Beruflich Dokumente

Kultur Dokumente

Section 2

Hochgeladen von

barelihbOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Section 2

Hochgeladen von

barelihbCopyright:

Verfügbare Formate

DISPLACEMENT VENTILATION: Theory and Applications This article is meant to be a brief discussion of Displacement Ventilation.

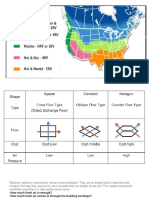

It will describe the fundamentals behind its use, as well as a couple potential applications, including Healthcare and Schools. For detailed information, refer to the Price Industries DISPLACEMENT VENTILATION DESIGN GUIDE, or contact Michigan Air Products. Theory Airflow in ventilated spaces generally can be classified by two different types; mixing (or dilution) ventilation and displacement ventilation. Mixing ventilation systems (Figure 1) generally supply air in a manner such that the entire room volume is fully mixed. The cool supply air exits the outlet at a high velocity, inducing room air to provide mixing and temperature equalization. Since the entire room is fully mixed, temperature variations throughout the space are small while the contaminant concentration is uniform throughout the zone. Displacement ventilation systems (Figure 2) introduce air into the space at low velocities which causes minimal induction and mixing. Displacement outlets may be located almost anywhere within the room, but have been traditionally located at or near floor level. The system utilizes buoyancy forces, generated by heat sources such as people, lighting, computers, electrical equipment, etc. in a room to remove contaminants and heat from the occupied zone. By so doing, the air quality in the occupied zone is generally superior to that achieved with mixing ventilation.

Displacement ventilation presents an opportunity to improve both the thermal comfort and indoor air quality (IAQ) of the occupied space. Displacement ventilation takes advantage of the difference in air temperature and density between an upper contaminated zone and a lower clean zone. Cool air is supplied at low velocity into the lower zone. Convection from heat sources creates vertical air motion into the upper zone where high level return outlets extract the air. In most cases, these convection heat sources are also the contamination sources, i.e. people or equipment, thereby carrying the contaminants up to the upper zone, away from the occupants. Since the conditioned air is supplied directly into the occupied space, supply air temperatures must be higher than mixing systems (usually above 63 degrees F) to avoid creating uncomfortable drafts. By introducing air at elevated supply air temperatures and low outlet velocity a high level of thermal comfort can be achieved with displacement ventilation.

Displacement Ventilation allows us to employ several key strategies for improved air quality, comfort and energy savings. DV systems provide an increase in the ventilation effectiveness of the air distribution system leading to higher IAQ and reduced energy consumption. Ventilation Effectiveness is defined by ASHRAE Standard 62.1 as: Ventilation Effectiveness (VE) = Concentration return / Concentration breathing zone

ASHRAE states that VE for mixing systems is 1.0, while Displacement Ventilation is 1.2, therefore outdoor air amounts may be able to be reduced, local codes permitting. Energy savings may come from lower air pressure drops associated with DV outlets, increased economizer operation, and increased chiller efficiency. Selection of DV outlets is recommended to have no greater than 40 ft/min outlet velocity, which inherently has lower noise levels. Displacement ventilation is an effective method of obtaining good air quality and thermal comfort in the occupied spaces. DV is usually a good choice in the following cases: Where the contaminants are warmer and/or lighter than the room air. Where the supply air is cooler than the room air. Where the room heights are 9 feet or more. Where low noise levels are desired.

Overhead air distribution may be a better choice than DV in the following cases: Where ceiling heights are below 8 feet. Where disturbances to room airflow are strong. Where contaminants are colder and/or denser than the ambient air. Where cooling loads are high and radiant cooling is not an option.

Healthcare Displacement Air Distribution Air Distribution for Healthcare facilities is much more critical and specialized than for a typical air conditioned ofce space. In addition to accurate control of temperature and velocity in the space to maintain acceptable comfort of the occupants the air distribution system must be able to dilute and effectively remove contamination (odor, airborne microorganisms and viruses) from the space. Traditionally overhead mixing systems have been used to supply sufficient quantity of ventilation air to dilute and carry away contaminants. ASHRAE provides guidelines for minimum air changes of total and outside air for the various types of spaces in a healthcare facility (ASHRAE HVAC Applications Handbook). Displacement ventilation has the potential to signicantly improve contaminant removal as well as provide superior thermal comfort levels in the space. Earlier in this article, it has been pointed out that the ventilation effectiveness of DV systems are greater than overhead systems with typical ventilation effectiveness of 1.2 or higher. Higher ventilation effectiveness translates directly to contaminant removal

