Beruflich Dokumente

Kultur Dokumente

Hfo To Mdo Change Over Procedure

Hochgeladen von

Janell PrinceOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hfo To Mdo Change Over Procedure

Hochgeladen von

Janell PrinceCopyright:

Verfügbare Formate

HFO TO MDO CHANGE OVER PROCEDURE

Main Engine and Auxiliary Engine

Changing Over At Sea 1. Check quantity of MDO in MDO service tank. 2. Check water or sludge by draining MDO service tank (valve no.FD055). 3. Close steam heating to the HFO service tank ( 4. Reduce the Engine load to 40% of MCR-load 5. Close following steam tracing line valves for M/E and A/E fuel oil lines in purifier room. (Valve nos.TH299-FO SUPP UNIT, 322-ME F.O SERVICE SYS, 323- ME F.O SERVICE SYS,324-AE FO SERVICE SYS,325-ME FO RETURN SYS,326-AE FO RETURN SYS, V081-MIX COLOUMN STEAM TRACING ,V080-STEAM TRACING FOR AUTO BACKFLUSH FILTER) (154V- ME FO LINE STEAM TRACING TO BE SHUT. LOCATION NEAR M/E MANOEUVRING PLATFORM) 6. Regulate the steam inlet to the fuel oil heater to achieve the oil outlet temp not less than 750C. 7. When said temperature is achieved open the MDO to system by opening MDO Service tank outlet v/v and by changing the position of 3 way valve (valve no.ZS). 8. Open Valve Nos. V300(Location : Purifier room) & 150V (Location : ECR Platform FWD port near HSFO service tank) to No.2 HSFO Fuel oil service tank in fuel oil return line. 9. Close Valve no. V301 (Location : Purifier room) in fuel oil return line to Mixing Column. 10. After completion of changeover Open valve V301 and close valves V300 & 150V. Changing over during Standstill 1. Stop preheating 2. Same temperature levels as said during change over at sea is to be maintained 3. When said temperature is achieved open the MDO to system by changing the position of 3 way valve (valve no.ZS). 4. Start F.O supply pumps and circulating pumps if they are not running change the return of main engine to HFO service tank in use 5. About 0.2 m3 of oil to be flushed through the Mixing column and fuel oil lines

6. It is sufficient enough to change that ME return back to mixing column after 1520min

Boiler 1. 2. 3. 4. 5. Check quantity of MDO in MDO service tank. Check water or sludge by draining MDO service tank (Valve no.FD055). Open MDO service tank valve to aux blr FO supply pump (Valve no.FL187V) Make sure that valve no.FL188 is open. Shut the steam tracing for boiler FO service system.

(Valve no.TH 328- aux blr FO service system,TH329-Aux Blr FO service system,TR350 DRN From AUX.BLR FO return system,TR348-DRN From Aux Blr FO Service System,TR-349 DRN From Aux Blr FO Service System) 6. Shut the steam inlet valve (TH 227) boiler FO heater 7. When oil temp is about 750C open the MDO to system by changing the position of three way valve (valve no.PB MP 2114). MDO TO HFO CHANGE OVER PROCEDURE

Main Engine and Auxiliary Engine

1. Fill service tank and open steam to bring temperature of service tank about 750C

2. Reduce the engine RPM to 40% of MCR

3. Regulate steam to fuel oil heater so that the outlet diesel oil temp is not more than 800C or the viscosity of oil should not drop below 3cSt

4. Open steam tracing lines for M/E and A/E fuel oil lines in purifier room (Valve nos.TH299- FO SUPP UNIT,322-ME F.O SERVICE SYS,323- ME F.O SERVICE SYS,324-AE FO SERVICE SYS,325-ME FO RETURN SYS,326-AE FO RETURN SYS, V081-MIX COLOUMN STEAM TRACING ,V080-STEAM TRACING FOR AUTO BACKFLUSH FILTER) 5. When said temperature is achieved open the HFO to system by changing the position of 3 way valve (valve no.ZS).

Boiler 1. Open the steam tracing for boiler FO service system (Valve no.TH 328- aux blr FO service system,TH329-Aux Blr FO service system,TR350 DRN From AUX.BLR FO return system,TR348-DRN From Aux Blr FO Service System,TR-349 DRN From Aux Blr FO Service System)

2. Open the steam inlet valve (TH 227) boiler FO heater

3. When oil temp is about 750C open the HFO to system by changing the position of three way valve (valve no.PB MP 2114).

Das könnte Ihnen auch gefallen

- Created by Ankur Sharma, Gurudayal Srivastava, Vikram Singh, Sanket TamhaneDokument7 SeitenCreated by Ankur Sharma, Gurudayal Srivastava, Vikram Singh, Sanket TamhaneSankash Sood100% (2)

