Beruflich Dokumente

Kultur Dokumente

Addition of Ester (Biodiesel) To Ethanol-Diesel Blend To Improve The Engine Performance and To Control The Emissions of Nitrous Oxides

Hochgeladen von

prasaad08Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Addition of Ester (Biodiesel) To Ethanol-Diesel Blend To Improve The Engine Performance and To Control The Emissions of Nitrous Oxides

Hochgeladen von

prasaad08Copyright:

Verfügbare Formate

Energy and Power: 2011; 1(1): 1-5 DOI: 10.5923/j.ep.20110101.

01

Addition of Ester (Biodiesel) to Ethanol-Diesel Blend to Improve the Engine Performance and to Control the Emissions of Nitrous Oxides

Donepudi Jagadish*, Ravi Kumar Puli, K. Madhu Murthy

Department of Mechanical Engineering, National Institute of Technology Warangal, 500604, Andhra Pradesh, India

creased emission legislation. Many ideas have been implemented upon usage of biofuels for energy production to achieve low-emission levels. Internal combustion engines are the basic prime movers for power generation as well as for transportation purpose, which are basically run on fossil petroleum. Usage of eco-friendly fuels like ethanol and biodiesel as alternate fuels in engines attracted the attention of researchers. The present work envisages the effects of ester addition to the ethanol-diesel blends like E10, E20 and E30. The performance and emissions nature of ethanol-diesel blended fuel was observed using a single-cylinder, direct injection, constant speed diesel engine. Exhaust gas recirculation was adopted to control NOx emissions. Engine performance in terms of brake specific fuel consumption, and brake thermal efficiency is compared. The results showed that, the engine performance has been improved with an addition of ester to ethanol-diesel blend. Considerable reductions in emissions also been observed with the addition of ester, and using the EGR option reduction of NOx emissions was observed.

Abstract Usage of biofuels received much attention in the current situation of depleting fossil-fuel reserves and in-

Keywords

Engine Combustion, Ethanol, Ester, EGR, Nitrous Oxide Emissions

1. Introduction

Ethanol is one of the possible alternative fuels for partial replacement of mineral diesel in C.I engines. Many authors have reported ethanol-diesel blends up to 20% can very well be used in a present-day engine with minor adjustments. The common observations are the brake specific fuel consumption is slightly increased when higher concentrations of ethanol were used. The advantage of adding ethanol to diesel being the reductions in particulate matter (PM) emissions, and this may increase CO and total HC emissions. However, ethanol-diesel blends may be a viable alternate fuel concerning overall performance of the engine and emissions. Many authors have reported that ethanol-diesel blends up to 20% can very well be used in the present day constant speed C.I engines without any modification. The common observations were the specific fuel consumption is slightly increased with higher concentrations of ethanol with no significant difference in the power produced and the thermal efficiency of the engine. Few authors reported that up to a 62% reduction in CO emission is possible with the use

* Corresponding author: jagadish.donepudi@gmail.com (Donepudi Jagadish) Published online at http://journal.sapub.org/ep Copyright 2011 Scientific & Academic Publishing. All Rights Reserved

of ethanol-diesel blends as compared to diesel alone, and NOx emissions also can be reduced[1]. Vegetable oil methyl ester being added to ethanol-diesel to prevent the separation of ethanol from diesel, and ethanol can be used up to 30% by volume in diesel with ester as an additive for best performance and low emissions[2]. Jincheng et al. has conducted experiments on a diesel engine with ethanol-diesel using an additive normal butanol. Thermal efficiency of the engine increased with the ethanol-diesel with a slight increase in fuel consumption, which is due to the less heating value of ethanol[3]. Hseyin et al. investigated the effects of the blends of biodiesel and ethanol in a single cylinder four stroke direct injection diesel engine. The comparison has been made between B20 (20% biodiesel and 80% diesel) and BE20 (20% ethanol and 80% biodiesel) showing that the engine performance was significantly improved with BE20 than with B20, and all the engine emissions are considerably reduced[4]. Hwanam et al. has used biodiesel-diesel, ethanol-biodiesel-diesel blends in a common rail direct injection diesel engine and observed that overall performance was similar to the diesel fuel, and high fuel consumption was observed due to a decrease in heating value of biofuel blends resulted during mixing. The use of a both the blends reduced the total hydrocarbons, smoke and CO emissions but NOx emissions increased due to the increased oxygen content in the fuel[5].

