Beruflich Dokumente

Kultur Dokumente

28 IM PR Sal Campy

Hochgeladen von

Nader SedighiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

28 IM PR Sal Campy

Hochgeladen von

Nader SedighiCopyright:

Verfügbare Formate

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

Pathogen Reduction Salmonella and Campylobacter Performance Standards Verification Testing

Objectives

To demonstrate mastery of Pathogen Reduction the trainee will: 1. Explain why Salmonella and Campylobacter testing is used. 2. State who will conduct Salmonella and Campylobacter testing. 3. List the species and types of product eligible for testing under the Salmonella performance standards. 4. List the species and types of product eligible for testing under the Campylobacter performance standards. 5. Describe how and when Salmonella and Campylobacter samples are taken. 6. Explain how to obtain completed Salmonella and Campylobacter results from LEARN and PHIS.

References

1. FSIS Regulations 310.25(b) and 381.94(b) 2. FSIS Directive 7355.1, Use of Sample Seals for Laboratory Samples and Other Applications 3. Directive 10,200.1, Accessing Laboratory Sample Information via LEARN 4. FSIS Directive 10,210.1, Unified Sampling Form 5. FSIS Directive 10,230.5 and the Self-Instruction Guide for Collecting Raw Meat and Poultry Product Samples for Salmonella Analysis , and the DVD titled, Sampling Raw Meat and Poultry for Salmonella 6. FSIS Notice 57-12 Young Chicken Carcass Sampling Eligibility 7. FSIS Notice 54-12 Performance Standards For Salmonella and Campylobacter in Chilled Carcasses at Young Chicken and Turkey Slaughter Establishments 8. FSIS Notice 6-12 Raw Product Destined For Ready-To-Eat Product Excluded From Salmonella Testing.FSIS Notice 25-11 Sampling of Low Production Volume Raw Ground Beef Establishments For Salmonella and Escherichia Coli O157:H7

Inspection Methods

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

9. Notice 42-11: Requesting Scheduling of Salmonella Verification set when an establishment process changes 10. Notice 59-11: Revisions to Salmonella and Campylobacter end-of-set letters. 11. PHIS Directive 13,000.1 Scheduling In-Plant Inspection Tasks in the Public Health Information System (PHIS) 12. PHIS Directive 13,000.2 Performing Sampling Tasks In Official Establishment Using The Public Health Information System 13. PHIS User Guide

Introduction

Salmonella has been a major concern to the Agency for the last 15 years. In 1996 FSIS established the pathogen reduction performance standards (Salmonella Verification Program) for Salmonella bacteria for certain product classes and they were published in the 9 CFR 310.25(b)(1) and 381.94(b)(1) for livestock and poultry products, respectively (see Attachment 3 of this module). The regulatory performance standards covers raw product classes including carcasses of cows/bulls, market hogs, broilers (young chickens), and ground beef, ground chicken, and ground turkey. On February 17, 2005, the Agency developed a non-regulatory performance standard for turkey carcasses based on a 1997 baseline survey (Federal Register Notice Docket No. 02-46N). Furthermore, the 1996 Pathogen Reduction/HACCP rule indicated that the pathogen reduction performance standards would be changed as new data became available, and that the Agency would periodically repeat its baseline surveys to obtain updated data. On May 14, 2010, FSIS published a Federal Register Notice (Docket No. FSIS2009-0034) posting new performance standards for the pathogenic microorganism Salmonella and Campylobacter for chilled carcasses in young chicken (broiler) and turkey slaughter establishments. These new performance standards were based on data collected during recent Nationwide Microbiological Baseline Data Collection Programs (July 2007 June 2008). A follow-up Federal Register notice was published in March of 2011 (Docket No. FSIS-2010-0029) stating that the updated performance standards for young chickens and turkeys would take effect with FSIS verification sample sets scheduled for July 2011. The FSIS Salmonella performance standards established and published in 9 CFR 310.25(b)(1) are still in effect for raw meat product classes. As mentioned above, the Agency established new performance standards for both Salmonella and Campylobacter in young chicken and turkey carcasses in July 2011. These performance standards are the basis of assessing an establishments level of process control for Salmonella and Campylobacter as well as for determining whether an establishment passes or fails a Salmonella or Campylobacter verification set.

Inspection Methods

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

The new Salmonella performance standards are to be applied to sample sets from establishments included in the Agencys Salmonella verification program in the place of the performance standards for young chickens (as broilers) codified in the 9 CFR 381.94 and the standards for turkeys announced in the Federal Register Notice of February 17, 2005. The Agency intends to issue a proposed rule that would formally rescind the codified standards that are no longer in effect. Salmonella was selected as the target organism because it is a commonly reported cause of food borne illness and is present to varying degrees in all major species. The Salmonella genus includes over 2,300 serotypes (i.e., distinguish the organism based on of their antigenic components present in the bacterial cell wall). There are several Salmonella serotypes commonly associated with human illness, including Salmonella Enteritidis and Salmonella Typhimurium. Salmonella bacteria are the most frequently reported cause of food borne illness. According to the Centers for Disease Control and Prevention (CDC), salmonellosis causes an estimated 1.4 million cases of food borne illness and more than 400 deaths annually in the United States. Campylobacter species, specifically C. jejuni and C. coli, are most often isolated from the intestinal tract of poultry as well as in poultry products. Campylobacter bacteria are the second most frequently reported cause of food borne illness, and Campylobacter jejuni is the most common strain causing illness. Salmonella and Campylobacter can be transmitted to humans by eating foods contaminated with animal feces. The goal of the newly revised Salmonella and Campylobacter testing program is to protect the consumer from contaminated products, especially from fecal contamination, by verifying that each establishments performance meets the new performance standards for poultry as well as the Salmonella performance standard for meat products as codified in 9 CFR 310.25(b). In addition to reporting individual Salmonella and Campylobacter sample results to establishments, FSIS posts nationwide Salmonella and Campylobacter data on its website on a quarterly basis.

Salmonella and Campylobacter Verification Testing The Role of the Inspector

The Salmonella and Campylobacter verification sampling is conducted in establishments by FSIS Inspection Program Personnel (IPP). IPP will be collecting sample sets for both, carcass and ground products. The following raw product samples are analyzed for Salmonella only: carcasses of cows/bulls carcasses of steers/heifers

Inspection Methods

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

carcasses of market hogs ground products including: o beef products include ground and chopped raw meat from cattle carcasses (beef or veal; may or may not contain added ingredients, spices, or seasonings), that meet the standards of identity for ground and chopped beef (9 CFR 319.15(a)) and hamburger (9 CFR 319.15(b)) according to the base-line studies for Salmonella Performance Standards. Sampled products may contain meat derived from advanced meat recovery (AMR) systems, but AMR meat by itself is not sampled. In addition, beef patties as defined in 9 CFR 319.15(c), fabricated steaks and similar products as defined in 9 CFR 319.15(d) are not covered. o chicken includes any product labeled ground chicken or fresh ground chicken (may or may not contain added ingredients, spices, or seasoning, but not curing agents); excludes products labeled as mechanically separated chicken (9 CFR 381.173). o turkey includes any product labeled ground turkey or fresh ground turkey (may or may not contain added ingredients, spices, or seasoning, but not curing agents); excludes products labeled as mechanically separated turkey (9 CFR 381.173). IPP also collect the following samples in sets to be analyzed for both Salmonella and Campylobacter: young chicken carcasses including broilers, fryers, and roasters as described in 9CFR 381.170(a), as well as Cornish game hens (Notice 5712) turkey (young breeders) carcasses Samples are collected by IPP using a carcass sponge swab, a whole bird rinse, or a ground product sampling technique. Samples are collected from beef, swine, and turkey carcasses using the sponge technique. Turkey carcasses will be sampled using two sponges, one to be analyzed for Salmonella and the other for Campylobacter. Sponge sites are the same as those used for generic E. coli sampling as shown below. Sponge Sample Sites Beef flank, brisket, and rump Swine belly, ham, and jowls Turkey back and thigh Chickens are sampled using whole bird rinses. Ground products are sampled by taking 25 grams of the ground product. A sterile ring of a standard size is filled level with the top of the ring with product. The ring is not sent to the lab, only the ground product.