- Air Bottle InspectionDokument1 SeiteAir Bottle InspectionSaifful Nasir67% (3)

- PURIFIERSDokument7 SeitenPURIFIERSjames dogelioNoch keine Bewertungen

- Oral Candy Meo Class 4Dokument32 SeitenOral Candy Meo Class 4deepanck0% (2)

- MEO CLASS IV OralsDokument25 SeitenMEO CLASS IV OralsAnoop Vijayakumar0% (1)

- The Air Starting System How An Engine Starts On AirDokument6 SeitenThe Air Starting System How An Engine Starts On AirBharatiyulamNoch keine Bewertungen

- Tie BoltsDokument31 SeitenTie BoltsMuhammad Nasim AbbasNoch keine Bewertungen

- MEO Class 4B Motor Orals Exam QuestionsDokument3 SeitenMEO Class 4B Motor Orals Exam QuestionsInzaHopeNoch keine Bewertungen

- Why EGE safety valve pressure is greater than auxiliary boiler pressureDokument3 SeitenWhy EGE safety valve pressure is greater than auxiliary boiler pressureKišić SpasojeNoch keine Bewertungen

- Mep Oral AnswersDokument28 SeitenMep Oral AnswersAshjo Gamer100% (1)

- 200 OralDokument295 Seiten200 OralSamarendu Tiwari100% (7)

- MEO Class 2 Orals Function 4 & 6 Q & ADokument8 SeitenMEO Class 2 Orals Function 4 & 6 Q & Aneeraj118578% (9)

- Meo Class IV Steam BitsDokument26 SeitenMeo Class IV Steam BitsVijay Prakash100% (3)

- IMP Main Engine and Aux EngineDokument37 SeitenIMP Main Engine and Aux EngineLOKINoch keine Bewertungen

- Puncture ValveDokument2 SeitenPuncture ValveSanjeev SainiNoch keine Bewertungen

- Purifier Manual Starting StoppingDokument3 SeitenPurifier Manual Starting Stoppingavm4343Noch keine Bewertungen

- Fuel Pump Cam Lead Adjustment MC-CDokument4 SeitenFuel Pump Cam Lead Adjustment MC-CPrashanthNoch keine Bewertungen

- Stuffing BoxDokument6 SeitenStuffing BoxrajishrrrNoch keine Bewertungen

- Oral QuestionsDokument145 SeitenOral QuestionsVinothen Raj100% (2)

- Assorted QuestionsDokument17 SeitenAssorted QuestionsRohit MishraNoch keine Bewertungen

- Operational Information The MAN B&W MC Engine VIT Fuel PumpDokument16 SeitenOperational Information The MAN B&W MC Engine VIT Fuel PumpAbhishek Singh Chauhan100% (2)

- Oily Water SeparatorDokument7 SeitenOily Water SeparatorVishu Sharma100% (2)

- MEO Class 2 Orals Function 6 Q & ADokument7 SeitenMEO Class 2 Orals Function 6 Q & Aneeraj11850% (1)

- Cross Head Removal For Man B WDokument13 SeitenCross Head Removal For Man B WMOHAN100% (1)

- Procedure for Overhaul of A/E GeneratorDokument20 SeitenProcedure for Overhaul of A/E GeneratorKapil Verma100% (1)

- Connecting Rod BoltsDokument2 SeitenConnecting Rod BoltsRachitNoch keine Bewertungen

- Notes RohitDokument66 SeitenNotes RohitRohit MishraNoch keine Bewertungen

- Cleaning FIVA ValvesDokument5 SeitenCleaning FIVA ValvesValeriy DomashenkoNoch keine Bewertungen

- MEO Class 4 Oral and Written Questions Part 4Dokument43 SeitenMEO Class 4 Oral and Written Questions Part 4amitt.rulezz80% (5)

- ReversingDokument28 SeitenReversingrakesh0212100% (1)

- Slide Fuel Valves Reduce EmissionsDokument5 SeitenSlide Fuel Valves Reduce EmissionsParthiban NagarajanNoch keine Bewertungen

- Alpha Lubricator System OperationDokument190 SeitenAlpha Lubricator System Operationlalinda67% (3)

- MAN B&W Fuel System 12K90MCDokument4 SeitenMAN B&W Fuel System 12K90MCRaunaq Arora100% (3)

- Marine Boiler Question AnswersDokument9 SeitenMarine Boiler Question AnswersSumeet SawantNoch keine Bewertungen

- Class 4 EoowDokument74 SeitenClass 4 EoowRyan Cardoza0% (1)

- Safety-Overall MEO Class 4 Part BDokument21 SeitenSafety-Overall MEO Class 4 Part Blazyreaderr100% (1)

- Class 4 Frequent Asked Qs Shashwat000Dokument168 SeitenClass 4 Frequent Asked Qs Shashwat000Lovy Singh100% (1)