Donepudi Jagadish et al.: Addition of Ester (Biodiesel) to Ethanol-Diesel Blend to Improve the Engine Performance and to Control the Emissions of Nitrous Oxides

Table 2. Ranges and Sensitivities of Test Devices. Analyzer CO CO2 NO HC Smoke meter Name Kane-May Quintox Kane-May Quintox Kane-May Quintox Kane-May Quintox AVL 437 Range 0-10% 0-10% 0-5000 ppm 0-3000 ppm 0-100% Sensitivity 0.01% 0.01% 1 ppm 1 ppm 0.01%

The amount of energy released is dependent on the oxidation state of the carbons in the hydrocarbon which is related to the H/C ratio. The more hydrogen per carbon the lower the oxidation state results in more energy that will be released during the oxidation reaction, thus the greater the H/C ratio and better energy release on combustion. Ethanol generally has H/C ratio nearly 3 promotes an improved combustion, and even the blends of ethanol-diesel may have similar effects. This may slightly increase the peak temperatures of combustion. Biodiesel usually expected to have higher H/C ratios promotes better combustion, and the same time offers less CO and UBHC emissions[6]. This also offers the flexibility of usage of biodiesel-diesel, biodieselethanol-diesel blend fuels with options like EGR to control the NOx emissions, without much loss of engine mean torque. The motive has been taken to observe the performance aspects of the engine fuelled with ethanol-ester-diesel with option EGR. Nevertheless, the EGR has been the most effective technique to reduce the NOx emissions from a diesel engine[7-19]. However, the reduction of NOx with EGR is limited due to adverse effects like increased particulates, increased UBHC, and severe effects on engine torque performance. The addition of ester to ethanol-diesel blends may permit to use high EGR rates while promising the considerable low levels of other emissions like PM and UBHC. Even to the present date similar kind of research is already available this work has been taken to support the concept of biofuels for the future energy needs.

3. Experimental Methodology

Biodiesel was prepared from palm stearin through the process of transesterfication using catalyst NaOH. Palm stearin is the solid fraction obtained during the fraction of palm oil and is a co-product of palm olein. Small fractions of biodiesel were added to ethanol-diesel blends; the mixtures are named as E10B, E20B, and E30B. The properties of the base fuels are shown in Table 3. And the heating values of mixtures have been determined using a bomb calorimeter.

Table 3. Properties of Fuels. Property Density (kg/m3) Kinematic Viscosity (cSt) Heating Value(kJ/kg) Cloud Point,0C Pour Point, C Flash Point,0C

0

Diesel 840 2.44 42,500 3 -6 70

Ethanol 789 1.52 29700 -25 -113 17

Palm stearin methyl ester 874 4.76 39,900 16 19 145

2. Details of Experimental Setup

A naturally aspirated single cylinder diesel engine with a DC shunt dynamometer was used for experimentation. Slight modifications were made to the original engine set up to work with option cooled EGR. A heat exchanger was used to cool the exhaust gases while entering the inlet to maintain constant temperature (340C) throughout the experiment. Venturi arrangement was provided for effective mixing of exhaust gas and fresh air. Rotameters were used to measure the flow rates of inlet air and exhaust gas. Table 1 gives the details of the engine, and Table 2 provides the details of the exhaust gas analyzer with ranges and sensitivities. The schematic of experimental setup is shown in Figure 1.

