Beruflich Dokumente

Kultur Dokumente

How To Make A Solar Still PDF

Hochgeladen von

Luis MartinezOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

How To Make A Solar Still PDF

Hochgeladen von

Luis MartinezCopyright:

Verfügbare Formate

----I

STEANNE

DE BELEVUE CANADA

800

QUEBEC,

HOWTO MAKE A SOLAR STILL (PLASTIC COVERED)

FOREWORD A solar still is a simple device brackish,polluted or other water into saple--basically The latter water permits plastic

long-term

which can be used to convert drinking water, Its function is enclosed by a transparent the enclosure,

saline, is very cover.

a pan of impure water solar energy within evaporation cover, and condensation water

traps

This heats up the face of the sloping potable, primarily unit This a that as leaflet out of

causing

on the inner is generally unit,

transparent

This distilled It

HOweveX,

the user to make a relatively sheets and brick, used for installation, this

inexpensive plastic

is not what might be reconunended for covered It installation. principles should

can certainly be stressed material

be adequately possible while

temporary

the user should use as much flexibility not changing the general

and adaptation

of local

of the operation.

INTRODUCTION The availability construct solar and in any sunny area, of modern engineering equipnent solar where good drinking materials sizes costs water makes it at relatively worth designs operate of ior possible to distillation in large distillation low cost,

more than about

W.S.)$5.00 per 1,000 gallons, consideration, The description solar distillation anywhere producing equipment, from l-gallon

is certainly

given below represents

one of many possible of being per day, and will

No auxiliary

It has the advantage to 1,000 gallons

suitable

for units power and no site

long periods in isolated source is needed, other levelling is necessary, In hot dry areas, between one half ARRA OF SOLAR STILL

locations without attention. than means for feeding water

into

the unit,

each square quarters

foot pound

of area in a solar distilled so that, water generally

still daily,

will speaking, of water quantities

produce upon about daily.

Of

and three still

depcndinq

the time of year and amount of cloud 12 sq. ft. pure water, -lof solar Hence relatively large

cover,

area are needed to produce areas are needed to produce

one gallon significant

DESCRIJTION OF SOLAR STILL (see.Fig.

1)

Fig. 1 shows a cross-sectional view through a solar still that incorporates a black plastic water tray and a transparent plastic cbv@r, galvanized steel guttering and concrete or brick side and end walls. The width is chosen to suit the width of the transparent plastic cover material, usually available in rolls 6 ft. wide, The length can be al.ything from a few feet to several hundred feet, Orientation of the still is of no great importance, although obviously land sloping gently down towards the equator is best. The is run down or across the natural slope of long dimension of the still the land, The impure water is introduced in a slow steady stream at the high end and a small overflow at the ?.ow end carries away the remaining of salts in the unit. salts. Thus there is never any crystallization Small sand mounds beneath the bottom plastic liner create a series of impounding dams down the slope, DEPTH OF WATER The depth of water that is evaporated each day is about l/8 inch, so nowhere should the water in the tray be less than about t inch deep. The maximum desirable depth is 1 inch. COLLECTION OF CONDENSED WATER The condensed water droplets run down the underside of the transparent plastic cover into the side trough and then flow downhill to This tank can be a staled be stored in a suitable tank or reservoir, spiggot for drawing off plastic bag lying on the ground, with a suitable the water when needed, The storage tank could also feed directly into animal drinking troughs with float control. MATERIALS OF CONSTRUCTION Most of the parts of the still are made from materials which are only a small number of parts, which locally available in rural arid areas, are needed to give the still a good output and to prevent corrosion, must These are both cheap and easy to transport. A be imported into the area, materials list is given at the back of this leaflet, The foundations are two strips of concrete 9 inches ,.:de, 3 inches deep and 100 feet long, The bed of the salt water pond is simply levelled ground. The side and end walls do not need to be strong and can be made Concrete block or pre-cast from local unburnt sun dried brick (adobe). Wood should not Concrete sections may be cheaper for large installations, be uL"d because of possible termite attack, but the roof support props (items 16, 17) may be made frcan wood as they stand in the water. The beds of the side gutters to collect the fresh water are made from galvanized steel sheets (Item 10). Other small items from galvanized steel are the two turnbuckles (7) for tightening the roof suspension cable, the six anchor posts (8) for holding the roof cable and the nails (9) for pinning the guttering to the concrete foundation.

_' d'

-2-

,,

.,,

_--

,,v/--

mr7

--__

,l~i

T)~-

._

~.

,,.,

~~ .,,7.$

-~-y-F?-

-._

1,

(I,

<..

(,,;

,_j

, ..

The made from should be Two types

items which may have to be specially brought into the area are plastic, The first is the transparent cover material, which of plastic sheeting, 0,010 inch thick, (See Item 1, materials list) which are suitable and relatively inexpensive are:

(1) ultra-violet resistant polyethylene sheet such as that developed for the greenhouse industry and fabricated by the principal chemical companies, e.g. Union Carbide, Canadian Industries Ltdi, etc. Please bear in mind.that this sheet will prcbably not last The cost more than 6 months to 1 year in a very sunny region, Hence this unit will is of the order of $0.02 per square foot. be suitable to cover installations that are only used seasonally, It would be necessary to replace say 3 to 6 months of the year. the cover every season, (2) ultra-violet resistant transparent polyvinyl as that made by B,F, Goodrich Co,This will chloride shttt such probably last 2 to 4 Y@WS-

