Beruflich Dokumente

Kultur Dokumente

Reasonable Tolerances For Cast-In-Place Concrete - tcm45-345550

Hochgeladen von

Magdy BakryOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Reasonable Tolerances For Cast-In-Place Concrete - tcm45-345550

Hochgeladen von

Magdy BakryCopyright:

Verfügbare Formate

How close is close enough?

Reasonable tolerances for cast-in-place concrete

he reinforced concrete frame of a new resort hotel was several stories in the air when the plumbing contractor arrived on the job. His piping had been preassembled to fit the standarized floor layouts. When he couldnt install the pre f a b ri c a ted waste lines because the openings left for them failed to align, he complained. The architect came to measure and check alignment of the completed concrete members. In addition to misaligned plumbing sleeves he found columns out of plumb, some of them twisted, beam-column joints misplaced by 112 inches and slabs too thin. He accused the contractor of gross failure to meet the specified construction tolerances. The contractor charged that the tolerances were unreasonable and all parties seemed to be well on the way to costly litigation. It is rare, howe ve r, for out-of-tolerance work to be rejected and replaced solely because it is out of tole ra n c e. In the building described the frame would eventually be concealed behind a variety of surface finishes. If the structural safety and building function were not impaired by dimensional deviations, there might be little reason to reject the inaccurate construction. Whether anyone would ever be fully satisfied is doubtful.

and specifications. No structure is ever exactly level, plumb, straight and true. Fortunately such perfection is not necessary. Wide dimensional variations may occur in practice and pass unnoticed by constructors, designers, and owners alike. Inherent in traditional on-site construction practices are many design and workmanship skills that conceal and correct for dimensional variations as they occur. Craftsmen have customarily fitted their own work into a building as they find it. Howe ve r, problems and hardships develop when pre f a b ri c a t e d components wont fit the spaces left for them or errors are so gross as to make the building unsafe or unsightly. Then the question must be answered: How far can the structure vary from planned line and dimension and still be considered to accord sufficiently with the plans? How much variation is consistent with full performance of the contract? This is a matter of tolerance, whether stated or implied.

The first definition, which appears to be more widely accepted in building construction, is the one used in this discussion. In the interest of economy the standard of accuracy or tolerance specified should be based on what is really necessary rather than what one feels is ideally desirable. A fully satisfactory job may often be less precise than what is attainable. The required accuracy depends on an interrelationship of several factors: St ru c t u ral strength and other functional requirements. A building must be safe and strong, and near enough to size and shape to do the job for which it was built. Esthetics. The structure must satisfy the appearance needs or wishes of the owner and designer. Economic feasibility. Can the owner afford to pay what it costs to attain a specified degree of accuracy? Fitting of parts. Required precision of the concrete members depends on tolerances of accessories and tolerances of adjacent units, joint and connection design, and the possibility of accumulative errors in critical dimensions. Construction techniques available. The degree of precision possible depends on the level of local craftsmanship and technology as well as the materials available.

A common ground for discussion

To establish a common ground in discussing tolerances it must be acknowledged that the dictionary provides two valid definitions which are applicable: permissible deviation from a specified value of a structural dimension the range or difference between limits within which a size, dimension or position must lie

How tolerant?

Tolerances may be thought of as a recognition of the fact that a structure cannot be built exactly to nominal dimensions given in the plans

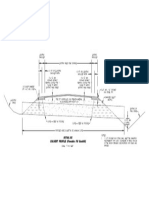

One builder compensated for excessive tolerances on the vertical by adjusting the building lines when foundation problems caused the building to tilt during construction. The foundation problems continued to cause tilting after the building was completed. A Straight line B Line parallel to A maintained for one or two stories C Line adjusted to the vertical during construction of top story (lines of intervening stories progressively adjusted) D True vertical

concepts which will accommodate tolerances that are realistically attainable. He should plan joints and other details which will absorb or conceal the inevitable variations.