Table 1. Details of Engine Test Setup. Manufacturer Engine Type Rated Power Bore/Stroke Compression ratio Start of Fuel Injection Nozzle Opening Pressure Kirloskar Oil Engines Limited, India Single cylinder, 4-stroke, naturally aspirated, Direct injection, water cooled C.I.Engine 3.7 kW at 1500 rpm 80/110 (mm) 17.5 260 BTDC 180 bar

Engine coolant temperature was kept constant at 550C during entire engine operation, and inlet air temperature is maintained at 340C during all the periods of operation. The tests were conducted on the engine without EGR and with EGR and the performance parameters like BSFC, BTE are compared. EGR rate is calculated using equation (1). Volume flow rate of EGR % EGR= ------------------------------------------------100(1) Volume flow rate of inlet air charge

4. Engine Performance

The variation of BSFC with load is shown in Figure 2 and Figure 3. Under normal operation, and during exhaust gas recirculation, there is a rise in fuel consumption. Ethanol-ester-diesel blends with EGR showed less loss in the fuel economy, when compared with only diesel; and the values are comparable with no-EGR since the oxygenate quality of the ethanol compensates for the non-availability excess oxygen during EGR. Out of the selected blends E10B showed a good fuel economy even with higher EGR rates, which can be noticed from Figure 4. Fuel conversion capability seems to decrease with an increase in EGR percentage, nevertheless E10B showed better values of thermal

Energy and Power: 2011; 1(1): 1-5

efficiency and comparable with diesel. Whereas E20B, E30B showed higher values of BSFC when compared with diesel at all loads of engine operation.

Figure 4. Comparison of BSFC with EGR rate for different fuels.

5. Engine Emissions

5.1. Nitrous Oxides

Figure 1. Schematic of Experimental Setup.

Figure 2. Variation of BSFC with Load at different EGR rates using fuel diesel.

Figure 3. Variation of BSFC with load at different EGR rates using fuel E10B.

Nitrous oxide formation mainly depends on temperature, and a reduction in temperature can cause a reduction in NOx. With ethanol addition to diesel, the maximum temperatures of combustion may be raised, and the reasons can be attributed to a low burning rate of ethanol causing a rise in ignition delay causing a rise in the temperature of exhaust. However, with more ethanol concentrations, the peak temperatures of combustion may come down due to bulk quenching of the combustion products resulting in lower fuel-air ratios. A major obstacle to the extensive application of diesel engines is their high levels of nitrogen oxides (NOx) and particulate matter emissions, both of which have negative effects on the environment. NOx contribute to ground level ozone (smog) and acid rain with the consequent detrimental effects on human health. Introduction of the exhaust gas into the combustion chamber causes the dilution of the air charge by replacing O2 with the non-reacting CO2, as a consequence both the specific heat capacity of the in cylinder gas mixture, the peak flame temperatures of the cycle is reduced. As a result NOx emissions are reduced too, aided by the lower oxygen availability. However, a sharp increase in hydrocarbon emissions, particle size, and density was observed at higher EGR rates, while only slight changes were observed in conventional combustion parameters such as heat release and work[7, 8]. Having understood the advantages of adding ethanol to diesel, only fewer amounts of ethanol can be permitted to take the advantage of the oxygenate quality. The higher ethanol concentration in the diesel is limited due to increased fuel consumption. If high peak temperatures exist then EGR would be one technique to reduce NOx emissions. A comparison is made for NO emissions with different EGR rates in the Figure 5, and it can be observed that an increased ethanol concentration showed considerable reduction of NO emissions. However, in the performance point

Donepudi Jagadish et al.: Addition of Ester (Biodiesel) to Ethanol-Diesel Blend to Improve the Engine Performance and to Control the Emissions of Nitrous Oxides

increased ethanol concentration decreases the fuel economy, so E10B can be a best combination, and a low EGR rate (<10%) can be effectively used to control NO emissions. It can be understood from the Figure 5, that the addition of ester to ethanol-diesel has considerable influence the combustion process resulting more reductions of NO emissions in comparison with only ethanol-diesel blends. The EGR rate is limited due to increased fuel consumption, and UBHC with higher rates. The addition of ester to ethanol-diesel enhances the blend stability thus providing chances for efficient combustion resulting in the reduction of UBHC emissions, which are profound during the burning of ethanol-diesel blends. The addition of ester to ethanol diesel blends may increase the chances of low temperature combustion, contemplating the advantages of ethanol addition to diesel.

the exhaust observed besides a drastic rise with higher EGR rates. However, less UBHC emissions during engine tests with ethanol-ester-diesel was observed. 5.3. Carbon Monoxides Exhaust gas recirculation causes an increase in CO formation, and with high EGR rates, more CO emission was observed. Using the fuel diesel, a little rise in CO emissions was observed with a rise in EGR percentage, and also as the load on the engine increases CO formation increased. For ethanol-diesel blends drastic rise in CO formation was observed as shown in Figure 6, and the emissions were observed to be further aggravated with increased ethanol concentration. An outcome of less CO emissions was noticed with ester addition to ethanol-diesel blends.

