Beruflich Dokumente

Kultur Dokumente

Weldgrp - Weld Group Analysis Program

Hochgeladen von

emoriderOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Weldgrp - Weld Group Analysis Program

Hochgeladen von

emoriderCopyright:

Verfügbare Formate

"WELDGRP" --- WELD GROUP ANALYSIS PROGRAM

Program Description:

"WELDGRP" is a spreadsheet program written in MS-Excel for the purpose of analysis of weld groups using either the ultimate strength method (also known as "instantaneous center of rotation" method) or the "elastic" (vector) method ("Alternate Method 1" in AISC Manual). A separate worksheet contains data tables for welds. This program is a workbook consisting of eleven (11) worksheets, described as follows:

Worksheet Name

Doc Table XIX Table XX Table XXI Table XXII Table XXIII Table XXIV Table XXV Table XXVI Weld Group (elastic) Weld Data

Description

This documentation sheet Weld group instantaneous center analysis for vertical parallel welds Weld group instantaneous center analysis for horizontal parallel welds Weld group instantaneous center analysis for vertical rectangular welds Weld group instantaneous center analysis for horizontal rectangular welds Weld group instantaneous center analysis for C-shaped welds (case 1) Weld group instantaneous center analysis for C-shaped welds (case 2) Weld group instantaneous center analysis for L-shaped welds (case1) Weld group instantaneous center analysis for L-shaped welds (case 2) Weld group elastic analysis for up to 24 total weld lines and 4 load points Fillet Weld Data Tables

Program Assumptions and Limitations:

1. The AISC eccentric loads on weld groups worksheets (Tables XX through XXVI, pages 4-75 through 4-82) are applicable for only in-plane shear loads and torques (moments) on the weld group. With the one exception being the "Special Case" of out-of-plane loading for vertical parallel welds, AISC Table XIX. 2. The "Weld Group (elastic)" worksheet can be used for all cases of in-plane and out-of-plane loads on the weld group, or where geometry limitations of the AISC Tables XIX through XXVI are ecceeded. The "elastic" method (AISC "Alternate" Method 1) will always give conservative results when compared to using the AISC Tables. 3. The "Weld Group (elastic)" worksheet assumes a minimum of 1 weld and a maximum of 24 welds in a group. 4. In the "Weld Group (elastic)" worksheet, the welds are treated as "lines" possessing a length, but no actual theoretical thickness. All welds are assumed to contribute to the moment of inertia of the group, and the applied loads are linearly distributed among the welds based on the location of the welds from the centroidal axes. 5. In the "Weld Group (elastic)" worksheet, the weld group must be composed of straight lines/segments, but they all need not be connected. Circular or portions of a circular pattern weld may be adequately modeled by using a series of segments. (Note: see below for an example of modeling a circular weld pattern.) 6. In the "Weld Group (elastic)" worksheet, each weld line/segment is defined by its own start (X1,Y1) and end (X2,Y2) sets of coordinates. Coordinates defining weld lines/segments can be input irrespective of direction. That is, a weld line/segment may be defined from left-to-right and top-to-bottom or vice-versa. 7. The "Weld Group (elastic)" worksheet assumes an orthogonal X-Y-Z coordinate system. All welds and loads points MUST BE located in the "positive" (1st) quadrant. "Negative" weld or load point location coordinates are NOT permitted. "Right-Hand-Rule" sign convention is used for all applied forces and moments at load point locations. 8. In the "Weld Group (elastic)" worksheet, the welds and load points can be numbered in any desired order. However, the user should make sure to either clear the contents of all spreadsheet cells that are not used for input or those cell values should be input = 0. All welds and load points MUST BE input in proper numerical

sequence with no "breaks" in the numerical order of input data. 9. The "Weld Group (elastic)" worksheet calculates the required weld size in terms of both fillet leg and effective throat dimensions, based on the assumption of using E70XX welding electrodes. The user should check AISC specification for limitations on minimum and maximum weld sizes. 10. This program contains numerous comment boxes which contain a wide variety of information including explanations of input or output items, equations used, data tables, etc. (Note: presence of a comment box is denoted by a red triangle in the upper right-hand corner of a cell. Merely move the mouse pointer to the desired cell to view the contents of that particular "comment box".) 11. Weld Data worksheet shows data tables for minimum size of fillet welds, allowable force on fillet welds, and intermittent fillet weld lengths and spacings.

Circular Weld Example (using elastic method): A circular weld of diameter, 'D', with its center located at 0.50*D from both the origin X and Y axes, may be modeled as 24-sided shape inscribed within the circle. The coordinates of the 24 connected segments can be described as follows: Weld Coordinates: Start Weld #1 Weld #2 Weld #3 Weld #4 Weld #5 Weld #6 Weld #7 Weld #8 Weld #9 Weld #10 Weld #11 Weld #12 Weld #13 Weld #14 Weld #15 Weld #16 Weld #17 Weld #18 Weld #19 Weld #20 Weld #21 Weld #22 Weld #23 Weld #24 X1 0 0.0170*D 0.0670*D 0.1464*D 0.2500*D 0.3706*D 0.50*D 0.6294*D 0.7500*D 0.8536*D 0.9330*D 0.9830*D 1.0*D 0.9830*D 0.9330*D 0.8536*D 0.7500*D 0.6294*D 0.50*D 0.3706*D 0.2500*D 0.1464*D 0.0670*D 0.0170*D Y1 0.50*D 0.3706*D 0.2500*D 0.1464*D 0.0670*D 0.0170*D 0 0.0170*D 0.0670*D 0.1464*D 0.2500*D 0.3706*D 0.50*D 0.6294*D 0.7500*D 0.8536*D 0.9330*D 0.9830*D 1.0*D 0.9830*D 0.9330*D 0.8536*D 0.7500*D 0.6294*D End X2 Y2 0.0170*D 0.3706*D 0.0670*D 0.2500*D 0.1464*D 0.1464*D 0.2500*D 0.0670*D 0.3706*D 0.0170*D 0.50*D 0 0.6294*D 0.0170*D 0.7500*D 0.0670*D 0.8536*D 0.1464*D 0.9330*D 0.2500*D 0.9830*D 0.3706*D 1.0*D 0.50*D 0.9830*D 0.6294*D 0.9330*D 0.7500*D 0.8536*D 0.8536*D 0.7500*D 0.9330*D 0.6294*D 0.9830*D 0.50*D 1.0*D 0.3706*D 0.9830*D 0.2500*D 0.9330*D 0.1464*D 0.8536*D 0.0670*D 0.7500*D 0.0170*D 0.6294*D 0 0.50*D