Tolerance standards

One prominent concrete cons t ru c t o r, when asked what tolerances were attainable in concrete, stated emphatically that a construction tolerance is some part of an inch. His reply reflects the lack of knowledge as to standards of accuracy that are being achieved as a matter of course by competent builders in their day-to-day work. The concrete industry has been groping for practical tolerance guidelines for some time. Early in 1940 John Nichols, a prominent consulting engineer, suggested that the American Concrete Institute set up some standard tolerances, and for openers he proposed a scheme of limiting values based on his own judgment and experience.1 In the ensuing years these proposals were accepted in varying degree by many designers and contractors as a measure of adequate performance that could be applied to any contract for which the designer had not specifically stated tolerance standards. In 1963 when the American Co n c re t e

When specifying tolerances, the designer must consider all of these items and decide what the client really needs and whether he can and will pay for that level of precision. Specifying unnecessarily close dimensional tolerances for hardened concrete can lead to considerable expense. Because of the deflection and yielding of forms and shoring that occurs during concrete placement, formwork must be built to even closer tolerances than required in the concrete. Even higher precision forms do not guarantee the same as-constructed tolerance on the concrete member. This is because of shrinkage of concrete during curing and deflection after the forms are removed. The designer can save money by selecting design

Institute adopted its first formwork standard, Nichols values, with only minor changes, were included as part of the official ACI recommendation. Since 1963 there has been considerable acceptance of these standards with only a few changes proposed, and these modified standards are carried forward to the current ACI 347-68, Recommended Practice for Concrete Fo rm w o rk . 2 Almost identical values are found in Specifications for St ru c t u ral Concrete for Buildings (ACI 301-72), and the ACI 347 values are referenced by the Construction Specifications Institutes Guide Specification for Wood Fo rm s (03110, March 1973). Although the ACI values are admittedly based on judgment and experience rather than on quantitative field measurements they appear to be the most widely accepted standard available in the United States for ordinary structural concrete. Even those critics who have intimated that the tolerances were compiled in some equivalent of the smoke-filled room have provided field measurements that make the ACI values appear reasonable.3 In the absence of a tolerance specification by the designer, ACI 347 suggests the tolerances given in the table for completed construction of o rd i n a ry structural concrete in buildings.* A rc h i t e c t u ral concrete may require closer tolerances and the upper stories of high rise stru c t u re s may also require special tolerances for variations from plumb and linear building lines. Slab and beam soffits should be measured before removal of supporting shores, thus placing responsibility for structural deflection with the designer, who is best qualified to make the allowances needed for it. ACI 347 recommends that the designer anticipate occasions where the project may have features sensitive to the cumulative effects of these general tolerances, and that

* Refer to ACI 347-68 for suggested tolerances for other structures including bridges, mass concrete, tunnel and canal linings, and culverts.

he set an added limit or cumulative tolerance. If there are several applicable tolerances (for example on f o rm s, fabrication of reinforcement and setting of reinforcement) which may be in conflict, the designer should anticipate this too by specifying special tolerances or indicating which one must control. Some years ago the Building Research Advisory Board of the National Academy of Sciences recommended considerably more restrictive tolerances, some as little as half the values given by ACI 347. Since some Government agencies may still be following these recommendations, anyone working on a Federal contract should carefully check his specifications.

s e ve ral classes of tolerances, something like the following: O rd i n a ry tolerancesto provide the structure with basic serviceability. These, if followed, will prevent problems of fit for elevators, partitions, curtain walls and ceilings. The ACI tolerances would probably fit into this class. Special tolerancesto provide a structure with consistently close fit for auxiliary structural steel or pre cast floor and wall units. Appearance tolerancesto set a standard for exterior columns, beams and walls where the applied finish cannot mask errors. Unique high-precision requirementssuch as for tool or turbine installation.

This approach is used by seve ra l European standards-writing bodies and may point the way for future development in the United States. The American Concrete Institute has a special committee assigned to development of a system of tolerances for concrete construction. Their present activities, howe ve r, are being directed toward gathering data on field performance as a necessary first step toward making new tolerance recommendations.