Inspection Methods

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

In establishments which produce more than one type of product subject to testing, such as both carcass and ground product, only one type of product sampling is conducted at a time. Circumstances in Which Sampling is not Warranted Even though most raw meat and poultry products are subject to Salmonella testing, there is a narrow set of circumstances in which sampling is not warranted. According to FSIS Notice 06-12, when an establishment processes all its products into ready-to-eat (RTE) product or diverts all of its raw products to another federally inspected establishment for further processing into a RTE product, FSIS will exclude the establishment from the Salmonella verificationtesting program. Additionally, if the establishment irradiates its raw ground product, then FSIS Directive 7700.1, Irradiation of Meat and Poultry Products, should be followed. If the establishments HACCP plan states that the product will be irradiated, even off-site, then no sample of that product is collected. For example, an establishment slaughters steers and heifers and produces ground beef as one of its products. The establishment ships all of the ground beef product to another establishment that uses it to make a RTE product. In this example, IPP would not sample the ground beef. However, if other raw products were produced from the carcasses, then the steer and heifer carcasses would still be eligible for Salmonella sampling. If an establishment claims that all product is processed into RTE product, then IPP are to verify that the intended use of all the product the establishment produces is for processing into RTE product (9 CFR 417.2(a)(2)) while performing the appropriate HACCP task. In addition, IPP are to verify by observing that all the product is actually further processed into RTE product in the establishment, or by reviewing records to ensure that all product is further processed into RTE products in the establishment. If an establishment claims to move all products from a particular product class to another federally inspected establishment for further processing into RTE products, IPP are to verify this by reviewing the establishments HACCP plan and hazard analysis for the intended use of the products. In addition, IPP are to verify that the establishment has procedures incorporated in its food safety system that affect the movement of all products from that product class to another federallyinspected establishment at which the product is further processed into RTE product.

Inspection Methods

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

If the establishment cannot produce sufficient documentation to demonstrate the assertion that the product is further processed into RTE product, then the product is still eligible for sampling under the verification testing program. If IPP verify that the product in question meets one of the exclusion criteria above, then IPP are to follow the additional instructions in FSIS Notice 06-12.

The Performance Standards

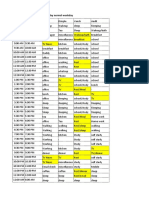

The Salmonella and Campylobacter performance standards apply to establishments overall process control, not to individual products. Products are not tested to determine their disposition, but rather to measure the effectiveness of the slaughter and grinding process in limiting contamination. Establishments do not have to hold product or recall product based on results of the Salmonella and Campylobacter samples. Salmonella and Campylobacter performance standard verification samples are taken in sets and the results of an entire set are used to determine if an establishment is meeting the performance standard. Failure to meet the Salmonella or Campylobacter performance standards is based on whether or not a set passes, not on an individual sample result. The charts below show the number of samples required to complete a sample set for the different product classes, and the maximum number of positive results allowed before a set fails to meet the performance standards. Note: Three product classes, cow/bulls, steer/heifers, and market hogs, have been temporarily suspended from routine Salmonella sampling. Testing of these product classes can be resume at any time. A test is considered positive when any Salmonella or Campylobacter organisms are found. SALMONELLA PERFORMANCE STANDARDS Number of Samples Tested (n) 82 58 53 55 N/A 51 53 53 Maximum Number of Positives Allowed to Achieve Standard (c) 1 2 5 6 N/A 5 26 29

Class of Product Steers/heifers Cows/bulls Ground beef Hogs Fresh pork sausages Young chickens/broilers* Ground chicken Ground turkey

Inspection Methods

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

Turkeys*

56

*Note: The maximum number of positives allowed to achieve the standard for young chicken/broilers and turkeys in the table reflects the new Salmonella performance standards published in the March 21, 2011 Federal Register Notice that have been in effect since July 2011.

CAMPYLOBACTER PERFORMANCE STANDARDS Number of Samples Tested (n) 51 56 Maximum Number of Positives Allowed to Achieve Standard (c) 8 3

Class of Product Broilers carcasses Turkey carcasses

Note: The Campylobacter sample set criteria for tracking and reporting the performance standards are from the smaller of the two lab sample portions (1 ml) which detects the higher levels of contamination.

The charts above, taken from the regulations and current performance standard policies, show that the performance standard specifies a maximum number of positive test results permitted in a specified number of samples (the sample set) for each species and category of raw product. The set is the required number of samples to be tested for a product class (for example, for young chicken/broilers it is 51 and for ground chicken it is 53). Heres how to use these charts. For young chicken/broilers, to meet the Salmonella performance standard an establishment can have no more than five positive sample result out of each set of 51 carcasses sampled. For ground chicken, an establishment can have no more than 26 positive sample results out of each set of 53 samples.

Inspection Methods

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

Workshop 1: Salmonella and Campylobacter Performance Standards

1. Select from the list below the species and types of product eligible for testing under the Salmonella performance standards. ____ ____ ____ ____ ____ Beef carcasses Chicken carcasses Duck carcasses Equine carcasses Geese carcasses ____ ____ ____ ____ ____ Ground chicken Ground pork Ground turkey Sheep carcasses Swine carcasses

____ Goat carcasses ____ Ground beef

____ Turkey carcasses

2. Select from the list below the species and types of product eligible for testing under theCampylobacter performance standards. ____ ____ ____ ____ ____ Beef carcasses Chicken carcasses Duck carcasses Equine carcasses Geese carcasses ____ ____ ____ ____ ____ Ground chicken Ground pork Ground turkey Sheep carcasses Swine carcasses

____ Goat carcasses ____ Ground beef 3. True or False:

____ Turkey carcasses

_____ Each sample collected in a young chicken or turkey set will be analyzed for both Salmonella and Campylobacter. _____ Turkey carcasses are sampled using only one sponge that is analyzed for both Salmonella and Campylobacter. _____When an establishment processes all of its raw product into RTE products, FSIS will collect samples for all the raw product that the establishment produces for the Salmonella verification testing program. _____ A sample set is the required number of samples to be tested for a product class.

Inspection Methods

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

_____ For swine carcasses, an establishment can have no more than 6 individual sample results positive for Salmonella out of each set of 55 samples. _____ FSIS uses the results of an entire set to determine if an establishment is meeting the performance standard.

Sampling Procedure

As stated previously, the purpose of the Salmonella and Campylobacter verification sampling program is to verify the establishments process control for all applicable products and for all shifts. If the establishment produces more than one product type that is eligible for sampling (for example, carcass whole bird and raw ground product), IPP would be performing a sample set for one product type per se (i.e., carcass whole bird or raw ground product). IPP will collect a sample at an unannounced time each day the product is produced until enough samples have been taken and analyzed to constitute a set of samples. FSIS inspection personnel should collect samples in accordance with the step-by-step directions found in FSIS Directive 10,230.5 for all other product classes and the instructions in FSIS Notice 54-12 for young chicken and turkey carcasses. Attachment 1 in this module describes detailed procedures for collecting samples, and Attachment 4 provides Questions & Answers related to the Salmonella and Campylobacter performance standards. Salmonella and Campylobacter verification sampling is a directed sampling task. The Public Health Information System (PHIS) displays sampling tasks on the establishment task list for the sampling programs that apply to the establishment. There are two sampling codes for the Salmonella sampling programs. The HC01 sampling code corresponds to Salmonella verification sets for any product class other than young chicken or turkey carcasses. The HC11 sampling code is used for all young chicken and turkey carcasses sample sets. IPP document the completion of the HC01 or HC11 sampling task in PHIS. IPP schedule verification sampling tasks to complete a Salmonella (and Campylobacter, if applicable) sample set following the instructions in FSIS Directive 13,000.1. IPP perform the sampling tasks following the instructions FSIS Directive 13,000.2. The IIC at establishments subject to Salmonella and Campylobacter verification testing should ensure that adequate sampling supplies are available prior to the start of sample set collection. If sampling supplies are needed follow the instructions as previously discussed in the Sample Management section of this training. IPP are to schedule the directed sampling tasks on the task calendar (refer to Sample Management Module, section Scheduling and Submitting a Directed Lab Sample) and collect a sample over the course of a defined number of

