Beruflich Dokumente

Kultur Dokumente

Cultivating Mushrooms Making Composted Substrated

Hochgeladen von

vas2000Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cultivating Mushrooms Making Composted Substrated

Hochgeladen von

vas2000Copyright:

Verfügbare Formate

Volume 10, Part 2, May 1996

CULTIVATING MUSHROOMS: MAKING COMPOSTED AND NON-COMPOSTED SUBSTRATES

RICHARD SCRASE

'Mushroom makers', 38 Eastbourne Avenue, Bath BA1 6EN, UK Tel./Fax: 01255338165/01225447962

This article describes the range of materials used for mushroom cultivation and introduces the methods for their preparation. The production of sufficient mycelial biomass to support a useful mushroom yield has traditionally taken place within large quantities of naturally occurring materials. These can be relatively unprocessed, ego freshly cut wood (logs), or transformed by procedures known as 'composting' The compost (using the term loosely, as some substrates mentioned have not necessarily been through a composting process of alteration by microorganisms) not only provides the nutritional requirements of the fungus but also the physical and chemical conditions that give the fungus a competitive edge over other microorganisms. All saprotrophic basidiomycetes require carbon compounds which are usually obtained from plant polymers. The enzymes that break down these polymers can together be effective against a wide range of cellular architectures, and so have an action that is non-specific enough to allowthe grower to replace the natural diet with more readily available alternatives, ego substituting straw for wood. Nitrogen compounds also have to be provided and sources containing the nitrate ion are usually acceptable. Essential elements and vitamins are not usually growth-limiting except for calcium which is often added to regulate pH and to modify the structure of the compost. Almost any organic material can be composted, but it must be mixed to give a carbon/nitrogen ratio of between 80:1 and 10:1 (Charlesworth, 1995). Chemical analysis of wood shows a C/N ratio of 500-1250:1 (Stamets & Chilton, 1983). Other natural substrates have nitrogen contents that are growth-limiting so nitrogen supplementation increases mushroom yields in many compost systems. One example is Lepista nuda (Bull. : Fr.)Cooke, the Wood Blewit; this fungus utilises leaf-litter in nature but has been grown semi-commercially on Agaricus bisporus (Lange)Imbach mushroom compost (Frische & VanLoone, 1989). The fact that Lepista nuda can fruit on this range of composts demonstrates a fundamental ecological niche for the Wood Blewit that is wider than its perceived ('realised') niche in the wild. This contrast between the perceived and fundamental niches may well be found in other species, in which case the example of Lepista nuda is a message of hope to the cultivator because it raises the possibility that the composts listed below may serve as suitable substrates for many different species. Those fungi which are currently under largescale cultivation are grown on a spectrum of composts; from non-sterile fresh lignocellulosic material such as straw used for Pleurotus spp. (Zadrazil & Reiniger, 1988) and logs used for Lentinus edodes (Berk.)Sing. (Przybylowicz & Donoghue, 1990) through Volvariella volvacea (Bull. : Fr.)Singer (Chang & Hayes, 1978) on straw composted for a few days, to Agaricus bisporus on straw supplemented with nitrogen (manure) composted in two phases over three weeks. The processes of compost preparation will only be outlined below, fuller treatments are available in the references (Stamets & Chilton, 1993; Fermor et aI, 1985).

Natural bulk substrates

The use of non-composted materials is common among commercial growers of Pleurotus, Volvariella, Flammulina and Stropharia. These materials can be sterilised, pasteurised, or used untreated in their natural state. For example I have grown Pleurotus ostreatus (Jacq. : Fr.)Kummer outdoors on a 'bale' of unsterilised wheat straw, soaked in cold tap-water, with good results. The Pleurotus mycelium grew in all but the outer 5cm of the bale. When growing mushrooms indoors however, problems with fungal and other contaminants make it prudent to pasteurise or sterilise the compost. Steineck (1984) lists many species he has grown on straw or wood-chips buried in damp and shady places in his garden and these materials can form the basis of both garden and commercial

Volume 10, Part 2, May 1996

scale cultivation. growth . Because alder is high in sugar content, without resins, and abundant, it has often been selected (Stamets & Chilton, 1983). In spring, fresh cut branches are chipped, mixed wit h the inoculum (which itself can be grown on wood-chips) and made into a ridge bed on the ground. Pieces 2-8 em long give better results than sawdust in non-sterile conditions. The bed size commonly used is 60 em wide by 15 em deep. Incidentally, the beds of wood-chips and bark used to cushion falling children in parks frequently support massive fruitings of mushrooms, ego Hypholoma fasciculare (Huds.: Fr.)Kummer (sulphur tuft) and the false morel Gyromitra esculenta (Pers.)Fr. (personal observation).

