Beruflich Dokumente

Kultur Dokumente

Valve Philosophy Valve Application General

Hochgeladen von

Wade ColemanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Valve Philosophy Valve Application General

Hochgeladen von

Wade ColemanCopyright:

Verfügbare Formate

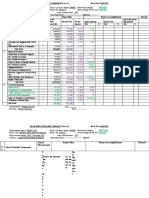

VALVE PHILOSOPHY Valve Application General a.

. In general, block valves that are used to isolate equipment or process unit shall be of gate, ball or plug type. Hand control valves shall be of globe type. Gate valves should not be used in throttling services due to high erosion rate of gate and seat particularly at low flow rates. Other types of valves such as diaphragm, pinch, knife gate, ball & plug may be when advantageous for specific application. b. Reduced port ball or plug type valves are used instead of gate valves in services like where solids may collect and polymerization may occur. c. Butterfly valves should be used in cooling water services generally 6 or larger. d. Use of globe valves in sizes 3 or larger should be avoided due to high cost. Valve Types Gate Physical Characteristics Gate like disc actuated by stem, screw & hand wheel move at right angles to flow. Use On-off service requiring infrequent throttling. Limitation Not good for throttling services which cause erosion, wire drawing. Pocket at bottom of valve fill with foreign particles and prevent closing of valve. Purging should be considered for service which may contain solids. Not recommended for on-off service. Cost and throttling efficiency above 6 become unfavourable. Not recommended where solids and corrosives are present. Same as above.

Globe Standard

Disc attached to stem seats on circular opening. Fluid changes direction in passing through valve.

Preferred for throttling services. Most throttling services where corrosion or erosion are not problem.

Globe Y pattern

Angle (90)

Similar to globe valve except inlet and outlet makes 90 angle.

Plug

Tampered plug, open & closes valve with min travel. th turn required to fully open or close.

Y type produces lower pressure drop and turbulence than standard globe valve. Preferred for high T/P services, corrosion & erosion services. Same as globe. Use for large Bends in piping systems pressure drop service. are subjected to strains that should not be placed on valves. On-off service. May be difficult to More positive shut off than operate. gate valve. Low pressure drop service.

Plug Lubricated

Plug Non lubricated Ball Valves

Screw in top of the plug is used to force lubricant into grooves in plug. Only th turn require to open or close. Plug usually coated with TFE for ease of turning. Similar to plug except movable element is ball. Resilient seat used. th turn from full open to full close. Flow keeps swing gate open while gravity or reversal flow keeps it close. Spring loaded.

Not normally used in chemical industry.

Lubricant can cause undesirable contaminants in high purity products.

Excellent for corrosive alloys and linings. Low pressure drop across valve. Full port valve reduces hold up of solids. Prevent back flow in lines. Best for liquids and less affected by solids in fluid. Lower P than swing check type valve. Wafer type requires no flange. Less affected by solids in fluid. Good for steam, vapors and water. Suitable for pulsating flow. Usually low temp range due to elastomer seat. Tight shut off than plug valve. Not suitable for pulsating flow. Some style operates only in horizontal position. Not suitable for pulsating flow.

Check Valves Swing check

Check valves Dual flapper (Butterfly)

Piston check

Flow patterns same as globe valve.

Ball check

Lift type check consisting of ball with guides.

Needle

Similar to plug except plug is pointed at end.

Stops reversal flow rapidly than others. Good for viscous fluid. Vertical or horizontal installation is possible. Valves smaller than 2 used in pilot plants and benchscale equipments and instruments. Good for manual control.

Mainly designs for horizontal service only. Not common in line size over 6 Not recommended for fluids having solids content. Not common in line size more than 6 Not suitable for pulsating flow. Positive shut off not always possible. In some design seat is scored if shut down tightly.

Automatic control

Similar in principle to globe valve but precision design for automatic control. Air pressure actuates the diaphragm causing stem to move, opening or closing valve orifice. Air pressure is controlled by primary measuring instrument. The valve plug is tapered or has V-port to give desired throttling characteristics. Double port valve give better control range & require small force to move stem.