"WELDGRP.xls" Program Version 2.1

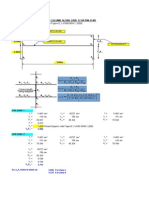

ECCENTRIC LOADS ON VERTICAL PARALLEL WELD GROUPS

Based on the Instantaneous Center of Rotation Method and Alternate Method 2 Using Table XIX from AISC 9th Ed. Manual (ASD) - page 4-75 Job Name: Subject: Job Number: Originator: Checker:

Pv=22 k

Input Data: Vertical Weld Length = Spacing of Welds = Weld Size, w = Vertical Load, Pv = Horizontal Load, Ph = Dist. from Pv to C.G. = Use Special Case? Nomenclature: 8.000 4.000 1/4 22.00 0.00 6.000 No

in. in. in. = 4 (1/16's) kips kips in.

aL=6

q =0

P=Pv

L= 8.000

C.G.

Ph=0

(kL)/2 kL= 4

(kL)/2

Pv

P = Pv = C*C1*D*L (for vertical load only) P = allowable load on eccentric weld group (kips) C = coefficient interpolated from Table XIX C1 = coefficient for electrode, use 1.0 for E70XX D = number of 1/16's of an inch (weld size) L = vertical weld length

q

aL P L Ph

eq. spaces

Special Case (out of plane) (Use C values for k=0)

Results: L= kL = aL = a= k= C1 = C= P= Angle q = Co = C(max) = A= Ca/Co = Ca = D(req'd) = L(req'd) = 8.000 4.000 6.000 0.750 0.500 1.0 0.712 22.00 0.000 N.A. N.A. N.A. N.A. N.A. 3.862 7.725

in. in. in.

kips deg.

1/16's in.

(Note: AISC Alternate Method 2 is not used for P=Pv) L = vertical weld length kL = spacing of vertical welds aL = dist. from Pv to C.G. a = (aL)/L k = (kL)/L C1 = 1.0 for E70XX electrode (interpolated from Table XIX, page 4-75) P = SQRT(Pv^2+Ph^2) q = 90-(ATAN(Pv/Ph)) Co = C (from AISC Table XIX, page 4-75) C(max) = 0.928*(2) A = C(max)/Co >= 1.0 Ca/Co = A/(SINq+A*COSq) >= 1.0 Ca = (Ca/Co)*Co D(req'd) = P/(C*C1*L) L(req'd) = P/(C*C1*D) Weld is adequate! D(req'd) = 3.862 <= 4 (1/16's) L(req'd) = 7.725 <= 8 in.

3 of 16

3/12/2013 4:00 AM

'"WELDGRP.xls" Program Version 2.1

ECCENTRIC LOADS ON HORIZONTAL PARALLEL WELD GROUPS

Based on the Instantaneous Center of Rotation Method and Alternate Method 2 Using Table XX from AISC 9th Ed. Manual (ASD) - page 4-76 Job Name: Subject: Job Number: Originator: Checker: Input Data: Horiz. Weld Length = Spacing of Welds = Weld Size, w = Vertical Load, Pv = Horizontal Load, Ph = Dist. from Pv to C.G. = Nomenclature: P = Pv = C*C1*D*L (for vertical load only) P = allowable load on eccentric weld group (kips) C = coefficient interpolated from Table XX C1 = coef. for electrode, use 1.0 for E70XX D = number of 1/16's of an inch (weld size) L = horizontal weld length 10.000 5.000 3/8 27.40 0.00 10.000

in. in. in. = 6 (1/16's) kips kips in.

Pv=27.4 k aL=10

q= 0

P=Pv

kL = 5.000

C.G.

Ph=0 L = 10

Results: L= kL = aL = a= k= C1 = C= P= Angle q = Co = C(max) = A= Ca/Co = Ca = D(req'd) = L(req'd) = 10.000 5.000 10.000 1.000 0.500 1.0 0.553 27.40 0.000 N.A. N.A. N.A. N.A. N.A. 4.955 8.258

in. in. in.

kips deg.

1/16's in.

(Note: AISC Alternate Method 2 is not used for P=Pv) L = horizontal weld length kL = spacing of horiz. welds aL = dist. from Pv to C.G. a = (aL)/L k = (kL)/L C1 = 1.0 for E70XX electrode (interpolated from Table XX, page 4-76) P = SQRT(Pv^2+Ph^2) q = 90-(ATAN(Pv/Ph)) Co = C (from AISC Table XX, page 4-76) C(max) = 0.928*(2) A = C(max)/Co >= 1.0 Ca/Co = A/(SINq+A*COSq) >= 1.0 Ca = (Ca/Co)*Co D(req'd) = P/(C*C1*L) L(req'd) = P/(C*C1*D) Weld is adequate! D(req'd) = 4.955 <= 6 (1/16's) L(req'd) = 8.258 <= 10 in.