Cereal straw

Straw, clean and unspoiled by any previous decomposition, is prepared by chopping it into 2-8 cm lengths and soaking in water for about three days to achieve 75% moisture. Baled cereal straw is ideal as it needs no further chopping. This is sufficient for competitive species such as Pleurotus ostreatus but to reduce losses from competition the straw can be pasteurised by using hot water or sterilised by steam. Straw is usually ino culated with grain spawn at the rate of 1-2% by weight (Stamets & Chilton, 1983).

Deciduous leaves

Leaves were used by Matruchot (1917) to grow Lepista nuda in caves left by limestone mining. In the process of replicating his experiments in a local disused mine , I discovered that standard mushroom compost could be used as a substrate instead. The yields from mushroom compost are higher, but it is generally used in a less romantic setting . Leaf mould has a long history of use in horticulture , traditionally by being stacked outdoors in piles 60-90 em deep for t wo years to allow it to decompose (Larkcom, 1976). The resulting fibrous material is used as a mulch or as the water-holding component of seed, cutting and potting composts. The need to replace peat (Pryce, 1991) may create a niche for leaf-mould. Preliminary experiments using leaves inoculated with Lepista nuda produced horticulturally useful leaf-mould in six months (Scrase, 1993). Leaves are often available in the autumn from civic authorities and should not be collected from the wild.

Sawdust

The particulate nature of sawdust makes nutrients more readily available, consequently competing organisms can rapidly invade these materials. Therefore the sawdust-based substrate is usually sterilised or pasteurised prior to inoculation. Generally the sawdust type is matched to the fungus, but alternatives to the usual host species can be substituted. Even softwood sawdust can be substituted for hardwood if it is aged for about a year to allow the reduction in the amount of resins and phenolics ; more commonly growers use a blend. The time taken to degrade the substratum is related to particle size and with shiitake the optimum is 2-3 mm (Nisikado et al, 1942). Smaller particles reduce gas-flow and restrict growth. Sawdust is usually supplemented to increase the amount of nitrogen and easily assimilated carbohydrates. While high levels of supplementation result in higher yields it also encourages the growth of competitors . The recipes below are a result of finding a balance between these two opposing considerations (Stamets & Chilton, 1983). standard formula sawdust 80% cereal bran 20% low contamination formula sawdust 90% cereal bran 10%

Wood-logs

The most notable commercial species grown on wood is Lentinus edodes or Shiitake. Logs (traditionally oak) 7-15 em in diameter and 90 em long are cut between autumn and spring when sap content is highest. Care is taken to leave the bark intact as this has consequences for subsequent fruiting. Holes 2-3 cm deep are drilled 20 em apart into the log, then plugged with sawdust spawn or mycelium-colonised dowels (Przybylowicz & Donoghue, 1990).

Wood-chips

Freshly cut chips of alder (Alnus glutinosus), maple (Acer spp.), and fir (Abies spp.) can support mycelial

The optimum moisture level is between 55% and 70% by dry weight before heat treatment. This can be established by oven-drying a sample ; however many growers estimate the proper moisture content by squeezing the mixture in one hand ; drops of free water should be squeezed out. Air exchange is enabled by using low density polyethylene bags or by inserting cotton wool, foam,