Inspection Methods

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

sequential days of production (i.e., each day the product class is produced) to complete the sample set. Once the IPP schedules the sample task on the the date the product is produced, using the PHIS Laboratory Capacity Reservation System in the Task Calendar, then the IPP can proceed to collect the sample. To assist the IPP in their sampling task, they may choose to print a draft copy of the Sample Analysis Request form to be used as a reference during sample collection and to document product information, if applicable. Some information is already preprinted in the Collection and Animal Information data fields of the sampling form (i.e., sample form ID, project code, sample source, etc; Refer to Attachment 2 FSIS Form 8000-19 in this module). Carcasses and ground product must be randomly collected based on time, and shift if more than one shift operates. IPP are to sample each shifts production on a random basis so that the full sampling set includes representative samples from both shifts. Shift sampling proportions may vary and there is no requirement that exactly half of the samples must be taken from each production shift. Note: Random refers to the time the samples are selected, not to when the sponging or rinsing is initiated or completed. The time entered for collection is when the carcass is removed from the line and the "date" is the day the carcass is actually sponged or rinsed, which could be the day after the carcass was removed from the line. For poultry carcasses, at the post-chill sampling location, IPP are to determine a random time at which the carcass will reach the end of the drip line or the equivalent point in air-chill systems. IPP are to randomly select a poultry carcass from the post-chill area (after all interventions have taken place) and to allow drip time to prevent dilution of the sample. All samples are to be refrigerated or placed on ice immediately after sample collection and maintained under refrigeration at 40F or lower, until shipped. Samples should not be frozen and should be kept secure at all times. Sample boxes should never be stored near heaters or areas exposed to excessive heat. The laboratory will discard rinse samples that arrive above 50F or below 32F. It is critical that refrigerated sample temperature is maintained during collection and shipment. When a sample is collected, IPP need to enter the data requested in the data fields on the sampling form, submit the sample form through PHIS, print and sign the form, pack and ship the sample as described in PHIS Directive 13,000.2 and the Sample Management module of this training. The lab analyzes the samples and the Data Analysis and Integration Group (DAIG) tracks the data and results. IPP receive laboratory testing results when they are posted in LEARN and in the

Inspection Methods

10

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

establishments home page in PHIS for both pathogens. IPP receive an alert on the PHIS Inspector home page when an FSIS sample result is positive. FSIS will collect follow-up sample sets responding to sample set failure for either organism.

Reports

Numerous reports are generated by the Pathogen Reduction Enforcement Program (PREP) regarding Salmonella and Campylobacter sample set collection and results. Schedule Report This report notifies the District Office of establishments within their jurisdiction that have been mailed supplies for compliance testing. This report is also accessible to the field inspection team, via Outlook, to alert them about the scheduled sampling. Sample collection can be verified by the FLS through the Laboratory Electronic Application for Results Notification (LEARN) FSIS Intranet site. Set Full Report This report notifies the District Office and inspection personnel that sufficient analyzable samples have been received in the lab to complete the sample set. Completed Set Report This report notifies the District Office and establishment management that the set analysis is complete and whether the set passed or failed to meet the performance standard for the tested product. This report is also accessible to the IIC at the establishment through LEARN. The IIC should share report results with establishment management. Non-Responders Report This report periodically identifies the establishments under a District Office jurisdiction that are scheduled for sampling but have not provided a sample or feedback in the previous 30 days. The DM should be able to account for each establishment on this list and be able to support the absence of sampling during this period. Current Testing Status Report - This report periodically identifies the establishments under a District Office jurisdiction that are scheduled for sampling. It also provides the current set status, when sample collection began, how many samples have been analyzed to date, as well as when the most recent sample was submitted.

Sets and Categories

If the sample set meets the Salmonella and Campylobacter performance standards, it passes. Sets that exceed the standards fail.

Inspection Methods

11

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

FSIS uses three categories in evaluating an establishments level of process control and in scheduling Salmonella and Campylobacter Performance Standard verification testing. The four process control categories are determined by the number of positive samples in a verification sample set. Category 1 Consistent Process Control: Establishments with the total number of positive Salmonella samples in the two most recently completed set is 50% or less of the performance standard, i.e. the number of positives is at or below half of the performance standard. This performance demonstrates the best process control for this pathogen. Category 2T Variable Process Control but Transitioning Towards Consistent Process Control: Establishments with percent positive Salmonella samples at or below 50% of the performance standard in the most recently completed sample set, but greater than 50% of the performance standard in the previously completed sample set. Category 2 Variable Process Control: Establishments with the total number of positive samples in the set is greater than 50% of the performance standard but does not exceed the performance standard in the most recently completed sample set. This performance demonstrates intermediate process control for this pathogen. Category 3 Highly Variable Process Control: Establishments with positive Salmonella samples exceeding the performance standard in the most recently sample set. This performance demonstrates the least process control for this pathogen and means the establishment has failed the Salmonella verification set. For establishments whose process control is questionable (takes into account the establishments process control category), and who have had a high percentage of positives, FSIS will intensify its scheduling of Agency verification sample sets. The Agency will also post the test results and names of establishments that fail to effectively control this pathogen on the FSIS Web site. www.fsis.usda.gov/Science/Salmonella_Verification_Testing_Program/index.asp As outlined in the Federal Register Notice published on May 14, 2010, it states that after 90 percent of eligible establishments have been sampled for two full sets, the Agency will consider setting establishment categories 1/2/3 for Campylobacter under the new performance standard (separate from Salmonella) and publishing Campylobacter Category 2/3 establishments. Set Results

Inspection Methods

12

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

According to FSIS Notice 59-11, when reporting sampling results, FSIS will now include information on serotypes found in the sample, including whether the serotypes are on the CDCs list of the twenty serotypes most frequently associated with human illness, and will include the additional subtype information (pulsed-field gel electrophoresis (PFGE) pattern-based information and antimicrobial resistance profile). Set results will be aggregated quarterly and published on the FSIS website, to show the number and percentage of establishments in Category 1, 2, and 3 for all sampled product classes. Results will be presented for Salmonella. http://www.fsis.usda.gov/Science/Q1_2011_Salmonella_Testing/index.asp Establishments that fail the Performance Standard for Campylobacter will not be posted on the FSIS Web page as mentioned above. FSIS will evaluate industry performance trends with regard to both Salmonella and Campylobacter. In response to adverse trends, the Agency may consider further actions. Salmonella and Campylobacter End of Set Letter (EOS) Upon completion of each set, the District Office (DO) sends an End of Set Letter (EOS) to the establishment explaining the establishments status with respect to the risk-based Salmonella and Campylobacter testing program and strategy (combination of an establishments overall process control and individual Salmonella subtype results). The EOS letters are organized into the following sections (refer to FSIS Notice 59-11, Attachment 1: Sample Salmonella/Campylobacter End-of-Set Letter): Process control this section states whether an establishment has maintained consistent process control. The Summary Results from Last Two Sampling Sets table identifies the product tested, date set completed, number of samples analyzed, number of Salmonella and Campylobacter (when applicable) positives, and current Salmonella process control category (Categories 1/2/3). Public Health-focused information on isolates by serotype this section provides detailed serotyping information from the establishments last Salmonella verification test. This section includes the Serotype Results for the Most Recent Sampling Set table, which gives the details of the serotype results for the current set as well as a brief explanation of the type of information provided in the table. Discussion of compiled set results this section provides a brief explanation of the information provided in the letter, including information on future Salmonella and Campylobacter (where applicable) verification testing scheduled at the establishment and Agency expectations.

Inspection Methods

13

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

IPP are to advise establishment management that the Agency expects the establishment to consider the FSIS results provided in EOS letters and Salmonella/Campylobacter testing process control and subtype results when evaluating the effectiveness of its overall food safety system. IPP are to communicate this information at a weekly meeting in accordance with the instructions in FSIS Directive 5000.1 and are to document this discussion in the memorandum of interview (MOI) of the weekly meeting. If IPP have concerns that an establishment has not considered the Salmonella and Campylobacter data when evaluating its food safety system, they are to contact their immediate supervisor for guidance. The fact that Salmonella isolates have a subtype historically associated with human illness does not automatically implicate the sample product class as the cause of any human illness or necessarily mean that the establishments food safety system is ineffective. Unless instructed by the District Office, there is no follow-up verification for IPP to perform or enforcement action to take based on the information and results provided in the EOS letter. An EIAO will verify the appropriateness of the establishments response to the results in the next FSA performed at the establishment.

Pathogen Reduction Example

Example: You are an IPP assigned to a large, two-shift broiler slaughter operation. Today, you receive shipping containers and sampling supplies from the Eastern laboratory for Salmonella and Campylobacter Performance Standard sampling set for broilers. You and the second shift IPP perform the sampling task following the instructions in FSIS directives and notices, and select the samples randomly at unannounced times each day the product is produced within the date range reflected in the establishment task list. A couple of months elapse. Throughout the sampling process, you have tracked the progress through daily monitoring of LEARN and PHIS for sample receipt and individual sample results. You have submitted 53 samples to date. The 53rd sample was sent yesterday. LEARN indicates that two have been discarded. Is it time to stop sampling? Answer: No. Do not stop sampling. IPP can verify that the set is complete for a specific establishment by checking LEARN regularly and clicking on the box for CHECK FOR PR/HACCP COMPLETED SET RESULTS. LEARN will also indicate if any of the samples were discarded and these samples will be recorded as Not Analyzed. IPP can only collect a sample in PHIS if a sampling task is available on the task list. Currently, PHIS will automatically add additional sampling tasks to the task list, when sample discards occur at the laboratory, to complete the

Inspection Methods

14

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

set. The IPP need to request additional tasks if the appropriate sampling task is not available in the calendar task list in PHIS.