4 of 16

3/12/2013 4:00 AM

"WELDGRP.xls" Program Version 2.1

ECCENTRIC LOADS ON RECTANGULAR WELD GROUPS

Based on the Instantaneous Center of Rotation Method and Alternate Method 2 Using Table XXI from AISC 9th Ed. Manual (ASD) - page 4-77 Job Name: Subject: Job Number: Originator: Checker: Input Data:

aL=10

Vertical Weld Length = Horiz. Weld Length = Weld Size, w = Vertical Load, Pv = Horizontal Load, Ph = Dist. from Pv to C.G. = Nomenclature:

10.000 5.000 1/2 76.00 0.00 10.000

in. in. in. = 8 (1/16's) kips kips in.

Pv=76 k

q= 0

P=Pv L= 10.000

C.G.

Ph=0

P = Pv = C*C1*D*L (for vertical load only) P = allowable load on eccentric weld group (kips) C = coefficient interpolated from Table XXI C1 = coef. for electrode, use 1.0 for E70XX D = number of 1/16's of an inch (weld size) L = vertical weld length

kL= 5

Results: L= kL = aL = a= k= C1 = C= P= Angle q = Co = C(max) = A= Ca/Co = Ca = D(req'd) = L(req'd) = 10.000 5.000 10.000 1.000 0.500 1.0 0.951 76.00 0.000 N.A. N.A. N.A. N.A. N.A. 7.992 9.989

in. in. in.

kips deg.

1/16's in.

(Note: AISC Alternate Method 2 is not used for P=Pv) L = vertical weld length kL = horizontal weld length aL = dist. from Pv to C.G. a = (aL)/L k = (kL)/L C1 = 1.0 for E70XX electrode (interpolated from Table XXI) P = SQRT(Pv^2+Ph^2) q = 90-(ATAN(Pv/Ph)) Co = C (from AISC Table XXI) C(max) = 0.928*(2+2*k) A = C(max)/Co >= 1.0 Ca/Co = A/(SINq+A*COSq) >= 1.0 Ca = (Ca/Co)*Co D(req'd) = P/(C*C1*L) L(req'd) = P/(C*C1*D) Weld is adequate! D(req'd) = 7.992 <= 8 (1/16's) L(req'd) = 9.989 <= 10 in.

5 of 16

3/12/2013 4:00 AM

"WELDGRP.xls" Program Version 2.1

ECCENTRIC LOADS ON RECTANGULAR WELD GROUPS

Based on the Instantaneous Center of Rotation Method and Alternate Method 2 Using Table XXII from AISC 9th Ed. Manual (ASD) - page 4-78 Job Name: Subject: Job Number: Originator: Checker: Input Data: Horiz. Weld Length = Vertical Weld Length = Weld Size, w = Vertical Load, Pv = Horizontal Load, Ph = Dist. from Pv to C.G. = Nomenclature: P = Pv = C*C1*D*L (for vertical load only) P = allowable load on eccentric weld group (kips) C = coefficient interpolated from Table XXII C1 = coef. for electrode, use 1.0 for E70XX D = number of 1/16's of an inch (weld size) L = horizontal weld length 10.000 5.000 1/2 68.00 0.00 11.000

in. in. in. = 8 (1/16's) kips kips in.

Pv=68 k q =0 aL=11 P=Pv kL = 5.000

C.G.

Ph=0 L = 10

Results: L= kL = aL = a= k= C1 = C= P= Angle q = Co = C(max) = A= Ca/Co = Ca = D(req'd) = L(req'd) = 10.000 5.000 11.000 1.100 0.500 1.0 0.802 68.00 0.000 N.A. N.A. N.A. N.A. N.A. 8.479 10.599

in. in. in.

kips deg.

1/16's in.

(Note: AISC Alternate Method 2 is not used for P=Pv) L = horizontal weld length kL = vertical weld length aL = dist. from Pv to C.G. a = (aL)/L k = (kL)/L C1 = 1.0 for E70XX electrode (interpolated from Table XXII) P = SQRT(Pv^2+Ph^2) q = 90-(ATAN(Pv/Ph)) Co = C (from AISC Table XXII) C(max) = 0.928*(2+2*k) A = C(max)/Co >= 1.0 Ca/Co = A/(SINq+A*COSq) >= 1.0 Ca = (Ca/Co)*Co D(req'd) = P/(C*C1*L) L(req'd) = P/(C*C1*D) Weld is overstressed! D(req'd) = 8.479 > 8 (1/16's) L(req'd) = 10.599 > 10 in.

6 of 16

3/12/2013 4:00 AM

"WELDGRP.xls" Program Version 2.1

ECCENTRIC LOADS ON C-SHAPED WELD GROUPS

Based on the Instantaneous Center of Rotation Method and Alternate Method 2 Using Table XXIII from AISC 9th Ed. Manual (ASD) - page 4-79 Job Name: Subject: Job Number: Originator: Checker: Input Data: Vertical Weld Length = Horiz. Weld Length = Weld Size, w = Vertical Load, Pv = Horizontal Load, Ph = Dist. from Pv to Weld = Nomenclature: P = Ca*C1*D*L (for inclined load) P = allowable load on eccentric weld group (kips) Ca = coefficient for inclined load, Alt. Method 2 C1 = coef. for electrode, use 1.0 for E70XX D = number of 1/16's of an inch (weld size) L = vertical weld length

L= 10.000

C.G.

10.000 5.000 1/2 23.29 86.93 10.000

in. in. in. = 8 (1/16's) kips kips in.

