Beruflich Dokumente

Kultur Dokumente

Industrial Separation Processes

Hochgeladen von

Jaimie DonovanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Industrial Separation Processes

Hochgeladen von

Jaimie DonovanCopyright:

Verfügbare Formate

Jaimie Donovan

Industrial Separation Processes

Sugarcane

Sugarcane is a plant that is used to make sugar. It belongs in the Biosphere, or the living part of the Earth, which also contains cells made up mostly of complex carbon compounds. The Sugarcane plant itself is made up of roots from which a main stalk protrudes. The leaves shoot of the stalk from leaf sheaths. The Sucrose from the Sugarcane plants comes from photosynthesis, in which the plant provides energy for itself. This can be written as: Carbon dioxide + water=sucrose + oxygen 12 CO2 + 11 H2 O=C12 H22 O11 + 12 O2 Sugarcane, as a mixture, is made up of a variety of different sugars and compounds that are separated out into the various products produced. Once the Sugarcane has been grown and harvested, the first process it undergoes is washing and then crushing. The sweet juice is removed from the pulp in a milling tandem, which crushes the pulp to release the juices. This process of crushing is also known as Comminution. From here, Sulphur Dioxide is steamed through it in a process known as Sulfidation. This bleaches the juice, turning it from a murky brown to lighter brown. Lime solution is then added to the juice to regulate its pH and clarify it. This process is known as Alkalisation. The juice is then poured into tanks where it is distilled to produce purified juice. This is then further clarified by boiling. As it is boiling, any solid particles still in the juice rise to the top and are skimmed off. This process is similar to froth flotation. This produces syrup, which is then boiled to form crystals. Crystallisation is used to form them. The syrup is then poured into a centrifuging machine which removes the crystals from the syrup. The process relies on a variety of chemical and physical properties, including: Weight/ density Particle size State at room temperature Solubility Boiling Point

During the Production of Sugar from Sugarcane, several by-products are created. However, unlike in many other industries, these products are not wasted. When the juice is first separated from the

Jaimie Donovan remaining pulp, this pulp or bagasse is used to cover the fields growing sugarcane. When the juice is distilled, the think sludge-like mud is separated out. This is then used as a fertiliser for growing sugarcane. Finally, when the sugar crystals are separated from the syrup using centrifuging, this syrup or molasses is then cleaned and sold either as molasses or further refined as golden syrup. The production of sugarcane doesnt create much waste, as all the by-products are reused. However in the process, a lot of water and energy is used.

Jaimie Donovan

References SKIL - Learn How Sugar Is Made. (n.d.). Sugar Knowledge International Limited SKIL. Retrieved February 22, 2012, from http://www.sucrose.com/learn.html Silverman, J. (n.d.). HowStuffWorks "Sugar Production". HowStuffWorks "Science". Retrieved February 22, 2012, from http://science.howstuffworks.com/innovation/edibleinnovations/sugar4.htm Sucrose - Wikipedia, the free encyclopedia. (n.d.). Wikipedia, the free encyclopedia. Retrieved February 22, 2012, from http://en.wikipedia.org/wiki/Sucrose#Chemical_synthesis Sugar - Wikipedia, the free encyclopedia. (n.d.). Wikipedia, the free encyclopedia. Retrieved February 22, 2012, from http://en.wikipedia.org/wiki/Sugar#Chemistry Sugar Australia. (n.d.). Sugar Australia. Retrieved February 22, 2012, from http://www.sugaraustralia.com.au/Industry.aspx?content=MillingBusiness Sugar Production from Sugar Cane. (n.d.). Practical Action. Retrieved February 22, 2012, from practicalaction.org/docs/technical_information_service/sugar_production_from_ca ne.pdf

Das könnte Ihnen auch gefallen

- The Distilleries of Vancouver Island: A Guided Tour of West Coast Craft and Artisan SpiritsVon EverandThe Distilleries of Vancouver Island: A Guided Tour of West Coast Craft and Artisan SpiritsNoch keine Bewertungen

- Sugar Manufacture DR Vijaya ShastryDokument40 SeitenSugar Manufacture DR Vijaya ShastryAyanda HlanzeNoch keine Bewertungen

- Chemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastVon EverandChemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastNoch keine Bewertungen

- The Sugar IndustryDokument22 SeitenThe Sugar IndustryAbraham wisdomNoch keine Bewertungen

- Sugar Manufacture-Dr Vijaya ShastryDokument40 SeitenSugar Manufacture-Dr Vijaya ShastryVijaya Shastry100% (2)

