Beruflich Dokumente

Kultur Dokumente

Appendix - Ii: Principles of Construction, Material and Design of Ferrocement Tank

Hochgeladen von

benzzenhdOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Appendix - Ii: Principles of Construction, Material and Design of Ferrocement Tank

Hochgeladen von

benzzenhdCopyright:

Verfügbare Formate

Appendix-II Page 1 of 5

APPENDIX - II : PRINCIPLES OF CONSTRUCTION , MATERIAL AND DESIGN OF FERROCEMENT TANK

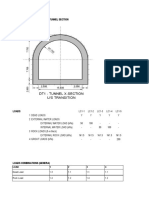

Figure A-2.1 : Principles of Construction of Small Ferrocement Standing Tanks

Appendix-II Page 2 of 5

MATERIALS NEEDED FOR FERROCEMENT TANK CONSTRUCTION Cement Three types of cement are available in the Indian Market and all the three can be used for ferrocement tank construction: 1. 2. 3. Ordinary Portland Cement (O.P.C.) may be used in normal conditions. Portland Puzolona Cement (P.P.C.) may be used in normal conditions but after checking the mortar setting. High-early-strength Cement (quick setting cement) may be used in cold climatic zones and also in places where early setting and strength gaining is desired.

Sand Sand from local sources may be checked/ tested and depending upon its properties, can be selected to meet the requirement in terms of silt contents, freedom from chemical pollution and trading. Medium coarse sand with grading may be used for ferrocement jobs. In order to find strength of mortar for designing, the tank mortar specimens may be made from these local sands. The ratio of cement : sand is 1:2 to 1:3 by volume, and water : cement ratio is 1:3 0.45 by weight (Recommended WC is 0.4) but 0.45 may be used to allow for the variation in the degree of control in the field. The desirable strengths of the mortar are as follows : Tensile strength at 28 days : (direct tension test ASTM, C190) Compressive strength at 28 days : (2 cube) Wire Mesh The most common wire meshes used for ferrocement are hexagonal wire mesh, square welded mesh and woven square mesh. Use of woven square mesh is preferred for F.C. Water Tanks. Chemical Admixtures Selected grade of poresealing compound and plasticizer may be added to the mortar to be used for construction of F.C. Tanks. Table A-2.1 : Description and Properties of Hexagonal & Square Woven Wire Meshes Ultimate Strength Yield Strength Modulus of elasticity 8740 kg/cm2 2100 kg/cm2 93.75 x 104 kg/cm2 17-30 kg/cm2 200 kg/cm2

Appendix-II Page 3 of 5

Mesh mm 19

Size (inch) (3/4)

Wire diameter commonly available (mm) 0.5 to 1.2

10

(3/8)

0.5 to 1.2

12.5

(1/2)

0.5 to 1.2

Roll size generally available 0.91 to 1.2m x 45.7 m (3 to 4 x 150) for hexagonal mesh 0.75 to 1.5m x 15 to 30 m (2.5 x 100) for square woven mesh -

For water tank construction without the aid of a formwork, the tank reinforcement must be strong enough to hold the weight of mortar applied on it and must also be stiff enough to prevent slumping of motor during plastering. Hence the square woven mesh of grid size 12.5 mm (0.91 30.5 m roll size) has been chosen because to its stiffness when compared to hexagonal mesh and cost advantage when compared to welded wire meshes. Tank Dimensions Diameter Area (in plan) of tank Height Wall Thickness Actual Volume of container Capacity for water storage 12m3 Unit 2.5 m 4.90 m2 2.50 m 30 mm 12.27 m3 12 m3 15m3 Unit 2.5m 4.90 m2 3.11 m 30 mm 15.19 m3 15 m3

The maximum hoop stresses obtained from an analysis of fixes and hinged types connections between the wall and the base are 6.64 kg/cm2 and 7.18 kg/cm2 respectively. The maximum bending moment at the base of the wall is 34.20 kg-cm/cm width, which creates a maximum fibre stress of 12.83 kg/cm2, if the wall is not reinforced. DESIGN The stresses occurring in the tank are small and do not exceed event the tensile strength of unreinforced mortar (17 kg/cm2) hence, in this case, the design of the tank is controlled partly by construction techniques and the sizes of materials available. For ease in construction, the tank reinforcement chosen of 6 mm skeletal steel rods sandwiched between two layers of 12.5 mm squares, woven 20g (0.9 mm) wire G.I. mesh should be used. The distance between the mesh layers should be 13 to 15 mm. A single tank can be constructed in four days. Construction can be carried out by unskilled labour if good finishing, plastering is not required. Water tightness of the tank is excellent. A waterline or a seepage loss, which is normally visible in a concrete tank when it is first filled with water, does not exist. Villagers may at first be sceptical because of the thickness of the walls of the tank but these reactions, however, will change when the tank shows its remarkable strength.