10.000 aL=8.75 Pv=23.29 k

q = 75

P=90 k

Ph=86.93 k (@ C.G.)

xL=1.25 kL=5

3.75

Results: L= kL = xL = aL = a= k= C1 = C= P= Angle q = Co = C(max) = A= Ca/Co = Ca = D(req'd) = L(req'd) = 10.000 5.000 1.250 8.750 0.875 0.500 1.0 0.704 90.000 75.002 0.704 1.856 2.636 1.600 1.126 7.993 9.991

in. in. in. in.

kips deg.

1/16's in.

(Note: AISC Alternate Method 2 is used for inclined load) L = vertical weld length kL = horizontal weld length xL = ((kL)^2/(2*kL+L)) aL = (Dist. to Pv)-(xL) a = (aL)/L k = (kL)/L C1 = 1.0 for E70XX electrode (interpolated from AISC Table XXIII, page 4-79) P = SQRT(Pv^2+Ph^2) q = 90-(ATAN(Pv/Ph)) Co = C (from AISC Table XXIII, page 4-79) C(max) = 0.928*(1+2*k) A = C(max)/Co >= 1.0 Ca/Co = A/(SINq+A*COSq) >= 1.0 Ca = (Ca/Co)*Co D(req'd) = P/(Ca*C1*L) L(req'd) = P/(Ca*C1*D) Weld is adequate! D(req'd) = 7.993 <= 8 (1/16's) L(req'd) = 9.991 <= 10 in.

7 of 16

3/12/2013 4:00 AM

"WELDGRP.xls" Program Version 2.1

ECCENTRIC LOADS ON C-SHAPED WELD GROUPS

Based on the Instantaneous Center of Rotation Method and Alternate Method 2 Using Table XXIV from AISC 9th Ed. Manual (ASD) - page 4-80 Job Name: Subject: Job Number: Originator: Checker: Input Data: Vertical Weld Length = Horiz. Weld Length = Weld Size, w = Vertical Load, Pv = Horizontal Load, Ph = Dist. from Pv to Weld = Nomenclature: P = Ca*C1*D*L (for inclined load) P = allowable load on eccentric weld group (kips) Ca = coefficient for inclined load, Alt. Method 2 C1 = coef. for electrode, use 1.0 for E70XX D = number of 1/16's of an inch (weld size) L = vertical weld length

Ph=86.93 k (@ C.G.)

10.000 5.000 1/2 23.29 86.93 7.500

in. in. in. = 8 (1/16's) kips kips in.

aL=8.75 7.500 Pv=23.29 k q = 75 P=90 k

Pv=23.29 k L=10

xL=1.25 kL=5

3.75

Results: L= kL = xL = aL = a= k= C1 = C= P= Angle q = Co = C(max) = A= Ca/Co = Ca = D(req'd) = L(req'd) = 10.000 5.000 1.250 8.750 0.875 0.500 1.0 0.722 90.000 75.002 0.722 1.856 2.571 1.576 1.138 7.909 9.886

in. in. in. in.

kips deg.

1/16's in.

(Note: AISC Alternate Method 2 is used for inclined load) L = vertical weld length kL = horizontal weld length xL = ((kL)^2/(2*kL+L)) aL = (Dist. to Pv)+(xL) a = (aL)/L k = (kL)/L C1 = 1.0 for E70XX electrode (interpolated from AISC Table XXIV, page 4-80) P = SQRT(Pv^2+Ph^2) q = 90-(ATAN(Pv/Ph)) Co = C (from AISC Table XXIV, page 4-80) C(max) = 0.928*(1+2*k) A = C(max)/Co >= 1.0 Ca/Co = A/(SINq+A*COSq) >= 1.0 Ca = (Ca/Co)*Co D(req'd) = P/(Ca*C1*L) L(req'd) = P/(Ca*C1*D) Weld is adequate! D(req'd) = 7.909 <= 8 (1/16's) L(req'd) = 9.886 <= 10 in.

8 of 16

3/12/2013 4:00 AM

"WELDGRP.xls" Program Version 2.1

ECCENTRIC LOADS ON L-SHAPED WELD GROUPS

Based on the Instantaneous Center of Rotation Method and Alternate Method 2 Using Table XXV from AISC 9th Ed. Manual (ASD) - page 4-81 Job Name: Subject: Job Number: Originator: Checker: Input Data:

Pv=25 k

Vertical Weld Length = Horiz. Weld Length = Weld Size, w = Vertical Load, Pv = Horizontal Load, Ph = Dist. from Pv to Weld = Nomenclature:

11.500 3.000 3/16 25.00 0.00 4.000

in. in. in. = 3 (1/16's) kips kips in.

4.000 aL=3.69

q= 0

P=Pv

C.G.

L= 11.500

Ph=0 yL=4.56

P = Pv = C*C1*D*L (for vertical load only) P = allowable load on eccentric weld group (kips) C = coefficient interpolated from Table XXV C1 = coef. for electrode, use 1.0 for E70XX D = number of 1/16's of an inch (weld size) L = vertical weld length Results: L= kL = xL = yL = aL = a= k= C1 = C= P= Angle q = Co = C(max) = A= Ca/Co = Ca = D(req'd) = L(req'd) = 11.500 3.000 0.310 4.560 3.690 0.321 0.261 1.0 0.742 25.00 0.000 N.A. N.A. N.A. N.A. N.A. 2.930 11.231

in. in. in. in. in.

xL=0.31 kL= 3

2.69

kips deg.

1/16's in.