Das könnte Ihnen auch gefallen

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988Von EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNoch keine Bewertungen

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDokument7 SeitenMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHINoch keine Bewertungen

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsVon EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNoch keine Bewertungen

- Evaporative Rates of A SpillDokument3 SeitenEvaporative Rates of A SpillkurtbkNoch keine Bewertungen

- Piping Design 5 PDFDokument9 SeitenPiping Design 5 PDFSandra MArrugo100% (1)

- Statistics for Process Control Engineers: A Practical ApproachVon EverandStatistics for Process Control Engineers: A Practical ApproachNoch keine Bewertungen

- Updating The Rules For Pipe SizingDokument5 SeitenUpdating The Rules For Pipe SizingBehroozRaadNoch keine Bewertungen

- Ips e PR 850 PDFDokument73 SeitenIps e PR 850 PDFdeyanshu7Noch keine Bewertungen

- Natural Gas Processing from Midstream to DownstreamVon EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNoch keine Bewertungen

- Article 5 Piping Design Part 5 Installation and CleaningDokument9 SeitenArticle 5 Piping Design Part 5 Installation and Cleaningharoon_siyech_engg100% (1)

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- Evaluate Heat-Exchanger Tube Rupture Scenarios Using Dynamic Simulation PDFDokument6 SeitenEvaluate Heat-Exchanger Tube Rupture Scenarios Using Dynamic Simulation PDFZhen Kai OngNoch keine Bewertungen

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationVon EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNoch keine Bewertungen

- Joule-Thomson (JT) Assembly: Oil and Gas Process and Production EquipmentDokument2 SeitenJoule-Thomson (JT) Assembly: Oil and Gas Process and Production Equipmentpedro100% (1)

- Tube Rupture. Dynamic SimulationDokument5 SeitenTube Rupture. Dynamic SimulationAbbasNoch keine Bewertungen

- Process Isolation Guidelines - Refining, Hydrocarbons, Oil, and Gas - CheresourcesDokument5 SeitenProcess Isolation Guidelines - Refining, Hydrocarbons, Oil, and Gas - Cheresourcesjayrolling dollazNoch keine Bewertungen

- Kg-Tower ManualDokument5 SeitenKg-Tower ManualJohnny50% (2)

- ClydeBergemannSootblowers PrinceGeorge06Dokument36 SeitenClydeBergemannSootblowers PrinceGeorge06Arun YogaNoch keine Bewertungen

- Air Coolers Excerpt From Rules of Thumb For Chemical EngineersDokument3 SeitenAir Coolers Excerpt From Rules of Thumb For Chemical Engineershalder_kalyan9216Noch keine Bewertungen

- Unit Operations Thumb RulesDokument9 SeitenUnit Operations Thumb RuleshibhavuNoch keine Bewertungen

- Column Hydraulics NotesDokument4 SeitenColumn Hydraulics NotessatishchemengNoch keine Bewertungen

- PP Aaa PP1 122Dokument19 SeitenPP Aaa PP1 122Rabah AmidiNoch keine Bewertungen

- Vent Sizing Applications For Reactive SystemsDokument10 SeitenVent Sizing Applications For Reactive SystemsAritraDalalNoch keine Bewertungen

- Air Coolers Versus Shell-And-tube Water CoolersDokument8 SeitenAir Coolers Versus Shell-And-tube Water CoolersDefenceDog67% (3)

- STD 111Dokument25 SeitenSTD 111Sanjay Patel0% (1)

- TSP0013 Steam Tracing DesignDokument23 SeitenTSP0013 Steam Tracing DesignFabio TemporiniNoch keine Bewertungen

- Gas Dehydration (ENGINEERING DESIGN GUIDELINE)Dokument23 SeitenGas Dehydration (ENGINEERING DESIGN GUIDELINE)Tu Dang TrongNoch keine Bewertungen

- 4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDokument6 Seiten4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDavid VMNoch keine Bewertungen

