Beruflich Dokumente

Kultur Dokumente

Method Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)

Hochgeladen von

Nigin ParambathOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Method Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)

Hochgeladen von

Nigin ParambathCopyright:

Verfügbare Formate

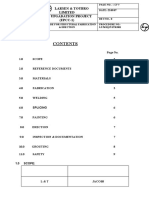

PT.

DUTA GRAHA INDAH Tbk

Project Karebbe HEP- Package K-8A Road and Oil Pipeline Realignment

Method Statement

ITEM: 00 16-Jul-09

MS 16

Revision Date

WELDING PROCEDURE (PREPARATION)

Prepared by Approve to issue TS SKW

Location Pages

Soroako Sulawesi Selatan 2 of 5

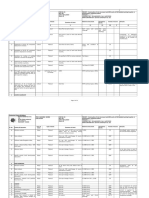

1.0 PURPOSE The purpose of this procedure is to provide guidelines for qualifying WPS required in the pipeline welding work. 2.0 SCOPE This procedure shall be applied for welding procedure qualification test on all WPS established in the pipeline welding work and related works. 3.0 REFERENCE ASME B31.4-2002 : Pipeline Transportation System for Liquid Hydrocarbon and Other Liquid API 1104-2005 : Welding of Pipeline and related Facilities. 4.0 DEFINITION /ABBREVIATION WPS - Welding Procedure Specification. WPQT - Welding Procedure Qualification Test. PQR - Procedure Qualification Record. WQT - Welder Qualification Test. 5.0 PROCEDURES 5.1 WPS preparation 5.1.1 DGI Welding Engineer and Sucofindo Crew would identify and submit to KHP the list of relevant WPS to be used for the project from the pre-accepted WPS. If additional WPS is required, WPS shall be developed and submitted for KHP approval before WPQT. 5.1.2 The Welding Engineer and Sucofindo Crew would formulate the welding procedures to the joint configuration and application. The WPS would reference to ASME B31.4-2002, Pipeline ASME B31.4 paragraph 434.8.3 for WPS for Cross Country Pipeline would be performed in accordance with API 1104. 5.1.3 The proposed WPS would contain all Specification Information (API 1104-2005 paragraph 5.3.2) including the essential welding parameters (API 1104-2005 paragraph 5.4) 5.1.4 Upon approval of the WPS, a WPQT would be carried out in the presence of KHP. KHP shall be informed as soon as possible in advance prior to the testing. 5.2 Step in Conducting WPQT 5.2.1 Prior to commencement of WPQT, the following shall be verified by KHP, DGI welding engineer, Sucofindo Crew. a) Test materials used, including the pipe number, heat number. b) Dimensions of the test materials e.g. length, diameter, thickness etc. c) Edge preparation of the test materials. d) Adequacy of lighting for cleaning and visual inspection.

PT. DUTA GRAHA INDAH Tbk

Project Karebbe HEP- Package K-8A Road and Oil Pipeline Realignment

Method Statement

ITEM: 00 16-Jul-09

MS 16

Revision Date

WELDING PROCEDURE (PREPARATION)