: 0

The plastic water tray and side liners (Items 2,3,4) should be made of 0,010 inch thick black polyethylene film, This is made by a number of different manufacturers in several countries. Polyethylene sheet is by no means the best liner material but it is inexpensive and in this regard it can be used for temporary installations of this nature, It would of course, be preferable for more permanent installations to use butyl rUbber sheet such as that manufactured by the Miner Rubber Co, of Granby, Qu&tc, Canada. The total cost of Items 2,3,4 is under U.S. $23, for each still, The salt water inlet and fresh water outlet pipes (Item 5) should be one half inch diameter heavy duty polyethylene hosepipe which is generally available and costs about $0.15 (U.S.) per foot, The plastic Galvanized sheet roof is held up by a stretched steel wire (Item 6). Steel wire (1000 lb, breaking strength) may be used for cheapness but will have a short life due to corrosion. The best material is the stainless wire used by fishermen (1000 lb, breaking strength) which Costs about $2 .OO (U.S,)for the 120 feet length needed for the still. A better alternative is plastic covered galvanized steel wire which is used to make gabions for control of sea beach erosion, Thie is made by the and is marketed in many countries Maccaferri Organization, Bologna, Italy, by River and Sea Gabions (London) Ltd., Engliind, They supply plastic covered galvanized steel wire, 15 metric gauge,0,0945 inches diameter, in The 120 feet length of wire needed for rolls weighing 70 kg. (154 lbs,). one still costs about $1.50 (U.S.) and one roll is enough for about 45 stills. THE TRANSPARENTCOVER I Select the transparent sheet compatible with the installation you have of the in mind, as outlined earlier, It is important to check the lifetime plastic under the severe conditions of exposure that prevail in this application, The plastic sheet will not last indefinitely, but the still design is such as to permit its replacement with relative ease, whenever necessary. Plastic sheet is not normally wettable so, unless the underside is pretreated, the condensing water will tend to fall back into the brine rather than run down the film into the fresh water troughs at the edges. -3-

This treatment is not very complex. It involves merely roughening the underside by carefully scratching with a very fine grit of wettable sandpaper. This treatment creates a network of very fine scratches on the surface, and is best carried out before construction of the still commences, The film should be wet sanded while being removed from its original roll, being transferred to a second roll in the process. Srnd in one direction only - along the width of the plastic film. The wet sanding need not be carried to the extreme outer edges of the plastic; a 4 inch to 6 inch strip on each edge should be left tnsanded, It must be remembered that sanding will weaken the film, Hence it is recommended to use 0,010 inch thick film so that it can withstand stress, On the other hand, there are certain wetting agents One that are reputed to cause filmwise condensation on plastic sheets. of these is called Sun Clear and is manufactured by Solar Sunstill Inc., Setauket, New York 11733, U.S.A. One of the most difficult facets of this entire process is producing the wettable surface on the plastic film, If a wetting agent is used successfully, then there is no harm in using a thinner film such as 0,004 to 0,006 inches thick, FOr plastic Current prices see materials list given at the back of this leaflet, STEPS IN CONSTRUCTION STILL OF (1) Choose a suitable site, preferably along the side of an existing fence that is on ground sloping gently towards the equator. Allow 6 ft. clearance to the fence, Remove all bushes and large stones, also smooth any gross irregularities, The site should not be shaded from 0800 hrs, to 1600 hrs, (2) Dig two trenches for the foundation about 3 inches deep and 9 inches wide, Dig similar The trenches should be 4 ft. apart, trenches for the two end walls, (3) Cast the concrete foundation (mix 8 : ?1 : 1 stone: sand:cement). The top of the concrete must not be levelled into steps, as is usual when building walls, but must slope generally the same as the terrain and must be free of humps and dips, the two concrete foundat ims, Ideally, one along each side, should be perfectly parallel with each other. (4) Remove all grass and 4 inches of soil from between the concrete footwalls, Replace with an equal volume of sand, Spray with a powerful grass killer and insecticide to prevent subsequent root growth under the still and insect damage to the plastic, (5) Lay the 6 ft. lengths of galvanized steel guttering on the concrete footwall, pinning to the concrete with short nails, if necessary. The This is best done on the day after the concrete footwall is laid. It would guttering along the two footwalls should be exactly 4 ft. apart. be better, This, of if available to utilize asbestos cement stripping. course, would be far more difficult and costly to attach to the concrete footings, but it would not deteriorate which is unfortunately the case with the galvanized strip, Pieces of asbestos stripping could be used and attached onto the short vertical wall of the concrete foundation or, better still, cast directly into the footing, (6) Lay the first row of bricks on the footwall, bedding firmly in mortar (mix 6 : 1). These bricks should rest partly on top of the