resulting in a healthier, cleaner occupied space. Two areas in health care facilities particularly well suited for displacement ventilation are patient rooms and waiting rooms. 1. Patient Rooms: The air distribution system in a patient room (figure 79) must maintain thermal comfort, avoid objectionable drafts and remove contaminants to protect both the patient and visitor from infection. By supplying the ventilation air at low velocity and elevated temperature the DV system maintains comfort conditions. As the supply air is drawn to and up the occupants and equipment contaminants are effectively captured by the thermal plume and carried out of the occupied zone. If the patient room contains a large amount of medical equipment with high heat output, the room load may exceed the limit for the DV system (38 BTU/hr/ft2). In this case the DV system can be combined with radiant cooling to counteract the loads. In this case the DV system is sized to distribute the ventilation air requirement while the radiant cooling system deals with the cooling load.

2. Waiting Rooms: Waiting rooms pose a special challenge to the air distribution system. Occupancy in the room can vary greatly and the health status of the occupant is not known. People in the waiting area could be extremely infectious or on the other hand extremely susceptible to infection. Obviously infection control is a priority consideration of the air distribution system but comfort condition must also be maintained. Displacement ventilation is again ideally suited to this application (figure 82). Fresh clear air is distributed directly to the occupants and contaminants removed with the thermal plumes. Unless seated directly in front of a displacement outlet, occupants will also experience a high level of thermal comfort. School Displacement Air Distribution Because Displacement Ventilation is a flexible technology, it can be applied throughout the school, adapting to the requirements of spaces as diverse as classrooms and gymnasiums. Low level, heat seeking air flows around obstacles in a space, ensuring only occupied zones are cooled and supplied with clean fresh air. Applications in schools include classrooms, gymnasiums, assembly halls, libraries, cafeterias, and even kitchens.

1. Gymnasiums: Because Displacement Ventilation only cools the occupied zone, it is perfectly suited for the high ceilings and large open spaces of the gymnasium. A mixing system would typically cool the entire space, leading to increased energy consumption. The rugged construction of the DV diffusers means they can handle abuse taken in the gymnasium, such as repeated impacts from a basketball. Optional heavier gauge faces are also available. Diffusers can be aesthetically integrated into the design of the gymnasium, and their effectiveness is not compromised when placed behind bleachers or similar areas, mounted high in the wall or the ceiling of the gymnasium. 2. Assembly Rooms: Displacement Ventilation and Underfloor Air Distribution are ideal for theaters and auditoriums. Fresh air supply is delivered directly to the occupants. Because only the occupied space is cooled, energy is not wasted cooling the significant lighting load. The quiet nature of Displacement contributes to the quality of the artistic environment. The RFTD twist diffuser or RFDD Displacement Diffusers integrate almost seamlessly into the floor of the theatre and deliver air directly to the occupants. Typically one diffuser is used for each 2 or 3 occupants which allows for the highest level of indoor air quality while keeping velocities sufficiently low as to be draft-free. 3. Library: Libraries have unique design considerations because they are generally mixed use spaces with areas for computer use, book storage, reading and meetings. With an access floor, optimizing these spaces as the building evolves is simplified. Wiring for offices and computer stations is easily changed, diffusers are simply relocated to where they are needed, often without having to modify ductwork. Because of this, Underfloor Air Distribution or Displacement Ventilation are a great choice. 4. Cafeteria / Kitchens: Displacement Ventilation ensures that clean, fresh air is delivered to kitchen and cafeteria occupants where it is needed. In the kitchen, the low velocity air does not disrupt the function of the exhaust hoods. The cooling load is also decreased, as heat generated by cooking equipment rises to the ceiling rather than being recirculated throughout the room. In the cafeteria, Displacement Ventilation offers a more comfortable environment and adapts to the changing nature of the space. 5. Classrooms: Below are a couple examples of applying Displacement Ventilation to classrooms.