(Note: AISC Alternate Method 2 is not used for P=Pv) L = vertical weld length kL = horizontal weld length xL = (kL)^2/(2*(kL+L)) yL = L^2/(2*(kL+L)) aL = (Dist. to Pv)-(xL) a = (aL)/L k = (kL)/L C1 = 1.0 for E70XX electrode (interpolated from Table XXV) P = SQRT(Pv^2+Ph^2) q = 90-(ATAN(Pv/Ph)) Co = C (from AISC Table XXV) C(max) = 0.928*(1+k) A = C(max)/Co >= 1.0 Ca/Co = A/(SINq+A*COSq) >= 1.0 Ca = (Ca/Co)*Co D(req'd) = P/(C*C1*L) L(req'd) = P/(C*C1*D) Weld is adequate! D(req'd) = 2.93 <= 3 (1/16's) L(req'd) = 11.231 <= 11.5 in.

9 of 16

3/12/2013 4:00 AM

"WELDGRP.xls" Program Version 2.1

ECCENTRIC LOADS ON L-SHAPED WELD GROUPS

Based on the Instantaneous Center of Rotation Method and Alternate Method 2 Using Table XXV1 from AISC 9th Ed. Manual (ASD) - page 4-82 Job Name: Subject: Job Number: Originator: Checker: Input Data:

Pv=26 k

Vertical Weld Length = Horiz. Weld Length = Weld Size, w = Vertical Load, Pv = Horizontal Load, Ph = Dist. from Pv to Weld = Nomenclature:

11.500 3.000 3/16 26.00 0.00 3.150

in. in. in. = 3 (1/16's) kips kips in.

aL=3.46 3.150

q

P=Pv

C.G.

yL=4.56

L= 11.500

Ph=0

P = Pv = C*C1*D*L (for vertical load only) P = allowable load on eccentric weld group (kips) C = coefficient interpolated from Table XXVI C1 = coef. for electrode, use 1.0 for E70XX D = number of 1/16's of an inch (weld size) L = vertical weld length Results: L= kL = xL = yL = aL = a= k= C1 = C= P= Angle q = Co = C(max) = A= Ca/Co = Ca = D(req'd) = L(req'd) = 11.500 3.000 0.310 4.560 3.460 0.301 0.261 1.0 0.768 26.00 0.000 N.A. N.A. N.A. N.A. N.A. 2.944 11.285

in. in. in. in. in.

xL=0.31 kL= 3

2.69

kips deg.

1/16's in.

(Note: AISC Alternate Method 2 is not used for P=Pv) L = vertical weld length kL = horizontal weld length xL = (kL)^2/(2*(kL+L)) yL = L^2/(2*(kL+L)) aL = (Dist. to Pv)-(xL) a = (aL)/L k = (kL)/L C1 = 1.0 for E70XX electrode (interpolated from Table XXVI) P = SQRT(Pv^2+Ph^2) q = 90-(ATAN(Pv/Ph)) Co = C (from AISC Table XXVI) C(max) = 0.928*(1+k) A = C(max)/Co >= 1.0 Ca/Co = A/(SINq+A*COSq) >= 1.0 Ca = (Ca/Co)*Co D(req'd) = P/(C*C1*L) L(req'd) = P/(C*C1*D) Weld is adequate! D(req'd) = 2.944 <= 3 (1/16's) L(req'd) = 11.285 <= 11.5 in.

10 of 16

3/12/2013 4:00 AM

"WELDGRP.xls" Program Version 2.1

WELD GROUP ANALYSIS

Using the Elastic Method for up to 24 Total Welds Job Name: Job Number: Input Data: Number of Welds, Nw = 3 Weld Coordinates: Start End X1 (in.) Y1 (in.) X2 (in.) Y2 (in.) 0.000 0.000 5.000 0.000 0.000 0.000 0.000 10.000 0.000 10.000 5.000 10.000

14.0

Subject: Originator:

Checker:

12.0

Y - AXIS (in.)

Weld #1 Weld #2 Weld #3

10.0

8.0

6.0

4.0

2.0

0.0 0.0 2.0 4.0 6.0 8.0 10.0 12.0

X - AXIS (in.)

WELD GROUP PLOT

+Y

1 2 2

1=Start 2=End

No. of Load Points =

1 Load Point Data: Point #1 3.000 5.000 0.000 0.00 86.93 -23.29 0.00 0.00 0.00

1 1

0

Weld #3 Weld #2 Weld #1 2

X-Coordinate (in.) = Y-Coordinate (in.) = Z-Coordinate (in.) = Axial Load, Pz (k) = Shear Load, Px (k) = Shear Load, Py (k) = Moment, Mx (in-k) = Moment, My (in-k) = Moment, Mz (in-k) =

+X

Origin

+Z NOMENCLATURE

(continued)

11 of 16

3/12/2013 4:00 AM

"WELDGRP.xls" Program Version 2.1

Results: Weld Group Properties: Lw = 20.000 in. Xc = 1.250 in. Yc = 5.000 in. Ix = 333.33 in^3 Iy = 52.08 in^3 J= 385.42 in^3 S Loads @ C.G. of Weld Group: S Pz = 0.00 kips S Px = 86.93 kips S Py = -23.29 kips S Mx = 0.00 in-k S My = 0.00 in-k S Mz = -40.76 in-k

Weld #1 Weld #2 Weld #3

Weld Forces (k/in.) Fw(1) Fw(2) 3.955 4.125 3.955 4.983 4.983 5.119

Required E70XX Weld Size: Fw(max) = 5.119 kips/in. Fillet (leg) = 0.345 in. Throat (eff) = 0.244 in.