-4-

I '-

PI . I

I ,.: ,v

The top of the bricks should and should be 4 ft. 4 in. apart, guttering, slope towards the inside to facilitate drainage, the outer edge being about t inch higher ,than the inner edge. (7) Build a series of earth mounds across the space between the guttering, so as to make a series of dams to impound the water? The mo*nds should be built almost up to the level of the top edge of the guttering, but with one low spot to create an overflow weir about )s Level the sand inch below the level of the top edge of the guttering, il both directions between the footw;llls and the earth mounds, (8) Build the end walls, with the ridge point being about 16 inches above the footwall, In the end wall at the high end of the still, build into the wall a short length of 4 inch polyethylene hose-pipe; for the salt water feed, This pipe should be about 6 inches above the foundation. In the end wall, at the low end of the still, leave a 3 inch square opening opposite each of the two gutters, and another near the middle. These openings should be immediately above the concrete foundation so that, when the polyethylene liners are eventually laid, the overflow water can be guided through these openings, (9) Lay the 18 in. wide black polyethylene plastic along each side wall, tucking it down into the guttering so as to form a waterproof liner to carry the distilled water down to the bottom drain holes. Fit plastic elbows and nipples with suitable nuts and washers to form Attach polyethylene w"etertight distillate and drain exits*,* (See Fig, 1). tubing to carry distilled water to a storage reservoir, (10) Starting at the low end of the still lay the 8 ft. wide black polyethylene liner, carefully folding it up and over the g-uttering on top of the first liner, This liner must be loosely laid, Water should be led into each dam as the liner is laid, to ensure that the entire width of the still is covered with water and that the earth mounds are adequate to impound the water, (11) Cut sections of 4 inch rigid polyethylene tubing llr inches long; split the piece lengthwise on one side and clamp over the plastic liners covering the guttering strip. This should keep the liners in placd, (12) Place the stainless steel ridge-wire threaded through the polyethylene tubing (Item No, 18) in place with firm anchors at each end as shown in Fig, 2, (13) Place the support props in position, being particularly careful These supports should be placed not to puncture the plastic liner. roughly every 8 to 10 feet so as to prevent any severe sagging of the gabion wire. It would be wise to attach the wire to the top of the A-frame prop. This could be fixed in place with some plastic sheeting. One suitable way of building these A-frames has been to make them of wood, treat them against rot in humid atmospheres, and then cover them with The pad plastic sheets, This would at least extend their life somewhat. resting in the distillate gutter should be firmly wedged against the brick wall, This pad should be encased in black polyethylene sheet so as to prevent its deterioration by the distillate water, The A-frame should be built as solidly as possible as this will be the basis of the support of the transparent cover, The angle of the A-frame with the horizontal should be between 15 and 20 degrees, (14)In order to ensure that the condensed water droplets on the inside of the plastic sheet tent cover fall directly into the guttering, *Build earth mounds every lo to 12 feet, ** Fit plastic elbows, nipples etc. only after completing step 10. - 5 -

cast a lt inch semi-circular cement lip (2 to 1 sand, cement mix) on the underside of the retaining bricks, (See Fig. 3). There should be at least 1 inch clearance between the base of the lip and the top of the guttering strip, (15) Unroll the plastic sheet tent cover pinning it to the lower end wall with suitable straps. Open the entire length of plastic sheet using bricks temporarily placed on the side walls to keep it in position. ':e sure that the roughened surface of the plastic sheet is on the underside, when the plastic sheet is correctly positioned it can be firmly fixed along both edges by two work crews working opposite each ather, starting from the lower end. This is done by stretching the plastic sideways and pinning into the mortar between the bricks of the lower brick layer, using large-head 1 inch galvanized nails. The top weighting bricks should be placed in position before the pinning nails are driven in, If the weighting bricks are very rough, they are likely to cut the plastic sheet unless lined, The 15 inch wide roll of black polyethylene plastic must be used for lining the top bricks. A second layer of weighting bricks might have to be placed on top of the first layer, to be sure that the wind will not cause the flapping plastic sheet tent to work loose, While the plastic sheet is being installed, it keep the still filled with water in order to prevent the inner liner, is advisable overheating to of

Finally the plastic sheet tent should be stretched and fixed to the outer edge of the footwalls with aluminum strips secured by screws, (16) Rain water should be allowed to drain off the tent at intervals along the length of the unit, so as not to cause the plastic to sag in heavy rain storms, This is best done by leaving a spacing of a few inches between each adjacent block at the lower end of the still, (17) Storm water should be kept away from the still because moisture in the soil beneath the tray will greatly increase the loss of -5 heat through the bottom, (18) The still area should be fenced to keep animals out. Since excess wind can reduce the output of water, low windbreaks, such as uncut grass one or two feet high aroundthe still should be encouraged, OPERATION OF THR STILL Other than to ensure a regular supply of water to the tray, the still requires no attention, If sea water is being used, it is important that the concentrated brine be flushed out daily, so as to prevent salt deposition in the tray, The flushing operation is best started at dawn, and should iast only about one hour, It is sufficient to add twice as much makeup waLer each day, as is produced as fresh water, allowing the excess to drain away from the lower end of the still. Alternatively, if the still is to operate without daily attention for flushing, the excess Salts can be flushed away by providing a slow steady feed of the salt water all day and night, The feed rate should be adjusted so that the overflow from the bottom end will just cease in the middle of the afternoon when evaporation is greatest, A steady glow of 2 to 3 gallons per hour would