Importance of a good tolerance specification

Some specifications include detailed provisions for tolerances while others are silent on the subject. Either course can have its pitfalls. Unfortunately the oft-ignored tolerances can be used as a weapon against the contractor. If things go well, no thought is given to checking

An alternative approach

A more complicated approach, which has some merit, is to set up

TOLERANCES RECOMMENDED BY ACI COMMITTEE 347

Variation from plumb In the lines and surfaces of columns, piers, walls and arrises 14 inch per 10 feet but not much more than 1 inch Variation in cross-sectional dimensions of columns and beams and in thickness of slabs and walls 14 inch + 12 inch Variation in footing size and location Plan dimensions 14 inch 12 inch

For exposed corner columns, control-joint grooves and other conspicuous lines In any bay or 20 feet maximum In 40 feet or more

2 inch + 2 inches*

-1

Thickness

Variation from level or indicated grade In slab soffits, ceilings, beam soffits and in arrises In 10 feet 14 inch In any bay or 20 feet maximum 38 inch In 40 feet or more 34 inch For exposed lintels, sills, parapets, horizontal grooves and other conspicuous lines In any bay 20 feet maximum In 40 feet or more

-5 percent of specified thickness; no limit on increased thickness 2 percent of ooting width in direction of misplacement but not more than 2 inches*

Misplacement or eccentricity

14 inch 12 inch

Variation of linear building lines from plan position; variation in related position of columns, walls and partitions In any bay or 20 feet maximum 12 inch In 40 feet or more 1 inch Variation in size and location of sleeves, floor openings and wall openings 14 inch

Variation in steps In a flight of stairs Riser Tread In consecutive steps Riser Tread

18 inch 14 inch

116 inch 18 inch

* Applies to concrete only, not to reinforcing bars or dowels.

tolerances but if bickering and bad feeling develop for whatever reason, strict enforcement of tolerance requirements may be used to penalize the builder. Similar things happen even though tolerances are not specified; someone dissatisfied with the work tries to invoke reasonable tolerances. The ideal situation would be to have a clear-cut specification with frequent enough checking to see that reasonable compliance is being achieved. One of the basic hazards in specifying tolerances is the possibility of more than one interpretation. Wording of the specification is as important as the numerical values that are given. A good tolerance specification should include definitions of special terms and state the tolerances as nearly as possible in the same order as the construction

sequence. It is also important to provide that in the event of conflict a variation permitted in one section of the specification for concrete work is not to be construed as permitting violation of more stringent requirements in another section. There should also be an explicit statement of whether a permitted variation for any element is unidirectional or multidirectional. No tolerance specified for building lines or footings should be interpreted to permit encroachment beyond legal site boundaries. Where other than ordinary tolerances are required, the designer should indicate how measurements will be taken and suggest possible means of obtaining acceptable work. If the bidder is aware that special screeds, steel forms, extra bracing, permanent shores and the like

may be needed he will be able to allow for these items and avoid negotiating for extras later on. The designer can avoid arguments by showing dimensions that can be directly measured, such as distances between column faces rather than center line to center line.

Camber and deflection problems

Special problems of deflection and shortening are inherent in every structure and these should be dealt with by the correct selection of a design concept rather than by inclusion in a tolerance specification. The contractor should not be held responsible for deflections which occur after forms and shores are removed (assuming that the shoring remains in place the correct length of time). This is why the ACI 347 re-

quirements indicate that slab soffit elevations should be measured before shore removal. In the past, deflections of concrete structures were rarely a problem and the builder used a rule of thumb for form camber to compensate for deflection and optical sag of the finished structure. Today, with increasing use of flat plates, thin shells, and strength design methods that lead to members with larger span-depth ratios than formerly, the deflection of the finished structure is a bigger problem. Since accurate deflection calculations are difficult and beyond the normal expertise of the builder, the designer should specify the amount and shape of camber desired to compensate for structural deflection. He should also decide how much added camber is needed to overcome optical sag in long-span horizontal members.