- Indus - PGD Process Design EngineeringDokument2 SeitenIndus - PGD Process Design EngineeringAmarjeet SandhuNoch keine Bewertungen

- Aspen Simulation Workbook Webinar FAQDokument3 SeitenAspen Simulation Workbook Webinar FAQluaweb123Noch keine Bewertungen

- Mechanical RegulatorDokument12 SeitenMechanical Regulatorshashi chauguleNoch keine Bewertungen

- Optimizing Pressure Relief SystemsDokument6 SeitenOptimizing Pressure Relief SystemssgrsthNoch keine Bewertungen

- Structured Packing BrochureDokument12 SeitenStructured Packing BrochureMoad Bouzida100% (1)

- Piping Design Articles by Robert Kern PDFDokument53 SeitenPiping Design Articles by Robert Kern PDFDiego IQ100% (1)

- Design Requires A Systematic Methodology, Planning,: TechnicalDokument8 SeitenDesign Requires A Systematic Methodology, Planning,: Technicaladamaso09Noch keine Bewertungen

- Control Valve DPDokument8 SeitenControl Valve DPAmit SawantNoch keine Bewertungen

- E 106Dokument1 SeiteE 106Bith SMGNoch keine Bewertungen

- 2nd Part of CalculationDokument26 Seiten2nd Part of CalculationLohith NatarajNoch keine Bewertungen

- Overpressure and Vacuum Protection Challenges For Low Pressure and AtmosphericDokument14 SeitenOverpressure and Vacuum Protection Challenges For Low Pressure and AtmosphericHsein WangNoch keine Bewertungen

- Reboilers - Kettle Versus Thermosiphon DesignsDokument3 SeitenReboilers - Kettle Versus Thermosiphon Designschem_iaf100% (1)

- Reboiler HydraulicDokument3 SeitenReboiler Hydraulic54yreyeNoch keine Bewertungen

- CMPAPPP Separator Vessel and Filter Design GuideDokument18 SeitenCMPAPPP Separator Vessel and Filter Design GuideJWilson73Noch keine Bewertungen

- Process Basis of DesigneDokument14 SeitenProcess Basis of Designeamini_mohiNoch keine Bewertungen

- Section 06B - PumpsDokument62 SeitenSection 06B - PumpsRajesh KumarNoch keine Bewertungen

- High Integrity Protective SystemsDokument9 SeitenHigh Integrity Protective SystemsAbhiyan Anala ArvindNoch keine Bewertungen

- G3ir 1000 25 SP 9001 - R1Dokument72 SeitenG3ir 1000 25 SP 9001 - R1Ramu NallathambiNoch keine Bewertungen

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDokument7 SeitenOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- 8-0241-4503-Flare System Design PDFDokument8 Seiten8-0241-4503-Flare System Design PDFVinothrajaNoch keine Bewertungen

- Integrated NGL and LNG ProcessDokument16 SeitenIntegrated NGL and LNG ProcessD K SNoch keine Bewertungen

- Pressure Testing of Unfired Pressure Vessels: ScopeDokument9 SeitenPressure Testing of Unfired Pressure Vessels: Scopebenedicto soto mestanzaNoch keine Bewertungen

- GoyalDokument3 SeitenGoyalVan LeNoch keine Bewertungen

- Problem Is The Result of Industry 'S Move To Use Higher PressuresDokument2 SeitenProblem Is The Result of Industry 'S Move To Use Higher PressuresFadhliNoch keine Bewertungen

- CEeNews2 04Dokument6 SeitenCEeNews2 04Antonio MezzopreteNoch keine Bewertungen

- Saes L 140 PDFDokument13 SeitenSaes L 140 PDFsamsurendran_mech4020Noch keine Bewertungen

- Implement A Sustainable Steam Trap Management Program AicheDokument7 SeitenImplement A Sustainable Steam Trap Management Program AicheSai Praneethtej SaspretNoch keine Bewertungen