Prepared by Approve to issue TS SKW

Location Pages

Soroako Sulawesi Selatan 3 of 5

5.2.2

5.2.3 5.2.4 5.2.5

5.2.6 5.2.7

5.2.8 5.2.9

e) Current i.e. amperage and voltage by mean of AC/DC Digital Clamp Meter. f) Setting of current type, polarity including amperage and voltage. g) Correctness of welding consumables to be used as per proposed WPS. Upon fit-up, weld preparation and alignment shall be checked for compliance to the proposed WPS. After fit-up inspection, mark the PQR number, test position and indicate the top of joint position. The test piece shall be secured firmly per the required test position. A trial test may be carried out on a separate specimen prior to welding on the test piece to ensure the welding parameters set out in the WPS are maintained. Monitor and record the following welding parameters in the PQR form on each pass until completion of test weld to ensure compliance within the ranges specified in the proposed WPS. a) Travel speed, wire feed speed current i.e. Amperage and voltage by mean of AC/DC Digital Clamp meter. b) Type of Shielding Gas, Purging Gas & flow rate. c) Direction of travel for vertical welding d) Use of specified welding consumables diameter, electrode stick out length. e) Welding technique i.e. string, weave, split layer. f) Interpass temperature by use of Thermosticks or digital thermometer. g) Approximate width of weld pass. h) Approximate thickness of welds layer. i) Interpass cleaning method. j) Sequence and number of weld passes per layer. Welding would be check with visual inspection and NDT RT (Refer to ASME 13.4-2002 paragraph 434.8.5(a)(1)) DGI Welding Engineer would procees the locations of test specimens on the welded test piece for each type of destructive test before cutting at site or direct dispatch to aft approved independent testing laboratory for both cutting and machining work. The location for removal of the required specimen shall be in accordance with API 1104-2005 paragraph 5.6. The entire required test carried out in the laboratory would be witnessed by the Sucofindo, DGI Representative and Clients Representative. Accordance to API 1104 table 2, type and number of test speciments for PQT are a) For tensile strength are 2 spicements b) For nick-break test are 2 spicements c) For root bend test are 2 spicements d) Fof face bend test are 2 speciments

PT. DUTA GRAHA INDAH Tbk

Project Karebbe HEP- Package K-8A Road and Oil Pipeline Realignment

Method Statement

ITEM: 00 16-Jul-09

MS 16

Revision Date

WELDING PROCEDURE (PREPARATION)

Prepared by Approve to issue TS SKW

Location Pages

Soroako Sulawesi Selatan 4 of 5

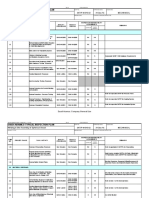

5.2.10 The following would be checked during the course of mechanical testing: a) Identification markings on the specimen (refer to API 1104 Fig-3) to its related PQR number, type of test and number of specimens required. b) Dimensions of Tensile-Strength Test, Nick-Breake Test, Root-and Face-Bend Test, specimens (Refers to API 1104 Fig-4, Fig-5, Fig-6, Fig-7) c) Calibration certificates of Tensile Test and Nick-Break Test equipment are valid. d) Dimensions of guided bend test equipment must be adequate to produce bending radius specified by test code for root (Refer to API 1104 Fig-9). e) Imperfections dimension after Nick-Break Test in exposed weld surface shown in API 1104 Fig-8. 5.2.11 During each test all results would be recorded on the draft copies of test report by the laboratory tester. 5.2.12 Upon completion, test results shall be signed off and a copy extended to the DGI, Sucofindo and KHP representative for signature and evaluation against the test code and specification. 5.2.13 Upon acceptance of the mechanical test results, the WPS/PQR would be prepared by the DGI welding engineer using the format shown in appendix I. The WPS/PQR would be submitted to CLIENT for review and approval. 5.3 Retest 5.3.1 When Retest is not allowed unacceptable defects evaluated by visual, NDT and Mechanical testing shall be cause for rejection. A new test weld shall be required. 5.3.2 When retest is allowed when one of the following mechanical test specimens fails to meet the required acceptance criteria, two additional specimens shall be prepared for retesting. The location of the two additional specimens shall reflect the location of the failed specimen. If one or both of the retest specimens fail, then this shall be cause for rejection. A new weld would be required Prior to retest, a study and evaluation shall be made on the failed test to established probable cause of failure. 6.0 SPECIAL REQUIREMENTS 6. 1 DGI welding engineer and Sucofindo shall be prepared the WPS to simulate, the actual welding conditions and materials to be used for production welding. Limitations imposed by the essential variables of the procedure qualification shall be adhered to in production welding. 6. 2 Only skilled and experienced welder(s) shall be assigned for WPQT to minimize rework.

PT. DUTA GRAHA INDAH Tbk

Project Karebbe HEP- Package K-8A Road and Oil Pipeline Realignment

Method Statement

ITEM: 00 16-Jul-09

MS 16

Revision Date

WELDING PROCEDURE (PREPARATION)

Prepared by Approve to issue TS SKW

Location Pages

Soroako Sulawesi Selatan 5 of 5

7.0 RECORDS All records pertaining to welding qualification test shall be kept by the DGI Welding Engineer. All copies of the approved WPS shall be readily available for reference by the Welders, Welding Engineers and KHP.