Figure 7. Comparison of smoke emissions for different EGR rates for different fuel blends Figure 5. Comparison of Nitric oxide emissions under different EGR.

5.4. Smoke Opacity As the load on the engine increased there is a little rise in smoke emissions from the engine exhaust. Exhaust gas recirculation aggravates the formation of smoke. From Figure 7, the increased amount of ethanol in diesel resulted in less smoke in the exhaust, and the addition of ester slightly reduced these emissions.

6. Conclusions

Addition of esters to ethanol-diesel blends can cause an improvement in stability of the fuel blend, and during engine performance test some desirable effects like low NOx, low UBHC was noticed. The following overall conclusions may be drawn from the present work. 1. Lower fuel economy was observed with higher EGR rates (more than 10%), and ethanol blending to diesel resulted in further increase in brake specific fuel consumption values. 2. Brake thermal efficiency slightly improved for ethanol-ester-diesel blends without EGR and reduced with higher EGR rates. 3. Ethanol content in the diesel helped in a reduction of

Figure 6. Variation of CO emissions with load and with different EGR rates for fuel E10B.

5.2. Unburned Hydrocarbons Generally as the load on the engine increased, UBHC in the exhaust increases in many of the cases. It was observed during engine operation that as EGR percentage increases hydrocarbons in the exhaust increased. And further as the ethanol content in the diesel increased a rise in UBHC in

Energy and Power: 2011; 1(1): 1-5

NOx emissions and comparable better reductions were observed with addition of palm stearin methyl ester, which permits to use higher EGR rates. However, different feed stocks have different fatty acid composition even though many esters of different origin normally exhibit similar properties. 4. Common observations like increased hydrocarbon, carbon monoxide, and carbon dioxide emissions noticed with higher EGR rates while engine operated with ethanol-diesel. However, these concentrations are slightly reduced with ester addition. 5. Optimum value of EGR rate can be selected between 5-10% for ethanol-diesel fuel (E10B) with compromise between engine torque, fuel economy and HC, CO emissions, and a rate of 10-15% can be safely used with ester addition since it minimizes the fuel losses.

[5] Hwanam, K., and Byungchul, C., 2008, Effect of ethanol-diesel blend fuels on emission and particle size distribution in a common-rail direct injection diesel engine with warm-up catalytic converter., J. Renewable Energy., 33, 2222-2228 [6] Nabi, N., Akhter, S., and Shahadat, M. Z., 2006, Improvement of engine emissions with conventional diesel fuel and dieselbiodiesel blends., J. Bio Resource Technology., 97, 372-378 [7] Sasaki, M., Kishi, Y., Hyuga, T., Okazaki, K., Tanaka, M., and Kurihara, I., Effect of EGR on Diesel Engine Oil, and its Counter measures, SAE Paper No. 971695 [8] Kreso, A, M., Johnson, J, H., Gratz, L, D., Bagley, S, T., and Leddy, D, G., A Study of the Effects of Exhaust Gas Recirculation on Heavy Duty Diesel Engine Emissions., SAE Paper No.981422 [9] Hribernik, A., and Samec, N., 2004, Effect of Exhaust Gas Recirculation on Diesel Combustion., J.KONES Internal Combustion Engines.,11, No.1-2 http://www.ilot.edu.pl/KONES/2004/01/24.pdf [10] Agrawal. A. K, Singh. S., Sinha. S., and Shukla. M. K., 2004, Effect of EGR on the exhaust gas temperature and exhaust opacity in compression ignition engines., Sadhana, 29(3), 275-284 [11] Haupt, D., Nord, K., Ahlvik, P., Egeback, K, E., Tingwall, B., Anderson, S., and Blomquist, M., Investigating the Potential to Obtain Low Emissions From a Diesel Engine Running on Ethanol and Equipped With EGR, Catalyst and DPF., SAE Paper No.2004-01-1884 [12] Pradeep, V., and Sharma, R, P., 2007, Use of Hot EGR for NOx control in a compression ignition engine fuelled with biodiesel from Jatropha oil., J. Renewable Energy., 32, 1136-1154