-6-

---

It may be necessary to add be suitable for this 100 ft. long still, small quantities of acid to the still to prevent the formation of In this case, keeping the pH of the still scale within the basin, about 6 should prevent all possibility of scale formation, DISTILLED WATERFOR CAR RATTERlES usually costs about 10 U.S. Distilled water for car batteries Since solar stills produce distilled water for about cents per gallon. one tenth of this cost, small solar stills should find wide use on farms and at service stations Igarages). TOTAL COST OF THE STILL Representative figures for the cost of the materials for the still The total cost of are given in the last column of the Materials List, materials is the local currency equivalent of about U.S. $228. The cost of the labour to construct the still will vary widely with location, but will probably be of the same order as the materials cost. The completed still of 400 square feet active area will therefore cost that is at a rate of U.S. $1.10 per square about U.S. $450, equivalent, foot, Of the total cost, only one quarter part, that is the U.S. $100. Many of the to pay for Items 1 to 6, may require foreign exchange. other items may be improvised using suitable substitutes of locally This still has therefore potential application available materials, The capital cost is about U-S ,$ll, per imperial in many countries. gallon per day output, which is competitive with other small distillation plants. The solar still, however, has the great advantage that at least three quarters of its cost is composed of local labour and materials, whereas mechanical distillation plants have to be imported from abroad. Even on a strict economic basis the still should pay for itself within a period of five years,

It is recommended that persons intending to build these units make use It is essential that they adhere to of this brochure as a guide only, the principle of the operation involved, However, they must show as much flexibility as possible in actually effecting any installations as to the The application of this adaptation and use of locally available materials, plastic covered still would be best for temporary, semi-permanent installations, due to the very nature of the materials involved which occasionally need renewing, If indeed a permanent installation is required In this case please then a glass-covered still would be recommended, contact this Institute and order the following publications: (see following page)

-7-

T.17 T.58 I.66 I.67

Simple Solar Still for the Production of Distilled Water, by T.A. Lawand, 6 p., September 1967, Price - $0.75 Plans for a Glass and Concrete Solar and R. Alward, 9 p., December 1968, Still, Price T.A. - $3.00

by

Lawand

Some Notes on the Construction Cost of Auxiliaries for the by R, Alward, 10 p,,,March 1970. Price - $0.50 Haiti Solar Still, Installation of a Solar Distillation Plant on 110 de la Gonave, Haiti, by R. Alward; May 1970, Price - $0-50

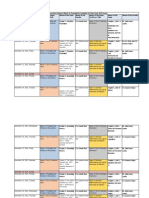

PRICE RANGE OF DIFFERENT Approximate Prices Film

THICKNESSES OF PLASTIC FILM $U,S, per square foot ' Thickness 0,004g@(4 mil) of Film 0.006" (6 mil) 0.010" 0.025 (10 mill

Ultra-violet polyethylene Ultra-violet polyvinyl

resistant, resistant, chloride

transparent transparent

0.015

0.020

0,045

0.070

0.115

-8-

MATERIALS LIST FOR 400 SQ, FT, STILL ITEM 1 2 3 4 5 DESCRIPTION Transparent Plastic Plastic liner Plastic liner Brine outlet salt trough plastic roof MATERIAL ultra-violet polyvinyl black black black resistant chloride film film film film DIMENSIONS 0,010 in. 100 ft. 0.010 in, 100 ft. 0.010 in. 100 ft. 0,010 in. 100 ft. thick, thick, thick, thick, 6ft. 10 ft. 18 in, 15 in, x x x x one piece

one

PRICE 66.00 15.00 3.60 3.75 7.00

pond liner (lower) (upper) water

polyethylene polyethylene polyethylene

piece

two pieces two pieces nineteen pieces

side wall

inlet and fresh pipes

polyethylene hosepipe, clips and fittings

+ in, dia. x 14 ft. long, stainless steel clips, plastic elbows, nuts and washers 120 ft. long

Roof suspension

wire

stainless steel wire, 1000 lb. breaking strength or gabion wire galvanized steel steel

one piece

2.00

7 8 9 10 11 12 13 14

Cable turnbuckles Anchor posts Nails Steel to pin guttering guttering

t in. x 4 in. 4 ft. (clouts) 1 in, head long long, large flat

two pieces six pieces 500 pieces 40 pieces 150 pieces 6 bags 6 cu. yds. 2 cu. yds.

4.00 9.00 .50 21.20 18.00 0.30 16.00 7.00

fence posts steel steel blocks

galvanized galvanized concrete foundations foundations sand graded local

26 gauge, 3 in. x 3 in. right angle, 6 ft. long 4 in, 94 lb. x 8 in. bags x 16 in.

Wall bricks Cement Sand Stone

and basin stone

-9-

Table ITEM 15 16

continued DESCRIPTION aas wfite paint prop to hold up

(brace)

MATERIAL

DIMENSIONS

QUANTITY lpint

PRICE 1.70

A-frame wire A-frame A-frame

wood or other material

suitable

1s in,

x 1% in.

x 28zi.n.

22 pieces

foot

pad polyethylene polyethylene Gramevin-Fenac Type

lf x lt x 16 in. + in. x 24 in. x 9 in. 0.010 in. thick I.D., 5/16 in,

11 pieces 22 pieces

20 sq,

6.00

17 18 19 20 21 22 23 24

plastic sheet needed for covering for A-frames Tubing for wire

ft.

0.30

3/16 in. sufficient applications 11 in. l/16 in.

O-D, 100 ft.

8.00 8.30

Weedkiller Sandpaper Transparent attachment Screws Guttering End doors attachments roof

for multiple wide x 6 ft. 14 sheets 36 pieces 1 gross 60 pieces 3 pieces

NO. 180-C-W 661~

long x 9 in. x 3/4 in,

1.80 16.00

2.00

aluminium

strips

No, 7 - 1 in. plastic plywood hose clips

aluminum dia.,

lf in, long - f in, rigid plastic hose Ja in. thick, 4 ft.