12 of 16

3/12/2013 4:00 AM

FILLET WELD DATA TABLES

AISC Table J2.3 - Minimum Effective Throat Thickness of Partial-Penetration Groove Welds Material Thickness of Minimum Effective Throat Thicker Part Joined (in.) Thickness (in.) To 1/4 Inclusive 1/8 Over 1/4 to 1/2 3/16 Over 1/2 to 3/4 1/4 Over 3/4 to 1-1/2 5/16 Over 1-1/2 to 2-1/4 3/8 Over 2-1/4 to 6 1/2 Over 6 5/8 AISC Table J2.4 - Minimum Size of Fillet Welds Material Thickness of Minimum Size of Thicker Part Joined (in.) Fillet Weld (in.) To 1/4 Inclusive 1/8 Over 1/4 to 1/2 3/16 Over 1/2 to 3/4 1/4 Over 3/4 5/16 Notes: 1. Sizes of fillets welds shown are "leg" dimensions. 2. Single-pass welds must be used. Allowable Force on Fillet Welds (k/in.) Weld Size (in.) Weld Force (for E70XX) 1/8 1.856 3/16 2.785 1/4 3.713 5/16 4.641 3/8 5.569 7/16 6.497 1/2 7.426 Note: Weld force is calculated by 0.928*D, where 'D' is the number of 1/16's of an inch for the weld size. Intermittent Fillet Welds % of Continuous Weld Weld Length and Spacing (in.) 75 --3-4 --66 ----4-6 60 --3-5 --50 2-4 3-6 4-8 44 ----4-9 40 2-5 --4 - 10 37 --3-8 --33 2-6 3-9 4 - 12 30 --3 -10 --25 2-8 3 -12 --20 2 - 10 ----16 2 - 12 -----

Das könnte Ihnen auch gefallen

- Anthony Robbins' 7 Life-Changing Lessons for Success and FulfillmentDokument60 SeitenAnthony Robbins' 7 Life-Changing Lessons for Success and Fulfillmentemorider100% (2)

- Anthony Robbins' 7 Life-Changing Lessons for Success and FulfillmentDokument60 SeitenAnthony Robbins' 7 Life-Changing Lessons for Success and Fulfillmentemorider100% (2)

- Anthony Robbins' 7 Life-Changing Lessons for Success and FulfillmentDokument60 SeitenAnthony Robbins' 7 Life-Changing Lessons for Success and Fulfillmentemorider100% (2)

- Anthony Robbins' 7 Life-Changing Lessons for Success and FulfillmentDokument60 SeitenAnthony Robbins' 7 Life-Changing Lessons for Success and Fulfillmentemorider100% (2)

- Anthony Robbins' 7 Life-Changing Lessons for Success and FulfillmentDokument60 SeitenAnthony Robbins' 7 Life-Changing Lessons for Success and Fulfillmentemorider100% (2)

- Anthony Robbins' 7 Life-Changing Lessons for Success and FulfillmentDokument60 SeitenAnthony Robbins' 7 Life-Changing Lessons for Success and Fulfillmentemorider100% (2)

- Anthony Robbins' 7 Life-Changing Lessons for Success and FulfillmentDokument60 SeitenAnthony Robbins' 7 Life-Changing Lessons for Success and Fulfillmentemorider100% (2)

- Interactive Notebook Pieces PDFDokument15 SeitenInteractive Notebook Pieces PDFAshley JohnsonNoch keine Bewertungen

- Calculation PDFDokument126 SeitenCalculation PDFmohammed almahrooqiNoch keine Bewertungen

- Punching Shear StandardDokument4 SeitenPunching Shear StandardjanethNoch keine Bewertungen

- TIMBER PILE CONNECTION DESIGNDokument5 SeitenTIMBER PILE CONNECTION DESIGNSandesh Kumar100% (1)

- Design of Steel ColumnDokument7 SeitenDesign of Steel ColumnKim Javier EstaNoch keine Bewertungen

- POLEFDNDokument10 SeitenPOLEFDNcoolkaisyNoch keine Bewertungen

- Surcharge CalculatorDokument7 SeitenSurcharge CalculatorJunnoKaiserNoch keine Bewertungen

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Dokument14 SeitenSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqNoch keine Bewertungen

- STD-Insurance Commission TRAD REVIEWER Rev1 PDFDokument24 SeitenSTD-Insurance Commission TRAD REVIEWER Rev1 PDFJomar Carabot100% (1)

- Effective Length For Moment FrameDokument5 SeitenEffective Length For Moment FramenhulugallaNoch keine Bewertungen

- Sta 11+320 PDFDokument4 SeitenSta 11+320 PDFJaime Francisco SimithNoch keine Bewertungen

- Bolted Cover SpliceDokument4 SeitenBolted Cover SpliceChee Fong MakeNoch keine Bewertungen

- Lab 7 RC Time ConstantDokument8 SeitenLab 7 RC Time ConstantMalith Madushan100% (1)

- "Bracket13" - Bracket Plate Stress Analysis ProgramDokument7 Seiten"Bracket13" - Bracket Plate Stress Analysis ProgramFarid TataNoch keine Bewertungen

- SX019a-Example Column Base Connection Under Axial Compression PDFDokument5 SeitenSX019a-Example Column Base Connection Under Axial Compression PDFdvelchev100% (1)

- Concrete-Filled Double-Skin Steel Tubular Columns: Behavior and DesignVon EverandConcrete-Filled Double-Skin Steel Tubular Columns: Behavior and DesignNoch keine Bewertungen

- 48 Concrete ShearDokument10 Seiten48 Concrete ShearspattiwarNoch keine Bewertungen

- Opening in Slab and BeamDokument13 SeitenOpening in Slab and BeamYohan LimNoch keine Bewertungen

- Antenna Tilt GuidelinesDokument24 SeitenAntenna Tilt GuidelinesJorge Romeo Gaitan Rivera100% (5)

- Concrete Batch CONCRETE BATCH PLANTSPlantsDokument23 SeitenConcrete Batch CONCRETE BATCH PLANTSPlantsemorider100% (4)

