Beruflich Dokumente

Kultur Dokumente

Lathe

Hochgeladen von

Nimesh GunasekeraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lathe

Hochgeladen von

Nimesh GunasekeraCopyright:

Verfügbare Formate

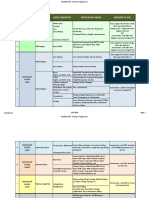

Manufacturing the shaft Mount the work-piece on the lathe First take the billet in the necessary dimensions

and shear it using hacksaw to the required length keeping the allowances for facing the both ends. After shearing the work-piece measure the length of the shaft using vernire caliper to verify the length we need to reduce by facing. Then clamp the workpiece tightly in the 3-jaw chuck which is attached to the spindle. In order to get the work properly centered close the jaws until they just touch the surface of the work. Then twist the work-piece in the jaws to seat it. Next tight the jaws from all 3 chuck key positions to ensure even gripping by the jaws. Facing both ends Next operation we need to do is face both ends of the shaft according to the required length. First we need to mount the cutting tool. Clamp the cutting tool in the tool post and turn the tool post so that the tip of the cutting tool will meet the end of the work-piece at a slight angle. It is important that the tip of the cutting tool be right at the centerline of the lathe. If it is too high or too low work-piece will be left with a little bump at the center of the face. After clamping the tool post in place, advance the carriage until the tool is about even with the end of the work-piece. When adjusting the tool use the compound crank to advance the tip of the tool until it just touches the end of the work-piece and use the cross feed crank to back off the tool until it is beyond the diameter of the work-piece. Set the lathe to necessary speed and turn it on. Start the facing operation with the roughing cut. Now slowly advance the cross feed crank to move the tool towards the workpiece. When the tool touches the workpiece it starts to remove metal from the end. Continue advancing the tool until it reaches the center of the workpiece and thenc rank the tool back in the opposite direction until it is back past the edge of the workpiece. It may need to make minimum of 3 passes to get a nice smooth finish across the face. Complete the facing with the finishing cut. The remove the workpiece form the 3-jaw chuck and measure the length. Verify the required length need to reduce. Mount the shaft with opposite side and follow the same operations until the material is removed for required length. Center drilling The easier way of doing this is using the work-holding method. After facing we need to mark the live centers in both ends using the center drill. This is necessary for the turning operation we have to perform later on. The alignment between the headstock and tailstock of the lathe enables us to drill holes that are precisely centered in a cylindrical piece of stock. First mount the drill chuck into the tailstock and make sure it is firmly seated. Then chose the appropriate center drill bit and mount on the drill chuck. Turn on the lathe and set the speed. Use the tailstock crank to advance the drill slowly into the end of the work-piece and continue until the required amount of depth is obtained. Straight turning Turning is performed to reduce the diameter of the shaft according to the required amount. Since the larger diameter of the shaft is 23mm we need to step down the diameter of the whole shaft in to 23mm. Since the work piece is relatively longer we need to center drill the free end and use a live center in the tailstock to support the work-piece. After center drilling the shaft remove the center drill bit and drill chuck from the tailstock and mount live center to the tail stock and make sure it is seated tightly. Then advance the live center using tailstock crack until the tip of the live center touches the drilled hole.

In the drawing the surface roughness is specifically indicated. So choose a single point cutting tool with a slightly rounded tip. This type of tool should produce a nice smooth finish. Make sure that the tool is tightly clamped in the tool holder. Adjust the angle of the tool holder so the tool is approximately perpendicular to the side of the work-piece. Move the carriage until the tip of the tool is near the free end of the work-piece, then advance the cross slide until the tip of the tool just touches the side of the work. Move the carriage to the right until the tip of the tool is just beyond the free end of the work. We can perform this using hand feed. Since the turning length is less than 120mm we dont need to use power feed. Set the lathe into necessary speed and turn on. Turn the carriage hand wheel counter clockwise to slowly move the carriage towards the headstock. As the tool starts to cut into the metal, maintain a steady cranking motion to get a nice even cut. Continue advancing the tool towards the headstock until it is about 3-4 cm away from the chuck jaw since we need to be careful by avoiding the tool from touching the chuck jaws. Perform several passes until it reaches the required amount of 23mm diameter. Then mount the opposite side of the shaft to perform the turning on the area which was unable to do due to the clamping of the 3-jaw chuck. Follow the same method to turn the remaining surface. After this you get a shaft which has 23mm diameter. Step turning From a one end we need to reduce the diameter by 16mm up to length of 20mm. We need to perform step down turning. A step is a point at which the diameter of the work-piece changes with no taper from one diameter to the other. Now determine the 20mm mark up. Advance the cross slide and use the hand feed to turn down. Since this is such a short distance, we can use hand feed, not power feed. Taper turning We can use the compound rest method to machine the taper. Its the cheapest and easiest way of obtaining steep and short tapers other than offsetting the tailstock method and taper attachment method. We can use a same single point cutting tool. The compound rest base is graduated in degrees and can be set at the required angle for taper turning. With this method, it is necessary to know the included angle of the taper to be machined. First we have to find the taper angle. 20mm

Tan() = 23mm 16mm 9.9

Now turn workpiece to maximum diameter of taper. Loosen compound rest lock screws and swivel the compound rest by angle of 9.9.