- Fight The Sugar Addiction : Low Carb and Sugar-Free recipes ideas: A Short Guide to Fight Efficiently Sugar Addiction Withdrawal SymptomsVon EverandFight The Sugar Addiction : Low Carb and Sugar-Free recipes ideas: A Short Guide to Fight Efficiently Sugar Addiction Withdrawal SymptomsNoch keine Bewertungen

- Muscovado SugarDokument15 SeitenMuscovado SugarkirbeyNoch keine Bewertungen

- Sugar PlantDokument7 SeitenSugar PlantRohit JainNoch keine Bewertungen

- Production and Total Quality ManagementDokument12 SeitenProduction and Total Quality ManagementPrachi PatilNoch keine Bewertungen

- Extraction of Sucrose From Sugar CaneDokument6 SeitenExtraction of Sucrose From Sugar CaneUnknownKidNoch keine Bewertungen

- SugarDokument18 SeitenSugarjantskieNoch keine Bewertungen

- Chem AssignmentDokument6 SeitenChem AssignmentJasonKoylass100% (1)

- Operations at Daurala Sugar ComplexDokument2 SeitenOperations at Daurala Sugar ComplexShubhamNoch keine Bewertungen

- Sugar Cane Process Chemistry ProjectDokument12 SeitenSugar Cane Process Chemistry ProjectJekilyah50% (2)

- Ch7 Food Industries Part 2Dokument17 SeitenCh7 Food Industries Part 2فرحNoch keine Bewertungen

- The Technology of Sugar ProductionDokument7 SeitenThe Technology of Sugar ProductionPopa Anne MarieNoch keine Bewertungen

- Sugar IndustryDokument7 SeitenSugar IndustryNimra MalikNoch keine Bewertungen

- Inside A Sugar Factory June 2014Dokument21 SeitenInside A Sugar Factory June 2014Nikola PuljićNoch keine Bewertungen

- The Production of Sugar From Sugar CaneDokument9 SeitenThe Production of Sugar From Sugar CaneNeiliah Jackson50% (2)

- Chemical Engineering Basics Lec (5) Sugar Production T. Alaa KhalidDokument37 SeitenChemical Engineering Basics Lec (5) Sugar Production T. Alaa KhalidjoNoch keine Bewertungen

- Manufacturing Process of Sugarcane To SugarDokument12 SeitenManufacturing Process of Sugarcane To SugarNur Hanani100% (1)

- 13ch156sugurindustry 131113014208 Phpapp02Dokument12 Seiten13ch156sugurindustry 131113014208 Phpapp02adNoch keine Bewertungen

- Role of Sugar, Gur, Liquid SweetnersDokument10 SeitenRole of Sugar, Gur, Liquid SweetnersBharath Jaganathan100% (1)

- Processing Lines: Hector GarzaDokument17 SeitenProcessing Lines: Hector GarzaAleem AhmedNoch keine Bewertungen

- Refining and Processing SugarDokument4 SeitenRefining and Processing SugarRocío CapuñayNoch keine Bewertungen

- Sugar Cane ProcessingDokument17 SeitenSugar Cane Processingsangener100% (1)

- Chemical Process TechnologyDokument19 SeitenChemical Process TechnologysepticmoneyNoch keine Bewertungen

- Carbohydrate Rich FoodsDokument26 SeitenCarbohydrate Rich FoodsAniisahNoch keine Bewertungen

- Tan Quiz 2Dokument3 SeitenTan Quiz 2Bryan TanNoch keine Bewertungen

- Sugar Industry, Group 1Dokument23 SeitenSugar Industry, Group 1Abraham wisdomNoch keine Bewertungen

- REPORT On Sugar IndustryDokument13 SeitenREPORT On Sugar IndustrySagar KakadeNoch keine Bewertungen

- Sugar ProcessingDokument46 SeitenSugar ProcessingChristian Jay Baliling Sablada100% (1)

- Chapter 2 Review Related LiteratureDokument14 SeitenChapter 2 Review Related Literatureapi-3740268100% (7)

- Sugar BeetDokument21 SeitenSugar BeetAnurag SrivastavaNoch keine Bewertungen

- Friction FactorsDokument4 SeitenFriction FactorsYasir AzeemNoch keine Bewertungen

- Unit 10 Jams, Jellies, Marmalade and Other Sugar-Based ProductsDokument24 SeitenUnit 10 Jams, Jellies, Marmalade and Other Sugar-Based ProductsFaizurNoch keine Bewertungen