- Safety Devices in Air Compressors On ShipsDokument30 SeitenSafety Devices in Air Compressors On ShipsSwarg VibhaNoch keine Bewertungen

- HITACHI-MAN B&W Stroke Sensor AdjustmentDokument2 SeitenHITACHI-MAN B&W Stroke Sensor Adjustmentg arvNoch keine Bewertungen

- Oral Ques and AnsDokument8 SeitenOral Ques and AnsVarun Ranjan100% (1)

- Sketch and Describe A Two-Stage Air Compressor Suitable For Marine Use Up To 30 Bar PressureDokument4 SeitenSketch and Describe A Two-Stage Air Compressor Suitable For Marine Use Up To 30 Bar PressureA NNoch keine Bewertungen

- Fuel Valve, Fuel Pump, Relief Valve, Starting Air Valve, Air Distributor Automatic Valve, EXHAUSTDokument81 SeitenFuel Valve, Fuel Pump, Relief Valve, Starting Air Valve, Air Distributor Automatic Valve, EXHAUSTsuraj0% (1)

- Reversing Gears of A Marine Diesel EngineDokument4 SeitenReversing Gears of A Marine Diesel Engineashry_tarekNoch keine Bewertungen

- Camshaft timing chain drive and reversing mechanismsDokument55 SeitenCamshaft timing chain drive and reversing mechanismsMeghanath AdkonkarNoch keine Bewertungen

- Actual Sysem Setup Alpha LubricatorDokument7 SeitenActual Sysem Setup Alpha LubricatorRanjan DiptanshuNoch keine Bewertungen

- Meo cl2 MMDDokument38 SeitenMeo cl2 MMDAurvin SinghNoch keine Bewertungen

- Puncture ValveDokument1 SeitePuncture ValveAnkit DedhiyaNoch keine Bewertungen

- 78 - RT-Flex - CLU-4 Cylinder Lubricating SystemDokument19 Seiten78 - RT-Flex - CLU-4 Cylinder Lubricating SystemVignesh Krishnamoorthy100% (2)

- MAN B&W Radial Air Start Distributor OperationDokument1 SeiteMAN B&W Radial Air Start Distributor OperationArun SNoch keine Bewertungen

- Common Rail Fuel Injection Technology in Diesel EnginesVon EverandCommon Rail Fuel Injection Technology in Diesel EnginesNoch keine Bewertungen

- Marine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionVon EverandMarine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionBewertung: 5 von 5 Sternen5/5 (1)

- New Technologies for Emission Control in Marine Diesel EnginesVon EverandNew Technologies for Emission Control in Marine Diesel EnginesNoch keine Bewertungen

- Revised Change Over Procedure HSFO To LSMGO at SECADokument4 SeitenRevised Change Over Procedure HSFO To LSMGO at SECAJames CK100% (2)

- Hsfo Lsmgo PDFDokument2 SeitenHsfo Lsmgo PDFRajTiwariNoch keine Bewertungen

- HFO MDO ChangeoverDokument1 SeiteHFO MDO ChangeoverStewart LongNoch keine Bewertungen

- Trinity & Matrix: Natural To LP Conversion InstructionsDokument4 SeitenTrinity & Matrix: Natural To LP Conversion InstructionsFREDNoch keine Bewertungen

- 300 MW ThermalPower Plant Cold Start UpDokument4 Seiten300 MW ThermalPower Plant Cold Start Upsunil481100% (1)

- Tr7-8fi ManualDokument82 SeitenTr7-8fi ManualClint CooperNoch keine Bewertungen

- WR 250 RDokument364 SeitenWR 250 RDragomir IonutNoch keine Bewertungen

- PacificAerospace PAC750XL POH PDFDokument278 SeitenPacificAerospace PAC750XL POH PDFPaulNoch keine Bewertungen

- Toyota 1ZZ FE 3ZZ FE Engine Repair Manual RM1099E PDFDokument141 SeitenToyota 1ZZ FE 3ZZ FE Engine Repair Manual RM1099E PDFJhorwind Requena87% (15)

- Chemistry Notes Class 11 Chapter 13 HydrocarbonsDokument26 SeitenChemistry Notes Class 11 Chapter 13 HydrocarbonsShashank PratapNoch keine Bewertungen

- Bitumen delivery and storage hazardsDokument13 SeitenBitumen delivery and storage hazardshasriyaniNoch keine Bewertungen

- Ujian Nasional Bahasa Inggris SMA Tahun 1988Dokument5 SeitenUjian Nasional Bahasa Inggris SMA Tahun 1988Andhika A. SetiyonoNoch keine Bewertungen

- USDA Biofuels 06232010Dokument21 SeitenUSDA Biofuels 06232010sslome@nexant.comNoch keine Bewertungen