Volume 10, Part 2, May 1996

etc. into the neck of the container holding the substrate. inorganic nitrogen can be used. Elephant manure has been found satisfactory (Genders , 1969). The aim is to create an initial mixture with a nitrogen content of 1.5-1.7%, a water content of 70% (+/-3%), and a carbon/nitrogen ratio of approximately 30:1. Many materials can be used as supplements to modify the C/N ratio, egourea, cereal bran, or sugar beet pulp. The following recipes are based on using fresh materials but are given as dry weight ratios . Horse manure has proportions of manure and straw 100 to gypsum 5 while synthetic compost is made up in these proportions: wheat straw 52, chicken manure 45, gypsum 3.5. To make mushroom compost, fresh manure and straw is mixed, soaked and then stacked. To prevent the development of anaerobic conditions within the stack the vertical cross-section is generally not more that 2 x 2 metres. This allows the microorganisms present in the raw materials to begin to degrade the stack. Their activity heats up the stack which in turn makes conditions ideal for further decomposition by other microorganisms. The stack core is depleted of oxygen in 48 to 96 hours and it is then rebuilt. This procedure is repeated three times during the first phase to allow decomposition to continue, typically during the third, fifth and seventh day after initial mixing. The centre of the stack, should reach 65-80C. At the end of this first phase the compost should be deep brown, be flecked with whitish colonies of actinomycetes , smell of ammonia, have a pH of 8.08.5, and release liquid when firmly squeezed. In the second phase, the compost is filled into trays , beds or bags and pasteurised (58-60C). This kills nematodes, fly eggs and larvae, mites and competitor fungal mycelium and spores. The compost is 'fermented' for a further 5-8 days. During this time the internal temperature of the compost is held at about 50C by controlling ventilation. This is optimal for the actinomycetes that incorporate ammonia at this stage. The presence or rather absence of ammonia is usually detected by smell, but cresyl orange indicator or gas detection tubes can be used. After the ammonia concentration has dropped to 10-20 [lgg-l, the temperature is allowed to drop to 25C and the compost is inoculated. In the process of 'long composting' the whole composting procedure takes place outdoors . The stack is turned four times, on days 6, 10-12, 13-15 and 15-17. The anaerobic centre zone is moved to the outside on each occasion. The finished compost is pasteurised for four hours. If this is not pos-

Other lignocellulosic wastes A tremendous range of materials has been used, especially for the growth of Pleurotus spp. ego sugar cane bagasse, pomace (apple waste), sugar beet pulp, coffee, tea, cotton wastes etc. Unless the waste contains a toxic component, it is likely that by adjusting moisture levels to around 70%, providing aeration, and optimising carbon/nitrogen ratios, any plant waste can be degraded by basidiomycete fungi. At the 1995 congress on the science and cultivation of edible fungi delegates reported on several examples of using basidiomycetes to transform waste materials , egoAuricularia polytricha has been grown on coffee wood in Mexico, and Pleurotus ostreatus used to turn waste-paper into horticultural mulching material in the Seychelles.

Agaricus bisporus compost

Fermor et al (1985) give a very full account of the processes involved in preparing compost for Agaricus bisporus while Genders (1969) gives a more colloquialdescription; the following howeveris drawn primarily from Stamets & Chilton (1983). I personally obtain mushroom compost from a commercial compost producer, complete except for the inoculation of mushroom spawn. The commercial composting process is divided into two stages, commonly called Phase 1 and Phase 2, but the process, called 'Long composting' is more appropriate for the amateur grower, as there is no need for the environmentally controlled rooms used for phase 2 processing. Both systems willbe described here. The raw materials for the compost are straw, manure, calcium sulphate (gypsum), water and nutritional supplements. Wheat straw is preferred because its resilience maintains an open well-ventilated compost structure. The straw is the primary source of carbohydrates and in addition it provides lignin that is converted into the nitrogen rich ligninhumus-complex, which provides a source of protein to the mushroom mycelium. Calcium sulphate improves compost structure by aggregating colloidal particles and it also provides a source of metabolic calcium. Horse-manure (usually ready mixed with bedding-straw) is the traditional source of nitrogen; while so called 'synthetic' composts are made with chicken manure, but other sources of organic and

