Beruflich Dokumente

Kultur Dokumente

RichPROJECT GUIDE Text Editor File

Hochgeladen von

Maxwell SakutukwaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RichPROJECT GUIDE Text Editor File

Hochgeladen von

Maxwell SakutukwaCopyright:

Verfügbare Formate

Bachelor of Technology Honours Degree in Chemical and Process System Engineering Project outline Project Title: Project Code:

Duration: Weighting: Lecturers: 1.0 Preamble HIT400 is a capstone design project intended to demonstrate the students ability to solve a problem of a technical nature. It involves the conceptualization, analysis, synthesis, design and construction of a model of a real plant. The student works individually under the supervision of a senior member of the academic staff in the department. On completion of the project, the student is expected to produce a model and a project design report. The project should show innovation and demonstrate an apparent improvement from HIT 300 in terms of the degree of difficulty of the problem being solved and the extent to which Chemical and Process Systems Engineering concepts are applied. The practical exposure at HIT 301 must also be demonstrated and enable the student to solve real life challenges. Students should be able to demonstrate all chemical and process engineering concepts they assimilated in the previous years. The project must encompass the design of major pieces of equipment such as distillation columns, heat exchangers, chemical reactors evaporators and the sizing of other common equipment like pumps, valves storage tanks,and pipes. Capstone Design Project HIT 400 144 hrs 8 credits All Academic members of Department

2.0 Aims The broad aims of the capstone project are to demonstrate competence in technical problem solving by testing the ability of the student to design and conduct experiments; ability to analyse, interpret and use data; ability to design a system and its components;and an understanding of the economic, social and environmental impact of projects. 3.0 Objectives By the end of the course students should be able to: Apply principles and techniques learnt to the chemical and mechanical design, construction, process control and improvement of machines and equipment of processing plants. Apply skills to rehabilitate and show innovativeness in existing process manufacturing facilities. Be able to scale up and commercialise chemical engineering processes Solve real life technical problems Start their own high tech business enterprises 4.0 ProjectContent 4.1 Project Document Chapters

4.1.1 Chapter 1: INTRODUCTION The chapter should spell out clearly the problem the project is intended to address, the product to be manufactured, its role in in industry, consumption levels and choice of production level and an overview of the environmental issues including safety and toxicity of the product.

4.1.2 Chapter 2: LITERATURE REVIEW The chapter should contain literature review of the project. This is done to give a theoretical background to the chemical processes involved.as well as to collect physical data for design purposes. A comparison of the technologies available on the subject is undertaken and the best process option selected. 4.1.3 Chapter 3: RESEARCH METHODOLOGY The chapter includes the research methodology and design of experiments. It encompasses all the approaches to be employed to enable the student to design the process and the equipment. Algorithms to be followed are part of this chapter. Included are all the means of data gathering and processing to be done. Each experiment to be done should be for data required in the design of the capstone project. All the experiments to be undertaken are to be formulated and designed in this chapter. 4.1.4 Chapter 4: EXPERIMENTAL RESULTS AND ANALYSIS The chapter should contain results of experiments undertaken and the analysis of the results. All results are to be clearly tabulated in this chapter. A proper statistical analysis of the collected data using statistical packages where possible .should be undertaken. The student should use this data in designing pieces of equipment in the project. 1. Chapter 5: PROCESS DESIGN This chapter includes design assumptions, block flow diagram (BFD), material and energy balances for the entire process, process flow diagram (PFD) showing all major equipment and streams and their composition and process conditions; pipe and instrumentation diagrams, (PID) and process description 4.1.6 Chapter 6: EQUIPMENT DESIGN Students are expected to demonstrate an in-depth understanding of chemical engineering design principles and mechanical design of the equipment. The students should select at least two major equipment and carry out a detailed design of each. They should demonstrate understanding of equipment architecture, choice of material of construction, stress calculations and pressure vessels fabrication. An equipment specification sheet should be prepared for each piece of major equipment designed. 1. Chapter 7: PROCESS CONTROL AND HAZOP ANALYSIS Process control strategy for temperature, pressure, level and flow should be done and process instrumentation should be recommended Students should come up with HAZOP analysis of the chosen equipment. 4.1.8 Chapter 8: SITE SELECTION AND PLANT LAYOUT

The chapter deals withfactors affecting site selection, decision matrix for site selection, equipment

spacing assumptions made in deciding the plant layout and the plant layout diagram.

4.1.9 Chapter 9: ENVIRONMENT IMPACT ASSESSMENT The student should prepare a preliminary environment impact assessment as a result of the products and waste material produced by the project. The assessment should cover the impact of gaseous, liquid and solid pollutants on air, water, soil; and human and animal life 4.1.10 Chapter 10: ECONOMIC ANALYSIS The purpose of this chapter is to demonstrate the economic and financial viability of the project using profitability indicators such as return on investment (ROI), payback period (PP), break-even (BE) point analysis, net present value (NPV) and internal rate of return (IRR). The chapter will cover assumptions on financing (gearing ratio used, interest rate on any loan amount borrowed, and grace period) estimation of project cost (fixed cost and working capital), estimation of manufacturing unit cost, and calculation of annual net cash flows.