1.00

2.00

TOTAL U,S.$228.45 It must be appreciated that this price list has been prepared using locally West Indies. Basically however, these prices should not differ substantially elsewhere. It should therefore only be used as a guide. available costs in the from those encountered

- 10 -. . .

'LASTIC ELBOW DRAIN AND DISTILLATE CONNECTIONS

TRANSPARENTCOVERSUPPORTED BY A- FRAME PROP

---

-.o

FIG No 1 - CROSS SECTION OF THE SOLAR STILL

FIG.2 GENEiCAL~ VIZd OF SOLAR STILL

, * .

A-FRAME

PROP FOR COVER

TRANSPARENT

,PLASTIC

SHEET

CONCRETELIP

fUPPER LINER TRANSPARENT PLASTIC COVERSCREW ALUMINUM OR ;LOWER LINER BLACK PLASTIC UNER -~ --~ zc LmER ~_ ____ ~ _ _ __ & 7

-4

II

,-SALINE WHITE PAINI?

WATER

.). 0

c). .a ._* _ . _ _. GALVANIZED SECTION FOR DISTILLATE

TROUGH

CONCRETE

POSSIBLE ASBESTOS CplENT STRIP

GUTTER SUPPORT FOR DISTILLATE TROUGH

LDISTILLATE

TROUGH

FIG No. 3

CROSS SECTION OF SIDE WALL OF SOLAR STILL

Background

Information

on the

Brace

Research

Institute

Brace Research Institute of McGill University was founded in 1959 to develop equipment and techniques for making dry lands available and economically useful for agricultural purposes. The Institute has concentrated on the problems affecting individuals or small communities in rural areas and is one of the few organizations with this basic objective. equipment developed by this Institute utilizes as many local In general, resources as possible, whether human, energy or material, so that the technology can be easily adapted to the local environment. As a result, the Institute has concentrated on utilizing solar and wind energy as well as simple systems, desalination specifically concentrating on the problems that face isolated rural populations in developing arid areas. Instructional the manuals are available describing the

use

of solar

energy

for

(1)

(4

(3) (4)

heating of water for domestic and commercial cooking of food drying of agriculEura1 produce desalination of water for human, animal and agricultural use

use

The adaptation of simple greenhouses combined with solar desalination systems for the production of food and water in arid areas is also being developed. Greenhouses are also being adapted for colder regions. In addition, simple Llindmills for the production of electricity and the pump ing of water have been developed. Further inquiries should be directed to the

Brace Research Institute, Macdonald College of McGill University, H9X 3M1, ste. Anne de Bellevue QuGbec, Canada Other leaflets available: Price $1.25 $1.25 $0.75 $1.25 x.25 $0.75 $1.25 $1.25 $1.25 $1.25 ::1.25 Ll - How to Make a Solar Still (plastic covered) L2 - How to Make a Solar Steam Cooker L3 - How to Heat yo'x Swimming Pool using Solar Energy L4 - How to Build a Solar Water Heater L5 - How to Construct a Cheap Wind Machine for Pumping Water L5F- French version of L5 L6 - How to Make a Solar Cabinet Dryer for Agricultural Produce L7 - Arabic Translation of L6 L8 - Spanish Translation of L6 L9 - French Translation of L2 T17- Simple Solar Still for the Production of Distilled Water* Please remit payment with money order or ad< $0.25 to your cheque for bank handling charges. * Also available in French, Arabic and Spanish.

Das könnte Ihnen auch gefallen

- The Seasons of Life by Jim RohnDokument111 SeitenThe Seasons of Life by Jim RohnChristine Mwaura97% (29)

- Antenna Engineering Handbook PDFDokument1.512 SeitenAntenna Engineering Handbook PDFMatheus Freitas Kuhn100% (4)

- Automatic SketchUpDokument456 SeitenAutomatic SketchUpOliver Gonzalez100% (8)

- HOW To Use Jmeter To Load Test T24Dokument27 SeitenHOW To Use Jmeter To Load Test T24Hiếu KoolNoch keine Bewertungen

- ICO Basic SyllabusDokument11 SeitenICO Basic SyllabusRaúl Plasencia Salini100% (1)

- Paiute Deadfall-How To Make and UseDokument9 SeitenPaiute Deadfall-How To Make and UsePatrick McShane100% (1)

- Why Fire Starters Are ImportantDokument3 SeitenWhy Fire Starters Are ImportantMoreMoseySpeedNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Low Power AM Broadcasters HandbookDokument113 SeitenThe Low Power AM Broadcasters HandbookKyle DrakeNoch keine Bewertungen

- Sharpie 600 PDFDokument9 SeitenSharpie 600 PDFLuis Martinez100% (1)

- Internal Disease AnsDokument52 SeitenInternal Disease AnsKumar AdityaNoch keine Bewertungen

- Viscosity IA - CHEMDokument4 SeitenViscosity IA - CHEMMatthew Cole50% (2)

- Hireena Essay AnsDokument2 SeitenHireena Essay AnsTasniiem ChandraaNoch keine Bewertungen

- Laying A Small Concrete Slab in Your GardenDokument6 SeitenLaying A Small Concrete Slab in Your GardenLily ShubinaNoch keine Bewertungen

- Wicking Bed Gardening For Drought GardeningDokument5 SeitenWicking Bed Gardening For Drought GardeningU8x58Noch keine Bewertungen