Abbreviations

BSFC BTDC BTE EGR E10B E20B E30B NOx UBHC Brake Specific Fuel Consumption [kg/kW.hr] Before Top Dead Centre Brake Thermal Efficiency [%] Exhaust Gas Recirculation Blend of 10% ethanol,5% ester,85% diesel by volume Blend of 20% ethanol,10% ester,70% diesel by volume Blend of 30% ethanol,10% ester,60% diesel by volume Nitrous Oxides Unburned hydrocarbons

ACKNOWLEDGEMENTS

The authors are highly grateful to the staff I.C.Engines laboratory of mechanical engineering department, NITW for providing the test facilities and Chemical Engineering [13] Simoson, C., and Wagner,J., 2008, Effect of Cooled EGR on Small Displacement Diesel Engine: A Reduced Order DyDepartment, NITW for providing the Gas analyzer and Lanamic Modeling and Experimental Study., J. Energy Reboratory facilities. source and Technology, 130, 11102-11111

REFERENCES

[14] Saravanan, N., Nagarajan, G., Kalaiselvan, K, M and Dhanasekaran, C., 2008, An experimental Investigation of hydrogen as dual fuel for diesel engine system with Exhaust Gas Recirculation Technique., J. Renewable Energy, 33, 422-427.

[1] Agarwal, A. K., 2007, Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engine., J. [15] Rajan, K., and Senthil Kumar, K. R., 2009, Effect of exhaust gas recirculation (EGR) on the performance and emission Progress in Energy and Combustion Science., 33, 233-271 characteristics of diesel engine with sunflower oil methyl ester. Jordan J. Mechanical and Industrial Engineering, 3(4), [2] Hu, C., Shi-Jin, S., and Jian-Xin, W., 2007, Study on com306-311 bustion characteristics and PM emission of diesel engines using ester-ethanol-diesel blended fuels., J. Proceedings of [16] Donghui, Q., Michael, L., Yu, L., and Chia-fon, L., 2011, the Combustion Institute., 31, 2981-2989 Effect of EGR and Injection Timing on Combustion and Emissions Characteristics of Split Injection Strategy [3] Jincheng, H., Yaodong, W., Shuangding, L., Anthony, P. R., DI-diesel Engine Fuelled with Biodiesel, Fuel, 90(5), Hongdong, Y., and Huifen, L., 2009, Experimental investi1884-1891 gation on the performance and emissions of a diesel engine fuelled with ethanol-diesel blends., J. Applied Thermal En[17] Alain, M., and Xavier, T., 2011, NOx and PM reduction on gineering., 29, 2484-2490 an Automotive Diesel Engine with Water-in-Diesel Emulsion and EGR: Experimental Study, Fuel, 90(11), [4] Hyun, K. S., Hyun, G. R., and Chang, S. L., 2008, Spray and 3179-3192 combustion characteristics of biodiesel diesel blended fuel in a direct injection common rail diesel engine., J. Engineering for Gas Turbine and Power., 130, 32801-32809

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Fundamentals of SurveyingDokument611 SeitenFundamentals of Surveyingrvkumar361969091% (58)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Tajima TME, TMEF User ManualDokument5 SeitenTajima TME, TMEF User Manualgeorge000023Noch keine Bewertungen

- NotesDokument20 SeitenNotesprasaad08Noch keine Bewertungen

- HMT Mod 5 NotesDokument66 SeitenHMT Mod 5 Notesprasaad08Noch keine Bewertungen

- GearsDokument44 SeitenGearsprasaad08Noch keine Bewertungen

- Question Bank III B.Tech-II Sem Design of Machine Members-Ii Unit - I A Design of Curved Beams Short Answer QuestionsDokument11 SeitenQuestion Bank III B.Tech-II Sem Design of Machine Members-Ii Unit - I A Design of Curved Beams Short Answer Questionsprasaad08Noch keine Bewertungen

