument4 SeitenHabitat Herbicide MsdsSouth Santee AquacultureNoch keine Bewertungen

- Kammo Plus Surfactant MsdsDokument1 SeiteKammo Plus Surfactant MsdsSouth Santee AquacultureNoch keine Bewertungen

- Hydrothol 191 Granular Herbicide MsdsDokument6 SeitenHydrothol 191 Granular Herbicide MsdsSouth Santee AquacultureNoch keine Bewertungen

- Greenclean Pro Algicide MsdsDokument1 SeiteGreenclean Pro Algicide MsdsSouth Santee Aquaculture100% (1)

- Macrozyme Beneficial Bacteria MsdsDokument2 SeitenMacrozyme Beneficial Bacteria MsdsSouth Santee Aquaculture100% (1)

- Hydrothol 191 Herbicide MsdsDokument6 SeitenHydrothol 191 Herbicide MsdsSouth Santee Aquaculture100% (1)

- Floclog 730b Water Clarifier MsdsDokument2 SeitenFloclog 730b Water Clarifier MsdsSouth Santee AquacultureNoch keine Bewertungen

- Floclog 706b Water Clarifier MsdsDokument2 SeitenFloclog 706b Water Clarifier MsdsSouth Santee AquacultureNoch keine Bewertungen

- Floclog 704f Water Clarifier MsdsDokument2 SeitenFloclog 704f Water Clarifier MsdsSouth Santee AquacultureNoch keine Bewertungen

- Floclog 704b Water Clarifier MsdsDokument2 SeitenFloclog 704b Water Clarifier MsdsSouth Santee AquacultureNoch keine Bewertungen

- Floclog 703d3 Water Clarifier MsdsDokument2 SeitenFloclog 703d3 Water Clarifier MsdsSouth Santee AquacultureNoch keine Bewertungen

- Floclog 702b Water Clarifier MsdsDokument2 SeitenFloclog 702b Water Clarifier MsdsSouth Santee AquacultureNoch keine Bewertungen

- Floclog 703d3 Water Clarifier MsdsDokument2 SeitenFloclog 703d3 Water Clarifier MsdsSouth Santee AquacultureNoch keine Bewertungen

- Study Guide Questions Biology LabDokument6 SeitenStudy Guide Questions Biology LabZ0MBAYNoch keine Bewertungen

- General Biology 1: Quarter 1 - Cell: The Basic Unit of LifeDokument10 SeitenGeneral Biology 1: Quarter 1 - Cell: The Basic Unit of LifeMega CyclopsNoch keine Bewertungen

- Topic 3 - Cellular Level of OrganizationDokument6 SeitenTopic 3 - Cellular Level of OrganizationAdeyinka OluyoleNoch keine Bewertungen

- Worksheet: © 2013 Marshall Cavendish International (Singapore) Private LimitedDokument7 SeitenWorksheet: © 2013 Marshall Cavendish International (Singapore) Private LimitedKaung Myat SanNoch keine Bewertungen

- October 2019 NMAT Study Guide Ver. 1.BDokument75 SeitenOctober 2019 NMAT Study Guide Ver. 1.BAria DomingoNoch keine Bewertungen

- TBR Bio2 OptDokument495 SeitenTBR Bio2 Optmeyangli88% (25)

- SL Biology Syllabus NotesDokument52 SeitenSL Biology Syllabus NotesRyel MuchunkuNoch keine Bewertungen

- Cell Structure: Prof. Dr. Dr. Farhat, M.Ked (ORL-HNS), SP.T.H.T.K.L (K)Dokument21 SeitenCell Structure: Prof. Dr. Dr. Farhat, M.Ked (ORL-HNS), SP.T.H.T.K.L (K)Herison Efrata SinulinggaNoch keine Bewertungen

- Research: NA BIL ITY: AM E UR OP EA N Ricu LTU REDokument56 SeitenResearch: NA BIL ITY: AM E UR OP EA N Ricu LTU REtester1972Noch keine Bewertungen

- Class 6 ScienceDokument8 SeitenClass 6 Sciencemuzzammil.memonsNoch keine Bewertungen

- Final Exam BCH 3023: Multiple ChoiceDokument13 SeitenFinal Exam BCH 3023: Multiple ChoicecwodNoch keine Bewertungen

- Microbiology & ImmunologyDokument24 SeitenMicrobiology & ImmunologyKumuthaa ShroomNoch keine Bewertungen

- P5 Science - From Parents To YoungDokument38 SeitenP5 Science - From Parents To YoungBernard ChanNoch keine Bewertungen

- Test QuestionsDokument25 SeitenTest QuestionsssNoch keine Bewertungen

- Cell Transport Mechanisms: Simple Diffusion and Facilitated TransportDokument12 SeitenCell Transport Mechanisms: Simple Diffusion and Facilitated TransportKenneth Vince AlonzoNoch keine Bewertungen

- Label The Cell AnimalDokument3 SeitenLabel The Cell AnimalDaryhen GonzalezNoch keine Bewertungen

- 14-Kingdoms Classification-Review Sheet KeyDokument4 Seiten14-Kingdoms Classification-Review Sheet Keyapi-235364651Noch keine Bewertungen

- Differences Between Plant and Animal CellsDokument11 SeitenDifferences Between Plant and Animal CellsThet Yadanar ShuneNoch keine Bewertungen

- 1appl 11671 016 1257 4Dokument14 Seiten1appl 11671 016 1257 4Ethiopian MysticsNoch keine Bewertungen

- 9a Mark SchemesDokument6 Seiten9a Mark Schemesobomar2010Noch keine Bewertungen

- Name: - Strand: - DateDokument3 SeitenName: - Strand: - DateOwen OwenNoch keine Bewertungen

- iCell: Compare Animal, Plant and Bacteria CellsDokument3 SeiteniCell: Compare Animal, Plant and Bacteria CellsAnthony.sabaNoch keine Bewertungen

- Chapter 10 Cell Cycle and Cell DivisionDokument14 SeitenChapter 10 Cell Cycle and Cell DivisionPhoenix RockiNoch keine Bewertungen

- Y3 IP Biology Notes FYE EditionDokument72 SeitenY3 IP Biology Notes FYE Editionstopspam12345Noch keine Bewertungen

- Cytoplasm: Color Textbook of Histology, 3rd EdDokument8 SeitenCytoplasm: Color Textbook of Histology, 3rd EdJanet GonzálezNoch keine Bewertungen

- 29105-Medical Terminology WorkbookDokument344 Seiten29105-Medical Terminology WorkbookLee Hing Wah100% (2)

- Virus Powerpoint 12-9-2003Dokument34 SeitenVirus Powerpoint 12-9-2003yusiskaNoch keine Bewertungen

- Volutin Granule StainingDokument2 SeitenVolutin Granule StainingRajeev PotadarNoch keine Bewertungen

- CellsDokument46 SeitenCellsErfanShekarrizNoch keine Bewertungen

- Study Guide A: Key ConceptDokument17 SeitenStudy Guide A: Key ConceptKarla MaríaNoch keine Bewertungen