Beruflich Dokumente

Kultur Dokumente

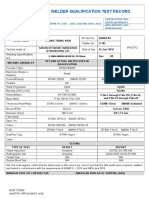

PQR & WPQ Standard Testing Parameter Worksheet

Hochgeladen von

cosmicbunnyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PQR & WPQ Standard Testing Parameter Worksheet

Hochgeladen von

cosmicbunnyCopyright:

Verfügbare Formate

Company Logo here

PQR / WPQ actual testing parameter values

Candidate Name Welding Process(es) WPS Type Backing Plate or Pipe Position Date:

observed values Volts (V) Amps (A) Wire Feed Rate Filler Metal Diameter Travel Speed (est) IPM Weld Progression interpass cleaning?

1st Pass

2nd Pass

3rd Pass

4th Pass

5th Pass

6th Pass

7th Pass

8th Pass

9th Pass

10th Pass

11th Pass

Filler Metal Current / Polarity Shielding Gas

type, flow rate, composition

Backing Gas

type, flow rate, composition

Trailing Gas

type, flow rate, composition

Base Metal(s) Coupon DIA / THK

Visual Inspection Results Additional notes

Welding witnessed by:

(Signature)

Date:

\\vboxsrv\conversion_tmp\scratch_1\133700587.xls.ms_office

Page# ____ of ____

SPX Flow Technology - APV Heat Transfer

PQR / WPQ actual testing parameter values

Candidate Name Welding Process(es) WPS Type Backing Plate or Pipe Position

Welder Name here

Welder Initials here

Date:

date of weld test

Welding process(es) is/are listed on the aplicable WPS; i.e. GTAW, GMAW, FCAW, GMAW-CRO, RSW, LBW, etc.

WPS number being used for the welding

GTAW = manual; GMAW = semi-automatic; GMAW-CRO = automatic, RSW and LBW = machine

if backing is used, list whether it is base metal, left-in-lplace backing strip, removable backing strip, etc. If no backing is used, indicate "None".

What is being welded

What position is being welded in? See figures at bottom of this worksheet

1st Pass 2nd Pass 3rd Pass 4th Pass 5th Pass 6th Pass 7th Pass 8th Pass 9th Pass 10th Pass 11th Pass

observed values Volts (V) Amps (A) Wire Feed Rate Travel Speed (est) Weld Progression interpass cleaning?

These readings come directly from the welding machine and are entered for each weld pass. These readings come directly from the welding machine and are entered for each weld pass. Currrently GMAW and GMAW-CRO only! These readings come directly from the welding machine wire feeder. Time welding operation for one minute and measure inches per minute for the Travel Speed.

Either uphill or downhill; each weld pass may be different if WPS states. Did the welder clean, grind, or wire brush between passes?

Filler Metal Current / Polarity Shielding Gas Backing Gas Trailing Gas Base Metal(s) Coupon DIA / THK

List the Manufacturer, Alloy, Diameter, amnd SFA No. of the filler metal being used.

AC or DC; Electrode Negative or Positive. Record the Shielding gas number, the mixture, and the flow rate in CFH when used. Record the Backing gas number, the mixture, and the flow rate in CFH when used.

Record the Trailinggas number, the mixture, and the flow rate in CFH when used.

Record the Material Specification of the base Metal(s).

If Plate, list the thickness; if Pipe, list the Diameter and wall thickness.

Visual Inspection Results Additional notes

Craig Wesson will perform visual inspection of completed coupon until a weld quality training class is given.

Any additional notes go here.

Welding witnessed by:

Sign here

Date:

Date that form is signed goes here

Groove Welds in Plate -- Test Positions

1G

2G

3G

4G

Groove Welds in Pipe -- Test Positions

1G Rotated

2G

5G

Fillet Welds in Plate -- Test Positions

6G

1F

2F

3F

4F

Das könnte Ihnen auch gefallen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- QW-483 BlankDokument2 SeitenQW-483 BlankCraftyBob100% (1)

- LBW WOPQ REV. 2010a Interactive FormDokument1 SeiteLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- Alu WpsDokument4 SeitenAlu WpsdselvakuuNoch keine Bewertungen

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Dokument5 SeitenWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- WPQR2Dokument3 SeitenWPQR2Thanasis KyrgiazoglouNoch keine Bewertungen