4.1.11 Chapter 10: CONCLUSION AND RECOMMENDATIONS This chapter should cover design results discussion, conclusion and recommendations 4.1.12REFERENCES All sources of information used should be listed in the references. Students must use the Harvard reference system. 4.2 MODEL OR PROTOTYPE PRODUCTION A HIT 400 project must be backed up with the production of either a model or a prototype for the production processor of the designed equipment. 4.3 REPORT WRITING The report should: Have a minimum of 80 pages and maximum of 100 Have a font size 12, Times New Roman Be presented in one an

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ieo Sample Paper Class-5Dokument2 SeitenIeo Sample Paper Class-5Dev AhanaNoch keine Bewertungen

- The Atom: Cornell Doodle NotesDokument22 SeitenThe Atom: Cornell Doodle NotesSalina SalujaNoch keine Bewertungen

- Mod6 4Dokument10 SeitenMod6 4mn3mNoch keine Bewertungen

- Lecture 6 OptimizationDokument41 SeitenLecture 6 Optimizationaku_la100% (2)

- Human Genetics: Ms MB KekanaDokument31 SeitenHuman Genetics: Ms MB Kekanavulkaan van huisNoch keine Bewertungen

- O-Ring UKDokument12 SeitenO-Ring UKAan Sarkasi AmdNoch keine Bewertungen

- Retscreen International: Clean Energy Project AnalysisDokument72 SeitenRetscreen International: Clean Energy Project AnalysisAatir SalmanNoch keine Bewertungen

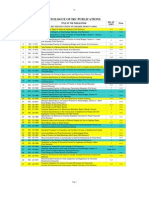

- 2022 FM1 Five-Star PhysicianDokument39 Seiten2022 FM1 Five-Star PhysicianVaghani Dhruv SumantbhaiNoch keine Bewertungen

- Industrial Automation Lab: Project ProposalDokument3 SeitenIndustrial Automation Lab: Project ProposalAmaan MajidNoch keine Bewertungen

- Hitachi ZX75USDokument9 SeitenHitachi ZX75US3man 9394Noch keine Bewertungen

- Big Breakfasts Help Us Burn Double The CaloriesDokument4 SeitenBig Breakfasts Help Us Burn Double The CaloriesBastian IgnacioNoch keine Bewertungen

- Week Logical FallaciesDokument79 SeitenWeek Logical FallaciesSaqib AbbasNoch keine Bewertungen

- CEP Presentation AOL 2023Dokument143 SeitenCEP Presentation AOL 2023Josh DezNoch keine Bewertungen

- HR-Security Profile OptionDokument1 SeiteHR-Security Profile Optionnil77Noch keine Bewertungen

- Function List of Car BrainDokument39 SeitenFunction List of Car BrainBogdan PopNoch keine Bewertungen

- Bilingual First Language Acquisition: January 2008Dokument11 SeitenBilingual First Language Acquisition: January 2008Katsiaryna HurbikNoch keine Bewertungen

- Qaisra Shahraz - A Pair of JeansDokument3 SeitenQaisra Shahraz - A Pair of Jeansmonkey3333389% (19)

- IRC CodesDokument23 SeitenIRC CodesabhijithavalNoch keine Bewertungen

- Module Virus Viroids PrionsDokument17 SeitenModule Virus Viroids PrionsJennifer MartinNoch keine Bewertungen

- General Lecture - Paper Deep RiversDokument13 SeitenGeneral Lecture - Paper Deep RiversAJ TabuenaNoch keine Bewertungen

- Iot Based Home Automation Using NodemcuDokument52 SeitenIot Based Home Automation Using NodemcuSyed ArefinNoch keine Bewertungen

- Spare Parts ListDokument29 SeitenSpare Parts ListRonaldNoch keine Bewertungen

- The BoarderDokument3 SeitenThe BoarderAnonymous iX6KV9LZzoNoch keine Bewertungen

- Los Ángeles Times BOLIVIADokument5 SeitenLos Ángeles Times BOLIVIAMarianita Guisselle Garcia SandovalNoch keine Bewertungen

- Renub Research: Singapore Medical Tourist Arrivals, Medical Tourism Market & Forecast To 2015Dokument13 SeitenRenub Research: Singapore Medical Tourist Arrivals, Medical Tourism Market & Forecast To 2015api-114525849Noch keine Bewertungen

- Il Ruolo Delle Esperienze Religiose Nella Cultura Della LegalitàDokument42 SeitenIl Ruolo Delle Esperienze Religiose Nella Cultura Della LegalitàMarisa La BarberaNoch keine Bewertungen

- Substantive Testing in The Revenue CycleDokument3 SeitenSubstantive Testing in The Revenue CycleGeorgia FlorentinoNoch keine Bewertungen

- Raman SpectraDokument22 SeitenRaman SpectraAnanda SelvamNoch keine Bewertungen

- ResumeDokument38 SeitenResumeRiyaz SiddiqueNoch keine Bewertungen

- OverlandersDokument17 SeitenOverlandersJoe FloodNoch keine Bewertungen