Das könnte Ihnen auch gefallen

- Lewis Corporation Case 6-2 - Group 5Dokument8 SeitenLewis Corporation Case 6-2 - Group 5Om Prakash100% (1)

- Mud PumpsDokument16 SeitenMud PumpsNigin Parambath100% (1)

- Inside BopDokument5 SeitenInside BopNigin Parambath100% (1)

- Ansible Playbook for BeginnersDokument101 SeitenAnsible Playbook for BeginnersFelix Andres Baquero Cubillos100% (1)

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDokument2 SeitenWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNoch keine Bewertungen

- Bs Tech: Electrodes Issue and Return RegisterDokument1 SeiteBs Tech: Electrodes Issue and Return RegisterRhannie GarciaNoch keine Bewertungen

- Fabrication Division QMDDokument11 SeitenFabrication Division QMDRakesh RanjanNoch keine Bewertungen

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionDokument1 SeitePunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoNoch keine Bewertungen

- Technofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIDokument9 SeitenTechnofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIElankumaran PeriakaruppanNoch keine Bewertungen

- Fit-Up Inspection ReportDokument27 SeitenFit-Up Inspection ReportAlfian ImaduddinNoch keine Bewertungen

- Fabrication Method For HSM 2 ProjectDokument14 SeitenFabrication Method For HSM 2 ProjectMikiRoniWijayaNoch keine Bewertungen

- Condensate Tank WELDING LOGDokument6 SeitenCondensate Tank WELDING LOGhasan shahriarNoch keine Bewertungen

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Dokument5 SeitenA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNoch keine Bewertungen

- Welder Test Param19!03!201211Dokument151 SeitenWelder Test Param19!03!201211VapaVapaNoch keine Bewertungen

- QAP ITP Bhogat - REV-01Dokument8 SeitenQAP ITP Bhogat - REV-01Ramkunwar YadavNoch keine Bewertungen

- Bending ProcedureDokument1 SeiteBending ProcedureabbasNoch keine Bewertungen

- Approved Welding Procedures List RegioDokument2 SeitenApproved Welding Procedures List Regiogabriel__regio100% (1)

- Replace No.3 API Oil Separator Project: Daily Fitup ReportDokument20 SeitenReplace No.3 API Oil Separator Project: Daily Fitup Reportsajay2010Noch keine Bewertungen

- Steel Structure Design and Fabrication RequirementsDokument11 SeitenSteel Structure Design and Fabrication RequirementssbunNoch keine Bewertungen

- Pressure Test Execution Plan Mar 24 Rev.cDokument12 SeitenPressure Test Execution Plan Mar 24 Rev.cAbdullah Al JubayerNoch keine Bewertungen

- Welding Control ProcedureDokument18 SeitenWelding Control ProceduresumitNoch keine Bewertungen

- FQP GeneralDokument21 SeitenFQP GeneralgaladrialNoch keine Bewertungen

- Company Logo Added to QAP DocumentDokument4 SeitenCompany Logo Added to QAP Documentmanoj thakkar100% (1)

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Dokument14 SeitenList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNoch keine Bewertungen

- Welding Coordinator WeldMap Weld Data Sheet PDFDokument1 SeiteWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNoch keine Bewertungen

- Inspection and Test Plan Piping Works Main Deck, Service Platform, Module, EtcDokument3 SeitenInspection and Test Plan Piping Works Main Deck, Service Platform, Module, Etcaditya kokoNoch keine Bewertungen

- Wps & PQR and Weld Map and Test PlanDokument67 SeitenWps & PQR and Weld Map and Test PlanmarghoobNoch keine Bewertungen

- QAQC Procedure For Fabrication - Flare KOD Rev ADokument9 SeitenQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- Optimized Title for Welspun MPQT ReportDokument84 SeitenOptimized Title for Welspun MPQT ReportAlam MD SazidNoch keine Bewertungen

- 01 Procedure For Structural SteelDokument9 Seiten01 Procedure For Structural Steelpunitg_2Noch keine Bewertungen