- Fcaw 16 THKDokument5 SeitenFcaw 16 THKparesh2387Noch keine Bewertungen

- Visual Inspection FormatDokument2 SeitenVisual Inspection Formattuan mai vanNoch keine Bewertungen

- WPS Resrvoire Sous Pression Smaw SawDokument6 SeitenWPS Resrvoire Sous Pression Smaw SawDanem HalasNoch keine Bewertungen

- WPS 2014-002 006 - 6G PipeDokument3 SeitenWPS 2014-002 006 - 6G PipejeswinNoch keine Bewertungen

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Dokument17 SeitenWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNoch keine Bewertungen

- WPS FormatDokument2 SeitenWPS FormatAmit SarkarNoch keine Bewertungen

- WPS, PQR 041Dokument21 SeitenWPS, PQR 041swamykommula100% (1)

- PQR WPQ Witness Report LatestDokument1 SeitePQR WPQ Witness Report LatestSatish KeskarNoch keine Bewertungen

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDokument5 SeitenWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNoch keine Bewertungen

- WPQ Template (Asme Ix) No LogoDokument4 SeitenWPQ Template (Asme Ix) No LogorcpretoriusNoch keine Bewertungen

- PT Kuwera Karya Me: PanduDokument2 SeitenPT Kuwera Karya Me: PanduGalang Pratama PutraNoch keine Bewertungen

- PQRDokument2 SeitenPQRSreenivas Kamachi Chettiar100% (1)

- BPV IX-16-3 QW-283 - ButteringDokument1 SeiteBPV IX-16-3 QW-283 - ButteringyutweldingNoch keine Bewertungen

- Welder Performance Qualification-Interactive Form QW-484ADokument1 SeiteWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- ASME 9 - CalculatorDokument2 SeitenASME 9 - CalculatorEmel Besir100% (1)

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Dokument2 SeitenWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNoch keine Bewertungen

- PQR Sample PrintoutDokument2 SeitenPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- SS WPSDokument1 SeiteSS WPSMOHAMEDABBASNoch keine Bewertungen

- 19403955-WPS M.S. Is 2062Dokument10 Seiten19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- 1035 03Dokument2 Seiten1035 03Anuj ShahiNoch keine Bewertungen

- Guidance To Prepare Wps PQR For WeldingDokument1 SeiteGuidance To Prepare Wps PQR For WeldingHamid MansouriNoch keine Bewertungen

- WPS - 024Dokument4 SeitenWPS - 024MAT-LIONNoch keine Bewertungen

- PQR 01 PDFDokument2 SeitenPQR 01 PDFVijay BhaleraoNoch keine Bewertungen

- Dokumen - Tips Wqt-FormatDokument2 SeitenDokumen - Tips Wqt-FormatMr Pie100% (1)

- Reports - QAQC - R0Dokument10 SeitenReports - QAQC - R0talupurumNoch keine Bewertungen

- Welding Procedure Specification: Technip KT India LimitedDokument5 SeitenWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- Wps Aws d1.1 NEWDokument2 SeitenWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDokument2 SeitenElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- WPQR No. 2016 02Dokument14 SeitenWPQR No. 2016 02GANESH ANoch keine Bewertungen

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDokument3 SeitenWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNoch keine Bewertungen

- WPS Pipe 08'' SHD 40 SMAW REV02Dokument2 SeitenWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNoch keine Bewertungen

- Page No: 01: SA 240 GR 304 SA 240 GR 304Dokument5 SeitenPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNoch keine Bewertungen

- WPS Sitelca S002Dokument2 SeitenWPS Sitelca S002Jose Antonio GomezNoch keine Bewertungen

- WPS-PQR (Er309l Mo)Dokument4 SeitenWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS Format For AWS D1.1 - WPS - FCAWDokument1 SeiteWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNoch keine Bewertungen

- Wps 1010 IfrDokument28 SeitenWps 1010 IfrSyed Mahmud Habibur RahmanNoch keine Bewertungen

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDokument2 SeitenBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNoch keine Bewertungen

- Welding Coordinator WeldMap Weld Data Sheet PDFDokument1 SeiteWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNoch keine Bewertungen

- Wqt-Visual-Mag - BS 2Dokument24 SeitenWqt-Visual-Mag - BS 2KyNoch keine Bewertungen