Allowable tolerance on d and on clear cover: d of 8 inches or less: 14 inch d between 8 and 24 inches: 38 inch d of 24 inches or more: 12 inch Howe ve r, the Code limits reduction in cover to one-third of the specified amount. Since the effective depth and clear concrete cover are parts of the total depth, the tolerances on these dimensions are directly related to tolerances on overall depth of member which must be considered by the form builder. Bar placing tolerances must not be allowed to become additive with tolerances for formwork, leaving the steel with insufficient cover or depth. This is a case where the designer may have to provide special tolerances as noted above.

their efforts. Practically speaking, the interests and objectives of all three must be considered simultaneously. A carefully prepared design that allows for reasonable deviations without sacrificing utility or appearance should help reduce building costs. Even more important is to have sufficient open communication before the job begins so that painful disagreement is avoided. If the builder knows in advance what tolerances are required and how they will be enforced he has a better chance to deliver on both price and promisesto fulfill the contract to the satisfaction of all concerned.

Tolerances for reinforcing steel

ACI 318-71 Building Code Requirements for Reinforced Conc re t e establishes cover requirements for rebars and defines tolerances in the cover as well as tolerances for bar placement. They vary with the effective stru c t u ra l depth d to the centroid of the reinforcement.

Toward a better understanding

It should be the responsibility of the designer to decide what tolerances are required and the responsibility of the builder to produce the s t ru c t u re to these tolerances. The owner must pay both of them for

REFERENCES 1. Nichols, John R., Tolerances in Building Construction, ACI Journal, April 1940, pages 493-496. 2. ACI Committee 347, Recommended Practice for Concrete Formwork (ACI 347-68), American Concrete Institute, 1968, 34 pages. 3. Birkeland, Philip W., and Westhoff, Leonard, Dimensional Tolerances in Tall Concrete Building, ACI Journal, August 1971, pages 600-607.

PUBLICATION#C740210

Copyright 1974, The Aberdeen Group All rights reserved

Das könnte Ihnen auch gefallen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Structural Precast ConcreteDokument39 SeitenStructural Precast ConcreteMherlieNoch keine Bewertungen

- Concrete Structures: Repair, Rehabilitation and StrengtheningVon EverandConcrete Structures: Repair, Rehabilitation and StrengtheningNoch keine Bewertungen

- Inspection-Test-plan For Block WorkDokument3 SeitenInspection-Test-plan For Block WorkAbdulrahman Alkilani100% (2)

- Guide Specification For Architectural Precast Concrete: This DocumentDokument37 SeitenGuide Specification For Architectural Precast Concrete: This DocumentOmar Mokhtar100% (1)

- Design ManualDokument867 SeitenDesign Manualvijaystructural83% (6)

- Hollow Core HandlingDokument4 SeitenHollow Core HandlingSulaiman Mohsin AbdulAzizNoch keine Bewertungen

- MSE Wall Engineering - A New Approach to Design and ConstructionDokument18 SeitenMSE Wall Engineering - A New Approach to Design and ConstructionUlissipo1955Noch keine Bewertungen

- Precast Concrete Frame Buildings Design GuideDokument91 SeitenPrecast Concrete Frame Buildings Design GuideAmiruddin Bin Mishad50% (2)

- Construction Process Planning and Management: An Owner's Guide to Successful ProjectsVon EverandConstruction Process Planning and Management: An Owner's Guide to Successful ProjectsBewertung: 4 von 5 Sternen4/5 (13)

- Concrete Floor SpecsDokument7 SeitenConcrete Floor SpecsrshyamsNoch keine Bewertungen

- MB Concrete Frames Oct06Dokument28 SeitenMB Concrete Frames Oct06MayMST100% (1)

- Soil Investigation and Foundation DesignVon EverandSoil Investigation and Foundation DesignBewertung: 4.5 von 5 Sternen4.5/5 (9)