Summary Displacement Ventilation is an alternative air distribution system that is redefining HVAC system performance standards for engineers and owners across North America. It delivers superior indoor air quality, excellent thermal comfort, low noise levels, and can result in reduced energy consumption. Contact Michigan Air Products to discuss how to apply Displacement Air Distribution on your next project. Overhead Mixing Systems: 55F Supply Air Mixes the entire space Diffusers drive air motion via high velocity supply air Uniform temperature throughout the space Distributes contaminants evenly throughout the space Conditions the entire room Displacement Ventilation Systems: 65 to 68F Supply Air No mixing in space Heat sources drive air motion via thermal plumes Stratified temperature above occupied zone Contaminants are removed from the breathing zone by the thermal plumes Only conditions the occupied zone

http://www.michiganair.com/newsletters/2011-1/section2.htm

Das könnte Ihnen auch gefallen

- Engineering Bulletin: Basics: Basics of Space Air DiffusionDokument5 SeitenEngineering Bulletin: Basics: Basics of Space Air DiffusionNiong DavidNoch keine Bewertungen

- Designing For ComfortDokument6 SeitenDesigning For ComfortMohsin ShaikhNoch keine Bewertungen

- Displacement Ventilation Is An Air Distribution Technology That Introduces Cool Air Into A Zone at Low VelocityDokument24 SeitenDisplacement Ventilation Is An Air Distribution Technology That Introduces Cool Air Into A Zone at Low VelocityBilal AhmedNoch keine Bewertungen

- BR409 DisplacementDesignGuideDokument52 SeitenBR409 DisplacementDesignGuidecarlcrowNoch keine Bewertungen

- Displacement Design GuideDokument52 SeitenDisplacement Design GuideNoushad P HamsaNoch keine Bewertungen

- Personal Ventilation: Emerging Technologies Emerging TechnologiesDokument6 SeitenPersonal Ventilation: Emerging Technologies Emerging Technologiesscribd99190Noch keine Bewertungen

- HVAC SystemDokument5 SeitenHVAC SystemMrinal Kanti RoyNoch keine Bewertungen

- Air Distribution Engg GuideDokument8 SeitenAir Distribution Engg GuideNiong DavidNoch keine Bewertungen

- HVAC - Part-1Dokument63 SeitenHVAC - Part-1ShubhaNoch keine Bewertungen

- A33 Si - Kitchen VentilationDokument1 SeiteA33 Si - Kitchen VentilationAhmed NabilNoch keine Bewertungen

- Tutorial - Ku Illyani Nadia BT Ku Aziz 2011478072 BCM5BDokument3 SeitenTutorial - Ku Illyani Nadia BT Ku Aziz 2011478072 BCM5Bnadia0109Noch keine Bewertungen

- Engineering GuideDokument43 SeitenEngineering GuideJohnMerrNoch keine Bewertungen

- Low Energy Consumption Hvac Systems For Green Buildings Using Chilled Beam TechnologyDokument9 SeitenLow Energy Consumption Hvac Systems For Green Buildings Using Chilled Beam TechnologyIAEME PublicationNoch keine Bewertungen

- Ventilation and Air-ConditioningDokument93 SeitenVentilation and Air-ConditioningEmmanuel P Dube100% (2)

- HVAC in Hospital PDFDokument7 SeitenHVAC in Hospital PDFMohammed Toema100% (1)

- Exp 2Dokument7 SeitenExp 2Philip Anthony MasilangNoch keine Bewertungen

- Computational Fluid Dynamics Analysis of HVAC System in AuditoriumDokument5 SeitenComputational Fluid Dynamics Analysis of HVAC System in AuditoriumMuhammad AshfaqNoch keine Bewertungen

- Tuttle and Bailey AdministrationDokument8 SeitenTuttle and Bailey AdministrationElvis FariasNoch keine Bewertungen

- HVAC Services in Buildings: Ar. Antara Nandy Assistant Professor Rani Rashmoni College of Architecture, Durgapur (W.B)Dokument18 SeitenHVAC Services in Buildings: Ar. Antara Nandy Assistant Professor Rani Rashmoni College of Architecture, Durgapur (W.B)Archi PinuNoch keine Bewertungen

- Hvac 160820181216Dokument33 SeitenHvac 160820181216mani aroraNoch keine Bewertungen

- Chilled Beam - Engineering - GuideDokument48 SeitenChilled Beam - Engineering - Guiderahulsoniin0% (1)

- VentilationDokument28 SeitenVentilationTannum Negi0% (1)

- Tutorial - Underfloor Air-ConditioningDokument8 SeitenTutorial - Underfloor Air-ConditioningJasper_HVACNoch keine Bewertungen