- Wps Mig PDF FreeDokument3 SeitenWps Mig PDF Freehanz bermejoNoch keine Bewertungen

- Welding Procedure Specification (WPS)Dokument2 SeitenWelding Procedure Specification (WPS)Abdulmecit YetisNoch keine Bewertungen

- Fitup (2019!06!01) Report-91 OfficialDokument2 SeitenFitup (2019!06!01) Report-91 OfficialCarlosNoch keine Bewertungen

- Control flow diagram for GACC's new welder qualification processDokument1 SeiteControl flow diagram for GACC's new welder qualification processSiddiqui Abdul KhaliqNoch keine Bewertungen

- Checklist for WPS-PQR certification requirementsDokument1 SeiteChecklist for WPS-PQR certification requirementsssNoch keine Bewertungen

- NDT Request (Template)Dokument4 SeitenNDT Request (Template)Bethel NdifonNoch keine Bewertungen

- Welder Qualification Test - WQT by ITPI-IWESDokument1 SeiteWelder Qualification Test - WQT by ITPI-IWESsanul mulyNoch keine Bewertungen

- Weld Book - Flare KOD - Structure Rev ADokument169 SeitenWeld Book - Flare KOD - Structure Rev ARajesh K PillaiNoch keine Bewertungen

- Fabrication Inspection Progress ReportDokument4 SeitenFabrication Inspection Progress ReportNorman MoralesNoch keine Bewertungen

- WPS ListDokument2 SeitenWPS ListAdeel OmerNoch keine Bewertungen

- 3 Steel Structure Installation CLDokument2 Seiten3 Steel Structure Installation CLwhah11Noch keine Bewertungen

- WPS - Smaw - 2Dokument6 SeitenWPS - Smaw - 2Harkesh RajputNoch keine Bewertungen

- Wps Model 2 PDFDokument17 SeitenWps Model 2 PDFbeyNoch keine Bewertungen

- N0200003 - NEW-F201-0 - Inspection & Test PlanDokument3 SeitenN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNoch keine Bewertungen

- Final Dimension Control Procedure - Flare KOD Rev ADokument9 SeitenFinal Dimension Control Procedure - Flare KOD Rev ARajesh K Pillai100% (1)

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDokument2 SeitenNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyNoch keine Bewertungen

- Procedure For WeldingDokument7 SeitenProcedure For WeldingMecon Hyderabad100% (1)

- Al-Suwaidi Industrial Welding ReportDokument85 SeitenAl-Suwaidi Industrial Welding ReportwalitedisonNoch keine Bewertungen

- Welding Map: PROJECT: Repair of Damaged Pipelines & Process Lines - MARETAP - EZZAOUIA FIELDDokument1 SeiteWelding Map: PROJECT: Repair of Damaged Pipelines & Process Lines - MARETAP - EZZAOUIA FIELDMajdi Jerbi100% (1)

- Back Weld Repair Procedure QualificationDokument15 SeitenBack Weld Repair Procedure QualificationFelipe Vásquez ArribasplataNoch keine Bewertungen

- Flash Report-2016-2-21Dokument3 SeitenFlash Report-2016-2-21sujinlongNoch keine Bewertungen

- Welder ID Card BRE KarahaDokument5 SeitenWelder ID Card BRE KarahaHerruSetiawan100% (1)

- WelderPOT 2009finalDokument160 SeitenWelderPOT 2009finalMayo de la PazNoch keine Bewertungen

- Offshore Marinetech PVT - LTD: Electrode Baking RegisterDokument3 SeitenOffshore Marinetech PVT - LTD: Electrode Baking RegisterPrathamesh OmtechNoch keine Bewertungen

- Material Inspection ReportDokument2 SeitenMaterial Inspection ReportReza AchmalyadiNoch keine Bewertungen

- WFP 2-01 ASME B31 Piping Welding ProcedureDokument8 SeitenWFP 2-01 ASME B31 Piping Welding Procedureleodavid87Noch keine Bewertungen

- Saudi Aramco WPS Procedure ApprovalDokument7 SeitenSaudi Aramco WPS Procedure ApprovalAkansha SharmaNoch keine Bewertungen