- Concept Preliminary DesignDokument11 SeitenConcept Preliminary Designricosanojuan100% (2)

- Hand Book For Steel Structure Quality Control on SiteVon EverandHand Book For Steel Structure Quality Control on SiteNoch keine Bewertungen

- U.S. ARMY CORPS OF ENGINEERS DESIGN CHECKLISTDokument15 SeitenU.S. ARMY CORPS OF ENGINEERS DESIGN CHECKLISTSankar CdmNoch keine Bewertungen

- Steel-Tables 2 PDFDokument110 SeitenSteel-Tables 2 PDFMahmoud AllamNoch keine Bewertungen

- Steel-Tables 2 PDFDokument110 SeitenSteel-Tables 2 PDFMahmoud AllamNoch keine Bewertungen

- Strengthening Existing BuildingsDokument56 SeitenStrengthening Existing BuildingsKrish D.Noch keine Bewertungen

- Concrete Structures: Protection, Repair and RehabilitationVon EverandConcrete Structures: Protection, Repair and RehabilitationBewertung: 3 von 5 Sternen3/5 (4)

- Design Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesDokument9 SeitenDesign Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesMagdy Bakry100% (1)

- ACI 301 Specifications For Structural Concrete For Buildings - tcm45-346207Dokument3 SeitenACI 301 Specifications For Structural Concrete For Buildings - tcm45-346207msohaibaziz50% (4)

- Requirements Template Software EngrngDokument9 SeitenRequirements Template Software EngrngJenny Yu CaramolNoch keine Bewertungen

- Design & Construction of the Contract Package ConceptVon EverandDesign & Construction of the Contract Package ConceptNoch keine Bewertungen

- Form WorkDokument23 SeitenForm WorkleorajNoch keine Bewertungen

- 00-10-001 - F - Nov.2000Dokument0 Seiten00-10-001 - F - Nov.2000Levi MurdokNoch keine Bewertungen

- Plant Quality Management System OverviewDokument43 SeitenPlant Quality Management System Overviewsalah abddayem100% (1)

- Specifying Concrete For Durability Cif Dec 05Dokument9 SeitenSpecifying Concrete For Durability Cif Dec 05Veio MacieiraNoch keine Bewertungen

- Field Inspection of RFTDokument8 SeitenField Inspection of RFTHany Seif-Aldien NasserNoch keine Bewertungen

- Application of Internal Linings - Sample - PIPDokument15 SeitenApplication of Internal Linings - Sample - PIPgbuckley9630100% (1)

- Chapter Six: Guide Specification For Architectural Precast ConcreteDokument38 SeitenChapter Six: Guide Specification For Architectural Precast ConcreteAbu BiduNoch keine Bewertungen

- Sample Earthwork Take Off 1Dokument7 SeitenSample Earthwork Take Off 1Magdy BakryNoch keine Bewertungen

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- AISC Design Guides Steelwise 042010Dokument4 SeitenAISC Design Guides Steelwise 042010Ricardo García G. Ingeniero Electríco100% (1)

- Elementary Design of StructuresDokument75 SeitenElementary Design of StructuresNADS UG100% (1)

- Concrete Structures DesignDokument66 SeitenConcrete Structures Designmadkik100% (1)

- Tolleranze PCIDokument20 SeitenTolleranze PCIkurtainNoch keine Bewertungen

- Rebar InspectionDokument3 SeitenRebar InspectionSturuj100% (2)

- Hollow CoreDokument41 SeitenHollow Corepaulo_arrieiroNoch keine Bewertungen

- 98 Tips For Designing Structural SteelDokument6 Seiten98 Tips For Designing Structural SteelVinod Kumar ReddyNoch keine Bewertungen

- GMW14400 May2007 PDFDokument9 SeitenGMW14400 May2007 PDFAkmal NizametdinovNoch keine Bewertungen