Appendix-II Page 4 of 5

Casting of Roof for Tanks Ferrocement roofs for water tanks are also precast over masonry moulds in one piece or in 4 to 6 pieces depending upon size and height of the tank. Jointing method for roof segments is the same as for wall segment. If the roof is in pieces, the pieces are erected, placed in position at the top and supported temporarily. The laps of reinforcement for joints are fixed up and the joints are filled with mortar. Two types of joints between wall and roof can be adopted. 1. 2. The edge cast around the roof is placed in collar provided at the top of the wall (assembled with segments) and the mortar is filled in the wall roof paint. The roof/ roof segment edge beam covers the wall top edge, like a cover

Various stages of construction of Roofing Units for Ferrocement tanks have been shown in Figure A-2.2. Dos and Donts for Ferrocement Tanks Dos 1. 2. Use the best quality material for constructing the tank. Take all care to see that there are no lose pockets or honey-combed areas in the surface of wall or base of ferrocement tank. If such a defect is detected, repair it by chipping mortar on inside and outside surfaces (exposing the wire mesh in that area) and replastering. Cure F.C. tanks for a minimum of 10 days. Clean the tank from inside atleast twice a year. Keep the top of the tank clean to avoid entry of waste material in the tank. Construct the tank at higher point so that drainage of water is proper or construct a soaking pit and connect it to the tank by a drain. Take all care during mortar application and ensure that the mortar enters behind the seat rods and wires provided as skeletal steel and into the wire mesh layer reinforcement. Ensure that the cover over outer and inner mesh layer is not less than 3 mm.

3. 4. 5. 6. 7.

Donts 1. 2. 3. 4. 5. 6. Do not allow animals to come near the tank. Do not allow children to climb over the tank. Do not use corrected steel or mesh for construction of the tank. Do not use old stocks of cement for tank construction. Sand to be used should be graded and clean sand having silt contents within 3 percent of the volume. Extra fine or coarse sand must not be used. Do not allow water fittings fixed in the tank to leak, it will not only waste water but may also prove a base for algae growth on fitting joints or surface of the tank and lead to development of bacteria colonies in these. Do not use chemically polluted water on mixing the mortar or curing of ferrocement tank. Do not paint drinking water tank without confirmation of specifications laid down by the Indian Standard Specifications 158 (I.S.158).

7. 8.

Appendix-II Page 5 of 5

Figure A-2.2 : Mould and Reinforcement Cage for Roof of Ferrocement Water Tanks

Rise of Roof Dome Dia of Tank (cm) Rise in Roof Dome, (cm) 65 10 75/80 10 90 10 120 12 160 18 200 20 300 25

Reinforcement Cage for 60, 65, 75 & 90 cm Diameter F.C. Tanks

- Reinforcement Cage for Roof of F.C. Tanks

of 120, 130, 140 & 160 cm Diameter - Wire Mesh Reinforcement 1 Layer of 22G G.I. Woven Mesh on inside & outside surfaces

- Reinforcement Cage for Roof of F.C. Tanks

of Diameters upto 2.25 m - Wire Mesh 2-22G G.I. Woven Mesh one on each side

Casting Matrix -

Cement Medium Coarse Graded Sand Water Poresealing Compound Plasticizer

- 1 Part - 2 Part - 0.4 Parts - 0.5 Percent of Cement - 0.5 Percent of Cement

Das könnte Ihnen auch gefallen

- Slab Design of Partially Fixed Circular SlabDokument4 SeitenSlab Design of Partially Fixed Circular SlabBithika DattaNoch keine Bewertungen

- Steel Grillage Fondation: Presented byDokument12 SeitenSteel Grillage Fondation: Presented byAbhishek ChaurasiaNoch keine Bewertungen

- ASCE 7-02 Errata First PrintingDokument8 SeitenASCE 7-02 Errata First PrintingC. Todd St. GeorgeNoch keine Bewertungen

- 2911 3Dokument44 Seiten2911 3rambinodNoch keine Bewertungen

- XyzDokument64 SeitenXyzP S HARSHITANoch keine Bewertungen

- Design Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesDokument9 SeitenDesign Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesMagdy Bakry100% (1)