- SurThrival Growing Guide 2nd Edition Complete-ADokument54 SeitenSurThrival Growing Guide 2nd Edition Complete-APaul GhingaNoch keine Bewertungen

- Small Farm 2017 DicDokument80 SeitenSmall Farm 2017 Dicmalpaso4242Noch keine Bewertungen

- Yard Pond Maintenance: Obtaining Your Garden Fish Pond Ready For SpringtimeDokument3 SeitenYard Pond Maintenance: Obtaining Your Garden Fish Pond Ready For Springtimealleylock8ennacoNoch keine Bewertungen

- How to Grow Oyster Mushrooms at HomeDokument26 SeitenHow to Grow Oyster Mushrooms at HomeMatavi ManoharNoch keine Bewertungen

- Twelve Plant Hydroponic Flood and Drain System: Parts ListDokument7 SeitenTwelve Plant Hydroponic Flood and Drain System: Parts Listtraj17Noch keine Bewertungen

- Earthbag Building Step-by-Step GuideDokument15 SeitenEarthbag Building Step-by-Step GuideVander De Almeida Candido0% (1)

- How to Live Without ElectricityDokument7 SeitenHow to Live Without Electricityzed2099296Noch keine Bewertungen

- Pelt Handling Tips for Maximum Fur ValueDokument28 SeitenPelt Handling Tips for Maximum Fur ValueRalf Snell0% (1)

- How To Store Your Home Grown Produce - John and Val HarrisonDokument23 SeitenHow To Store Your Home Grown Produce - John and Val HarrisonConstable & Robinson100% (1)

- Growing VinesDokument4 SeitenGrowing Vinesmatifernandez27Noch keine Bewertungen

- Improved Charcoal and Biomass Stoves ManualDokument234 SeitenImproved Charcoal and Biomass Stoves ManualpcbstepNoch keine Bewertungen

- Killing Hogs and Curing PorkDokument41 SeitenKilling Hogs and Curing PorklouiscoraxNoch keine Bewertungen

- Diy DeckDokument3 SeitenDiy DeckSollmeisterNoch keine Bewertungen

- How To Make Rope: Hickory Withes. Select A Green Branch of Mockernut, Shagbark, or PignutDokument3 SeitenHow To Make Rope: Hickory Withes. Select A Green Branch of Mockernut, Shagbark, or PignutnightclownNoch keine Bewertungen

- Culinary Herbs: Their Cultivation Harvesting Curing and Uses by Kains, M. G.Dokument76 SeitenCulinary Herbs: Their Cultivation Harvesting Curing and Uses by Kains, M. G.Gutenberg.org100% (7)

- Abundant Water PDFDokument29 SeitenAbundant Water PDFJames McDonald100% (1)

- 12 Basic Plumbing Supplies For Home Tool Kits - DIY GuyDokument8 Seiten12 Basic Plumbing Supplies For Home Tool Kits - DIY GuyuraiNoch keine Bewertungen

- Cord Wood MasonryDokument3 SeitenCord Wood MasonryJason DiGiulioNoch keine Bewertungen

- Electro FishingDokument2 SeitenElectro FishingSujit ShandilyaNoch keine Bewertungen

- Field Care of Harvested Big GameDokument11 SeitenField Care of Harvested Big Gamexj35sNoch keine Bewertungen

- How To Keep Your Produce Fresh For Weeks - WirecuDokument14 SeitenHow To Keep Your Produce Fresh For Weeks - Wirecujunaa Albayati100% (1)

- DIY Solar Drip IrrigationDokument7 SeitenDIY Solar Drip IrrigationsubxaanalahNoch keine Bewertungen

- Wilderness Survival: Merit Badge WorkbookDokument4 SeitenWilderness Survival: Merit Badge WorkbookagungpremonoNoch keine Bewertungen

- Learn Ancient Basketry SkillsDokument16 SeitenLearn Ancient Basketry SkillsLeeNoch keine Bewertungen

- Drying Foods: Guide E-322Dokument8 SeitenDrying Foods: Guide E-322MoreMoseySpeedNoch keine Bewertungen

- How To Make Bricks From ConcreteDokument12 SeitenHow To Make Bricks From ConcreteCheyzeeNoch keine Bewertungen

- How To Make Animal Traps PDFDokument3 SeitenHow To Make Animal Traps PDFGreen MeisterNoch keine Bewertungen

- Setting SnaresDokument6 SeitenSetting SnaresxxxrainbowxxxNoch keine Bewertungen

- How To Make Monosodium Glutamate Waste Liquid Into FertilizerDokument2 SeitenHow To Make Monosodium Glutamate Waste Liquid Into Fertilizerluna leNoch keine Bewertungen

- Worms Can Recycle Your Garbage-1 1996Dokument6 SeitenWorms Can Recycle Your Garbage-1 1996soulshineta2Noch keine Bewertungen

- Pond Plants Guide: How to Control Algae NaturallyDokument15 SeitenPond Plants Guide: How to Control Algae NaturallyAdina PopescuNoch keine Bewertungen

- OKCG Permaculture Food Forest Field Guide 2016 - FINAL 4.3.17Dokument99 SeitenOKCG Permaculture Food Forest Field Guide 2016 - FINAL 4.3.17The Garden Project of Southwest ColoradoNoch keine Bewertungen

- Getting Groundwater - Safe Wells and WaterholesDokument7 SeitenGetting Groundwater - Safe Wells and WaterholesGreen Action Sustainable Technology Group100% (1)