Inspection Methods

15

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

Workshop 2: Salmonella and Campylobacter Performance Standards

1. How do IPP document the Salmonella and Campylobacter performance standard verification sampling task?

2. Match the correct Category with its description. a. Category 1 b. Category 2 c. Category 3 _____ the most recent set does not meet the performance standards _____ passed last 2 consecutive sets with the total number of positives in each set at or below half of the maximum number of positives allowed to achieve the performance standard _____ passed the last 2 consecutive sets, but while the most recent set meets the performance standard, the total number of positives is above 50 percent of the standard

Inspection Methods

16

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

Hands-on Exercise: PHIS Instructions

Working independently, log into PHIS. You will: Add the (HC11_BR)-PR/HACCP-Broilers-Salmonella & Campylobacter sampling verification task to the calendar, and Complete the task. Use the following instructions as needed. If you need further instructions, consult the PHIS Quick Reference Guide. Logging in to PHIS 1. Log-in as: User Name: Password: FSIS_user FSIS

2. If needed, start Internet Explorer using the Icon on upper left of the desktop: Double click the Internet explorer ( PHIS comes up. Log In as: User name: Cindy Soundly Add the generic (HC11_BR)-PR/HACCP-Broilers-Salmonella & Campylobacter Sampling Verification Task to the Task Calendar 1. Left click on Task Calendar from the Navigation menu on the Home page, then left click the down arrow in the box next to select establishment and select Novosibar; in the box next to filter task by select Lab Sampling 2. In the Task Name column, scroll through the list until you find a directed (HC11_BR)-PR/HACCP-Broilers-Salmonella & Campylobacter sampling verification task with the appropriate start and end dates 3. Find the Assign column for the task, and then left click on the Add link for the (HC11_BR)-PR/HACCP-Broilers-Salmonella & Campylobacter sampling task ) icon

Inspection Methods

17

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

4. In the Lab capacity pop-up window, Type Todays Date in the Collection Date and Parcel Pickup Date boxes or use the calendar icon to select todays date and left click on the Save button. 5. After scheduling the sample, collect the sample. Documenting the (HC11_BR) Task Results 1. Scroll down to the Task Calendar panel, left click the down arrow in the box next to Establishment that has the word all and select Novosibar 2. Right click on the (HC11_BR) task you added to your task calendar 3. Highlight and left click Document 4. After the Sample Management-Sample Collection page opens Enter all the appropriate information in each tab Verify that the pertinent information is accurate, click Submit to Lab button to transmit the information Click Print Form at the top right of the page. Affix the sample ID seal in the designated space at the top center of the form and follow the steps to ship the sample to the appropriate lab.

Inspection Methods

18

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

Attachment 1

General Sampling Procedures It is important to have good aseptic sampling techniques and follow the step-bystep procedure when sampling. Information regarding the sampling procedure IPP use to collect samples for Salmonella testing is available in FSIS Directive 10,230.5, Amendment 1. If an establishment has an antimicrobial spray as a CCP in their HACCP plan, carcass samples are taken after the spray and prior to packaging or cut-up. If poultry carcasses are cut into major portions (e.g., front and rear halves) prior to entering the chill tank, equivalent pieces that make a whole bird can be selected and sampled for Salmonella testing. Ground product samples are collected after grinding and before final packaging. When possible, samples should be collected before spices or seasonings are added. The sample location and time for the product identified for sampling (beef, chicken, or turkey) are randomly selected. The sampling area is sanitized. The FSIS sampler must wash and sanitize hands and arms to the mid-forearm, and then dry them. Procedure for Collecting Young Chicken Rinsate IPP are to take all necessary precautions not to contaminate any of the sampling supplies and are to discontinue the sampling procedure if a contamination event occurs that would compromise the integrity of the submitted sample. IPP are to review and follow the instructions in FSIS Notice 54-12; and FSIS Directive 10,230.5, Attachment 1, Section 4(a), Aseptic Sampling Techniques, Putting on the Gloves, and Section 6(c), Sample Collection, Chicken, for placing the chicken carcass in the large sterile plastic sample bag, adding prechilled Buffered Peptone Water (BPW), and thoroughly rinsing the bird. IPP are to remove the chicken aseptically from the sample bag before collecting the 100 ml rinsate. To do this, carefully open the bag containing the bird. Work the plastic bag down around the carcass and firmly grip one leg, without touching the inside of the plastic bag while holding the bag with the one hand, carefully remove the bird from the bag with the other hand; and place the bird back on the conveyor or table. IPP are to collect the 100 ml rinsate sample from the sample bag immediately. Remove the lid from the empty 120 ml sterile specimen jar container. Be careful not to contaminate the inside of the specimen jar or the lid, and do not allow the bag to contact the interior surfaces of the jar. Using the V formed by the bag at the lower corner as a pouring spout, carefully pour the rinsate into the open jar. Collect as much of the BPW rinsate as possible, but at least 100 ml. Place the

Inspection Methods

19

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

cap back on the jar and check to be sure that the lid is securely in place. Place the collected and labeled sample container in a Ziploc-type bag. Hold the sample under refrigeration and FSIS control until shipment to the laboratory. Sampling Procedures for Turkeys The following sampling procedure instructions are for young turkey slaughter establishments only. IPP that are assigned to such establishments are to use the sample collection methods described in FSIS Notice 54-12 instead of the sample collection instructions in FSIS Directive 10,230.5, except where FSIS Directive 10,230.5 is referenced. IPP are to take all necessary precautions not to contaminate any of the sampling supplies and are to discontinue the sampling procedure if a contamination event occurs which would compromise the integrity of the submitted samples. IPP are to review and follow the instructions in FSIS Directive 10,230.5, Attachment 1, Section 4(a), Aseptic Sampling Techniques, Putting on the Gloves, and Section 6(d), Sample Collection, Turkey, for general turkey sponging technique, but with the following additional instructions. Note that the turkey sample kit will contain two tubes of Buffered Peptone Water (BPW): one 10-ml tube marked S designated for Salmonella sampling and another 25-ml tube marked C designated for Campylobacter sampling. While wearing the first pair of sterile gloves, remove the turkey in a safe manner. Holding the turkey by the legs and avoiding contact with the back or thigh areas, place the turkey breast down on a sanitized work surface covered with clean paper towels or absorbent pads to prevent the carcass from slipping during sponge sampling. Remove and discard the gloves. If heavy birds, require assistance for lifting, have helpers wear sterile gloves and ensure that they do not touch the sampling areas. Open the sponge bag by tearing off the top perforated strip. Do not remove the wire closures from the bag. Pull apart the two small white tabs on either side to open the mouth of the bag. Remove the cap from the smaller, 10-ml prechilled sterile BPW container marked S, being careful not to touch the container opening. Carefully pour the entire contents of the BPW container into the sponge bag marked S. Do not contaminate the top inside of the Whirl-Pak bag. Set the empty BPW container aside. Press the wire closures back together to close the top of the sponge bag. Use hand pressure on the outside of the bag to carefully massage the sponge until it is fully moistened. With the bag still closed, squeeze any excess diluent out of the sponge while carefully pushing the moistened sponge to the uppermost portion of the bag. Open the sponge sample bag, being careful not to touch its inner surface. The wire closure should keep the bag open. Set the bag aside, being careful not to contaminate the sponge and careful not to spill the remaining BPW fluid.