- TSS 35 205Dokument1 SeiteTSS 35 205Akhil VNNoch keine Bewertungen

- Earthquake Resistant StructuresDokument6 SeitenEarthquake Resistant StructuresAmith KeshvtakarNoch keine Bewertungen

- Huong Dan MegafloorDokument11 SeitenHuong Dan Megafloortrung1983Noch keine Bewertungen

- Staircase Design 001Dokument18 SeitenStaircase Design 001Er navneet jassiNoch keine Bewertungen

- Steel Column DesignDokument3 SeitenSteel Column DesignGlenn TeNoch keine Bewertungen

- 4B4DC764AC39AFAD5D5F9C87B731618Dokument12 Seiten4B4DC764AC39AFAD5D5F9C87B731618Rama KrishnaNoch keine Bewertungen

- Types of Ties For and Placement of Reinforcing SteelDokument8 SeitenTypes of Ties For and Placement of Reinforcing Steelइंजि कौस्तुभ पवार100% (1)

- Chapter 2 Design For Serviceability PDFDokument14 SeitenChapter 2 Design For Serviceability PDFChee Fong MakeNoch keine Bewertungen

- Civil Pile Foundation ReportDokument33 SeitenCivil Pile Foundation ReportAnonymous sus3ugOxkwNoch keine Bewertungen

- Given Data: Given Data:: Design of Raft Foundation Design of Raft FoundationDokument8 SeitenGiven Data: Given Data:: Design of Raft Foundation Design of Raft FoundationBikram BhusalNoch keine Bewertungen

- KN/M KN/M 30: Design The Shown Reinforced Concrete Retaining WallDokument3 SeitenKN/M KN/M 30: Design The Shown Reinforced Concrete Retaining Wallbadr amNoch keine Bewertungen

- SAP2000 Section PropertiesDokument3 SeitenSAP2000 Section PropertiesCon Can100% (1)

- Design of Long Wall: Tank Full and No Soil PressureDokument6 SeitenDesign of Long Wall: Tank Full and No Soil PressureAshoka YadavNoch keine Bewertungen

- Comparative Study of Supporting System of Elevated Billboard (Hoarding) Structures Having Different ConfigurationDokument5 SeitenComparative Study of Supporting System of Elevated Billboard (Hoarding) Structures Having Different ConfigurationBhavin JoshiNoch keine Bewertungen

- Amendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeDokument9 SeitenAmendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeAKSNoch keine Bewertungen

- Dynamic Active Earth Pressure On Retaining StructuresDokument10 SeitenDynamic Active Earth Pressure On Retaining StructurescristiannecivilNoch keine Bewertungen

- Aisc 01Dokument5 SeitenAisc 01amokhtaNoch keine Bewertungen

- Shear Lug Verification Example 2Dokument1 SeiteShear Lug Verification Example 2Nasrul AdliNoch keine Bewertungen

- CF1Dokument9 SeitenCF1joeNoch keine Bewertungen

- Tower Design SheetDokument41 SeitenTower Design Sheet14pcashNoch keine Bewertungen

- Truss DesignDokument16 SeitenTruss DesignRabindraUpretiNoch keine Bewertungen

- StruCad Evolution Getting Started TutorialDokument41 SeitenStruCad Evolution Getting Started Tutorialnifty25Noch keine Bewertungen

- Shallow Foundation Design 2: SettlementDokument32 SeitenShallow Foundation Design 2: SettlementPhanna MongNoch keine Bewertungen

- A&m BSR-2011Dokument26 SeitenA&m BSR-2011Mukesh Jangid100% (1)

- Effective LengthDokument17 SeitenEffective LengthJob NantawatNoch keine Bewertungen

- Modus Operandi - Proflex - Self Supported Roof - All Technical DetailsDokument19 SeitenModus Operandi - Proflex - Self Supported Roof - All Technical Detailsuday Ravi100% (1)

- End Plates - Worked Examples With Partial Depth End Plate - Example 5Dokument1 SeiteEnd Plates - Worked Examples With Partial Depth End Plate - Example 5Kimutai Kirui AlphonceNoch keine Bewertungen

- 4 Numerical Example On Design of 3 or More Span Cont. BeamDokument21 Seiten4 Numerical Example On Design of 3 or More Span Cont. BeamAshok Kumar RajanavarNoch keine Bewertungen

- Beggs Deformeter CalculationsDokument5 SeitenBeggs Deformeter CalculationsCivil EngineerNoch keine Bewertungen

- Day 2 S3 BNBC 2020Dokument75 SeitenDay 2 S3 BNBC 2020November RainNoch keine Bewertungen