- Manual Joints (QW - 402) : Page 1 of 12Dokument12 SeitenManual Joints (QW - 402) : Page 1 of 12miteshpatel191Noch keine Bewertungen

- Welder Qualification Test RequestDokument1 SeiteWelder Qualification Test RequestgoguluNoch keine Bewertungen

- QW-484A (WPQ) GTAW 4MM FilletDokument2 SeitenQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- WPS Asme IxDokument4 SeitenWPS Asme Ixjcarlosherrerac7100% (1)

- wps63 PDFDokument4 Seitenwps63 PDFErick HoganNoch keine Bewertungen

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDokument6 SeitenWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNoch keine Bewertungen

- Registro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Dokument2 SeitenRegistro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Anonymous Xa5rkMZm9ZNoch keine Bewertungen

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDokument1 SeitePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNoch keine Bewertungen

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Dokument3 SeitenHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNoch keine Bewertungen

- PQR Amp WPQ Standard Testing Parameter WorksheetDokument4 SeitenPQR Amp WPQ Standard Testing Parameter WorksheetvinodNoch keine Bewertungen

- RSW WOPQ REV. 2010a Interactive FormDokument1 SeiteRSW WOPQ REV. 2010a Interactive FormcosmicbunnyNoch keine Bewertungen

- Interactive Form QW-485 PDFDokument1 SeiteInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNoch keine Bewertungen

- 14033Dokument2 Seiten14033Priyanathan ThayalanNoch keine Bewertungen

- Sa 516 GR 70 WPSDokument5 SeitenSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- WPQ PDFDokument0 SeitenWPQ PDFstanleyNoch keine Bewertungen

- 5 Whys TrainingDokument14 Seiten5 Whys TrainingMd Majharul Islam100% (2)

- All Processes ChecklistDokument8 SeitenAll Processes ChecklistcosmicbunnyNoch keine Bewertungen

- Externally Provided Products and Services ChecklistDokument3 SeitenExternally Provided Products and Services Checklistcosmicbunny100% (1)

- Corrective Action Process ModelDokument1 SeiteCorrective Action Process ModelcosmicbunnyNoch keine Bewertungen

- ACME Process MapDokument1 SeiteACME Process MapcosmicbunnyNoch keine Bewertungen

- Design and Development Process ChecklistDokument4 SeitenDesign and Development Process ChecklistcosmicbunnyNoch keine Bewertungen

- Corrective Action Process ModelDokument1 SeiteCorrective Action Process ModelcosmicbunnyNoch keine Bewertungen

- RSW WOPQ REV. 2010a Interactive FormDokument1 SeiteRSW WOPQ REV. 2010a Interactive FormcosmicbunnyNoch keine Bewertungen

- Process Chart in Word FormatDokument1 SeiteProcess Chart in Word FormatcosmicbunnyNoch keine Bewertungen

- WPQ REV. 2010a Interactive FormDokument2 SeitenWPQ REV. 2010a Interactive FormcosmicbunnyNoch keine Bewertungen

- PQR REV. 2010a Interactive FormDokument2 SeitenPQR REV. 2010a Interactive FormcosmicbunnyNoch keine Bewertungen

- BPQ REV. 0 Interactive FormDokument2 SeitenBPQ REV. 0 Interactive FormcosmicbunnyNoch keine Bewertungen

- Weld Fit-Up Inspection Employee TrainingDokument10 SeitenWeld Fit-Up Inspection Employee Trainingcosmicbunny100% (22)

- Homework (Lecture 4)Dokument31 SeitenHomework (Lecture 4)anh anhNoch keine Bewertungen

- 1-04-012-11 - 0 TrafoDokument9 Seiten1-04-012-11 - 0 TrafonishantpsbNoch keine Bewertungen

- 3203-MANUL-V00.00.06 Astute HV Monitoring Op ManualDokument40 Seiten3203-MANUL-V00.00.06 Astute HV Monitoring Op ManualHiếu Phan ThànhNoch keine Bewertungen

- Datasheet 586320 (50-8231) en 120V 60Hz Motor BobinadoDokument5 SeitenDatasheet 586320 (50-8231) en 120V 60Hz Motor BobinadoMelissa AlvaradoNoch keine Bewertungen

- Practical Electronics 2023-01Dokument76 SeitenPractical Electronics 2023-01László JásznagyNoch keine Bewertungen