Volume 10, Part 2, May 1996

sible, discard the outer shell of the stack, and use the compost showing the white flecking indicating strong actinomycete activity. Inoculation and spawn running Mushroom spawn is mixed into the compost, usuallyas 1-2% by wet weight. Conditions then need to be maintained for the strain in question. The primary requirement is to maintain the core compost temperature at the optimum temperature. This is 25C for many commercial strains of Agaricus, Lepiota, Lepista and Coprinus. The compost usually contains sufficient oxygen and water to support the development of the fungal mycelium for the duration of the growth period. The success of themycelial growth or 'spawn-run' can be seen by the change in colour of the compost. The whitish colour of mycelium is also evident. Similar changes can also be seen with other compost types, leafmould and straw become paler as the fungal enzymes bleach the substrate. However, the apparanently successful utilisation of the substrate is no guarantee of success with mushroom production. On several occasions I have had straw bales smelling sweetly of fungal decomposition, all but the outermost layer of straw charged with mycelium, ready to produce ..nothing! In essence the mycelium is induced to go through a developmental switch from mycelial extension to the production of mushroom primordia. Conditions are then maintained that facilitate the development of these primordia into mushrooms. The initial switch is usually achieved by radically altering the environmental conditions surrounding the mycelium; typically by reducing temperature and increasing oxygen supply. Subsquent development then requires higher humidity (Flegg & Wood, 1985). The understanding of the mechanisms of basidiomycete morphogenesis have yet to be synthesised into a complete story; some of the components can be found in Moore et al (1985), but this area is undoubtedly a major problem in the scientific understanding of mushroom growing. We cannot yet definitely say why on some occasions mushrooms fruit from a mycelium, and on other occasions they do not, it is another part of life's rich complexity. The methods for initiating and maintaining fruiting willform the basis for a further article.

References

Charlesworth, K. (1995) Life, the universe & (almost) everything. Muck and Magic.New Scientist 1979:53. Chang, S.T. & Hayes, W.A. (eds) (1978) The Biology and Cultivation of Edible Mushrooms. Academic Press, New York. Fermor, TR, Randle, P.E. & Smith, J.F. (1985) Compost as a substrate and its preparation. In P.E. Flegg, D.M. Spencer, D.A. Wood (eds): The Biology and Technology of the Cultivated Mushroom. John Wiley & Sons: Chichester & New York. pp. 81-110. Flegg, P.E. & Wood, D.A. (1985) Growth and fruiting. In P.E. Flegg, D.M. Spencer, D.A. Wood (eds): The Biology and Technology of the Cultivated Mushroom. John Wiley & Sons: Chichester & New York. pp. 141-178. Frische, G. & vanLoone, P. (1989) Breeding experiments with the wood blewit (Lepista nuda). In Mushroom Science XII (partl), Proceedings of the Twelfth

International Congress on the Science and Cultivation of Edible Fungi, Germany (1987). Genders, R. (1969) Mushroom growing for everyone. Faber &

Faber, London. Larkcom, J. (1976) Vegetables from small gardens. Faber & Faber, London. Matruchot, L. (1917) Variations experimentales due Tricholoma nudum. Revue Generale Botanique. 503. Moore, D., Casselton, L.A., Wood, D.A. & Frankland, J.C. (eds) (1985) Developmental Biology of Higher Fungi. BMS Symposium 10, Cambridge University Press. Nisikado, Y., Kimura, K. & Miyawaki, T. (1942) The mycelial growth in pure culture on the sawdust medium prepared of various kinds of tree. Ber. Ohara Inst.

Landw. Forsch. 9:39-60.

Pryce, S. (1991) The Peat Alternatives Manual. Friends of the Earth, London. Przybylowicz, P. & Donoghue, J. (1990) Shiitake Growers Handbook, Kendall/Hunt, Iowa. Scrase, R.J. (1993) The Cultivation of Basidiomycetes. M Phil thesis, Bath University. Stamets, P. & Chilton, J.S. (1983). The Mushroom Cultivator, Agarikon Press, Olympia, Washington. Steineck, H. (1984) Mushrooms in the Garden. Mad River Press, California. Zadrazil, F. & Reiniger, P. (eds) (1988) Treatment of lignocellulosics with white rot fungi. Elsevier, London.