- Wind Load On Cable TraysDokument10 SeitenWind Load On Cable TraysAaron EasleyNoch keine Bewertungen

- Slender Column - Sway Frame - ACI 318-08 Reinforced Concrete Design Example HassounDokument8 SeitenSlender Column - Sway Frame - ACI 318-08 Reinforced Concrete Design Example HassounMike2322100% (1)

- Ec7 WallapDokument20 SeitenEc7 WallapJJUOH85Noch keine Bewertungen

- Design Report PDFDokument439 SeitenDesign Report PDFKhaled Abdel SalamNoch keine Bewertungen

- Beams - ASD NSCP 2001 FlowchartDokument1 SeiteBeams - ASD NSCP 2001 FlowchartDavid Nelson AngiwanNoch keine Bewertungen

- Column Design - As Per BS CodeDokument16 SeitenColumn Design - As Per BS CodeYam BalaoingNoch keine Bewertungen

- False CeilingDokument23 SeitenFalse CeilingEng HatemNoch keine Bewertungen

- Design of Brick Wall For Ware House:-: 1 DataDokument3 SeitenDesign of Brick Wall For Ware House:-: 1 DataSovan PramanickNoch keine Bewertungen

- Sway Frame Steel Column DesignDokument1 SeiteSway Frame Steel Column DesignChirianu MarianNoch keine Bewertungen

- Procedure - Equivalent Diagonal StrutDokument5 SeitenProcedure - Equivalent Diagonal StrutHemant SonawadekarNoch keine Bewertungen

- Setha's CV & Cover LetterDokument10 SeitenSetha's CV & Cover LetterMen Keo RathaNoch keine Bewertungen

- 5-Design of Raft FoundationDokument2 Seiten5-Design of Raft FoundationheshamNoch keine Bewertungen

- Seismic Design of Concrete StructureDokument56 SeitenSeismic Design of Concrete Structureclarkgagui100% (1)

- Z Purlin Design Span 12 SL 0.3Dokument1 SeiteZ Purlin Design Span 12 SL 0.3arman malikNoch keine Bewertungen

- Explanatory Examples On Indian Seismic Code IS 1893 (Part I)Dokument27 SeitenExplanatory Examples On Indian Seismic Code IS 1893 (Part I)hitech ConsultancyNoch keine Bewertungen

- RCC Railing To OHSRDokument24 SeitenRCC Railing To OHSRNaga Bharath ReddyNoch keine Bewertungen

- ACI 318-14 ColumnaDokument4 SeitenACI 318-14 ColumnaMoy ReapNoch keine Bewertungen

- Specification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeDokument5 SeitenSpecification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeSOMNATH JANANoch keine Bewertungen

- Cladding& Runner DesignDokument1 SeiteCladding& Runner DesignDeepmalaJayeshNoch keine Bewertungen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- ConstructionDokument9 SeitenConstructionAna Bella RosarioNoch keine Bewertungen

- Semnalele Agentului Rutier Uk PDFDokument2 SeitenSemnalele Agentului Rutier Uk PDFbenzzenhdNoch keine Bewertungen

- Reflexive Pronouns Exercises Esl Grammar WorksheetDokument2 SeitenReflexive Pronouns Exercises Esl Grammar WorksheetbenzzenhdNoch keine Bewertungen

- Falconry Sau Soimarit in UKDokument44 SeitenFalconry Sau Soimarit in UKbenzzenhdNoch keine Bewertungen

- Photoshop User Magazine May-June 2013Dokument120 SeitenPhotoshop User Magazine May-June 2013benzzenhdNoch keine Bewertungen

- Ten Principles PruningDokument3 SeitenTen Principles PruningbenzzenhdNoch keine Bewertungen

- Stonewall Building: Fact Sheet No. 37 May 2006Dokument2 SeitenStonewall Building: Fact Sheet No. 37 May 2006benzzenhdNoch keine Bewertungen

- Ferro Cement Water TankDokument42 SeitenFerro Cement Water TankbenzzenhdNoch keine Bewertungen

- Formule Trigonometrice: A C B C A B B ADokument4 SeitenFormule Trigonometrice: A C B C A B B ABeldiman StefanNoch keine Bewertungen

- Tharmal Analysis BasicsDokument56 SeitenTharmal Analysis BasicsNetoNoch keine Bewertungen

- U042en PDFDokument12 SeitenU042en PDFTatiya TatiyasoponNoch keine Bewertungen

- Triaxial Test Systems enDokument10 SeitenTriaxial Test Systems enDetjan JuniorNoch keine Bewertungen