- RMP 121d Data SheetDokument7 SeitenRMP 121d Data Sheetmitchell morenoNoch keine Bewertungen

- TCN Journal 2021 June EditionDokument72 SeitenTCN Journal 2021 June EditiontcnjournalonlineNoch keine Bewertungen

- Fisika ListrikDokument5 SeitenFisika ListrikYopi RachmanaNoch keine Bewertungen

- 3RD PresentatiOn AcceptedDokument19 Seiten3RD PresentatiOn AcceptedZeeshan KhanNoch keine Bewertungen

- 980h CatDokument4 Seiten980h CatFreddy Villegas100% (4)

- Manual Monitoring Relay SIRIUS Monitoring DevicesDokument392 SeitenManual Monitoring Relay SIRIUS Monitoring DevicesDebye101Noch keine Bewertungen

- AH Deluxe ManualDokument7 SeitenAH Deluxe ManualJacimário Bonfim Santos'Noch keine Bewertungen

- Single-Channel Process Indicator 4003 Series: Potentiometer Et AlDokument5 SeitenSingle-Channel Process Indicator 4003 Series: Potentiometer Et Aldavidcristian2009Noch keine Bewertungen

- 7.5w Audio AmplifierDokument1 Seite7.5w Audio AmplifierSowjanya DaliparthiNoch keine Bewertungen

- Installation Manual Inmarsat-C Mes Felcom18: ModelDokument62 SeitenInstallation Manual Inmarsat-C Mes Felcom18: Modelsrinu19840% (1)

- Zenith E-Series ESP Gauge Technical Data SheetDokument2 SeitenZenith E-Series ESP Gauge Technical Data SheetMustafa LaghaNoch keine Bewertungen

- Excitation On Synchronous Motor Multiple Choice Questions (MCQ) and Answers - MechanicaltutorialDokument2 SeitenExcitation On Synchronous Motor Multiple Choice Questions (MCQ) and Answers - Mechanicaltutorialपंकज काळेNoch keine Bewertungen

- Phys133 Lab1Dokument7 SeitenPhys133 Lab1api-427609820Noch keine Bewertungen

- SCU E-Mobility - 2022Dokument22 SeitenSCU E-Mobility - 2022omedinaNoch keine Bewertungen

- Toshiba 2927DB - SB - 4643980011Dokument9 SeitenToshiba 2927DB - SB - 4643980011avi1991Noch keine Bewertungen

- Updated CV - Jeil G.Dokument5 SeitenUpdated CV - Jeil G.Charlie MendozaNoch keine Bewertungen

- Exp3 (Study of DSB-SC Modulation)Dokument6 SeitenExp3 (Study of DSB-SC Modulation)TA Tius100% (1)

- Disassembly Monito 201342494933Dokument5 SeitenDisassembly Monito 201342494933K.O.D.Noch keine Bewertungen

- Electromagnetic Flow MetersDokument11 SeitenElectromagnetic Flow MeterssethuraghulNoch keine Bewertungen

- Bảng thông số sản phẩm: Easergy P3U30, 4L ringlug, 4U, 16DI/8DO, Uaux: 48-230V, DI: 24-230V, RS-485Dokument6 SeitenBảng thông số sản phẩm: Easergy P3U30, 4L ringlug, 4U, 16DI/8DO, Uaux: 48-230V, DI: 24-230V, RS-485bakien-canNoch keine Bewertungen

- TYPES OF TOOLS 2Dokument53 SeitenTYPES OF TOOLS 2Ian MarianoNoch keine Bewertungen

- Datasheet Rish Insu 10 Rev C2Dokument3 SeitenDatasheet Rish Insu 10 Rev C2chandv7Noch keine Bewertungen

- Substrate Integrated Waveguide Microwave Encyclopedia Microwaves101Dokument5 SeitenSubstrate Integrated Waveguide Microwave Encyclopedia Microwaves101Dr-Pritam Singh BakariyaNoch keine Bewertungen

- Digital Circuits: Santanu ChattopadhyayDokument105 SeitenDigital Circuits: Santanu ChattopadhyaylvrevathiNoch keine Bewertungen

- KT-300 Installation Manual E F S DN1315-0411Dokument50 SeitenKT-300 Installation Manual E F S DN1315-0411Sándor PetrovicsNoch keine Bewertungen