- Textbook of Urgent Care Management: Chapter 4, Building Out Your Urgent Care CenterVon EverandTextbook of Urgent Care Management: Chapter 4, Building Out Your Urgent Care CenterNoch keine Bewertungen

- Bay' Al-Istisna'Dokument16 SeitenBay' Al-Istisna'Mahyuddin Khalid100% (7)

- Industrial Buildings-Guidelines and CriteriaDokument5 SeitenIndustrial Buildings-Guidelines and CriteriaAlexander Tavarez SantanaNoch keine Bewertungen

- Coordinating TolerancesDokument2 SeitenCoordinating TolerancesBruce SuprenantNoch keine Bewertungen

- Diseño Estructura MetalicaDokument8 SeitenDiseño Estructura MetalicajavierbsisoNoch keine Bewertungen

- Petra University (Architecture - Ebook) - Metal - Building - Systems - Design - and - Specifications-20610-Part145 PDFDokument2 SeitenPetra University (Architecture - Ebook) - Metal - Building - Systems - Design - and - Specifications-20610-Part145 PDFFWICIPNoch keine Bewertungen

- Chapter Ten: 10.2 Fixed-Base Versus Pinned-Base ColumnsDokument2 SeitenChapter Ten: 10.2 Fixed-Base Versus Pinned-Base ColumnsNani TirumalasettiNoch keine Bewertungen

- Approach Form Camber Specifications With CautionDokument4 SeitenApproach Form Camber Specifications With CautionDonald HamiltonNoch keine Bewertungen

- Si 11 2015 PDFDokument2 SeitenSi 11 2015 PDFAndres CasadoNoch keine Bewertungen

- Industrial Buildings-Guidelines and Criteria: Dr. James M. FisherDokument5 SeitenIndustrial Buildings-Guidelines and Criteria: Dr. James M. FisherersinNoch keine Bewertungen

- Proper Roof Slope and Drainage Are Important To Prevent Excessive Water AccumulationDokument5 SeitenProper Roof Slope and Drainage Are Important To Prevent Excessive Water AccumulationintequabNoch keine Bewertungen

- Concrete II Study Guide PDFDokument6 SeitenConcrete II Study Guide PDFdsalguero_2Noch keine Bewertungen

- Architectural concrete design and construction techniquesDokument6 SeitenArchitectural concrete design and construction techniquesfelipeNoch keine Bewertungen

- Long Span Steel TrussDokument4 SeitenLong Span Steel TrussDavid ReyesNoch keine Bewertungen

- Projek RC 1Dokument5 SeitenProjek RC 1Hani BarjokNoch keine Bewertungen

- Erection of Precast Concrete: C. Donald Johnson'Dokument9 SeitenErection of Precast Concrete: C. Donald Johnson'josephbawaNoch keine Bewertungen

- Proprietary Connections Hamburger CordovaDokument8 SeitenProprietary Connections Hamburger CordovaPauloAndresSepulvedaNoch keine Bewertungen

- Aci 117 R90Dokument11 SeitenAci 117 R90Rafael Elgueta Aravena100% (1)

- The Contractor's Role in Building Cost Reduction After Design (Bringing A Project Into Budget)Dokument8 SeitenThe Contractor's Role in Building Cost Reduction After Design (Bringing A Project Into Budget)arqsarqsNoch keine Bewertungen

- Variations in Position of Columns and SlabsDokument13 SeitenVariations in Position of Columns and SlabsuserinterestedNoch keine Bewertungen

- Test 3 FinalDokument8 SeitenTest 3 FinaladithyaNoch keine Bewertungen

- NotesDokument97 SeitenNotesSubalakshmi PNoch keine Bewertungen

- Plastic Formwork Advantages in ConstructionDokument12 SeitenPlastic Formwork Advantages in ConstructionNarlyn TevesNoch keine Bewertungen

- Civil KnowledgebleDokument5 SeitenCivil Knowledgeblegokulnath.asoorNoch keine Bewertungen