- Trolley Turning and Lifting Mechanism: Ayneendra B, Mohd Salman, Jimmy Thaddeus Ojyok Attari, Marvan EDokument8 SeitenTrolley Turning and Lifting Mechanism: Ayneendra B, Mohd Salman, Jimmy Thaddeus Ojyok Attari, Marvan ERahul PrasadNoch keine Bewertungen

- Pet CokeDokument12 SeitenPet Cokezementhead100% (1)

- ATL Fuel Cell DiagramDokument1 SeiteATL Fuel Cell DiagramMike DeSpenzaNoch keine Bewertungen

- Burnt TOST: Don't Let The TOST Test Burn Your Hydraulic Oil DecisionDokument2 SeitenBurnt TOST: Don't Let The TOST Test Burn Your Hydraulic Oil DecisionAnonymous alQXB11EgQNoch keine Bewertungen

- Marine Electric Power Generation: Jim Bertsch Marine Program ManagerDokument27 SeitenMarine Electric Power Generation: Jim Bertsch Marine Program ManagerFarhan Arif SantosoNoch keine Bewertungen

- Check Engine Codes for Air Flow, O2 Sensors & InjectorsDokument80 SeitenCheck Engine Codes for Air Flow, O2 Sensors & InjectorsLucio CaeiroNoch keine Bewertungen

- Petroleum - Nic.in - Newgazette - Lube Order 1987 - 45Dokument6 SeitenPetroleum - Nic.in - Newgazette - Lube Order 1987 - 45Prof C.S.PurushothamanNoch keine Bewertungen

- TracpipeFGP 001 DI GuideDokument112 SeitenTracpipeFGP 001 DI GuidenubazNoch keine Bewertungen

- Tank Farm Design GuidelinesDokument2 SeitenTank Farm Design GuidelinesSouparna DuttaNoch keine Bewertungen

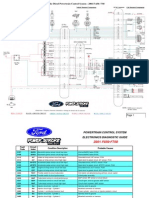

- F650 F750 PowerstrokeDokument3 SeitenF650 F750 Powerstrokemiguelcastillo100% (1)

- Indice de Aciditate ASTM Nou METROHM - AN-PAN-1037Dokument2 SeitenIndice de Aciditate ASTM Nou METROHM - AN-PAN-1037Corina StanculescuNoch keine Bewertungen

- Eg Basico 32.6 enDokument1 SeiteEg Basico 32.6 enAleksandar Nikolovski50% (2)

- 200CLC, 230CLC and 270CLC Operator OMT187348 (2017 - 03 - 08 20 - 12 - 32 UTC)Dokument184 Seiten200CLC, 230CLC and 270CLC Operator OMT187348 (2017 - 03 - 08 20 - 12 - 32 UTC)steve100% (1)

- Synthesis of FormalinDokument2 SeitenSynthesis of FormalinHaziq MatNoch keine Bewertungen

- E01 PDFDokument28 SeitenE01 PDFAnonymous HJZffHvTNoch keine Bewertungen

- Essential Requirements of Railway Traction SystemsDokument66 SeitenEssential Requirements of Railway Traction SystemsAkshay KatharNoch keine Bewertungen

- Passenger Provisions Table 23A enDokument3 SeitenPassenger Provisions Table 23A envannaviettelNoch keine Bewertungen

- Project On Indain Oil Corporation LimitedDokument93 SeitenProject On Indain Oil Corporation LimitedKavisha singhNoch keine Bewertungen

- Oman Oil & Gas Plants & PipelinesDokument4 SeitenOman Oil & Gas Plants & PipelinesItisha GuptaNoch keine Bewertungen

- BMK LTM 1100-4 1 Uw Von 063353 Bis 063448 0000000 enDokument62 SeitenBMK LTM 1100-4 1 Uw Von 063353 Bis 063448 0000000 enEdilsonNoch keine Bewertungen

- ASTM D287-92 (Metodo de Prueba Estandar para Gravedad API de Petroleo Crudo y Productos Del Petroleo Metodo Del Hidrómetro)Dokument3 SeitenASTM D287-92 (Metodo de Prueba Estandar para Gravedad API de Petroleo Crudo y Productos Del Petroleo Metodo Del Hidrómetro)Juan MonjeNoch keine Bewertungen

- CHEMISTRY Ch2 Solved Assignment Class 9 CBSEDokument5 SeitenCHEMISTRY Ch2 Solved Assignment Class 9 CBSEgurdeepsarora8738100% (1)

- The SERO Side Channel Pump - A niche product between displacement and centrifugal pumpsDokument5 SeitenThe SERO Side Channel Pump - A niche product between displacement and centrifugal pumpsAdanaNoch keine Bewertungen