Inspection Methods

20

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

Open the sterile template bag by tearing off the top perforated strip. Set the template bag aside, being careful not to contaminate the template. Put on the second pair of sterile gloves. Carefully remove the moistened sponge from the bag by grasping the end of the sampling sponge with your gloved sampling hand. Do not touch the outside of the Whirl-Pak bag. With your other gloved hand, retrieve the template by its outer edge, taking care not to contaminate the inner edges that define the templates sampling area. Place the template over the back sampling area and hold it in place to the left of the vertebral column. Using your sampling hand, wipe the sponge over the entire enclosed area approximately 10 times vertically and 10 times horizontally. Use only one side of the sponge. You may need to roll the template from side to side as you sponge since the carcass surface is not flat. Repeat the sponging procedure using the same sponge but with the template placed over the left thigh sampling area. Turn the sponge over so that the unused side of the sponge contacts the thigh surface, wiping the entire area enclosed by the template with approximately 10 vertical and 10 horizontal passes of the sponge. Discard the template. Carefully replace the sponge into the Whirl-Pak sample bag with any remaining portion of BPW without touching the outside of the bag with the sponge. Expel any excess air from the sample bag and fold over the top edge of the bag 3 or 4 times to close the top. Secure the top by folding the wire attachments back against the bag. Repeat the above steps using the other, larger, 25-ml prechilled sterile BPW container marked C and the Whirl-Pak sponge bag marked C. Swab the right side of the same turkey carcass using a new pair of gloves and a new template. Upon completion of the second swabbing, and securing the swab in its marked sample bag, return the turkey carcass to the point where you collected the bird. Each sponge should be carefully secured in its own separate Whirl-Pak sample bag (previously marked appropriately with either an S or a C). Place bagged carcass sponges under refrigeration within five (5) minutes of collection. Place the collected and labeled sample bags in their own separate ziplock type bag, which is provided, and hold under refrigeration and FSIS control until shipped. Salmonella Ground Sampling Open the Whirl-Pak filter bag identified with a pink fluorescent label and set it aside. Open the sterile bag containing the 25 gram sample ring and push the plastic-wrapped ring up to the top of the bag without touching the plastic wrap or

Inspection Methods

21

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

the inner surface of the bag. Then the bag and its contents are set aside on a sterile surface. The sampler puts on the sterile gloves. The sampler then removes the sterile plastic-wrapped ring template from the bag, without touching the outside of the bag or any other nonsterile surface. The sterile tape or seal on the plastic wrap is opened. The ring is unwrapped. The sterile sheet is placed on the sanitized work surface. The ring is placed in the center of the wrap. Without touching anything but the sample and the ring, the sampler collects enough raw ground product to fill the ring. Ground product is selected from various portions of the batch to ensure that the sample is representative of the product. On a sterile surface the sample is firmly packed into the ring (do not over-fill the ring, just make product level with the top), eliminating air pockets. The sample is packed until it is even with the top of the ring. The rings are designed to collect 25 grams of product, the required sample size for the laboratory analysis. The filled ring is lifted from the sheet and held over the open Whirl-Pak bag. With a gloved finger the sampler pushes the ground product out of the ring into the bag. Do not include the ring with the sample or the sample will be discarded. Excess air is expelled and the top of bag is folded over 3 to 4 times and sealed.

Inspection Methods

22

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

Attachment 2

FSIS Form 8000-19: Sample Analysis Request Form

P42 Safest and Best Poultry

Jane Doe

John Doe

Anywhere

00000

Inspection Methods

23

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

Attachment 3

Salmonella Regulations, Livestock, 310.25(b) and Poultry, 381.94(b) Sec. 310.25 Contamination with microorganisms; process control verification criteria and testing; pathogen reduction standards. (b) Pathogen reduction performance standard; Salmonella. (1) Raw meat product performance standards for Salmonella. An establishment's raw meat products, when sampled and tested by FSIS for Salmonella, as set forth in this section, may not test positive for Salmonella at a rate exceeding the applicable national pathogen reduction performance standard, as provided in Table 2: Table 2--Salmonella Performance Standards Performance Standard Number of Class of product (percent positive for samples Salmonella)a tested (n) Steers/heifers. Cows/bulls Ground beef ... Hogs. Fresh pork sausages..

a

1.0% 2.7% 7.5% 8.7% b N.A.

82 58 53 55 N.A.

Maximum number of positives to achieve Standard (c) 1 2 5 6 N.A.

Performance Standards are FSIS's calculation of the national prevalence of Salmonella on the indicated raw product based on data developed by FSIS in its nationwide microbiological data collection programs and surveys. Copies of Reports on FSIS's Nationwide Microbiological Data Collection Programs and Nationwide Microbiological Surveys used in determining the prevalence of Salmonella on raw products are available in the FSIS Docket Room. b Not available; values for fresh pork sausage will be added upon completion data collection programs for those products.

(2) Enforcement. FSIS will sample and test raw meat products in an individual establishment on an unannounced basis to determine prevalence of Salmonella in such products to determine compliance with the standard. The frequency and timing of such testing will be based on the establishment's previous test results and other information concerning the establishment's performance. In an establishment producing more than one class of product subject to the pathogen reduction standard, FSIS may sample any or all such classes of products.\3\ \3\ A copy of FSIS's ``Sample Collection Guidelines and Procedure for Isolation and Identification of Salmonella from Meat and Poultry Products'' is available for inspection in the FSIS Docket Room.

Inspection Methods

24

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

(3) Noncompliance and establishment response. When FSIS determines that an establishment has not met the performance standard: (i) The establishment shall take immediate action to meet the standard. (ii) If the establishment fails to meet the standard on the next series of compliance tests for that product, the establishment shall reassess its HACCP plan for that product and take appropriate corrective actions. (iii) Failure by the establishment to act in accordance with paragraph (b)(3)(ii) of this section, or failure to meet the standard on the third consecutive series of FSIS-conducted tests for that product, constitutes failure to maintain sanitary conditions and failure to maintain an adequate HACCP plan, in accordance with part 417 of this chapter, for that product, and will cause FSIS to suspend inspection services. Such suspension will remain in effect until the establishment submits to the FSIS Administrator or his/her designee satisfactory written assurances detailing the action taken to correct the HACCP system and, as appropriate, other measures taken by the establishment to reduce the prevalence of pathogens. Sec. 381.94 Contamination with Microorganisms; process control verification criteria and testing; pathogen reduction standards. (b) Pathogen reduction performance standards; Salmonella. (1) Raw poultry product performance standards for Salmonella. (i) An establishment's raw poultry products, when sampled and tested by FSIS for Salmonella as set forth in this section, may not test positive for Salmonella at a rate exceeding the applicable national pathogen reduction performance standard, as provided in Table 2: Table 2.--Salmonella Performance Standards Class of product Performance Number of Standard (per samples cent positive tested for (n) a Salmonella) Broilers............................................... Ground chicken.................................. Ground turkey.................................... Turkeys.............................................. Squabs............................................... Ratites................................................

a

20.0% 44.6 49.9 b N.A. b N.A. b N.A.

51 53 53 N.A. N.A. N.A.

Maximum number of positives to achieve Standard (c) 12 26 29 N.A. N.A. N.A.

Performance Standards are FSIS's calculation of the national prevalence of Salmonella on the indicated raw products based on data developed by FSIS in its nationwide microbiological baseline data collection programs and surveys. (Copies of Reports on FSIS's Nationwide Microbiological Data Collection Programs and Nationwide Microbiological Surveys used in determining the prevalence of Salmonella on raw products are available in the FSIS Docket Room.)

Inspection Methods

25

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

b

Not available; baseline targets for turkeys, squabs, or ratites will be added upon completion of the data collection programs for that product.

(2) Enforcement. FSIS will sample and test raw poultry products in an individual establishment on an unannounced basis to determine prevalence of Salmonella in such products to determine compliance with the standard. The frequency and timing of such testing will be based on the establishment's previous test results and other information concerning the establishment's performance. In an establishment producing more than one class of product subject to the pathogen reduction standard, FSIS may sample any or all such classes of products.\3\ \3\ A copy of FSIS's ``Sample Collection Guidelines and Procedure for Isolation and Identification of Salmonella from Raw Meat and Poultry Products'' is available for inspection in the FSIS Docket Room. (3) Noncompliance and establishment response. When FSIS determines that an establishment has not met the performance standard: (i) The establishment shall take immediate action to meet the standard. (ii) If the establishment fails to meet the standard on the next series of compliance tests for that product, the establishment shall reassess its HACCP plan for that product. (iii) Failure by the establishment to act in accordance with paragraph (b)(3)(ii) of this section, or failure to meet the standard on the third consecutive series of FSIS-conducted tests for that product, constitutes failure to maintain sanitary conditions and failure to maintain an adequate HACCP plan, in accordance with part 417 of this chapter, for that product, and will cause FSIS to suspend inspection services. Such suspension will remain in effect until the establishment submits to the FSIS Administrator or his/her designee satisfactory written assurances detailing the action taken to correct the HACCP system and, as appropriate, other measures taken by the establishment to reduce the prevalence of pathogens.

Inspection Methods

26

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

Attachment 4

FSIS Notice 54-12 Appendix II Performance Standards for Salmonella and Campylobacter Questions and Answers

1.