- Knee ConnectionsDokument13 SeitenKnee ConnectionsNag RajNoch keine Bewertungen

- Composite BeamDokument7 SeitenComposite Beamsaif.mullaNoch keine Bewertungen

- Combined Footing DesignDokument48 SeitenCombined Footing DesignWanda BeasleyNoch keine Bewertungen

- Connections I V2.0.6b FinalDokument71 SeitenConnections I V2.0.6b FinalNick Andrews50% (2)

- Structural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Dokument39 SeitenStructural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Henj MirasolNoch keine Bewertungen

- Reference Output Calculations & FormulasDokument4 SeitenReference Output Calculations & FormulasAddrien DanielNoch keine Bewertungen

- Slab With and Without OpeningDokument17 SeitenSlab With and Without Openingstructure123Noch keine Bewertungen

- Super Composite ColumnDokument2 SeitenSuper Composite ColumnCheng Por EngNoch keine Bewertungen

- Toc 82r-13Dokument7 SeitenToc 82r-13emorider0% (1)

- ACI Moment Coefficient Design AID PDFDokument13 SeitenACI Moment Coefficient Design AID PDFSufian Ahmad50% (4)

- Crack Width CheckDokument2 SeitenCrack Width CheckJitendra SinghNoch keine Bewertungen

- Steel to concrete connection design summaryDokument12 SeitenSteel to concrete connection design summaryCSEC Uganda Ltd.Noch keine Bewertungen

- PF2Dokument4 SeitenPF2nhulugallaNoch keine Bewertungen

- Splice Joint Design To EurocodeDokument3 SeitenSplice Joint Design To Eurocodeikanyu79Noch keine Bewertungen

- N F N A: Input Data & Design SummaryDokument9 SeitenN F N A: Input Data & Design SummaryOswaldo SuárezNoch keine Bewertungen

- Precast Concrete ConstructionDokument28 SeitenPrecast Concrete ConstructionGirl in the CityNoch keine Bewertungen

- Italian Renaissance Art: Prepared by Ms. Susan PojerDokument46 SeitenItalian Renaissance Art: Prepared by Ms. Susan Pojerragusaka100% (12)

- Bridge Column Design SummaryDokument1 SeiteBridge Column Design Summaryyanu13Noch keine Bewertungen

- Level 0 - Jan Thorburn - A New Zealand AdventureDokument12 SeitenLevel 0 - Jan Thorburn - A New Zealand AdventureOnurcan96% (25)

- B U D C E: Fatih Çardak Prof. Dr. Semih TezcanDokument23 SeitenB U D C E: Fatih Çardak Prof. Dr. Semih Tezcanemorider100% (8)

- Structural Analysis and Design Lectures PDFDokument354 SeitenStructural Analysis and Design Lectures PDFgongmaozheNoch keine Bewertungen

- Pipe Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryDokument1 SeitePipe Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryYatsen Jepthe Maldonado SotoNoch keine Bewertungen

- Health MonitoringDokument14 SeitenHealth MonitoringemoriderNoch keine Bewertungen

- MS Project For Construction Scheduler (Unreliable)Dokument29 SeitenMS Project For Construction Scheduler (Unreliable)Teniozo_Mesdward100% (1)

- Project Excecution and DeliverableDokument7 SeitenProject Excecution and DeliverableHari PrashannaNoch keine Bewertungen

- Pad Footing Analysis and Design (Bs8110-1:1997)Dokument6 SeitenPad Footing Analysis and Design (Bs8110-1:1997)ikanyu79Noch keine Bewertungen

- Anchor Design for 219mm Pole SupportDokument1 SeiteAnchor Design for 219mm Pole SupportS A K ClostreNoch keine Bewertungen

- GF SlabDokument8 SeitenGF Slabcheligp1981Noch keine Bewertungen

- Retwall 1Dokument7 SeitenRetwall 1John SmithNoch keine Bewertungen

- Beam DesignDokument7 SeitenBeam DesignKasi ViswanathanNoch keine Bewertungen

- Example 2a: All-Round Fillet Weld Connection Between I Beam and Plate (Simple)Dokument6 SeitenExample 2a: All-Round Fillet Weld Connection Between I Beam and Plate (Simple)Imran SaikatNoch keine Bewertungen

- INFASO 9.4 Example FinalDokument28 SeitenINFASO 9.4 Example Finalpperic13Noch keine Bewertungen

- Crack Width Calculation ExampleDokument3 SeitenCrack Width Calculation Examplebernie romeroNoch keine Bewertungen

- CASTELLATED BEAM PropertiesDokument2 SeitenCASTELLATED BEAM PropertiesHemant SonawadekarNoch keine Bewertungen

- AnchorageDokument8 SeitenAnchorageRicha MunjalNoch keine Bewertungen

- Members With Combined Bending and Axial ForceDokument32 SeitenMembers With Combined Bending and Axial ForceJohn RomanusNoch keine Bewertungen

- BS-5950-90 Example 001Dokument7 SeitenBS-5950-90 Example 001Win ThanNoch keine Bewertungen

- BoltDokument2 SeitenBoltmuhannedNoch keine Bewertungen

- Cell K11 1 Cell K11 0.5 For F 0, For F 0Dokument9 SeitenCell K11 1 Cell K11 0.5 For F 0, For F 0HaymanAHMEDNoch keine Bewertungen

- Footing BiaxialDokument33 SeitenFooting BiaxialSanthoshkumar RayavarapuNoch keine Bewertungen

- Cold Form Lipped C Purlin Design Calculations and ChecksDokument8 SeitenCold Form Lipped C Purlin Design Calculations and ChecksKTMONoch keine Bewertungen

