Beruflich Dokumente

Kultur Dokumente

Lot Inspection Report For LPG New Cylinders

Hochgeladen von

Jagannath MajhiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lot Inspection Report For LPG New Cylinders

Hochgeladen von

Jagannath MajhiCopyright:

Verfügbare Formate

BUREAU OF INDIAN STANDARDS

INSPECTION REPORT FOR NEW LPG CYLINDERS AS PER IS 3196(PT 1):2006

1. CM/L- No. :

Date :

Last Visit by : Date

M/s :

Person(s) :

Last Performance : Satisfactory / Not Satisfactory

2. Manufacturing activities being carried out at the time of visit (indicate by ) *

( ) Circle cutting ( ) Deep Drawing

( ) Bung Hole Punching ( ) Backing Strip Fitting

( ) Heat Treatment ( ) Hydrostatic Test

( ) Zinc Coating ( ) Painting

( ) Acceptance Test ( ) Burst Test

( ) Training ( ) Degreasing

( ) Bung Welding ( ) Circumferential Welding

( ) Pneumatic(1) Test ( ) Shot Blasting

( ) Valve Fixing ( ) Pneumatic(2) Test

( ) Other than Cylinder Manufacturing

3. Raw material Control ( since last visit )

a) Cylinder Body Steel ( Qty in no. of halves )

TISCO SAIL IMPORTED

A) Received B/F

B) Received ( Current)

C) Processed

D) Under Process

E) Used for B/S F/R

F) In Stock ( A+B) – (C+D+E)

Deshaped

b) Bung Test Certificate ( )

Inhouse Testing ( )

Change in Vendor ( )

Quantity ( )

Sc-F & Head(BHBO)

c) ERW Pipe Test Certificate ( )

Inhouse Testing ( )

Change in Vendor ( )

ISI marked Yes/No

Quantity ( )

d) Welding Consumables Test Certificate ( )

Inhouse Testing ( )

Change in Vendor ( )

Storing & Moisture ( )

Controlling ( )

e) Backing Strip/Foot Ring

4. Calibration Control :

Pressure Pyrometer Thread UTM Weighing Torque Others

gauges gauges Balance Wrench

5. INDEPENDENT TEST SAMPLE

a) Code d) Materials : IS 6240 Grade I

b) Batch e) Proposed Laboratory

c) Sl No.

f) Test Results of the Batch :

Yield Stress Elongation Ultimate Stress

Hoop Stress Expansion in HST

6. TEST WITNESSED

a) Acceptance Test d) Welding and Construction

Batch No Visual appearance of weld

Yield Stress,MPa Workmanship

Elongation, % Gap between ground and cylinder bottom

UTS, MPa

Macro examination e) Paint

Burst Pressure, MPa Thickness

Material Grade IS 6240 Grade I Appearance/Shade

Hoop Stress ,MPa

Expansion in HST, % f) Valve Fittings

Torque

b) Hydrostatic Test Gauging

Inside Cleaning

c) Pneumatic Test Pneumatic Test

BIS TEST AND INSPECTIONS

1. No. of Cylinders certified since last visit :

IOCL ________________ Freon 12 _______________ Others ________________

BPCL ________________ Freon ________________ RLHG __________________

HPCL ________________ TOTAL ______________________________________

2. No. of visits paid by inspecting officers :

3. Deficiency noted by IO yet to be resolved at the time of visit.

____________________________________________________________________________________

POINT FOR IMMEDIATE ACTION

____________________________________________________________________________________

POINT FOR IMPROVEMENT

____________________________________________________________________________________

OVERALL ASSESSMENTS

____________________________________________________________________________________

Use ( ) & ( * ) in appropriate box to indicate compliance and non-compliance if not specified.