Das könnte Ihnen auch gefallen

- Food IcpmsDokument82 SeitenFood IcpmsJose GarciaNoch keine Bewertungen

- Small-scale Rearing of Anagasta kuehniella for Trichogramma ProductionVon EverandSmall-scale Rearing of Anagasta kuehniella for Trichogramma ProductionNoch keine Bewertungen

- Hauser SoilChemistryDokument17 SeitenHauser SoilChemistrysom_bs79Noch keine Bewertungen

- Protozoa and Fungi Culturing in The LabDokument7 SeitenProtozoa and Fungi Culturing in The LabrorenNoch keine Bewertungen

- Plant Protection Outlook in the Asia-Pacific Region: Including an in-Depth View of the Invasive Fall ArmywormVon EverandPlant Protection Outlook in the Asia-Pacific Region: Including an in-Depth View of the Invasive Fall ArmywormNoch keine Bewertungen

- Package of Practices On CauliflowerDokument14 SeitenPackage of Practices On CauliflowertummalaajaybabuNoch keine Bewertungen

- Phyllosphere PDFDokument8 SeitenPhyllosphere PDFmanoj_rkl_07Noch keine Bewertungen

- The Mushroom, Edible and Otherwise Its Habitat and its Time of GrowthVon EverandThe Mushroom, Edible and Otherwise Its Habitat and its Time of GrowthBewertung: 5 von 5 Sternen5/5 (1)

- Isolation of Soil FungiDokument7 SeitenIsolation of Soil FungiShanmugaprakasham ShanNoch keine Bewertungen

- Review of Invertebrate Biological Control Agents Introduced into EuropeVon EverandReview of Invertebrate Biological Control Agents Introduced into EuropeNoch keine Bewertungen

- Growing Oyster Mushrooms On Straw Pellets PDFDokument2 SeitenGrowing Oyster Mushrooms On Straw Pellets PDFbravohr98Noch keine Bewertungen

- Booklet Truffle Cultivation and AnalysisDokument4 SeitenBooklet Truffle Cultivation and Analysisapi-246191251100% (1)

- Insect IdentificationDokument70 SeitenInsect Identificationmiki100% (3)

- Principles of Horticultural PhysiologyDokument401 SeitenPrinciples of Horticultural Physiologyamorio75Noch keine Bewertungen

- Coffee Grounds As An Alternative To SoilDokument15 SeitenCoffee Grounds As An Alternative To SoilMichelle AlcantaraNoch keine Bewertungen

- Potato Biology and Biotechnology: Advances and PerspectivesVon EverandPotato Biology and Biotechnology: Advances and PerspectivesDick VreugdenhilNoch keine Bewertungen

- Introduction To The Identification of Insects and Related Arthropods - P. M. ChoateDokument13 SeitenIntroduction To The Identification of Insects and Related Arthropods - P. M. Choateporq100% (1)

- Biology of Plant Litter Decomposition V1Von EverandBiology of Plant Litter Decomposition V1C.H. DickinsonBewertung: 5 von 5 Sternen5/5 (1)

- Practical Methods in Am Fungal Research 135Dokument63 SeitenPractical Methods in Am Fungal Research 135Malamine LayeNoch keine Bewertungen

- Plant Resources of Arid and Semiarid Lands: A Global PerspectiveVon EverandPlant Resources of Arid and Semiarid Lands: A Global PerspectiveJ. R. GoodinNoch keine Bewertungen

- InoculationDokument5 SeitenInoculationfreddymoralesNoch keine Bewertungen

- The Cereal Rusts: Origins, Specificity, Structure, and PhysiologyVon EverandThe Cereal Rusts: Origins, Specificity, Structure, and PhysiologyWilliam BushnellNoch keine Bewertungen

- Growing Mushrooms Commercially: - Risks and OpportunitiesDokument8 SeitenGrowing Mushrooms Commercially: - Risks and OpportunitiesSharad BhutoriaNoch keine Bewertungen

- Cultivation Psilocibe Sp.Dokument5 SeitenCultivation Psilocibe Sp.Christian Castro100% (1)

- Mushrooms for the Million - Growing, Cultivating & Harvesting MushroomsVon EverandMushrooms for the Million - Growing, Cultivating & Harvesting MushroomsNoch keine Bewertungen

- Biotechnology of Morel MushroomsDokument5 SeitenBiotechnology of Morel Mushroomsnonamer3100% (1)

- Shiitake Mushroom Growing InstructionsDokument4 SeitenShiitake Mushroom Growing InstructionsJoão RodriguesNoch keine Bewertungen