Feed direction

Now bring cutting tool near end of workpiece and set a depth of cut of 1 mm. Turn on the lathe and give feed by moving the compound rest handle. Bring tool to the start point again and set new depth of cut 1mm more than the previous. Then feed my moving the compound rest handle. Repeat this until smaller diameter of the steep become 16mm. Finally verify the dimensions of the workpiece. U cut Take a multiple cutting point round tool bit and cut the groove needed. Then take a pile and smooth the edge down to give it a chamfer. With the lathe running at fairly low speed, bring a smooth cut file up to the end of the workpiece at a 45 angle and apply a little pressure to the file. Thread cutting There are 2 things we should determine before we cut a thread which are nominal outside diameter of the thread and the threads per length. Refer the gear chart and setup the gear train properly. The cutting tool tip must have a 60 angle and use a multiple point cutting tool which is made out of HSS or carbide. Insert your thread cutting tool in the tool post and adjust the angle of the tool so that it is exactly perpendicular to the side of the work. Since this operation dissipates a lot of heat we must use cutting fluid to remove the heat as well as the chips formation. Now set the cross-feed to the original zero position and start up the lathe machine. Make a very shallow test cut to make sure that we are actually cutting the intended pitch. After checking the pitch using a screw pitch gage, advance the compound feed by smaller amounts on each pass. Disengage the half-nut lever when you reach the end of the thread. Back off the cross-feed one full turn and crank the carriage back to the starting point. Repeat above steps until depth has been cut to specified dial depth. Chamfering As the finishing move take down the larger diameter end of the shaft and chamfer the edge at an 45 angle using a file. Machine Shut Down Switch off the lathe machine from the main power and collet all the tools used. Clean all the chips on the lathe machine using a brush.

Safety precautions to follow when working with a lathe machine 1. Before starting any lathe operations, always prepare yourself by rolling up your shirt sleeves and removing your watch, rings, and other jewelry that might become caught while you operate the machine. 2. Wear goggles or an approved face shield at all times whenever you operate a lathe or when you are near a lathe that is being operated. The lathe can throw off sharp, hot metal chips at considerable speed as well as spin off spirals of metal that can be quite hazardous. 3. Wear shoes preferably leather work shoes to protect your feet from sharp metal chips on the shop floor and from tools and chunks of metal that may get dropped. 4. Tie back long hair so it can't get caught in the rotating work. Think about what happens to your face if your hair gets entangled. 5. Be sure the work area is clear of obstructions that you might fall or trip over. Keep the deck area around your machine clear of oil or grease to prevent the possibility of slipping or falling into the machine. 6. Get in the habit of removing the chuck key immediately after use. Some users recommend never removing your hand from the chuck key when it is in the chuck. The chuck key can be a lethal projectile if the lathe is started with the chuck key in the chuck. 7. Always use assistance when handling large workpieces or large chucks. 8. Never remove chips with your bare hands. Use a stick or brush, and always stop the machine. 9. Always secure power to the machine when you take measurements or make adjustments to the chuck. Be alert to the location of the cutting tool while you take measurements or make adjustments. 10. Be attentive, not only to the operation of your machine, but also to events going on around it. Never permit skylarking in the area.

Importance of cutting fluids The primary function of cutting fluid is cooling and lubrication. A fluid's cooling and lubrication properties are critical in decreasing tool wear and extending tool life. Cooling and lubrication are also important in achieving the desired size, finish and shape of the workpiece. A secondary function of cutting fluid is to flush away chips and metal fines from the tool and the workpiece interface to prevent a finished surface from becoming marred and also to reduce the occurrence of built-up edge. Cooling: Machining operations create heat. This heat must be removed from the process. The chip helps carry away heat from the tool and work piece. Coolant takes heat from the chips tool, and work piece. To be effective the fluid must be able to transfer heat very rapidly. The fluid absorbs the heat and carries it away. In a typical machining operation most of the heat is created by the resistance of the work piece atoms to being sheared. The friction of the chip sliding over the cutting tool face creates the rest. Cutting fluid with good lubrication qualities can reduce the friction of the chip sliding over the tool face.