Signature :

Name :

Designation :

Date :

-3-

Das könnte Ihnen auch gefallen

- Certificate of Origin Form F For China-Chile FTADokument2 SeitenCertificate of Origin Form F For China-Chile FTAinspectormetNoch keine Bewertungen

- Cold Tap Coating Report 2Dokument1 SeiteCold Tap Coating Report 2Jamal BakhtNoch keine Bewertungen

- Pt. Astar Testing & InspectionDokument2 SeitenPt. Astar Testing & InspectionSASINoch keine Bewertungen

- Procedure Qualification Record (PQR) FormDokument1 SeiteProcedure Qualification Record (PQR) FormEarl HarbertNoch keine Bewertungen

- T.C.L. Co. - Test & Control LaboratoriesDokument2 SeitenT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNoch keine Bewertungen

- Circularity Inspection Report: Shell Course (LW) CW CWDokument14 SeitenCircularity Inspection Report: Shell Course (LW) CW CWaszlizaNoch keine Bewertungen

- QAP For Conical StrainerDokument2 SeitenQAP For Conical StrainersatishchidrewarNoch keine Bewertungen

- TopCoreBelco 101 FCDokument9 SeitenTopCoreBelco 101 FCCesar ArellanoNoch keine Bewertungen

- PTS-1012 - RA Hardness Test ReportDokument1 SeitePTS-1012 - RA Hardness Test ReportPetrotrim ServicesNoch keine Bewertungen

- KBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3Dokument4 SeitenKBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3kamlNoch keine Bewertungen

- CV of Engineer MD Sazid Alam1Dokument8 SeitenCV of Engineer MD Sazid Alam1Alam MD SazidNoch keine Bewertungen

- Test Pack Clearance FormatDokument2 SeitenTest Pack Clearance FormatKarthikNoch keine Bewertungen

- Proposed WPS For API 5LDokument1 SeiteProposed WPS For API 5LMecon HyderabadNoch keine Bewertungen

- SA 387 Grade 91 Class 2Dokument4 SeitenSA 387 Grade 91 Class 2briang-2Noch keine Bewertungen

- Sample WPS 1Dokument13 SeitenSample WPS 1waqas pirachaNoch keine Bewertungen

- Astm A179 PDFDokument1 SeiteAstm A179 PDFgaminNoch keine Bewertungen

- SAIC-W-2078 Review PWHT Proc For TankDokument5 SeitenSAIC-W-2078 Review PWHT Proc For Tankkarioke mohaNoch keine Bewertungen

- Itp Electrical SwitchgearDokument4 SeitenItp Electrical SwitchgearpertmasterNoch keine Bewertungen

- Material Safety Data Sheet: Poly Cell AdhesiveDokument8 SeitenMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoNoch keine Bewertungen

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDokument9 Seiten2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNoch keine Bewertungen

- ITP For Piping SystemsDokument6 SeitenITP For Piping SystemsGia Minh Tieu TuNoch keine Bewertungen

- Roundness Before Weld TK012-strike 1Dokument2 SeitenRoundness Before Weld TK012-strike 1yuwantoniNoch keine Bewertungen

- Weld History SheetDokument2 SeitenWeld History SheetAjin S100% (1)

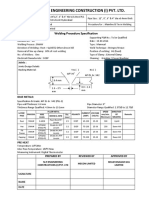

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDokument1 SeiteWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNoch keine Bewertungen

- Hardness Pro Form1Dokument2 SeitenHardness Pro Form1gst ajah100% (1)

- Welding Procedure Specification For GTAWDokument9 SeitenWelding Procedure Specification For GTAWraja reyhanNoch keine Bewertungen

- DVS 2207-3Dokument12 SeitenDVS 2207-3gura9054Noch keine Bewertungen

- F-035 (Valve Erection Format)Dokument1 SeiteF-035 (Valve Erection Format)Rajeev Kumar100% (1)

- Welding Procedure Specification (WPS) : in The Outer TubeDokument1 SeiteWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNoch keine Bewertungen

- Nde-1711-T393-F0005 Annular To Bottom Plate JointDokument1 SeiteNde-1711-T393-F0005 Annular To Bottom Plate Jointdada khalandar100% (1)

- Pretest Piping Punch List (Empty)Dokument1 SeitePretest Piping Punch List (Empty)Jorge GarciaNoch keine Bewertungen