- An Air Handling UnitDokument4 SeitenAn Air Handling UnitDono WayNoch keine Bewertungen

- ACTIVITY #4 - Castro, Xaira Alexa Mari L.Dokument19 SeitenACTIVITY #4 - Castro, Xaira Alexa Mari L.Xaira Alexa Mari CastroNoch keine Bewertungen

- Building Services-Iii: Hvac, Lifts and Escalators and Fire FightingDokument22 SeitenBuilding Services-Iii: Hvac, Lifts and Escalators and Fire FightingANURAG GAGANNoch keine Bewertungen

- Ventilation and Lighting in BuildingsDokument17 SeitenVentilation and Lighting in BuildingsT N Roland Bourge100% (1)

- Pros and Cons of Radiant Cooling in Humid Climates - Uponor BlogDokument8 SeitenPros and Cons of Radiant Cooling in Humid Climates - Uponor BlogMian RubbaniNoch keine Bewertungen

- Selection Tips For HVAC SystemsDokument41 SeitenSelection Tips For HVAC SystemsImtiaz Ahmed100% (1)

- VentilationDokument29 SeitenVentilationGaurika GroverNoch keine Bewertungen

- Clean RoomDokument9 SeitenClean Roomxyzscribd1988Noch keine Bewertungen

- HVAC - Cooling SysDokument14 SeitenHVAC - Cooling Sysknotship.comNoch keine Bewertungen

- Enews 30 03 090601Dokument4 SeitenEnews 30 03 090601sajuhereNoch keine Bewertungen

- Air Conditioning SystemDokument9 SeitenAir Conditioning SystemFahmy AfiffNoch keine Bewertungen

- Mechanical Ventilation Systems Are Frequently Applied To Commercial BuildingsDokument9 SeitenMechanical Ventilation Systems Are Frequently Applied To Commercial BuildingsIbn Shaffee IVNoch keine Bewertungen

- Sustainable and Energy-Efficient Heating Cooling System For HospitalDokument23 SeitenSustainable and Energy-Efficient Heating Cooling System For HospitalRISHAB KABDI JAINNoch keine Bewertungen

- Active Passive Beams Engineering GuideDokument48 SeitenActive Passive Beams Engineering GuideAshraf Adel Nashed ZakiNoch keine Bewertungen

- CB, VAV, VRF, Fan Coils - A Comparison StudyDokument6 SeitenCB, VAV, VRF, Fan Coils - A Comparison StudyprasathinusaNoch keine Bewertungen

- Air Handling UnitDokument11 SeitenAir Handling UnitSaranya Kannan100% (1)

- Course Content: Fundamentals of HVAC ControlsDokument39 SeitenCourse Content: Fundamentals of HVAC ControlsMuhammad AfzalNoch keine Bewertungen

- Air Conditioning SystemsDokument3 SeitenAir Conditioning SystemsArman Ul NasarNoch keine Bewertungen

- Ventilation (Architecture) : From Wikipedia, The Free EncyclopediaDokument8 SeitenVentilation (Architecture) : From Wikipedia, The Free EncyclopediagnitinNoch keine Bewertungen

- Chapter 3 The Air Distribution SystemDokument40 SeitenChapter 3 The Air Distribution SystemMuhammad Abdullah86% (7)

- Design Guide - Humidity ControlDokument2 SeitenDesign Guide - Humidity Controldzul92100% (1)

- Natural N Mechanical VentilationDokument33 SeitenNatural N Mechanical VentilationdevrishabhNoch keine Bewertungen

- Acb40-50 Metric UsDokument20 SeitenAcb40-50 Metric UsGeovanni Sanchez TrejoNoch keine Bewertungen

- The Basics of Heating, Ventilation and Air Conditioning: Rajneesh VachaspatiDokument85 SeitenThe Basics of Heating, Ventilation and Air Conditioning: Rajneesh VachaspatiRajneesh VachaspatiNoch keine Bewertungen

- Air Distribution N Outlet SelectionsDokument43 SeitenAir Distribution N Outlet SelectionsatiqulaNoch keine Bewertungen

- Hvac 4Dokument3 SeitenHvac 4zolalkkNoch keine Bewertungen

- Engineering Guide Price Critical Environments: Hospital Operating RoomsDokument6 SeitenEngineering Guide Price Critical Environments: Hospital Operating RoomsHenry SuarezNoch keine Bewertungen