- 10th Maths em 24-Jul-2016 21-44-08 - WatermarkedDokument1 Seite10th Maths em 24-Jul-2016 21-44-08 - Watermarkedprasaad08Noch keine Bewertungen

- Connecting RodDokument29 SeitenConnecting Rodprasaad08Noch keine Bewertungen

- FIE FormDokument10 SeitenFIE Formprasaad08Noch keine Bewertungen

- ES 2 MarksDokument17 SeitenES 2 Marksprasaad08Noch keine Bewertungen

- Energies: Emission Characteristics of A CI Engine Running With A Range of Biodiesel FeedstocksDokument17 SeitenEnergies: Emission Characteristics of A CI Engine Running With A Range of Biodiesel FeedstocksArul JONoch keine Bewertungen

- Experimental Studies On The Combustion and Emission Characteristics of A Diesel EngineFuelled With Used Cooking Oil Methyl Esterand Its Diesel BlendsDokument7 SeitenExperimental Studies On The Combustion and Emission Characteristics of A Diesel EngineFuelled With Used Cooking Oil Methyl Esterand Its Diesel Blendsprasaad08Noch keine Bewertungen

- DV03PUB1 Study GuideDokument5 SeitenDV03PUB1 Study Guideprasaad08Noch keine Bewertungen

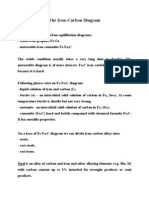

- Iron-Carbon DiagramDokument11 SeitenIron-Carbon DiagramrampradNoch keine Bewertungen

- IJEE 11 v4n5Dokument12 SeitenIJEE 11 v4n5prasaad08Noch keine Bewertungen

- M.Tech - F Semester Regulor Exqminotions April 20t5: TimetobleDokument1 SeiteM.Tech - F Semester Regulor Exqminotions April 20t5: Timetobleprasaad08Noch keine Bewertungen

- 9A01303 SurveyingDokument4 Seiten9A01303 Surveyingprasaad08Noch keine Bewertungen

- 9A01304 Fluid MechanicsDokument1 Seite9A01304 Fluid MechanicssivabharathamurthyNoch keine Bewertungen

- Nanotechnology: Course: B.E & B.Tech Subject: APPLIED CHEMISTRY Unit: VDokument10 SeitenNanotechnology: Course: B.E & B.Tech Subject: APPLIED CHEMISTRY Unit: Vprasaad08Noch keine Bewertungen

- Aluminium: A Large Aluminium Billet From Which Wrought Products Will Be ProducedDokument38 SeitenAluminium: A Large Aluminium Billet From Which Wrought Products Will Be Producedprasaad08Noch keine Bewertungen

- Design of Machine Members-IIDokument8 SeitenDesign of Machine Members-IIprasaad08Noch keine Bewertungen

- NMDC Et AdvertisementDokument8 SeitenNMDC Et AdvertisementbecbellaryNoch keine Bewertungen

- Cad Cam Viva QueDokument5 SeitenCad Cam Viva QueJeeva KarunyaNoch keine Bewertungen

- Production Engineering Syllabus (1) - 2Dokument34 SeitenProduction Engineering Syllabus (1) - 2prasaad08Noch keine Bewertungen

- After Gate Guide 2015Dokument100 SeitenAfter Gate Guide 2015JaydeepRanipaNoch keine Bewertungen

- Cad Cam Viva QueDokument5 SeitenCad Cam Viva QueJeeva KarunyaNoch keine Bewertungen

- YVC RaoDokument98 SeitenYVC Raoprasaad08Noch keine Bewertungen

- Lecture 1Dokument6 SeitenLecture 1prasaad08Noch keine Bewertungen

- Jntua B.tech Eee r13 SyllabusDokument116 SeitenJntua B.tech Eee r13 Syllabusprasaad08Noch keine Bewertungen

- Production Engineering Syllabus (1) - 2Dokument34 SeitenProduction Engineering Syllabus (1) - 2prasaad08Noch keine Bewertungen

- 9A03504 Design of Machine Elements - IDokument1 Seite9A03504 Design of Machine Elements - Iprasaad08Noch keine Bewertungen