- Unit 10 Jams, Jellies, Marmalade and Other Sugar-Based ProductsDokument24 SeitenUnit 10 Jams, Jellies, Marmalade and Other Sugar-Based ProductsFaizurNoch keine Bewertungen

- Process of Sugar - CompressedDokument4 SeitenProcess of Sugar - CompressedMade WidreNoch keine Bewertungen

- A Summer Training Project Report in KARTHICDokument47 SeitenA Summer Training Project Report in KARTHICBalu MahendraNoch keine Bewertungen

- Sugar Manufacturing ProcessDokument3 SeitenSugar Manufacturing ProcessAmod Prakash SinghNoch keine Bewertungen

- The Production of SugarDokument12 SeitenThe Production of SugarJan bonifasiusNoch keine Bewertungen

- Sugar and Confectionery-Presentation1Dokument26 SeitenSugar and Confectionery-Presentation1grace mwenjeNoch keine Bewertungen

- Production: Santosh Kr. Paswan Roll No 138510 ME3 YearDokument21 SeitenProduction: Santosh Kr. Paswan Roll No 138510 ME3 YearEricMargateNoch keine Bewertungen

- Sugar Cane Processing C9s10-1aDokument7 SeitenSugar Cane Processing C9s10-1aYogendra JaiswalNoch keine Bewertungen

- Sugar RefineryDokument6 SeitenSugar RefineryRoger Jayson MercadoNoch keine Bewertungen

- CP-XVIII (Sugar Industry)Dokument12 SeitenCP-XVIII (Sugar Industry)Usman AliNoch keine Bewertungen

- Fresh Refined Suger-Meghna Group of IndustriesDokument16 SeitenFresh Refined Suger-Meghna Group of Industriesiphone nokiaNoch keine Bewertungen

- SucroseDokument13 SeitenSucroseDanish Baig100% (1)

- 9.10.1.1 Sugarcane ProcessingDokument7 Seiten9.10.1.1 Sugarcane ProcessingAshish SrivastavaNoch keine Bewertungen

- Final Term Paper ParillaDokument3 SeitenFinal Term Paper ParillaKristyneNoch keine Bewertungen

- What Is A Sugar Refinery?: 4th Slide The Refining ProcessDokument2 SeitenWhat Is A Sugar Refinery?: 4th Slide The Refining Processbabe0% (1)

- Sugar Manufacturing ProcessDokument16 SeitenSugar Manufacturing ProcessKRUPALI RAIYANI88% (8)

- Processing Lines: Hector GarzaDokument17 SeitenProcessing Lines: Hector GarzaMuhammad AfzalNoch keine Bewertungen

- Brief Introduction To SugarDokument2 SeitenBrief Introduction To SugarCalvin BrownNoch keine Bewertungen

- Sugar Manufacturing ProcessDokument10 SeitenSugar Manufacturing ProcessAJAY YADAVNoch keine Bewertungen

- Sugar Industry Process Flow DiagramDokument11 SeitenSugar Industry Process Flow DiagramVashish Ramrecha75% (4)

- Glosario, Almacenaje y Transporte de Caña de AucarDokument14 SeitenGlosario, Almacenaje y Transporte de Caña de AucarPiedad PintoNoch keine Bewertungen

- Music in AdvertisingDokument2 SeitenMusic in AdvertisingJaimie DonovanNoch keine Bewertungen

- Background To AtonementDokument1 SeiteBackground To AtonementJaimie DonovanNoch keine Bewertungen

- Viva Voce OutlineDokument1 SeiteViva Voce OutlineJaimie DonovanNoch keine Bewertungen

- The Flowers Regina Spektor Sheet MusicDokument9 SeitenThe Flowers Regina Spektor Sheet MusicJaimie Donovan100% (1)

- Hungarian MusicDokument1 SeiteHungarian MusicJaimie DonovanNoch keine Bewertungen

- Definitions For Decade StudyDokument1 SeiteDefinitions For Decade StudyJaimie DonovanNoch keine Bewertungen

- Changing Government Policies Towards Indigenous AustraliansDokument2 SeitenChanging Government Policies Towards Indigenous AustraliansJaimie DonovanNoch keine Bewertungen

- The Use of MetalsDokument2 SeitenThe Use of MetalsJaimie DonovanNoch keine Bewertungen