- Plant Inspections PDFDokument5 SeitenPlant Inspections PDFMohamedNoch keine Bewertungen

- PWHT Procedure For Petrol Steel - CoreDokument9 SeitenPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluNoch keine Bewertungen

- Course Outline Cswip 3.1 PDFDokument2 SeitenCourse Outline Cswip 3.1 PDFdanghpNoch keine Bewertungen

- TDC 004 CS Fittings r0Dokument1 SeiteTDC 004 CS Fittings r0samkarthik47Noch keine Bewertungen

- (Painting Works) : Inspection and Test PlanDokument2 Seiten(Painting Works) : Inspection and Test Planrize1159Noch keine Bewertungen

- QA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsDokument1 SeiteQA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsvinothNoch keine Bewertungen

- WPS & SmawDokument12 SeitenWPS & Smawnuke apriyaniNoch keine Bewertungen

- Acceptance Criteria Asme B31.3 PDFDokument1 SeiteAcceptance Criteria Asme B31.3 PDFAhmad RizkiNoch keine Bewertungen

- Safe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallDokument1 SeiteSafe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallHarun AkkayaNoch keine Bewertungen

- Ug PipingDokument1 SeiteUg PipingVinoth KumarNoch keine Bewertungen

- N0200003 - NEW-F201-0 - Inspection & Test PlanDokument3 SeitenN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNoch keine Bewertungen

- PQR - PipeDokument3 SeitenPQR - PipeAdvanced Quality Centre AQC100% (1)

- Epilux 610 HBLD Primer Coating: Resistance Guide Product DataDokument2 SeitenEpilux 610 HBLD Primer Coating: Resistance Guide Product DataBijaya RaulaNoch keine Bewertungen

- Hydro TestDokument1 SeiteHydro TestMilan BanerjeeNoch keine Bewertungen

- Table - Qw-416 Welding Variables For Welder PerformanceDokument1 SeiteTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- QAP CondenserDokument3 SeitenQAP CondenserisaacNoch keine Bewertungen

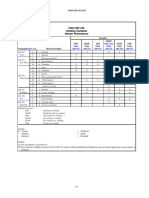

- Welding Report For Tank 1Dokument1 SeiteWelding Report For Tank 1Rifki HasyaNoch keine Bewertungen

- Coke Crusher - Lubrication Pumps Run in TestDokument26 SeitenCoke Crusher - Lubrication Pumps Run in TestsayedNoch keine Bewertungen

- Gate & Globe PDFDokument0 SeitenGate & Globe PDFZoebairNoch keine Bewertungen

- How To Calculate Hydrostatic Test Height in TanksDokument4 SeitenHow To Calculate Hydrostatic Test Height in TanksEric MagnayeNoch keine Bewertungen

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDokument4 SeitenProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNoch keine Bewertungen

- SS Pipe Welding ProcedureDokument5 SeitenSS Pipe Welding Procedureamit rajputNoch keine Bewertungen

- Approved Itp-Dss - 28 Sep 2016Dokument4 SeitenApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNoch keine Bewertungen

- Checklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSDokument1 SeiteChecklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSRizqiNoch keine Bewertungen

- Reference Manufacturing Quality Plan: For NTPC Use Review Ed by Approved byDokument4 SeitenReference Manufacturing Quality Plan: For NTPC Use Review Ed by Approved byNaresh RajuNoch keine Bewertungen

- Jash Engineering LTD.: Quality Assurance PlanDokument3 SeitenJash Engineering LTD.: Quality Assurance PlanShree ConstructionNoch keine Bewertungen

- Saudi Pipe System Co.: Glass Reinforced Pipe DivisionDokument8 SeitenSaudi Pipe System Co.: Glass Reinforced Pipe DivisionNADEEM AHMEDNoch keine Bewertungen

- Tech Specification For Civil WorkDokument97 SeitenTech Specification For Civil Worksndakshin@gmail.comNoch keine Bewertungen