- A.2 de - La - Victoria - v. - Commission - On - Elections20210424-12-18iwrdDokument6 SeitenA.2 de - La - Victoria - v. - Commission - On - Elections20210424-12-18iwrdCharisse SarateNoch keine Bewertungen

- To The Owner / President / CeoDokument2 SeitenTo The Owner / President / CeoChriestal SorianoNoch keine Bewertungen

- E OfficeDokument3 SeitenE Officeஊக்கமது கைவிடேல்Noch keine Bewertungen

- Fammthya 000001Dokument87 SeitenFammthya 000001Mohammad NorouzzadehNoch keine Bewertungen

- GSMDokument11 SeitenGSMLinduxNoch keine Bewertungen

- Strategic Management ModelsDokument4 SeitenStrategic Management ModelsBarno NicholusNoch keine Bewertungen

- Modal Case Data Form: GeneralDokument4 SeitenModal Case Data Form: GeneralsovannchhoemNoch keine Bewertungen

- List of Light Commercial LED CodesDokument8 SeitenList of Light Commercial LED CodesRenan GonzalezNoch keine Bewertungen

- I.V. FluidDokument4 SeitenI.V. FluidOdunlamiNoch keine Bewertungen

- DPC SEMESTER X B Project ListDokument2 SeitenDPC SEMESTER X B Project ListVaibhav SharmaNoch keine Bewertungen

- Attachment BinaryDokument5 SeitenAttachment BinaryMonali PawarNoch keine Bewertungen

- Medical Devices RegulationsDokument59 SeitenMedical Devices RegulationsPablo CzNoch keine Bewertungen

- Labor Law 1Dokument24 SeitenLabor Law 1Naomi Cartagena100% (1)

- Pet Care in VietnamFull Market ReportDokument51 SeitenPet Care in VietnamFull Market ReportTrâm Bảo100% (1)

- Characteristics of Planetary Candidates Observed by Kepler, IIDokument106 SeitenCharacteristics of Planetary Candidates Observed by Kepler, IIRick FeedNoch keine Bewertungen

- Chapter 11 Walter Nicholson Microcenomic TheoryDokument15 SeitenChapter 11 Walter Nicholson Microcenomic TheoryUmair QaziNoch keine Bewertungen

- Sappi Mccoy 75 Selections From The AIGA ArchivesDokument105 SeitenSappi Mccoy 75 Selections From The AIGA ArchivesSappiETCNoch keine Bewertungen

- Divider Block Accessory LTR HowdenDokument4 SeitenDivider Block Accessory LTR HowdenjasonNoch keine Bewertungen

- Carelink Connect: User GuideDokument41 SeitenCarelink Connect: User GuideMiha SoicaNoch keine Bewertungen

- A Varactor Tuned Indoor Loop AntennaDokument12 SeitenA Varactor Tuned Indoor Loop Antennabayman66Noch keine Bewertungen

- scx4521f SeriesDokument173 Seitenscx4521f SeriesVuleticJovanNoch keine Bewertungen

- Typical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpDokument2 SeitenTypical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpSabrinadeFeraNoch keine Bewertungen

- MDC PT ChartDokument2 SeitenMDC PT ChartKailas NimbalkarNoch keine Bewertungen

- WWW - Manaresults.co - In: Internet of ThingsDokument3 SeitenWWW - Manaresults.co - In: Internet of Thingsbabudurga700Noch keine Bewertungen

- SVPWM PDFDokument5 SeitenSVPWM PDFmauricetappaNoch keine Bewertungen

- Sikkim Manipal MBA 1 SEM MB0038-Management Process and Organization Behavior-MQPDokument15 SeitenSikkim Manipal MBA 1 SEM MB0038-Management Process and Organization Behavior-MQPHemant MeenaNoch keine Bewertungen

- Ap06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónDokument9 SeitenAp06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónJenny Lozano Charry50% (2)

- SWOT AnalysisDokument6 SeitenSWOT AnalysisSSPK_92Noch keine Bewertungen

- 1.6 Program AdministrationDokument56 Seiten1.6 Program Administration'JeoffreyLaycoNoch keine Bewertungen