Lubrication:

Benefits of using cutting fluids 1. Improve Part Quality - The use of cutting fluids reduces friction and heat. The removal of the heat prevents the work piece from expanding during the machining operation, which would cause size variation as well as damage to the materials microstructure. 2. Reduce tooling costs - Proper use of cutting fluids increases tool life, which reduces the tooling costs. Increased tool life also reduces tool changes and downtime which decreases labor costs. 3. Increase Cutting Speeds and Feeds - Cutting fluids reduce friction and heating a machining operation. This allows high speeds and feeds to be used to achieve optimal cutting conditions. 4. Improved Surface Finishes - Effective use of cutting fluids helps remove the chips. This prevents the chip from being caught between the tool and work piece where it causes scratches and a poor surface finish. 5. Rust and Corrosion Prevention - Cutting fluids should protect the tooling, machine, and work piece against rust and corrosion. Cutting fluids should leave a small residual film that remains after the water has evaporated.

Case study Sheering the workpiece The required length of the workpiece is 75mm. Generally we use 0.01-0.02 inches (0.254-0.508cm) of depth of cut when performing rough facing. So we need to shear the workpiece around 78mm long allowing margin of error in shearing using hacksaw. After shearing measure the length of the workpiece using vernier caliper.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Variaxis I SeriesDokument22 SeitenVariaxis I Seriesbhandge8850% (2)

- Hough TonDokument5 SeitenHough TonalexfoschecaNoch keine Bewertungen

- Porters Five Forces AnalysisDokument83 SeitenPorters Five Forces AnalysisNimesh Gunasekera67% (3)

- AccessoriesDokument6 SeitenAccessoriesNimesh GunasekeraNoch keine Bewertungen

- HR Practical ProblemsDokument8 SeitenHR Practical ProblemsNimesh GunasekeraNoch keine Bewertungen

- WoodDokument7 SeitenWoodNimesh GunasekeraNoch keine Bewertungen

- Job Description Accounting and Finance ManagerDokument5 SeitenJob Description Accounting and Finance ManagerNimesh GunasekeraNoch keine Bewertungen

- How To Write A Archival PaperDokument4 SeitenHow To Write A Archival PaperRanil FernandoNoch keine Bewertungen

- Literature Review and Proposed ResearchDokument34 SeitenLiterature Review and Proposed ResearchNimesh GunasekeraNoch keine Bewertungen

- Prosthetic Upper LimbDokument5 SeitenProsthetic Upper LimbNimesh Gunasekera100% (1)

- Porter Five Forces AnalysisDokument40 SeitenPorter Five Forces AnalysisNimesh Gunasekera100% (1)

- Design of An Articulated Thumb For A Low-Cost Prosthetic HandDokument12 SeitenDesign of An Articulated Thumb For A Low-Cost Prosthetic HandNimesh GunasekeraNoch keine Bewertungen

- Control Strategies For Hand ProsthesesDokument7 SeitenControl Strategies For Hand ProsthesesamirtempsNoch keine Bewertungen

- Fluidize BedDokument8 SeitenFluidize BedNimesh GunasekeraNoch keine Bewertungen

- A Closer Look at Componentry Upper Limb ProstheticsDokument4 SeitenA Closer Look at Componentry Upper Limb ProstheticsNimesh GunasekeraNoch keine Bewertungen

- DLR Hand II Experiments and Experiences With An Anthropomorphic HandDokument6 SeitenDLR Hand II Experiments and Experiences With An Anthropomorphic HandNimesh GunasekeraNoch keine Bewertungen

- PneumaticsDokument5 SeitenPneumaticsNimesh GunasekeraNoch keine Bewertungen

- The Development of A Prosthetic ArmDokument6 SeitenThe Development of A Prosthetic ArmNimesh GunasekeraNoch keine Bewertungen

- State of Art of The Prosthetic HandDokument14 SeitenState of Art of The Prosthetic HandNimesh GunasekeraNoch keine Bewertungen

- Centrifugal PumpsDokument5 SeitenCentrifugal PumpsNimesh Gunasekera100% (1)

- Sustainable Living A Global and Personal Perspective: Think Globally - Act NeighborlyDokument15 SeitenSustainable Living A Global and Personal Perspective: Think Globally - Act NeighborlyNimesh GunasekeraNoch keine Bewertungen

- Sustainability & Sustainable Development: Eng - Kapila PierisDokument30 SeitenSustainability & Sustainable Development: Eng - Kapila PierisNimesh GunasekeraNoch keine Bewertungen

- Introduction To Pneumatic SystemsDokument6 SeitenIntroduction To Pneumatic SystemsNimesh GunasekeraNoch keine Bewertungen

- Centrifugal PumpsDokument5 SeitenCentrifugal PumpsNimesh GunasekeraNoch keine Bewertungen

- Pneumatic Systems-Control SysDokument6 SeitenPneumatic Systems-Control SysNimesh GunasekeraNoch keine Bewertungen

- Versatile Geyser Control SystemDokument2 SeitenVersatile Geyser Control SystemNimesh GunasekeraNoch keine Bewertungen