- Field Qulity Plan: 1. Chemical TestDokument3 SeitenField Qulity Plan: 1. Chemical TestVinoth Kumar RavindranNoch keine Bewertungen

- PM IS 4246 2 (Title)Dokument1 SeitePM IS 4246 2 (Title)Jagannath Majhi100% (1)

- PM/ IS 4246/2/ May 2019 Annex - A: The Above List Is Indicative Only and May Not Be Treated As ExhaustiveDokument1 SeitePM/ IS 4246/2/ May 2019 Annex - A: The Above List Is Indicative Only and May Not Be Treated As ExhaustiveJagannath MajhiNoch keine Bewertungen

- PM IS 4246 2 (Scope) PDFDokument1 SeitePM IS 4246 2 (Scope) PDFJagannath MajhiNoch keine Bewertungen

- Bureau of Indian Standards: Please See Annex BDokument1 SeiteBureau of Indian Standards: Please See Annex BJagannath MajhiNoch keine Bewertungen

- Ispat ExpressDokument1 SeiteIspat ExpressJagannath MajhiNoch keine Bewertungen

- Registration Funpy36vDokument1 SeiteRegistration Funpy36vJagannath MajhiNoch keine Bewertungen

- Fil Ntra:l L6lna:ro: of :conoa: Ouia:tion, LlfiDokument1 SeiteFil Ntra:l L6lna:ro: of :conoa: Ouia:tion, LlfiJagannath MajhiNoch keine Bewertungen

- CM PF 311 Acceptance of Rate of Marking FeeDokument1 SeiteCM PF 311 Acceptance of Rate of Marking FeeJagannath MajhiNoch keine Bewertungen

- Periodic Inspection Report For LPG CylindersDokument9 SeitenPeriodic Inspection Report For LPG CylindersJagannath MajhiNoch keine Bewertungen

- Receipt of SamplesDokument1 SeiteReceipt of SamplesJagannath MajhiNoch keine Bewertungen

- CM PF 310 Acceptance of Scheme of Testing and InspectionDokument1 SeiteCM PF 310 Acceptance of Scheme of Testing and InspectionJagannath Majhi100% (1)

- Proforma For Hygienic Conditions Periodic InspectionDokument2 SeitenProforma For Hygienic Conditions Periodic InspectionJagannath Majhi50% (2)

- Hygienic Condition InspectionDokument14 SeitenHygienic Condition InspectionjoechengshNoch keine Bewertungen

- CM PF 307 Brand NameDokument1 SeiteCM PF 307 Brand NameJagannath Majhi100% (3)

- CM PF 260 Discrepancy-Variation ReportDokument1 SeiteCM PF 260 Discrepancy-Variation ReportJagannath MajhiNoch keine Bewertungen

- CM PF 299 Contact ReportDokument1 SeiteCM PF 299 Contact ReportJagannath MajhiNoch keine Bewertungen

- CM PF 305 Manufacturing Machinery Declaration FormDokument2 SeitenCM PF 305 Manufacturing Machinery Declaration FormJagannath MajhiNoch keine Bewertungen

- CM PF 306 Test Equipment Declaration FormDokument2 SeitenCM PF 306 Test Equipment Declaration FormJagannath Majhi100% (1)

- CM PF 201 Preliminary Inspection ReportDokument5 SeitenCM PF 201 Preliminary Inspection ReportJagannath MajhiNoch keine Bewertungen

- CM PF 251 Periodic Inspection ReportDokument10 SeitenCM PF 251 Periodic Inspection ReportJagannath MajhiNoch keine Bewertungen

- BIS Application FormDokument15 SeitenBIS Application FormJagannath Majhi80% (5)

- Audit Certificate: (On Chartered Accountant Firm's Letter Head)Dokument3 SeitenAudit Certificate: (On Chartered Accountant Firm's Letter Head)manjeet mishraNoch keine Bewertungen

- Chapter 5Dokument3 SeitenChapter 5Showki WaniNoch keine Bewertungen

- TEVTA Fin Pay 1 107Dokument3 SeitenTEVTA Fin Pay 1 107Abdul BasitNoch keine Bewertungen