- Bringing Life To The MojaveDokument44 SeitenBringing Life To The MojaveschyzeNoch keine Bewertungen

- Mushroom Growers Handbook 2 Shiitake Cultivation - 2005 - Mushworld - 17391377 - 256pgDokument256 SeitenMushroom Growers Handbook 2 Shiitake Cultivation - 2005 - Mushworld - 17391377 - 256pgAdrian Alberto Romero BernalNoch keine Bewertungen

- Mycelium Germination From SporesDokument3 SeitenMycelium Germination From Sporesbartolomej7Noch keine Bewertungen

- How To Set Up A Low Tech Mushroom FarmDokument29 SeitenHow To Set Up A Low Tech Mushroom FarmPsykonaut Nebulus100% (1)

- Paddy Straw Mushroom ProdnDokument44 SeitenPaddy Straw Mushroom ProdnmiradewiNoch keine Bewertungen

- PitahayaDokument11 SeitenPitahayajorgeNoch keine Bewertungen

- Lab 6 KNF CalculatorDokument6 SeitenLab 6 KNF Calculatorvital verity100% (1)

- Cultivation of Pleurotus Ostreatus and Other Edible MushroomsDokument17 SeitenCultivation of Pleurotus Ostreatus and Other Edible MushroomssiripornhassarangseeNoch keine Bewertungen

- Insect and Mite Pests in Food Volume IDokument316 SeitenInsect and Mite Pests in Food Volume ITheo BuchelosNoch keine Bewertungen

- Phytohormone - Types and FunctionsDokument23 SeitenPhytohormone - Types and FunctionsminiNoch keine Bewertungen

- Plant Anatomy and PhysiologyDokument55 SeitenPlant Anatomy and PhysiologyGEORGIA NAHAKNoch keine Bewertungen

- R Rush Wayne - Growing Mushrooms The Easy Way (Home Mushroom Ciultivation Using Hydrogen Peroxide Vol 1 & 2)Dokument68 SeitenR Rush Wayne - Growing Mushrooms The Easy Way (Home Mushroom Ciultivation Using Hydrogen Peroxide Vol 1 & 2)nahNoch keine Bewertungen

- MushroomsGB NLDokument16 SeitenMushroomsGB NLkalvinchaw100% (1)

- Fungi KeyDokument12 SeitenFungi KeySarie SutoroNoch keine Bewertungen

- Growing Panaeolus Tropicalus & Panaeolus Cyanescens 2Dokument5 SeitenGrowing Panaeolus Tropicalus & Panaeolus Cyanescens 2Eoghan Garcia0% (1)

- Best Practices For Cultivation of Truffles (2017) PDFDokument68 SeitenBest Practices For Cultivation of Truffles (2017) PDFb.shalabiNoch keine Bewertungen

- Probiotics in AquacultureDokument7 SeitenProbiotics in AquaculturemoiNoch keine Bewertungen

- Mites: - Class-Arachnida - Order-AcarinaDokument21 SeitenMites: - Class-Arachnida - Order-AcarinaVictor George SiahayaNoch keine Bewertungen

- Attracting Beneficial Insects ArticleDokument3 SeitenAttracting Beneficial Insects Articlein678Noch keine Bewertungen

- Mushroom Production and Processing Teach PDFDokument35 SeitenMushroom Production and Processing Teach PDFA-em Jaime AlbertusNoch keine Bewertungen

- Mushrooms Growing TechDokument9 SeitenMushrooms Growing TechSalik KhanNoch keine Bewertungen

- Shiitake On CoffeeDokument9 SeitenShiitake On CoffeeTeresa MataNoch keine Bewertungen

- Mushroom Growers Handbook 1 Mushworld Com Chapter 3 1 2Dokument2 SeitenMushroom Growers Handbook 1 Mushworld Com Chapter 3 1 2NathanielDarko100% (1)

- Morchella ChilenaDokument40 SeitenMorchella ChilenaMariano Espoz100% (1)

- 5B-Plant Tissue Culture PDFDokument50 Seiten5B-Plant Tissue Culture PDFSharvind Kumar Sharvind Kumar100% (1)