- 2014 CTS Hodgin WylieDokument10 Seiten2014 CTS Hodgin WylieCodey WilliamsNoch keine Bewertungen

- 2010v09 98 TipsDokument6 Seiten2010v09 98 Tipsvenkatesh19701Noch keine Bewertungen

- Building Envelope Failure Case Studies in High-Rise ConstructionDokument13 SeitenBuilding Envelope Failure Case Studies in High-Rise ConstructionAriep MontolivoNoch keine Bewertungen

- A Guide To Earthworks MeasurmentDokument6 SeitenA Guide To Earthworks Measurmentbuilder011Noch keine Bewertungen

- Backfilling Effects (April 2008)Dokument7 SeitenBackfilling Effects (April 2008)Magdy BakryNoch keine Bewertungen

- Backfilling Effects (April 2008)Dokument7 SeitenBackfilling Effects (April 2008)Magdy BakryNoch keine Bewertungen

- Proj Guidelines TM2 6 7R00Dokument51 SeitenProj Guidelines TM2 6 7R00rsirsi3742Noch keine Bewertungen

- Strengthening Dr. Farahat Cairo UniversityDokument134 SeitenStrengthening Dr. Farahat Cairo UniversityMagdy Bakry100% (2)

- SM CG BackfillDokument3 SeitenSM CG BackfillMagdy BakryNoch keine Bewertungen

- Culvert Profile (Aggregate Backfill) PDFDokument1 SeiteCulvert Profile (Aggregate Backfill) PDFMagdy BakryNoch keine Bewertungen

- Culvert Profile (Flowable Fill Backfill) PDFDokument1 SeiteCulvert Profile (Flowable Fill Backfill) PDFMagdy BakryNoch keine Bewertungen

- 1170 Structural Analysis and Design of Transferred Shear Wall Type StructureDokument6 Seiten1170 Structural Analysis and Design of Transferred Shear Wall Type StructureMagdy BakryNoch keine Bewertungen

- Damage Repair of Bridge Superstructures Using Bonded Composite PatchingDokument373 SeitenDamage Repair of Bridge Superstructures Using Bonded Composite PatchingMagdy BakryNoch keine Bewertungen

- Print TV - 21 - 2014!2!435 - 445 Assessment and Repair of The Bearing Structure of The Gradiska - NorestrictionDokument11 SeitenPrint TV - 21 - 2014!2!435 - 445 Assessment and Repair of The Bearing Structure of The Gradiska - NorestrictionMagdy Bakry100% (1)

- Design EconomyDokument18 SeitenDesign EconomyMagdy BakryNoch keine Bewertungen

- El-Samny M. Kassem and Abd El-Samee W. Nashaat Rehabilitation of Existing Foundation Building To ResistDokument12 SeitenEl-Samny M. Kassem and Abd El-Samee W. Nashaat Rehabilitation of Existing Foundation Building To ResistMagdy BakryNoch keine Bewertungen

- Form SlabDokument11 SeitenForm SlabSeifeldin Ali MarzoukNoch keine Bewertungen

- Anclaje 4Dokument14 SeitenAnclaje 4Magdy BakryNoch keine Bewertungen

- Northeast Chapter of Precast/Prestressed Concrete InstituteDokument32 SeitenNortheast Chapter of Precast/Prestressed Concrete InstituteMagdy BakryNoch keine Bewertungen

- 9.DFI Aliaga Jet Grouting PDFDokument5 Seiten9.DFI Aliaga Jet Grouting PDFSuyadi MeraukeNoch keine Bewertungen

- Cyclic Testing and Comparison ofDokument11 SeitenCyclic Testing and Comparison ofMagdy BakryNoch keine Bewertungen

- Swede BeamDokument12 SeitenSwede BeamMagdy BakryNoch keine Bewertungen

- Hollow CoreDokument23 SeitenHollow CoreMagdy BakryNoch keine Bewertungen

- Double Tee 12Dokument19 SeitenDouble Tee 12Mohammed AdelNoch keine Bewertungen

- Xypex Schematic Drawings PDFDokument22 SeitenXypex Schematic Drawings PDFk2v1n5100% (1)