- UOP Proper Pretreatment Systems Reduce Membrane Replacements Improve Reliability Tech Paper PDFDokument18 SeitenUOP Proper Pretreatment Systems Reduce Membrane Replacements Improve Reliability Tech Paper PDFMuhammadIrsyadRNoch keine Bewertungen

- How To Design Piping For Reboiling SystemsDokument7 SeitenHow To Design Piping For Reboiling SystemsSalim YilmazNoch keine Bewertungen

- ValvesDokument27 SeitenValvesWade ColemanNoch keine Bewertungen

- Choosing Process Vaccum PumpsDokument8 SeitenChoosing Process Vaccum PumpsWade ColemanNoch keine Bewertungen

- Dry Vacuum PumpsDokument10 SeitenDry Vacuum PumpsWade ColemanNoch keine Bewertungen

- Vessels For High Pressure Dust CollectorsDokument4 SeitenVessels For High Pressure Dust CollectorsWade ColemanNoch keine Bewertungen

- Condensate Line SizingDokument2 SeitenCondensate Line SizingWade ColemanNoch keine Bewertungen

- Life Cycle AssessmentDokument10 SeitenLife Cycle AssessmentWade Coleman100% (1)

- Fermentation FundamentalsDokument5 SeitenFermentation FundamentalsWade ColemanNoch keine Bewertungen

- Construction Cost IndicesDokument1 SeiteConstruction Cost IndicesWade ColemanNoch keine Bewertungen

- Propylene Via Propane Dehydrogenation Chemical EngineeringDokument7 SeitenPropylene Via Propane Dehydrogenation Chemical EngineeringWade Coleman0% (1)

- HE Vibration AnalysisDokument8 SeitenHE Vibration AnalysisWade ColemanNoch keine Bewertungen

- Selecting The Proper Flare System PDFDokument6 SeitenSelecting The Proper Flare System PDFjdgh1986100% (1)

- HRSG Basics PDFDokument14 SeitenHRSG Basics PDFNimeshNoch keine Bewertungen

- Flooding & Pressure Drop GraphDokument1 SeiteFlooding & Pressure Drop GraphWade ColemanNoch keine Bewertungen

- Co2 CaptureDokument24 SeitenCo2 CaptureWade ColemanNoch keine Bewertungen

- Bayer ProcessDokument1 SeiteBayer ProcessWade ColemanNoch keine Bewertungen

- Piping Material Specification - EILDokument1 SeitePiping Material Specification - EILWade ColemanNoch keine Bewertungen

- MCB Plant Flash Steam RecoveryDokument1 SeiteMCB Plant Flash Steam RecoveryWade ColemanNoch keine Bewertungen

- ValvesDokument27 SeitenValvesWade ColemanNoch keine Bewertungen

- Nfpa24 2007Dokument56 SeitenNfpa24 2007José Luis Núñez GutiérrezNoch keine Bewertungen

- Pressure Swing Distillation ProcessDokument12 SeitenPressure Swing Distillation ProcessWade ColemanNoch keine Bewertungen

- Equilibrium Separation ColumnsDokument18 SeitenEquilibrium Separation ColumnsWade ColemanNoch keine Bewertungen

- Espiritualidad AFPP - 2018 PDFDokument5 SeitenEspiritualidad AFPP - 2018 PDFEsteban OrellanaNoch keine Bewertungen

- Polikanov 2019-05-14 Curriculum Vitae YuryDokument6 SeitenPolikanov 2019-05-14 Curriculum Vitae Yuryapi-460295531Noch keine Bewertungen

- How To Create Your Cosmetic Product Information FileDokument12 SeitenHow To Create Your Cosmetic Product Information Filewill100% (3)

- 5L ReductionsDokument20 Seiten5L ReductionsCarlos Javier Orellana OrtizNoch keine Bewertungen

- Injection MouldingDokument241 SeitenInjection MouldingRAJESH TIWARINoch keine Bewertungen

- UK FreshTECH Jammer RecipeBook 0Dokument24 SeitenUK FreshTECH Jammer RecipeBook 0Temet NoscheNoch keine Bewertungen