- Crop File For Mushrooms in PennsylvaniaDokument6 SeitenCrop File For Mushrooms in Pennsylvaniavas2000Noch keine Bewertungen

- Basic Procedure For Mushroom GrowingDokument16 SeitenBasic Procedure For Mushroom GrowingYar Zar Naing WinNoch keine Bewertungen

- Index Specii Funga NordicaDokument38 SeitenIndex Specii Funga Nordicavas2000Noch keine Bewertungen

- Brochure On FungiDokument2 SeitenBrochure On Fungiapi-176194325Noch keine Bewertungen

- Phytophthora InfestansDokument10 SeitenPhytophthora Infestansvas2000Noch keine Bewertungen

- Bibliografie MushroomsDokument2 SeitenBibliografie Mushroomsvas2000Noch keine Bewertungen

- Cultivation of Pleurotus Ostreatus and Other Edible MushroomsDokument17 SeitenCultivation of Pleurotus Ostreatus and Other Edible MushroomssiripornhassarangseeNoch keine Bewertungen

- Morel CultivationDokument1 SeiteMorel Cultivationvas2000Noch keine Bewertungen

- Alaska Mushroom Guide For MorelsDokument8 SeitenAlaska Mushroom Guide For Morelsvas2000Noch keine Bewertungen

- A Case of Fatal Poisoning Gyromitra EsculentaDokument6 SeitenA Case of Fatal Poisoning Gyromitra Esculentavas2000Noch keine Bewertungen

- Turism Rural - Volum I Nr. 2Dokument189 SeitenTurism Rural - Volum I Nr. 2vas2000100% (1)

- Gemh 108Dokument20 SeitenGemh 108YuvrajNoch keine Bewertungen

- Lab Report Marketing Mansi 4Dokument39 SeitenLab Report Marketing Mansi 4Mansi SharmaNoch keine Bewertungen

- Syllabus Unit Iv Unit Commitment and Economic DispatchDokument23 SeitenSyllabus Unit Iv Unit Commitment and Economic DispatchBALAKRISHNANNoch keine Bewertungen

- Biophoton RevolutionDokument3 SeitenBiophoton RevolutionVyavasayaha Anita BusicNoch keine Bewertungen

- Implicit Explicit SignalsDokument8 SeitenImplicit Explicit SignalsVersoza Nel100% (2)

- G1CDokument12 SeitenG1CKhriz Ann C ÜNoch keine Bewertungen

- Table Equivalent Schedule 40 Steel PipeDokument1 SeiteTable Equivalent Schedule 40 Steel PipeorisNoch keine Bewertungen

- Faa Registry: N-Number Inquiry ResultsDokument3 SeitenFaa Registry: N-Number Inquiry Resultsolga duqueNoch keine Bewertungen

- Crouse Hinds XPL Led BrochureDokument12 SeitenCrouse Hinds XPL Led BrochureBrayan Galaz BelmarNoch keine Bewertungen

- OurCatholicFaith PowerPoint Chapter1Dokument21 SeitenOurCatholicFaith PowerPoint Chapter1VinNoch keine Bewertungen

- Soldier of Fortune PDFDokument208 SeitenSoldier of Fortune PDFNixel SpielNoch keine Bewertungen

- TNM History Updated June2017Dokument2 SeitenTNM History Updated June2017Lucas AndreoNoch keine Bewertungen

- Cambridge IGCSE Paper 2Dokument4 SeitenCambridge IGCSE Paper 2irajooo epik zizterNoch keine Bewertungen

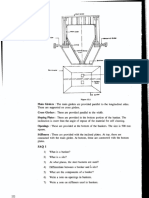

- Main Girders: CrossDokument3 SeitenMain Girders: Crossmn4webNoch keine Bewertungen

- SSDsDokument3 SeitenSSDsDiki Tri IndartaNoch keine Bewertungen

- Elements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesDokument8 SeitenElements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesSadman Shaid SaadNoch keine Bewertungen

- TreesDokument69 SeitenTreesADITYA GEHLAWATNoch keine Bewertungen

- Fines Reduction Project at Wendling Bowser QuarryDokument2 SeitenFines Reduction Project at Wendling Bowser QuarryMarcos Antonio ParoliniNoch keine Bewertungen