- Northeast Chapter of Precast/Prestressed Concrete InstituteDokument32 SeitenNortheast Chapter of Precast/Prestressed Concrete InstituteMagdy BakryNoch keine Bewertungen

- D 6663 - 01 Rdy2njmDokument4 SeitenD 6663 - 01 Rdy2njmJuanNoch keine Bewertungen

- Qualanod Spec. Ed 01.01.19Dokument78 SeitenQualanod Spec. Ed 01.01.19Abdul Rahman ObaidNoch keine Bewertungen

- Itb-Keoc-2012-014 - Annex II BoqDokument384 SeitenItb-Keoc-2012-014 - Annex II Boqelsabet gezahegnNoch keine Bewertungen

- EXIN Business Information Management Foundation: Sample ExamDokument34 SeitenEXIN Business Information Management Foundation: Sample ExamqassamiNoch keine Bewertungen

- Technical specifications for repairing water distribution networksDokument24 SeitenTechnical specifications for repairing water distribution networksSIVANoch keine Bewertungen

- W.3a Overview of LED-Related StandardsDokument36 SeitenW.3a Overview of LED-Related StandardsCarlos ArroyoNoch keine Bewertungen

- Defence Procurement Manual 2009Dokument108 SeitenDefence Procurement Manual 2009somnath sahuNoch keine Bewertungen

- Asme Section II A-2 Sa-592 Sa-592mDokument4 SeitenAsme Section II A-2 Sa-592 Sa-592mAnonymous GhPzn1xNoch keine Bewertungen

- Drawing Reading Module GuideDokument96 SeitenDrawing Reading Module GuideAshish GhadiyaNoch keine Bewertungen

- Astm F 2444-04 PDFDokument9 SeitenAstm F 2444-04 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Virtual-ED Software Requirements SpecificationDokument44 SeitenVirtual-ED Software Requirements SpecificationRavi KaushikNoch keine Bewertungen

- NE01 119revbDokument24 SeitenNE01 119revbMarlene Yuriserll Ruiz Muñoz100% (1)

- Bridge Works - MiscellaneousDokument26 SeitenBridge Works - MiscellaneousamitjustamitNoch keine Bewertungen

- Concrete Block Forms ColumnsDokument1 SeiteConcrete Block Forms ColumnsAKASH FERAGNoch keine Bewertungen

- Quality Control for Road WorksDokument23 SeitenQuality Control for Road WorkskvijayasokNoch keine Bewertungen

- Astm C717Dokument64 SeitenAstm C717Ryan LasacaNoch keine Bewertungen

- SAE J17 Dated 5-2003 Latex Foam Rubber PDFDokument11 SeitenSAE J17 Dated 5-2003 Latex Foam Rubber PDFanon_94010986Noch keine Bewertungen

- Booklet Tier I I PhaseDokument48 SeitenBooklet Tier I I PhaseAkhlaq HussainNoch keine Bewertungen

- Fire Hydrants PDFDokument22 SeitenFire Hydrants PDFangel onofre castelanNoch keine Bewertungen

- Building and Design CodesDokument15 SeitenBuilding and Design CodesKeangsinh TaingNoch keine Bewertungen

- PV Monitor Foresight Group International AG Submission Performance and Case List(s) (Report C11a) Traceability MatrixDokument33 SeitenPV Monitor Foresight Group International AG Submission Performance and Case List(s) (Report C11a) Traceability MatrixKavita AroraNoch keine Bewertungen

- Session 4 - Essential Design Features of Evacuation Center BuildingsDokument64 SeitenSession 4 - Essential Design Features of Evacuation Center BuildingsFrancis Emmanuel ReginioNoch keine Bewertungen

- Student Management SoftwareDokument11 SeitenStudent Management SoftwareBunny JainNoch keine Bewertungen