- 06-Apache SparkDokument75 Seiten06-Apache SparkTarike ZewudeNoch keine Bewertungen

- HRO (TOOLS 6-9) : Tool 6: My Family and My Career ChoicesDokument6 SeitenHRO (TOOLS 6-9) : Tool 6: My Family and My Career ChoicesAkosi EtutsNoch keine Bewertungen

- The Art of Blues SolosDokument51 SeitenThe Art of Blues SolosEnrique Maldonado100% (8)

- Production - The Heart of Organization - TBDDokument14 SeitenProduction - The Heart of Organization - TBDSakshi G AwasthiNoch keine Bewertungen

- Social Media Marketing Advice To Get You StartedmhogmDokument2 SeitenSocial Media Marketing Advice To Get You StartedmhogmSanchezCowan8Noch keine Bewertungen

- Audit On ERP Implementation UN PWCDokument28 SeitenAudit On ERP Implementation UN PWCSamina InkandellaNoch keine Bewertungen

- Efs151 Parts ManualDokument78 SeitenEfs151 Parts ManualRafael VanegasNoch keine Bewertungen

- Laporan Praktikum Fisika - Full Wave RectifierDokument11 SeitenLaporan Praktikum Fisika - Full Wave RectifierLasmaenita SiahaanNoch keine Bewertungen

- 21st Bomber Command Tactical Mission Report 178, OcrDokument49 Seiten21st Bomber Command Tactical Mission Report 178, OcrJapanAirRaidsNoch keine Bewertungen

- Research Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNADokument10 SeitenResearch Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNAAnonymous cgcKzFtXNoch keine Bewertungen

- Richards Laura - The Golden WindowsDokument147 SeitenRichards Laura - The Golden Windowsmars3942Noch keine Bewertungen

- Sourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyDokument58 SeitenSourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyAlaa Al HarbiNoch keine Bewertungen

- Linux For Beginners - Shane BlackDokument165 SeitenLinux For Beginners - Shane BlackQuod Antichristus100% (1)

- Methodical Pointing For Work of Students On Practical EmploymentDokument32 SeitenMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavNoch keine Bewertungen

- Forecasting of Nonlinear Time Series Using Artificial Neural NetworkDokument9 SeitenForecasting of Nonlinear Time Series Using Artificial Neural NetworkranaNoch keine Bewertungen

- 48 Volt Battery ChargerDokument5 Seiten48 Volt Battery ChargerpradeeepgargNoch keine Bewertungen

- Rofi Operation and Maintenance ManualDokument3 SeitenRofi Operation and Maintenance ManualSteve NewmanNoch keine Bewertungen

- Information Security Chapter 1Dokument44 SeitenInformation Security Chapter 1bscitsemvNoch keine Bewertungen

- Load Data Sheet: ImperialDokument3 SeitenLoad Data Sheet: ImperialLaurean Cub BlankNoch keine Bewertungen

- Ajp Project (1) MergedDokument22 SeitenAjp Project (1) MergedRohit GhoshtekarNoch keine Bewertungen

- Innovations in Land AdministrationDokument66 SeitenInnovations in Land AdministrationSanjawe KbNoch keine Bewertungen

- SBL - The Event - QuestionDokument9 SeitenSBL - The Event - QuestionLucio Indiana WalazaNoch keine Bewertungen

- Ces Presentation 08 23 23Dokument13 SeitenCes Presentation 08 23 23api-317062486Noch keine Bewertungen

- Shubham RBSEDokument13 SeitenShubham RBSEShubham Singh RathoreNoch keine Bewertungen

- Group 1 Disaster Management Notes by D. Malleswari ReddyDokument49 SeitenGroup 1 Disaster Management Notes by D. Malleswari Reddyraghu ramNoch keine Bewertungen

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Dokument3 SeitenAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariNoch keine Bewertungen

- Financial Derivatives: Prof. Scott JoslinDokument44 SeitenFinancial Derivatives: Prof. Scott JoslinarnavNoch keine Bewertungen