- Moment Generation FunctionDokument26 SeitenMoment Generation FunctionNimesh GunasekeraNoch keine Bewertungen

- Basic Understanding of PID ControllersDokument9 SeitenBasic Understanding of PID ControllersNimesh GunasekeraNoch keine Bewertungen

- Fluid Pneumatic CircuitsDokument7 SeitenFluid Pneumatic CircuitsNimesh GunasekeraNoch keine Bewertungen

- ME189 Chapter 7Dokument48 SeitenME189 Chapter 7Gaurav KulkarniNoch keine Bewertungen

- Dipped Products Annual Report AnalysisDokument106 SeitenDipped Products Annual Report AnalysisNimesh GunasekeraNoch keine Bewertungen

- Wood WorkingDokument8 SeitenWood WorkingNimesh GunasekeraNoch keine Bewertungen

- clv2010 Cleveland-Catalog PDFDokument332 Seitenclv2010 Cleveland-Catalog PDFhectorNoch keine Bewertungen

- Various Performance of Polyvinylether (PVE) Lubricants With HFC RDokument10 SeitenVarious Performance of Polyvinylether (PVE) Lubricants With HFC RJako MishyNoch keine Bewertungen

- Barnwell Rotary Shaft SealsDokument28 SeitenBarnwell Rotary Shaft SealsZoran JankovNoch keine Bewertungen

- Metal Cutting Forming Module 3Dokument52 SeitenMetal Cutting Forming Module 3Sathya DharanNoch keine Bewertungen

- Ted 221 - Machine Shop Practice 1Dokument34 SeitenTed 221 - Machine Shop Practice 1Mr. MushahidNoch keine Bewertungen

- Milling MachineDokument20 SeitenMilling MachineMohd Radzi Kaki Limo100% (1)

- HP Industrial Lubricants Product GuideDokument82 SeitenHP Industrial Lubricants Product GuidemrbairwaNoch keine Bewertungen

- NANOGUARD - Products and ApplicationsDokument2 SeitenNANOGUARD - Products and ApplicationsSunrise VenturesNoch keine Bewertungen

- Singapore Capability ProfileDokument20 SeitenSingapore Capability ProfileInsumos GygNoch keine Bewertungen

- G-Series: The Flexible Manufacturing SystemDokument28 SeitenG-Series: The Flexible Manufacturing SystempietroNoch keine Bewertungen

- Multi Spindel HeadsDokument72 SeitenMulti Spindel HeadsDaniel Garcia PeraltaNoch keine Bewertungen

- 21.3machining of MetalsDokument78 Seiten21.3machining of Metalsmarcos callaNoch keine Bewertungen

- MQL Performance in High Speed MillingDokument204 SeitenMQL Performance in High Speed MillingvijaykumarnNoch keine Bewertungen

- Making Refillable c02 CartridgesDokument20 SeitenMaking Refillable c02 Cartridgesmagatsu2099Noch keine Bewertungen

- VARIAXIS C 600 BrochureDokument24 SeitenVARIAXIS C 600 Brochureadrienbridel80Noch keine Bewertungen

- Molykote M Gear Oil AdditiveDokument3 SeitenMolykote M Gear Oil AdditiveJuan Pablo Fernandez ZuñigaNoch keine Bewertungen

- CNC Overview PresentationDokument50 SeitenCNC Overview PresentationVaibhav Vithoba Naik100% (1)

- Red Waste of MetalworkingDokument44 SeitenRed Waste of MetalworkingArtūrs CeimersNoch keine Bewertungen

- Cuprisan TDS 1Dokument2 SeitenCuprisan TDS 1Dinesh babuNoch keine Bewertungen

- Coolants - RhenusDokument26 SeitenCoolants - RhenusFLMNoch keine Bewertungen

- Mech 4sem MT IIDokument147 SeitenMech 4sem MT IITheVagabond HarshalNoch keine Bewertungen

- Mechanic Machine Tool MaintenanceDokument39 SeitenMechanic Machine Tool MaintenanceabhayNoch keine Bewertungen

- Southbend South Bend Sb1027 Users Manual 447654Dokument84 SeitenSouthbend South Bend Sb1027 Users Manual 447654Maximiliano Alvarez RinconNoch keine Bewertungen

- Bomba de RefrigeracionDokument1 SeiteBomba de RefrigeracionEdwin RodriguezNoch keine Bewertungen

- Product Information Flyer: CIMSTAR® 10-85VGDokument2 SeitenProduct Information Flyer: CIMSTAR® 10-85VGsobheysaidNoch keine Bewertungen

- Poliflock For Oil GeneralDokument7 SeitenPoliflock For Oil GeneralSaad KhalidNoch keine Bewertungen

- Nederman Enginering Guide enDokument145 SeitenNederman Enginering Guide enRyukiNoch keine Bewertungen