If an establishment passes for Salmonella but fails for Campylobacter, will the establishment be scheduled for another Salmonella/Campylobacter set? If a set fails for Salmonella but passes for Campylobacter will the establishment be scheduled for another Salmonella/Campylobacter set? Yes. If the establishment fails a set for either Salmonella or Campylobacter, the Agency will immediately scheduled another set at the establishment for both Salmonella and Campylobacter.

2.

Will the End of Set Letters include the Category 1, Category 2, and Category 3 rating? Yes, in a table showing the last two sets and the current Category status. The text of the End of Set Letter will inform the establishment as to whether its completed set results showed process control that was consistent, variable, or highly variable. The three terms define the Categories 1/2/3. Thus, the End of Set Letters will include the Category rating along with the Salmonella serotypes and other information when available, and those establishments that have Category 3 rating for Salmonella will be posted on the FSIS web page.

3.

Will establishments that fail the Performance Standard for Campylobacter be posted on the FSIS web page? No, establishments that fail the Performance Standard for Campylobacter will not be posted on the FSIS web page. When two sets for Campylobacter have been completed for 90 percent of establishments, the Agency will evaluate industry performance and determine what policy to follow.

4.

If I do not have a Sampling Raw Meat and Poultry for Salmonella DVD, how do I go about getting one? If you do not have a 30-minute Sampling DVD, which is the same as the VHS video originally issued in 1998, send an email message including the name of the DVD, a physical mailing address (no Post Office box), and telephone number to cedl@fsis.usda.gov.

5.

I have received a directed sampling task generated through PHIS, but have not received any supplies. How do I obtain the supplies needed?

Inspection Methods

27

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

If Inspection Program Personnel need sampling supplies, they should request them via email at least 72 hours before sampling is to begin. Request for sampling supplies for Salmonella and Campylobacter verification testing can be sent to any FSIS Laboratories using one of the following email addresses in Outlook: Sampling Supplies- Eastern Lab Sampling Supplies- Midwestern Lab Sampling Supplies-Western Lab The IPP are to include the following information in the supply request email: Sampling project code and project name Identify the exact supplies needed Establishment address (Not the Post Office Box) Establishment phone number 6. How can I best ensure that temperature requirements are met? The IPP are to ensure the following to achieve the best results: Refrigerate BPW upon receipt and use only prechilled BPW Collected samples are to be refrigerated within five minutes of collection Make sure the rinsate or sponge samples have been cooled down prior to shipping Make sure the cold packs are completely frozen Use sufficient coolant to maintain sample temperature during shipment Prechill the shipping container Pack the shipper as close to the expected FedEx pick up time as possible 7. When should samples be collected and shipped? First shift samples are to be shipped the same day collected or they will be discarded by the laboratory. The First shift samples may be collected Monday through Friday. Second shift samples are to be only collected Monday through Thursday and shipped the next available FedEx pick up. 8. What are some of the common reasons for samples to be discarded by the laboratory?

Inspection Methods

28

Pathogen Reduction Salmonella and Campylobacter 9-11-2012

Some of common reasons why samples will be discarded are: The temperature requirements are NOT met upon receipt at the Laboratory. The laboratory will discard samples that arrive above 50F (10C) or below 32F (0C). The sample form was incomplete, i.e. not signed or dated or omitted information. Sample containers other than those provided were used to submit samples Sample containers (bottles and/or bags) are leaking Samples were not received the day following the day of collection or shipment 9. How will I receive the laboratory testing results? The IPP can receive the laboratory testing results as soon as they are available through LEARN or PHIS. Sample information is entered into the FSIS laboratories databases throughout each day. The IPP should check LEARN or PHIS the following afternoon for sample receipt confirmation and at least once daily, until final results are posted.

Inspection Methods

29

Das könnte Ihnen auch gefallen

- FSIS guidance for small meat and poultry plants on Salmonella controlsDokument22 SeitenFSIS guidance for small meat and poultry plants on Salmonella controlsPaGaNoch keine Bewertungen

- 3MTM PetrifilmTM Plate Certificates, Recognitions and ValidationsDokument4 Seiten3MTM PetrifilmTM Plate Certificates, Recognitions and ValidationsDavidSargFolgar100% (1)

- Managing Microbiological Food Safety Risks in Poultry ProcessingDokument9 SeitenManaging Microbiological Food Safety Risks in Poultry ProcessingHumera SarfrazNoch keine Bewertungen

- Chapter 5 - Fish Quality Assurance: 5.1 Definition of Q.ADokument11 SeitenChapter 5 - Fish Quality Assurance: 5.1 Definition of Q.ADhaval BamaniyaNoch keine Bewertungen

- Antibiotic Residue Surveillance July 2003Dokument16 SeitenAntibiotic Residue Surveillance July 2003Kelma TayebaNoch keine Bewertungen

- Haccp For Irish Beef, Pork and Lamb Slaughter: AuthorsDokument16 SeitenHaccp For Irish Beef, Pork and Lamb Slaughter: Authorspopa.janossNoch keine Bewertungen

- JVMR Volume 26 Issue 2 Pages 151-163Dokument13 SeitenJVMR Volume 26 Issue 2 Pages 151-163sheila antonio maposseNoch keine Bewertungen

- Time-Temperature Tables for Cooking PoultryDokument16 SeitenTime-Temperature Tables for Cooking PoultrybillNoch keine Bewertungen

- E.Coli Essay FINAL PDFDokument8 SeitenE.Coli Essay FINAL PDFSaraturituriNoch keine Bewertungen

- Emea 2000 1/22Dokument22 SeitenEmea 2000 1/22independentwomenNoch keine Bewertungen

- Beef SamplingDokument69 SeitenBeef SamplingPaul PaulNoch keine Bewertungen

- Laboratory Methods - Chap 05. Bacteriological Analytical Manual (BAM) Chapter 5 - SalmonellaDokument24 SeitenLaboratory Methods - Chap 05. Bacteriological Analytical Manual (BAM) Chapter 5 - SalmonellaPhuong LeNoch keine Bewertungen

- Pork Meat FreshnessDokument8 SeitenPork Meat FreshnessGenesis HereNoch keine Bewertungen

- FDA Phil Revised Guidelines For The Assessment of Microbiological Quality of Processed FoodsDokument12 SeitenFDA Phil Revised Guidelines For The Assessment of Microbiological Quality of Processed FoodsclairealbertiniNoch keine Bewertungen

- Advisory Committee On The Microbiological Safety of FoodDokument5 SeitenAdvisory Committee On The Microbiological Safety of FoodLidiya YakubovskaNoch keine Bewertungen

- HOY Risk Factors For Salmonella Contamination of Whole Chicken Carcasses Following Changes in U.S. Regulatory OversightDokument9 SeitenHOY Risk Factors For Salmonella Contamination of Whole Chicken Carcasses Following Changes in U.S. Regulatory OversightKatia RamónNoch keine Bewertungen

- Campylobacter Isolation MLG - 41.07Dokument20 SeitenCampylobacter Isolation MLG - 41.07TeklewNoch keine Bewertungen

- Presentation PR2 Chap 4-5Dokument17 SeitenPresentation PR2 Chap 4-5Karylle Joy GarciaNoch keine Bewertungen

- Executive Summary: Supporting Document 4Dokument8 SeitenExecutive Summary: Supporting Document 4ghajiniiNoch keine Bewertungen

- Chapter 5 - FOOD SAFETY: A. IntroductionDokument21 SeitenChapter 5 - FOOD SAFETY: A. IntroductionMohsinNoch keine Bewertungen

- Jemra Campylobacter Summary and ConclusionDokument12 SeitenJemra Campylobacter Summary and ConclusionJohnson ojofuNoch keine Bewertungen

- Rapid - Test - Kits para Antibióticos Incluyendo Beta StarDokument23 SeitenRapid - Test - Kits para Antibióticos Incluyendo Beta Starapi-3697331100% (1)

- Manual: Quality Assurance For Microbiology in Feed Analysis LaboratoriesDokument210 SeitenManual: Quality Assurance For Microbiology in Feed Analysis LaboratoriesJyShe_la100% (1)

- Indicator Organisms Debate: Which to Use for TestingDokument6 SeitenIndicator Organisms Debate: Which to Use for Testingpalani velanNoch keine Bewertungen

- Aprovações PetrifilmDokument8 SeitenAprovações PetrifilmLeandro DornelesNoch keine Bewertungen

- culture methods.docxDokument2 Seitenculture methods.docxHƯƠNG NGUYỄN LÊ NGỌCNoch keine Bewertungen

- AcmsfcampylobacterDokument195 SeitenAcmsfcampylobacterKey JeyNoch keine Bewertungen