- The Light Fantastic by Sarah CombsDokument34 SeitenThe Light Fantastic by Sarah CombsCandlewick PressNoch keine Bewertungen

- Updated Factory Profile of Aleya Apparels LTDDokument25 SeitenUpdated Factory Profile of Aleya Apparels LTDJahangir Hosen0% (1)

- C.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)Dokument1 SeiteC.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)shabeerNoch keine Bewertungen

- Chapter 3.c (Centroid by Intergration)Dokument15 SeitenChapter 3.c (Centroid by Intergration)Ariff AziziNoch keine Bewertungen

- Tesla Coil ProjectDokument8 SeitenTesla Coil ProjectShivam singhNoch keine Bewertungen

- The FOA Reference For Fiber Optics - Fiber Optic TestingDokument19 SeitenThe FOA Reference For Fiber Optics - Fiber Optic TestingvsalaiselvamNoch keine Bewertungen

- DMDWLab Book AnswersDokument44 SeitenDMDWLab Book AnswersNarpat Makwana Pune100% (1)

- Safe Lorry Loader Crane OperationsDokument4 SeitenSafe Lorry Loader Crane Operationsjdmultimodal sdn bhdNoch keine Bewertungen

- Proefschrift T. Steenstra - tcm24-268767Dokument181 SeitenProefschrift T. Steenstra - tcm24-268767SLAMET PAMBUDINoch keine Bewertungen

- Introduction To LCCDokument32 SeitenIntroduction To LCCGonzalo LopezNoch keine Bewertungen

- Mockery Breed Murder Birds PDFDokument12 SeitenMockery Breed Murder Birds PDFLautaro BojanichNoch keine Bewertungen

- Clevo W940tu Service ManualDokument93 SeitenClevo W940tu Service ManualBruno PaezNoch keine Bewertungen

- The Future of Geography: How the Competition in Space Will Change Our WorldVon EverandThe Future of Geography: How the Competition in Space Will Change Our WorldBewertung: 4 von 5 Sternen4/5 (6)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaVon EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNoch keine Bewertungen

- Hero Found: The Greatest POW Escape of the Vietnam WarVon EverandHero Found: The Greatest POW Escape of the Vietnam WarBewertung: 4 von 5 Sternen4/5 (19)

- Sully: The Untold Story Behind the Miracle on the HudsonVon EverandSully: The Untold Story Behind the Miracle on the HudsonBewertung: 4 von 5 Sternen4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldVon EverandThe Fabric of Civilization: How Textiles Made the WorldBewertung: 4.5 von 5 Sternen4.5/5 (58)

- The End of Craving: Recovering the Lost Wisdom of Eating WellVon EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellBewertung: 4.5 von 5 Sternen4.5/5 (82)

- Pale Blue Dot: A Vision of the Human Future in SpaceVon EverandPale Blue Dot: A Vision of the Human Future in SpaceBewertung: 4.5 von 5 Sternen4.5/5 (588)

- Highest Duty: My Search for What Really MattersVon EverandHighest Duty: My Search for What Really MattersNoch keine Bewertungen

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureVon EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureBewertung: 5 von 5 Sternen5/5 (125)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- Reality+: Virtual Worlds and the Problems of PhilosophyVon EverandReality+: Virtual Worlds and the Problems of PhilosophyBewertung: 4 von 5 Sternen4/5 (24)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyVon EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNoch keine Bewertungen

- System Error: Where Big Tech Went Wrong and How We Can RebootVon EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootNoch keine Bewertungen

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestVon EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestBewertung: 4 von 5 Sternen4/5 (28)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterVon EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNoch keine Bewertungen

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeVon EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeBewertung: 4.5 von 5 Sternen4.5/5 (99)

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreVon EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreBewertung: 4.5 von 5 Sternen4.5/5 (33)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (54)

- Packing for Mars: The Curious Science of Life in the VoidVon EverandPacking for Mars: The Curious Science of Life in the VoidBewertung: 4 von 5 Sternen4/5 (1396)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterVon EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterBewertung: 5 von 5 Sternen5/5 (3)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceVon EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceBewertung: 5 von 5 Sternen5/5 (5)

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (122)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Von EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Noch keine Bewertungen