- Practical Farming and Gardening PDFDokument514 SeitenPractical Farming and Gardening PDFRobert RadmanNoch keine Bewertungen

- Gabions Install GuideDokument2 SeitenGabions Install GuideTele2 Phone2100% (1)

- Dual Tub Self Watering Container DesignDokument11 SeitenDual Tub Self Watering Container DesignjlpicardNoch keine Bewertungen

- Options For Storing Potatoes at HomeDokument4 SeitenOptions For Storing Potatoes at HomeElviraSyamsir-Siswanto100% (1)

- Glossary of Wood and Woodworking TermsDokument18 SeitenGlossary of Wood and Woodworking Termsmarco.msn.brNoch keine Bewertungen

- Backyard Aquaponics and Aquaculture System Brochure, Lanikai FarmsDokument1 SeiteBackyard Aquaponics and Aquaculture System Brochure, Lanikai FarmsAquaponicsNoch keine Bewertungen

- Thin Bamboo Culms For TrussesDokument19 SeitenThin Bamboo Culms For TrussessanjanaNoch keine Bewertungen

- Making and Using A Solar Cooker... by Joe RadabaughDokument4 SeitenMaking and Using A Solar Cooker... by Joe RadabaughBLINDED185231100% (1)

- Water Treatment For Off-The-Grid Rainwater Harvesting Systems - Water Organizing Modules (WOMS)Dokument11 SeitenWater Treatment For Off-The-Grid Rainwater Harvesting Systems - Water Organizing Modules (WOMS)Anonymous GnNuL058XSNoch keine Bewertungen

- Log Home ConstructionDokument23 SeitenLog Home ConstructionJP VersterNoch keine Bewertungen

- Permaculture For The Homestead FinalDokument14 SeitenPermaculture For The Homestead FinalharleyNoch keine Bewertungen

- MSBTE POWERPLANT EngineeringDokument21 SeitenMSBTE POWERPLANT EngineeringMonuNoch keine Bewertungen

- Building A Water WheelDokument5 SeitenBuilding A Water WheelMANNAJANELAGUNA100% (1)

- Water Filtration and PurificationDokument5 SeitenWater Filtration and PurificationDave Whitefeather100% (1)

- Moringa Cultivation and Its UsesDokument16 SeitenMoringa Cultivation and Its UsesFarhat Durrani100% (1)

- Design of Rainwater Storage Tanks For Use in Developing CountriesDokument76 SeitenDesign of Rainwater Storage Tanks For Use in Developing Countriesasrurifak100% (2)

- Saltpeter - Instructions For The Manufacture of Saltpetre by Joseph Leconte 1862Dokument13 SeitenSaltpeter - Instructions For The Manufacture of Saltpetre by Joseph Leconte 1862Fernando de AssisNoch keine Bewertungen

- Practical Plants: Useful Survival Products, Unusual Foods, Wood & Protective Charms from Northern Australia and the World Tropics.Von EverandPractical Plants: Useful Survival Products, Unusual Foods, Wood & Protective Charms from Northern Australia and the World Tropics.Noch keine Bewertungen

- Measurement of Evapotranspiration by LysimeterDokument12 SeitenMeasurement of Evapotranspiration by LysimeterDevendra SharmaNoch keine Bewertungen

- How To Build A Natural Swimming PoolDokument3 SeitenHow To Build A Natural Swimming PoolIgnacio Lopez DulceNoch keine Bewertungen

- Canal Lining ITRC Paper No. P 11-006Dokument3 SeitenCanal Lining ITRC Paper No. P 11-006Fiaz GujjarNoch keine Bewertungen

- An Introduction To Rainwater HarvestingDokument7 SeitenAn Introduction To Rainwater HarvestingAbhinandan PatilNoch keine Bewertungen

- There Is A Difference Between Tank MaterialsDokument3 SeitenThere Is A Difference Between Tank MaterialsReza KhajeNoch keine Bewertungen

- Mathsmagic FullDokument96 SeitenMathsmagic FullRohitKumarNoch keine Bewertungen

- Intro To Organic GardeningDokument29 SeitenIntro To Organic Gardeningwaterlife70100% (1)

- MathsDokument16 SeitenMathsKamleshNoch keine Bewertungen

- T-FLEX CAD User Manual. Fundamentals. 2D DesignDokument755 SeitenT-FLEX CAD User Manual. Fundamentals. 2D DesignLuis MartinezNoch keine Bewertungen

- 70 Wire Antenna Ideas for Ham RadioDokument45 Seiten70 Wire Antenna Ideas for Ham RadioJosias Camargo100% (8)

- Making Your Own Discone AntennaDokument172 SeitenMaking Your Own Discone AntennaTayyab Hassan100% (3)

- T-FLEX CAD Brief Introductory CourseDokument211 SeitenT-FLEX CAD Brief Introductory CourseLuis MartinezNoch keine Bewertungen

- Design and Construction of A Quadrifilar Helix Antenna For Receiving NOAA Satellites 1Dokument6 SeitenDesign and Construction of A Quadrifilar Helix Antenna For Receiving NOAA Satellites 1Luis MartinezNoch keine Bewertungen

- Antenna TheoryDokument46 SeitenAntenna TheoryDeepak PandeyNoch keine Bewertungen

- Soldering, Brazing & Welding-A Manual of Techniques - D. PritchardDokument150 SeitenSoldering, Brazing & Welding-A Manual of Techniques - D. PritchardDavid BogdanNoch keine Bewertungen