- GSO 1016-2000 STD Microbiological Criteria For Food Stuffs - Part 1Dokument25 SeitenGSO 1016-2000 STD Microbiological Criteria For Food Stuffs - Part 1Mm. Sharaby100% (2)

- Leclercq (Overview of Standard Methods Development of ISO and CEN)Dokument48 SeitenLeclercq (Overview of Standard Methods Development of ISO and CEN)Stathis GiaourisNoch keine Bewertungen

- 5 USDA FSIS 4.10 Isolation and Identification of SalmonellaDokument18 Seiten5 USDA FSIS 4.10 Isolation and Identification of SalmonellaAbdulrahmanNoch keine Bewertungen

- 29 IM Raw Beef Prod SamplingDokument71 Seiten29 IM Raw Beef Prod SamplingNader Sedighi100% (1)

- Guideline For Assessing Micro Safety of Rte FoodDokument34 SeitenGuideline For Assessing Micro Safety of Rte Foodheinz111Noch keine Bewertungen

- Guide to Meat Industry Microbial StandardsDokument32 SeitenGuide to Meat Industry Microbial StandardsSaraturituriNoch keine Bewertungen

- CarbapenemsDokument70 SeitenCarbapenemsproductionpoultryNoch keine Bewertungen

- Evaluation Methods-Science ResearchDokument37 SeitenEvaluation Methods-Science ResearchVíctor Manuel Pescorán DelfínNoch keine Bewertungen

- Final Report of An Audit Conducted in Brazil June 10 - 28, 2019Dokument70 SeitenFinal Report of An Audit Conducted in Brazil June 10 - 28, 2019Rudmar Luiz Pereira dos SantosNoch keine Bewertungen

- MLG 4Dokument20 SeitenMLG 4GS ShawonNoch keine Bewertungen

- Producto RetenidoDokument17 SeitenProducto RetenidoJesus Gerardo Lopez ColmanNoch keine Bewertungen

- Haccp v2 Appvix-1Dokument34 SeitenHaccp v2 Appvix-1popa.janossNoch keine Bewertungen

- BAM - Chapter 5 - SalmonellaDokument33 SeitenBAM - Chapter 5 - Salmonelladark DragonNoch keine Bewertungen

- Food Microbiology: Ihab Habib, Mieke Uyttendaele, Lieven de ZutterDokument7 SeitenFood Microbiology: Ihab Habib, Mieke Uyttendaele, Lieven de ZutterSarah InêsNoch keine Bewertungen

- Compliance Guidelines For Establishments On The Fsis Microbiological Testing Program and Other Verification Activities For Escherichia Coli O157:H7Dokument16 SeitenCompliance Guidelines For Establishments On The Fsis Microbiological Testing Program and Other Verification Activities For Escherichia Coli O157:H7PaGaNoch keine Bewertungen

- Food Control: Peter M. Horchner, Andrew M. PointonDokument15 SeitenFood Control: Peter M. Horchner, Andrew M. PointoncikizdNoch keine Bewertungen

- BIOHAZ PiensosSalmonella08Dokument84 SeitenBIOHAZ PiensosSalmonella08amamùra maamarNoch keine Bewertungen

- Microbiological Methods & Bacteriological Analytical Manual (BAM)Dokument3 SeitenMicrobiological Methods & Bacteriological Analytical Manual (BAM)alesraa jawharatNoch keine Bewertungen

- Screening of Antibiotic Residues and Quantitative Estimation of Oxytetracycline Residues in Chicken's EggDokument6 SeitenScreening of Antibiotic Residues and Quantitative Estimation of Oxytetracycline Residues in Chicken's Eggvetwaffaaqm3Noch keine Bewertungen

- BAM Chapter 5. SalmonellaDokument24 SeitenBAM Chapter 5. SalmonellaremyNoch keine Bewertungen

- Europese Audit Van Het Voedselagentschap (FAVV)Dokument27 SeitenEuropese Audit Van Het Voedselagentschap (FAVV)De StandaardNoch keine Bewertungen

- Food Control: I. Ghanem, M. OrfiDokument3 SeitenFood Control: I. Ghanem, M. OrfiHigor MarkovicNoch keine Bewertungen

- ScienceDokument5 SeitenScienceSayed ShalabyNoch keine Bewertungen

- Indicators of Food Microbial Quality and SafetyDokument12 SeitenIndicators of Food Microbial Quality and SafetyMaryam Sar100% (1)

- Application of Haccp Principles in The Meat Industry: United Kingdom PerspectiveDokument9 SeitenApplication of Haccp Principles in The Meat Industry: United Kingdom PerspectiveBianca IonescuNoch keine Bewertungen

- PDF Gso 1016 2015Dokument26 SeitenPDF Gso 1016 2015adamNoch keine Bewertungen

- Meat PieDokument13 SeitenMeat Piecrispitty100% (1)

- Practica 9 Cuenta Total BacteriasDokument3 SeitenPractica 9 Cuenta Total BacteriasKarla GrNoch keine Bewertungen

- Raw Milk Survey FINALDokument30 SeitenRaw Milk Survey FINALAnisoara GurbanNoch keine Bewertungen

- Alteration of Ovoproducts: From Metabolomics to Online ControlVon EverandAlteration of Ovoproducts: From Metabolomics to Online ControlOlivier GoncalvesNoch keine Bewertungen

- Handbook of Microbiological Criteria for FoodsVon EverandHandbook of Microbiological Criteria for FoodsNoch keine Bewertungen

- AA Plus Breeder Supplement PDFDokument12 SeitenAA Plus Breeder Supplement PDFNader SedighiNoch keine Bewertungen

- V205 FLOCKSCREEN Ae Instructions For Use (V3) A4 - 000Dokument5 SeitenV205 FLOCKSCREEN Ae Instructions For Use (V3) A4 - 000Nader SedighiNoch keine Bewertungen

- Cobb EMEA Breeder Update 2018Dokument2 SeitenCobb EMEA Breeder Update 2018Nader SedighiNoch keine Bewertungen

- Biosecurity-Fivet July 2014 DR D Bruce PIGS PDFDokument18 SeitenBiosecurity-Fivet July 2014 DR D Bruce PIGS PDFNader SedighiNoch keine Bewertungen

- V050 V054 V055 FLOCKSCREEN MG Instructions For Use (V2) A4 - 000Dokument6 SeitenV050 V054 V055 FLOCKSCREEN MG Instructions For Use (V2) A4 - 000Nader SedighiNoch keine Bewertungen

- v180 Flockscreen Art Diff Instructions For Use v1 - 000Dokument5 Seitenv180 Flockscreen Art Diff Instructions For Use v1 - 000Nader SedighiNoch keine Bewertungen

- V060 V064 V065 FLOCKSCREEN Ms Instructions For Use - v2 - 000Dokument7 SeitenV060 V064 V065 FLOCKSCREEN Ms Instructions For Use - v2 - 000Nader SedighiNoch keine Bewertungen

- V205 FLOCKSCREEN Ae Instructions For Use (V3) A4 - 000Dokument5 SeitenV205 FLOCKSCREEN Ae Instructions For Use (V3) A4 - 000Nader SedighiNoch keine Bewertungen

- Viper eDokument6 SeitenViper eNader SedighiNoch keine Bewertungen

- V160 V164 V165 FLOCKSCREEN ILT Instructions For Use - v2 - 000Dokument7 SeitenV160 V164 V165 FLOCKSCREEN ILT Instructions For Use - v2 - 000Nader SedighiNoch keine Bewertungen

- V020 V024 V025 FLOCKSCREEN ST Instructions For Use - v2 - A5 - 000Dokument7 SeitenV020 V024 V025 FLOCKSCREEN ST Instructions For Use - v2 - A5 - 000Nader SedighiNoch keine Bewertungen

- V205 FLOCKSCREEN Ae Instructions For Use (V3) A4 - 000Dokument5 SeitenV205 FLOCKSCREEN Ae Instructions For Use (V3) A4 - 000Nader SedighiNoch keine Bewertungen

- V080 V084 V085 FLOCKSCREEN CAV Instructions For Use - v2 - 000Dokument7 SeitenV080 V084 V085 FLOCKSCREEN CAV Instructions For Use - v2 - 000Nader SedighiNoch keine Bewertungen

- v170 v174 v175 Flockscreen Ai Instruction For Use v1Dokument7 Seitenv170 v174 v175 Flockscreen Ai Instruction For Use v1Nader SedighiNoch keine Bewertungen

- v140 v144 v145 Flockscreen Art Instructions For Use v1Dokument7 Seitenv140 v144 v145 Flockscreen Art Instructions For Use v1Nader SedighiNoch keine Bewertungen