- Notes For Advanced Building ServicesDokument14 SeitenNotes For Advanced Building Servicespriya dharshiniNoch keine Bewertungen

- Air Distribution System Equipment's and Duct DesignDokument36 SeitenAir Distribution System Equipment's and Duct DesignfekadeNoch keine Bewertungen

- Presented by Heena KousarDokument50 SeitenPresented by Heena KousarSreejil RaveendranNoch keine Bewertungen

- Concepts and Types of Ventilation - Natural Ventilation For Infection Control in Health-Care Settings - NCBI BookshelfDokument7 SeitenConcepts and Types of Ventilation - Natural Ventilation For Infection Control in Health-Care Settings - NCBI BookshelfkaustavNoch keine Bewertungen

- HVAC in HospitalsDokument19 SeitenHVAC in HospitalskanikaNoch keine Bewertungen

- Difference Between HRV/ ERV and HRWDokument13 SeitenDifference Between HRV/ ERV and HRWhbardhanNoch keine Bewertungen

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemVon EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNoch keine Bewertungen

- The Home Owner's Guide to HVAC: The Envelope and Green TechnologiesVon EverandThe Home Owner's Guide to HVAC: The Envelope and Green TechnologiesNoch keine Bewertungen

- Food Storage Guide: Answers The Question - .Dokument15 SeitenFood Storage Guide: Answers The Question - .barelihbNoch keine Bewertungen

- Correlation For Boiling Heat Transfer T O Saturated Fluids in Convective FlowDokument8 SeitenCorrelation For Boiling Heat Transfer T O Saturated Fluids in Convective FlowbarelihbNoch keine Bewertungen

- Refrigerant PumpDokument2 SeitenRefrigerant PumpbarelihbNoch keine Bewertungen

- Energy-Saving: Ammonia Refrigeration Applications Using Pump CirculationDokument11 SeitenEnergy-Saving: Ammonia Refrigeration Applications Using Pump CirculationbarelihbNoch keine Bewertungen

- Elec Valve Size Select GuideDokument16 SeitenElec Valve Size Select GuideNguyễn ĐệNoch keine Bewertungen

- Oil Storage Tank PDFDokument19 SeitenOil Storage Tank PDFalmadhagiNoch keine Bewertungen

- Hydrocarbon Refrigerants GuidelinesDokument36 SeitenHydrocarbon Refrigerants GuidelinesbarelihbNoch keine Bewertungen

- APV Evaporation HandbookDokument68 SeitenAPV Evaporation HandbookМаксим ХилоNoch keine Bewertungen

- Oil in Refrigeration Systems: LubricationDokument17 SeitenOil in Refrigeration Systems: LubricationbarelihbNoch keine Bewertungen

- Best Practice Guide RefrigerationDokument36 SeitenBest Practice Guide Refrigerationbarelihb100% (1)

- Price UfadDokument8 SeitenPrice UfadbarelihbNoch keine Bewertungen

- Design Basics: For Air and Surface DisinfectionDokument10 SeitenDesign Basics: For Air and Surface DisinfectionbarelihbNoch keine Bewertungen

- Refrigerant PipingDokument23 SeitenRefrigerant PipingbarelihbNoch keine Bewertungen

- Arc 315-18 Lecture Part 1Dokument3 SeitenArc 315-18 Lecture Part 1Melaine A. FranciscoNoch keine Bewertungen

- Design Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeDokument6 SeitenDesign Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeNeeraj SamadhiyaNoch keine Bewertungen

- To Write Me150p-1Dokument27 SeitenTo Write Me150p-1Cloie ChavezNoch keine Bewertungen

- 10 9Dokument20 Seiten10 9limlianpengNoch keine Bewertungen

- CRV07 Service Manual CH 10 PDFDokument74 SeitenCRV07 Service Manual CH 10 PDFPaoloPinardNoch keine Bewertungen

- 19-0019 (Electrical Trench Details Drawing)Dokument1 Seite19-0019 (Electrical Trench Details Drawing)Ajay RanganathanNoch keine Bewertungen

- Annexure II - Boq For AhuDokument11 SeitenAnnexure II - Boq For AhuMohsin Shaikh100% (1)

- Air Cooled Chiller NotesDokument3 SeitenAir Cooled Chiller NotesaxelNoch keine Bewertungen