- PD 984Dokument38 SeitenPD 984mav3riick100% (2)

- 2022.08.09 Rickenbacker ComprehensiveDokument180 Seiten2022.08.09 Rickenbacker ComprehensiveTony WintonNoch keine Bewertungen

- Narrative ReporDokument3 SeitenNarrative ReporMARK LUKE ULITNoch keine Bewertungen

- MSU-Iligan Institute of TechnologyDokument5 SeitenMSU-Iligan Institute of TechnologyYuvi Rociandel LUARDONoch keine Bewertungen

- Gloria Pfoltzer Theresa Morris, an Infant, by Mother and Next Friend Christopher Morris, an Infant, by Mother and Next Friend Randy Morris, an Infant, by Mother and Next Friend v. Fairfax County Department of Human Development Susan Manzo Paulette Byrd Florence Hannigan, and Louis Villafane, 966 F.2d 1443, 4th Cir. (1992)Dokument10 SeitenGloria Pfoltzer Theresa Morris, an Infant, by Mother and Next Friend Christopher Morris, an Infant, by Mother and Next Friend Randy Morris, an Infant, by Mother and Next Friend v. Fairfax County Department of Human Development Susan Manzo Paulette Byrd Florence Hannigan, and Louis Villafane, 966 F.2d 1443, 4th Cir. (1992)Scribd Government DocsNoch keine Bewertungen

- For Hand Grip Strength: NormsDokument7 SeitenFor Hand Grip Strength: NormsPraneethaNoch keine Bewertungen

- Mobil Delvac 1 ESP 5W-40Dokument3 SeitenMobil Delvac 1 ESP 5W-40RachitNoch keine Bewertungen

- Quarterly Progress Report FormatDokument7 SeitenQuarterly Progress Report FormatDegnesh AssefaNoch keine Bewertungen

- Full Bridge Phase Shift ConverterDokument21 SeitenFull Bridge Phase Shift ConverterMukul ChoudhuryNoch keine Bewertungen

- Dam Lecture 14 - Design Criteria Earth DamsDokument4 SeitenDam Lecture 14 - Design Criteria Earth DamsCarolineMwitaMoseregaNoch keine Bewertungen

- Effect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventDokument8 SeitenEffect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventMega MustikaningrumNoch keine Bewertungen

- Kern County Sues Governor Gavin NewsomDokument3 SeitenKern County Sues Governor Gavin NewsomAnthony Wright100% (1)

- Capstone-ModDokument25 SeitenCapstone-ModMohammad Ryyan PumbagulNoch keine Bewertungen

- SET 2022 Gstr1Dokument1 SeiteSET 2022 Gstr1birpal singhNoch keine Bewertungen

- English Language Paper 1 - Answer KeyDokument5 SeitenEnglish Language Paper 1 - Answer Keybangtansone1997Noch keine Bewertungen

- Imagine Unit 1 P 10 11Dokument1 SeiteImagine Unit 1 P 10 11נויה לבדובNoch keine Bewertungen

- Roadmap Video: Answer KeyDokument4 SeitenRoadmap Video: Answer KeyMaria JuneNoch keine Bewertungen

- TC 000104 - VSL MadhavaramDokument1 SeiteTC 000104 - VSL MadhavaramMK BALANoch keine Bewertungen

- W2 - Fundementals of SepDokument36 SeitenW2 - Fundementals of Sephairen jegerNoch keine Bewertungen

- The Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayDokument356 SeitenThe Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayClinica MonserratNoch keine Bewertungen

- Chapter 11-15Dokument172 SeitenChapter 11-15Mansoor AhmadNoch keine Bewertungen

- TelfastDokument3 SeitenTelfastjbahalkehNoch keine Bewertungen

- DSM-5 Personality Disorders PDFDokument2 SeitenDSM-5 Personality Disorders PDFIqbal Baryar0% (1)

- Reference Document GOIDokument2 SeitenReference Document GOIPranav BadrakiaNoch keine Bewertungen