- v090 v094 v095 Flockscreen Ibd Instructions For Use - v2 - A5 - 000Dokument7 Seitenv090 v094 v095 Flockscreen Ibd Instructions For Use - v2 - A5 - 000Nader SedighiNoch keine Bewertungen

- v180 Flockscreen Art Diff Instructions For Use v1 - 000Dokument5 Seitenv180 Flockscreen Art Diff Instructions For Use v1 - 000Nader SedighiNoch keine Bewertungen

- v120 V12flockscreen NDV Instructions For Use v2 - 000Dokument7 Seitenv120 V12flockscreen NDV Instructions For Use v2 - 000Nader SedighiNoch keine Bewertungen

- V130 V134 V135 FLOCKSCREEN IBV Instructions For Use - v3 - 000Dokument7 SeitenV130 V134 V135 FLOCKSCREEN IBV Instructions For Use - v3 - 000Nader SedighiNoch keine Bewertungen

- V130 V134 V135 FLOCKSCREEN IBV Instructions For Use - v3 - 000Dokument7 SeitenV130 V134 V135 FLOCKSCREEN IBV Instructions For Use - v3 - 000Nader SedighiNoch keine Bewertungen

- V060 V064 V065 FLOCKSCREEN Ms Instructions For Use - v2 - 000Dokument7 SeitenV060 V064 V065 FLOCKSCREEN Ms Instructions For Use - v2 - 000Nader SedighiNoch keine Bewertungen

- V060 V064 V065 FLOCKSCREEN Ms Instructions For Use - v2 - 000Dokument7 SeitenV060 V064 V065 FLOCKSCREEN Ms Instructions For Use - v2 - 000Nader SedighiNoch keine Bewertungen

- 33 Im Rte Ss ProcessDokument20 Seiten33 Im Rte Ss ProcessNader SedighiNoch keine Bewertungen

- V020 V024 V025 FLOCKSCREEN ST Instructions For Use - v2 - A5 - 000Dokument7 SeitenV020 V024 V025 FLOCKSCREEN ST Instructions For Use - v2 - A5 - 000Nader SedighiNoch keine Bewertungen

- V050 V054 V055 FLOCKSCREEN MG Instructions For Use (V2) A4 - 000Dokument6 SeitenV050 V054 V055 FLOCKSCREEN MG Instructions For Use (V2) A4 - 000Nader SedighiNoch keine Bewertungen

- 30 IM Sanitary DressingDokument15 Seiten30 IM Sanitary DressingNader SedighiNoch keine Bewertungen

- 29 IM Raw Beef Prod SamplingDokument71 Seiten29 IM Raw Beef Prod SamplingNader Sedighi100% (1)

- 31 IM Humane Handling GCPDokument37 Seiten31 IM Humane Handling GCPNader SedighiNoch keine Bewertungen

- 27 IM Sample MGMTDokument11 Seiten27 IM Sample MGMTNader SedighiNoch keine Bewertungen

- Effect of Plant Spacing and Use of Organo-Mineral Fertilizers On Biomass Yield and Profitability of Solanum Scabrum Cultivation On An Aquox in The Western Highlands of CameroonDokument10 SeitenEffect of Plant Spacing and Use of Organo-Mineral Fertilizers On Biomass Yield and Profitability of Solanum Scabrum Cultivation On An Aquox in The Western Highlands of CameroonsardinetaNoch keine Bewertungen

- A Review of Chitin and Chitosan ApplicationsDokument27 SeitenA Review of Chitin and Chitosan Applicationssins1984100% (2)

- Time Table For Monday To Saturday Normal WeekdayDokument9 SeitenTime Table For Monday To Saturday Normal WeekdayVansh GuptaNoch keine Bewertungen

- Nyffeler-Birkhofer2017 Article AnEstimated400800MillionTonsOfDokument12 SeitenNyffeler-Birkhofer2017 Article AnEstimated400800MillionTonsOfrodrigo marchizelliNoch keine Bewertungen

- Final CadburyDokument76 SeitenFinal CadburyAbhijeet_Sangw_4012Noch keine Bewertungen

- Art of Soap-MakingDokument272 SeitenArt of Soap-MakingSawyer_Books100% (1)

- Churros (Homemade Recipe With Step by Step Photos) - Cooking ClassyDokument1 SeiteChurros (Homemade Recipe With Step by Step Photos) - Cooking ClassyRyleigh NoelNoch keine Bewertungen

- Horses in New Zealand: Discover All About These Beautiful AnimalsDokument8 SeitenHorses in New Zealand: Discover All About These Beautiful Animalssafe_newzealandNoch keine Bewertungen

- The Great Book of Random TablesDokument175 SeitenThe Great Book of Random TablesShybe Elrik88% (8)

- The Culture Map: Chapter 6Dokument29 SeitenThe Culture Map: Chapter 6chaimaglasang100% (5)

- Fish As Feed Inputs For Aquaculture, Practices, Sustainability and ImplicationsDokument426 SeitenFish As Feed Inputs For Aquaculture, Practices, Sustainability and ImplicationsDARAVELLANoch keine Bewertungen

- 10 Day Daniel Fast Meal Plan DownloadDokument2 Seiten10 Day Daniel Fast Meal Plan Downloadmartha100% (1)

- New Sampling Plan Uses Angular Transformation for Food Safety TestingDokument9 SeitenNew Sampling Plan Uses Angular Transformation for Food Safety TestingMuhamad FaizinNoch keine Bewertungen

- For Household Use Only: Operation and Maintenance ManualDokument43 SeitenFor Household Use Only: Operation and Maintenance ManualБојана ТркуљаNoch keine Bewertungen

- 13 Natural Ways to Clear a Runny NoseDokument6 Seiten13 Natural Ways to Clear a Runny NoseAneek Kumar100% (1)

- Edgar Rice Burroughs - Tarzan 12 - Tarzan and The Lost EmpireDokument85 SeitenEdgar Rice Burroughs - Tarzan 12 - Tarzan and The Lost EmpireNiloticNoch keine Bewertungen

- Final-Term AssignmentDokument14 SeitenFinal-Term AssignmentZaw Myo HeinNoch keine Bewertungen

- Largest Exporter of Sesame Seeds in IndiaDokument13 SeitenLargest Exporter of Sesame Seeds in IndiaVaishnavi AegisNoch keine Bewertungen

- Ilocano foods influenced by foreign flavorsDokument2 SeitenIlocano foods influenced by foreign flavorsAllysa MendozaNoch keine Bewertungen

- MTB Detailed Lesson PlanDokument8 SeitenMTB Detailed Lesson PlanAilyn Batausa Cortez Lindo100% (6)

- Business Plan of KioskDokument20 SeitenBusiness Plan of KioskAvinash PrasadNoch keine Bewertungen

- Carbonack Business PlanDokument25 SeitenCarbonack Business PlanJustine Jake OchiaNoch keine Bewertungen

- Class-3 Science Chapter-6 Food We Get From Plants (Part-1) : Highlights of The ChapterDokument5 SeitenClass-3 Science Chapter-6 Food We Get From Plants (Part-1) : Highlights of The ChapterZangoNoch keine Bewertungen

- 03. Shopping - ВходDokument3 Seiten03. Shopping - ВходGeorgi BirdanovNoch keine Bewertungen

- SAFC Biosciences - Technical Bulletin - Microbe Selection For The SER-TAIN™ Process ValidationDokument2 SeitenSAFC Biosciences - Technical Bulletin - Microbe Selection For The SER-TAIN™ Process ValidationSAFC-GlobalNoch keine Bewertungen

- Actividad 8: 1. Complete The Sentences Using The Verbs in The Correct FormDokument5 SeitenActividad 8: 1. Complete The Sentences Using The Verbs in The Correct FormRicardo Chicaiza BuenoNoch keine Bewertungen

- Sensory Study in Restaurant Interior Design PDFDokument80 SeitenSensory Study in Restaurant Interior Design PDFPritha DubeyNoch keine Bewertungen

- Kaala Bhairava Homam PDFDokument35 SeitenKaala Bhairava Homam PDFsanchit_dalviNoch keine Bewertungen

- Ji'an Borui Spice Oil Co. LTD.: CatalogueDokument10 SeitenJi'an Borui Spice Oil Co. LTD.: CataloguemdjvdNoch keine Bewertungen

- Review Article: Impact of Water, Sanitation, and Hygiene Interventions On Improving Health Outcomes Among School ChildrenDokument11 SeitenReview Article: Impact of Water, Sanitation, and Hygiene Interventions On Improving Health Outcomes Among School ChildrenArum FibriantiNoch keine Bewertungen