- Honeywell th5110d1006 th5110d1022 th5220d1003 th5220d1029 Th5320u1001 Owner S ManualDokument20 SeitenHoneywell th5110d1006 th5110d1022 th5220d1003 th5220d1029 Th5320u1001 Owner S ManualRicardo J. Vaquera AgueroNoch keine Bewertungen

- New Pumping Station at Jabel Haffet Base EPC Contract No:-N-16297Dokument60 SeitenNew Pumping Station at Jabel Haffet Base EPC Contract No:-N-16297unnicyriacNoch keine Bewertungen

- HVAC Fundamentals PDFDokument296 SeitenHVAC Fundamentals PDFanthonyNoch keine Bewertungen

- AirconDokument24 SeitenAirconMelvin Mhds100% (1)

- Hvac Eguide: Instruments and ServicesDokument26 SeitenHvac Eguide: Instruments and ServicesMINoch keine Bewertungen

- 95 TOP Refrigeration and Air Conditioning - Mechanical Engineering Multiple Choice Questions and Answers List - MCQs Preparation For Engineering Competitive ExamsDokument19 Seiten95 TOP Refrigeration and Air Conditioning - Mechanical Engineering Multiple Choice Questions and Answers List - MCQs Preparation For Engineering Competitive ExamsNagaraj Muniyandi80% (5)

- Prince Faisal Bin Sultan Palace: Riyadh - Saudi ArabiaDokument10 SeitenPrince Faisal Bin Sultan Palace: Riyadh - Saudi Arabiarazi khanNoch keine Bewertungen

- Application of Fan and Blower in Room Air Heater: Engineering Design (Ta 103) ProjectDokument11 SeitenApplication of Fan and Blower in Room Air Heater: Engineering Design (Ta 103) ProjectManan AroraNoch keine Bewertungen

- ANSI - ASHRAE - IESNA Standard 90.1-1999 With 90.1-2001 Highlights (PDFDrive)Dokument193 SeitenANSI - ASHRAE - IESNA Standard 90.1-1999 With 90.1-2001 Highlights (PDFDrive)Roubio MohamedNoch keine Bewertungen

- Copia de Ficha Tecnica 2021-2022 AA 12,18,24,36 T. Solo Frio 410WHIDokument6 SeitenCopia de Ficha Tecnica 2021-2022 AA 12,18,24,36 T. Solo Frio 410WHIUlisesSoliherNoch keine Bewertungen

- PSD 01 2018 50 48 Ua Uh 135 205Dokument65 SeitenPSD 01 2018 50 48 Ua Uh 135 205Constantin294Noch keine Bewertungen

- Coolant Replace 26010-2Dokument4 SeitenCoolant Replace 26010-2aliNoch keine Bewertungen

- Reddot R9757 (Rh40e) - 1Dokument8 SeitenReddot R9757 (Rh40e) - 1Rodny Romero0% (1)

- DIB Testing & Commissioning BOQ Schedule BuildingDokument1 SeiteDIB Testing & Commissioning BOQ Schedule BuildingArmaghan ShahidNoch keine Bewertungen

- Multimatic - 700-System DiagramsDokument13 SeitenMultimatic - 700-System DiagramsenergiarenovadaNoch keine Bewertungen

- Relative Humidity: CalculationDokument6 SeitenRelative Humidity: CalculationAnto FumiantNoch keine Bewertungen

- Kcn411lag BXXXDokument5 SeitenKcn411lag BXXXRajeesh P RaviNoch keine Bewertungen

- Heathrow Terminal Ammonia ChillersDokument12 SeitenHeathrow Terminal Ammonia Chillerscefa84100% (1)

- Electronic Expansion Valve: DPF-T/S SeriesDokument3 SeitenElectronic Expansion Valve: DPF-T/S SeriesRicardo VianaNoch keine Bewertungen

- Nitrogen Vs AmmoniaDokument1 SeiteNitrogen Vs Ammoniadadangkoe100% (1)

- Description Description Cause Code Failure Class Failure CodeDokument389 SeitenDescription Description Cause Code Failure Class Failure CodeharshadNoch keine Bewertungen

- PURY-EM200-300YNW-A1 R32 PI Sheet 2020Dokument2 SeitenPURY-EM200-300YNW-A1 R32 PI Sheet 2020HannaanNoch keine Bewertungen