- (Ebook) Making and Testing Biodiesel Made Using EthanolDokument23 Seiten(Ebook) Making and Testing Biodiesel Made Using EthanolkaamaraajanNoch keine Bewertungen

- Alibre 2012 UserguideDokument844 SeitenAlibre 2012 UserguideLuis Martinez100% (1)

- How To Make Improvised Tools Peace Corp 1980Dokument57 SeitenHow To Make Improvised Tools Peace Corp 1980John J Johnson JrNoch keine Bewertungen

- R 22Dokument22 SeitenR 22Luis MartinezNoch keine Bewertungen

- Experimental Organic ChemistryDokument229 SeitenExperimental Organic ChemistryHamad Mohamad100% (6)

- Fundamentals of Delco Generators PDFDokument21 SeitenFundamentals of Delco Generators PDFLuis MartinezNoch keine Bewertungen

- Motors As Generators N Smith UK 1994Dokument92 SeitenMotors As Generators N Smith UK 1994wolfovic3932Noch keine Bewertungen

- Castinginfo PDFDokument32 SeitenCastinginfo PDFLuis MartinezNoch keine Bewertungen

- How To Build An Acid - Alkaline Water Charger PDFDokument72 SeitenHow To Build An Acid - Alkaline Water Charger PDFLuis MartinezNoch keine Bewertungen

- Window Box Solar Collector Design PDFDokument8 SeitenWindow Box Solar Collector Design PDFLuis MartinezNoch keine Bewertungen

- Car PlansDokument11 SeitenCar Planslaurlos100% (2)

- Liquid Resist For PCM PDFDokument18 SeitenLiquid Resist For PCM PDFLuis MartinezNoch keine Bewertungen

- Car PlansDokument11 SeitenCar Planslaurlos100% (2)

- Jump Start GuitarDokument62 SeitenJump Start GuitarVikas SrivastavaNoch keine Bewertungen

- AESCSF Framework Overview 2020-21Dokument30 SeitenAESCSF Framework Overview 2020-21Sandeep SinghNoch keine Bewertungen

- Mechanics of Materials: Combined StressesDokument3 SeitenMechanics of Materials: Combined StressesUmut Enes SürücüNoch keine Bewertungen

- User Manual: C43J890DK C43J892DK C49J890DK C49J892DKDokument58 SeitenUser Manual: C43J890DK C43J892DK C49J890DK C49J892DKGeorge FiruțăNoch keine Bewertungen

- HDL Coder™ ReferenceDokument487 SeitenHDL Coder™ ReferenceVictor Colpo NavarreteNoch keine Bewertungen

- Hci01 HumanComputerInteraction OverviewDokument140 SeitenHci01 HumanComputerInteraction OverviewAlexSpiridonNoch keine Bewertungen

- ICS Technical College Prospectus 2024 Edition 1Dokument36 SeitenICS Technical College Prospectus 2024 Edition 1samuel287kalumeNoch keine Bewertungen

- Transactionreceipt Ethereum: Transaction IdentifierDokument1 SeiteTransactionreceipt Ethereum: Transaction IdentifierVALR INVESTMENTNoch keine Bewertungen

- JASA SREVIS LAPTOP Dan KOMPUTERDokument2 SeitenJASA SREVIS LAPTOP Dan KOMPUTERindimideaNoch keine Bewertungen

- DX DiagDokument42 SeitenDX DiagVinvin PatrimonioNoch keine Bewertungen

- Aligning With New Digital Strategy A Dynamic CapabilitiesDokument16 SeitenAligning With New Digital Strategy A Dynamic Capabilitiesyasit10Noch keine Bewertungen

- Chapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsDokument10 SeitenChapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsALANKRIT TRIPATHINoch keine Bewertungen

- Rise of NationalismDokument19 SeitenRise of NationalismlolaNoch keine Bewertungen

- Catalogue PDFDokument4 SeitenCatalogue PDFShivam GuptaNoch keine Bewertungen

- Nurses Week Program InvitationDokument2 SeitenNurses Week Program InvitationBenilda TuanoNoch keine Bewertungen

- Black BeautyDokument70 SeitenBlack BeautyMeryem DevirgenNoch keine Bewertungen

- Bronchogenic CarcinomaDokument13 SeitenBronchogenic Carcinomaloresita_rebongNoch keine Bewertungen

- Henderson PresentationDokument17 SeitenHenderson Presentationapi-577539297Noch keine Bewertungen

- Restaurant Social Media GuideDokument30 SeitenRestaurant Social Media GuideHoàng gia NghiêmNoch keine Bewertungen

- Main: Exploded ViewDokument30 SeitenMain: Exploded ViewamokssantiagoNoch keine Bewertungen

- GooglepreviewDokument69 SeitenGooglepreviewtarunchatNoch keine Bewertungen

- 1st ClassDokument18 Seiten1st Classchitl.23bi14075Noch keine Bewertungen

- Equivalent Record Form: Department of Education MIMAROPA RegionDokument1 SeiteEquivalent Record Form: Department of Education MIMAROPA RegionEnerita AllegoNoch keine Bewertungen

- Ivf Market in IndiaDokument15 SeitenIvf Market in IndiaSunil Tak100% (1)

- Chair Locker Provides Storage and Space SavingsDokument32 SeitenChair Locker Provides Storage and Space SavingsElza S. GapuzNoch keine Bewertungen