- Yuroskys Account - AnastasiaDokument1 SeiteYuroskys Account - AnastasiaJaimie DonovanNoch keine Bewertungen

- Anc Hist Deir El Medina Timeline 12Dokument1 SeiteAnc Hist Deir El Medina Timeline 12Jaimie DonovanNoch keine Bewertungen

- Chemistry Final ReportDokument4 SeitenChemistry Final ReportJaimie DonovanNoch keine Bewertungen

- Industrial Separation ProcessesDokument3 SeitenIndustrial Separation ProcessesJaimie DonovanNoch keine Bewertungen

- DB Cooper TheoriesDokument1 SeiteDB Cooper TheoriesJaimie DonovanNoch keine Bewertungen

- Biotechnology: Jaimie DonovanDokument2 SeitenBiotechnology: Jaimie DonovanJaimie DonovanNoch keine Bewertungen

- Australia and The Boats The Malaysia SolutionDokument2 SeitenAustralia and The Boats The Malaysia SolutionJaimie DonovanNoch keine Bewertungen

- PABLO PICASSO - GuernicaDokument2 SeitenPABLO PICASSO - GuernicaJaimie DonovanNoch keine Bewertungen

- Industrial Separation ProcessesDokument3 SeitenIndustrial Separation ProcessesJaimie DonovanNoch keine Bewertungen

- Ephesians: What To DoDokument8 SeitenEphesians: What To DoJaimie DonovanNoch keine Bewertungen

- The Whitlam Dismissal: Political Crunch Time-The Constitutional CrisisDokument7 SeitenThe Whitlam Dismissal: Political Crunch Time-The Constitutional CrisisJaimie DonovanNoch keine Bewertungen

- Ow It Formed (Geograp Ical Processes)Dokument3 SeitenOw It Formed (Geograp Ical Processes)Jaimie DonovanNoch keine Bewertungen

- PABLO PICASSO - GuernicaDokument2 SeitenPABLO PICASSO - GuernicaJaimie DonovanNoch keine Bewertungen

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionVon EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionBewertung: 3 von 5 Sternen3/5 (1)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaVon EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaBewertung: 4 von 5 Sternen4/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretVon EverandWaste: One Woman’s Fight Against America’s Dirty SecretBewertung: 5 von 5 Sternen5/5 (1)

- The Cyanide Canary: A True Story of InjusticeVon EverandThe Cyanide Canary: A True Story of InjusticeBewertung: 4 von 5 Sternen4/5 (52)

- Introduction to Ecology and Environmental Laws in IndiaVon EverandIntroduction to Ecology and Environmental Laws in IndiaNoch keine Bewertungen

- Slow Violence and the Environmentalism of the PoorVon EverandSlow Violence and the Environmentalism of the PoorBewertung: 4 von 5 Sternen4/5 (5)

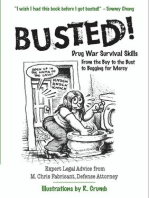

- Busted!: Drug War Survival Skills and True Dope DVon EverandBusted!: Drug War Survival Skills and True Dope DBewertung: 3.5 von 5 Sternen3.5/5 (7)

- The Rights of Nature: A Legal Revolution That Could Save the WorldVon EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldBewertung: 5 von 5 Sternen5/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontVon EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontBewertung: 4.5 von 5 Sternen4.5/5 (18)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionVon Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNoch keine Bewertungen

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksVon EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNoch keine Bewertungen

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Von EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Bewertung: 5 von 5 Sternen5/5 (2)

- Introduction to Ecology and Environmental Laws in IndiaVon EverandIntroduction to Ecology and Environmental Laws in IndiaNoch keine Bewertungen

- Environmental Education in Practice: Concepts and ApplicationsVon EverandEnvironmental Education in Practice: Concepts and ApplicationsNoch keine Bewertungen

- Down to the Wire: Confronting Climate CollapseVon EverandDown to the Wire: Confronting Climate CollapseBewertung: 4.5 von 5 Sternen4.5/5 (8)

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Von EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Noch keine Bewertungen

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksVon EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNoch keine Bewertungen

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawVon EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawBewertung: 4 von 5 Sternen4/5 (334)

- Obstacles to Environmental Progress: A U.S. perspectiveVon EverandObstacles to Environmental Progress: A U.S. perspectiveNoch keine Bewertungen

- Principles of direct and superior responsibility in international humanitarian lawVon EverandPrinciples of direct and superior responsibility in international humanitarian lawNoch keine Bewertungen