- Section Properties For Builtup and Unsymmetrical SectionsDokument5 SeitenSection Properties For Builtup and Unsymmetrical Sectionsdhamodharan24Noch keine Bewertungen

- ACI 350-06 & ACI224R-01 Rec Sec Flexural Crack Width Control Rev00 07-Sep-2013Dokument7 SeitenACI 350-06 & ACI224R-01 Rec Sec Flexural Crack Width Control Rev00 07-Sep-2013Muhammad Imran ZafarNoch keine Bewertungen

- Bolted Moment Connection Design CalculationsDokument63 SeitenBolted Moment Connection Design CalculationsblueswanNoch keine Bewertungen

- REINFORCEMENT CALCULATION FOR 1000MM THICK CF1Dokument3 SeitenREINFORCEMENT CALCULATION FOR 1000MM THICK CF1ARUNKUMAR KNoch keine Bewertungen

- Joist Girder DesignDokument42 SeitenJoist Girder DesignsravanNoch keine Bewertungen

- AngleDokument7 SeitenAngleNguyễnTúSơnNoch keine Bewertungen

- Add An Extra DL and Revise - 0.15 PSFDokument1 SeiteAdd An Extra DL and Revise - 0.15 PSFsharif uddinNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- Planning System in GermanyDokument288 SeitenPlanning System in GermanyemoriderNoch keine Bewertungen

- p1 Gen3 X1extreme Gen3 Ug enDokument102 Seitenp1 Gen3 X1extreme Gen3 Ug enemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- Ms Project 2010 EssentialDokument113 SeitenMs Project 2010 EssentialemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- CBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalDokument1 SeiteCBRE Group Inc. boosted CM/PM capacity by acquiring Heery InternationalemoriderNoch keine Bewertungen

- Planning System in GermanyDokument288 SeitenPlanning System in GermanyemoriderNoch keine Bewertungen

- Aircrew Standards Manual FY2015 V1Dokument211 SeitenAircrew Standards Manual FY2015 V1Anonymous Pb39klJ100% (1)

- QP ScriptDokument57 SeitenQP ScriptRitesh SharmaNoch keine Bewertungen

- Sanjay Chandra Vs Cbi On 23 November, 2011Dokument21 SeitenSanjay Chandra Vs Cbi On 23 November, 2011SaiBharathNoch keine Bewertungen

- The Bare Foot Boy 3 Ab 2 ManadoDokument100 SeitenThe Bare Foot Boy 3 Ab 2 ManadoKotakuNoch keine Bewertungen

- Relación Entre Séneca y MaquiaveloDokument14 SeitenRelación Entre Séneca y MaquiaveloJuan Pablo TorresNoch keine Bewertungen

- Physics 5th Edition Walker Test BankDokument24 SeitenPhysics 5th Edition Walker Test BankKathyHernandeznobt100% (31)

- Agenda For Regular Board Meeting February 18, 2022 Western Visayas Cacao Agriculture CooperativeDokument2 SeitenAgenda For Regular Board Meeting February 18, 2022 Western Visayas Cacao Agriculture CooperativeGem Bhrian IgnacioNoch keine Bewertungen

- Conquest of The Americas (Eakin-2002)Dokument81 SeitenConquest of The Americas (Eakin-2002)GregNoch keine Bewertungen

- Dendrinos, Multilingualism Language Policy in The EU TodayDokument20 SeitenDendrinos, Multilingualism Language Policy in The EU Todayi.giommettiNoch keine Bewertungen

- Exery Analysis of Vapour Compression Refrigeration SystemDokument22 SeitenExery Analysis of Vapour Compression Refrigeration Systemthprasads8356Noch keine Bewertungen

- Brochure KTM April 2008Dokument2 SeitenBrochure KTM April 2008sthapitNoch keine Bewertungen

- Gandhi and Indian Economic Planning (Unit III)Dokument21 SeitenGandhi and Indian Economic Planning (Unit III)Aadhitya NarayananNoch keine Bewertungen

- Physics EducationDokument14 SeitenPhysics Educationchrisuche100% (2)

- Regis Lesson Plan Template Edfd 405Dokument3 SeitenRegis Lesson Plan Template Edfd 405api-302321219Noch keine Bewertungen

- Africa S Top 15 Cities in 2030Dokument10 SeitenAfrica S Top 15 Cities in 2030loca018Noch keine Bewertungen

- Discourse and PragmaticsDokument10 SeitenDiscourse and PragmaticsDebby NatasyaNoch keine Bewertungen

- Creating A Seasonal Greeting Card RubricDokument3 SeitenCreating A Seasonal Greeting Card Rubricapi-244997750Noch keine Bewertungen

- LP Direct & Indirect SpeechDokument7 SeitenLP Direct & Indirect SpeechJoana JoaquinNoch keine Bewertungen

- DTF - Houses of The FallenDokument226 SeitenDTF - Houses of The FallenShuang Song100% (1)

- Conservation of Arabic ManuscriptsDokument46 SeitenConservation of Arabic ManuscriptsDr. M. A. UmarNoch keine Bewertungen

- Impact of Technology On Future JobsDokument29 SeitenImpact of Technology On Future Jobsmehrunnisa99Noch keine Bewertungen

- Shamanhood and Mythology: Archaic Techniques of Ecstasy and Current Techniques of ResearchDokument22 SeitenShamanhood and Mythology: Archaic Techniques of Ecstasy and Current Techniques of ResearchDunja Chrysina ChrysargyreaNoch keine Bewertungen

- Exercises in Linear Algebra - Erdman PDFDokument141 SeitenExercises in Linear Algebra - Erdman PDFMustafa YılmazNoch keine Bewertungen

- Assignment 1Dokument2 SeitenAssignment 1lauraNoch keine Bewertungen