- 6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFDokument31 Seiten6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFOwen PerrinNoch keine Bewertungen

- J.M. Hurst Cyclic AnalysisDokument45 SeitenJ.M. Hurst Cyclic AnalysisChristian Robinson80% (10)

- Schneider EngineeringDokument1 SeiteSchneider EngineeringT.J. MayesNoch keine Bewertungen

- Pioneer XDP - 30R ManualDokument213 SeitenPioneer XDP - 30R Manualmugurel_stanescuNoch keine Bewertungen

- UMTS AircomDokument20 SeitenUMTS AircomDũng PhạmNoch keine Bewertungen

- Materials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilDokument5 SeitenMaterials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilBart MaxNoch keine Bewertungen

- TDS Sadechaf UVACRYL 2151 - v9Dokument5 SeitenTDS Sadechaf UVACRYL 2151 - v9Alex MacabuNoch keine Bewertungen

- Huawei ACU2 Wireless Access Controller DatasheetDokument12 SeitenHuawei ACU2 Wireless Access Controller Datasheetdexater007Noch keine Bewertungen

- Diet Coke & Mentos Geyser Lab 2011-2012Dokument4 SeitenDiet Coke & Mentos Geyser Lab 2011-2012Frederick LoganNoch keine Bewertungen

- WEISER Locks and HardwareDokument24 SeitenWEISER Locks and HardwareMaritime Door & WindowNoch keine Bewertungen

- Simatic EKB Install 2012-03-08Dokument2 SeitenSimatic EKB Install 2012-03-08Oton SilvaNoch keine Bewertungen

- Lecture10 Combined FootingsDokument31 SeitenLecture10 Combined FootingsGopalram Sudhirkumar100% (3)

- AI in RobotsDokument75 SeitenAI in RobotsIslam SehsahNoch keine Bewertungen

- Marine Lubricants Equivalents List: Sae 50 TBN 57 Sae 50 TBN 55 Sae 40 TBN 60 Sae 50 TBN 50 Sae 50 TBN 55Dokument3 SeitenMarine Lubricants Equivalents List: Sae 50 TBN 57 Sae 50 TBN 55 Sae 40 TBN 60 Sae 50 TBN 50 Sae 50 TBN 55spyros_peiraiasNoch keine Bewertungen

- Comparative Tracking Index of Electrical Insulating MaterialsDokument6 SeitenComparative Tracking Index of Electrical Insulating MaterialsAbu Anas M.SalaheldinNoch keine Bewertungen

- Air-Bag: (1) Connector InformationDokument34 SeitenAir-Bag: (1) Connector InformationbakriramziNoch keine Bewertungen

- Optimasi Blending Pertalite Dengan Komponen Reformate Di PT. XYZ BalikpapanDokument7 SeitenOptimasi Blending Pertalite Dengan Komponen Reformate Di PT. XYZ BalikpapanFrizki AkbarNoch keine Bewertungen

- ChemCAD and ConcepSys AIChE Spring 09Dokument28 SeitenChemCAD and ConcepSys AIChE Spring 09ConcepSys Solutions LLCNoch keine Bewertungen

- Section 05120 Structural Steel Part 1Dokument43 SeitenSection 05120 Structural Steel Part 1jacksondcplNoch keine Bewertungen

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDokument15 SeitenAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNoch keine Bewertungen

- Deep Web Research and Discovery Resources 2019 by Marcus P. Zillman, M.S., A.M.H.A.Dokument67 SeitenDeep Web Research and Discovery Resources 2019 by Marcus P. Zillman, M.S., A.M.H.A.Tina CleoNoch keine Bewertungen

- Grundfos S Pump 5 - 29 KW Super VortexDokument20 SeitenGrundfos S Pump 5 - 29 KW Super Vortexdalveerchoudhary100% (1)

- Folder Fiamm Neptune 2010 EngDokument4 SeitenFolder Fiamm Neptune 2010 EngchokribNoch keine Bewertungen

- SF6 Novec 4710Dokument4 SeitenSF6 Novec 4710Fidya Eka PrahestiNoch keine Bewertungen

- Preview ISO+749-1977 PDFDokument3 SeitenPreview ISO+749-1977 PDFLiana GaniNoch keine Bewertungen

- RT L2 General Examination PaperDokument4 SeitenRT L2 General Examination PaperdaddadNoch keine Bewertungen

- EM230 BR BM3 Fitting InstructionsDokument2 SeitenEM230 BR BM3 Fitting InstructionsRoman BabaevNoch keine Bewertungen