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDokument5 SeitenSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinNoch keine Bewertungen

- Construction Steel Erection PlansDokument10 SeitenConstruction Steel Erection PlansTran KhuynhNoch keine Bewertungen

- Is Standard ListDokument5 SeitenIs Standard ListbalramkinageNoch keine Bewertungen

- JIMT Visual Inspection ReportDokument1.913 SeitenJIMT Visual Inspection Reportgomathyselvi100% (1)

- 5657-Jawad Hanif CV TakreerDokument6 Seiten5657-Jawad Hanif CV TakreerkanchithalaiNoch keine Bewertungen

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkDokument38 SeitenMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTNoch keine Bewertungen

- MS For Piping Installation in QChem 1 Site Rev0Dokument18 SeitenMS For Piping Installation in QChem 1 Site Rev0Manzar KhanNoch keine Bewertungen

- Heavy Wall DP & Drill CollarsDokument13 SeitenHeavy Wall DP & Drill CollarsNigin ParambathNoch keine Bewertungen

- Drill PipeDokument14 SeitenDrill PipeNigin Parambath100% (2)

- Ram PreventerDokument19 SeitenRam PreventerNigin Parambath100% (1)

- Crown BlockDokument6 SeitenCrown BlockNigin ParambathNoch keine Bewertungen

- HookDokument11 SeitenHookNigin ParambathNoch keine Bewertungen

- DiverterDokument9 SeitenDiverterNigin ParambathNoch keine Bewertungen

- DerrickDokument17 SeitenDerrickNigin Parambath100% (4)

- Of-Pla NF00074 1001D PDFDokument8 SeitenOf-Pla NF00074 1001D PDFNigin ParambathNoch keine Bewertungen

- B5Dokument1 SeiteB5Nigin ParambathNoch keine Bewertungen

- Jis Gate ValveDokument1 SeiteJis Gate ValveNigin ParambathNoch keine Bewertungen

- Nuflo Orifice Plate PDFDokument8 SeitenNuflo Orifice Plate PDFNigin ParambathNoch keine Bewertungen

- Stainless Steel Pressure RatingsDokument7 SeitenStainless Steel Pressure RatingsNauman KhanNoch keine Bewertungen

- Pfi-Es-44 (1999)Dokument13 SeitenPfi-Es-44 (1999)elangopi89100% (1)

- ASME B16.5 Ring Joint Facings Table DimensionsDokument1 SeiteASME B16.5 Ring Joint Facings Table DimensionsNigin ParambathNoch keine Bewertungen

- Ori Flo PDFDokument14 SeitenOri Flo PDFNigin ParambathNoch keine Bewertungen

- Coupling 2Dokument19 SeitenCoupling 2tushar9810080Noch keine Bewertungen

- Chicken RoastDokument5 SeitenChicken RoastNigin ParambathNoch keine Bewertungen

- FL4013Dokument4 SeitenFL4013elenic777Noch keine Bewertungen

- Boneless Chilly CHICKENDokument5 SeitenBoneless Chilly CHICKENNigin ParambathNoch keine Bewertungen

- Chicken GingerDokument1 SeiteChicken GingerNigin ParambathNoch keine Bewertungen

- Grundfos White PaperDokument8 SeitenGrundfos White PapermishraenggNoch keine Bewertungen

- Chapter5 - Drive CouplingsDokument90 SeitenChapter5 - Drive Couplingsvijay219100% (1)

- KTR Kat99pp01Dokument0 SeitenKTR Kat99pp01Nigin ParambathNoch keine Bewertungen

- Know Your Gym: Exercise SafetyDokument2 SeitenKnow Your Gym: Exercise SafetyNigin ParambathNoch keine Bewertungen

- KTR Pump-Couplings PDFDokument44 SeitenKTR Pump-Couplings PDFGeorge_Wabag_2014Noch keine Bewertungen

- InspireFitness M2 WallChartDokument1 SeiteInspireFitness M2 WallChartNigin ParambathNoch keine Bewertungen

- DIN 2566 Threaded Flange PN10 and PN16Dokument1 SeiteDIN 2566 Threaded Flange PN10 and PN16Nigin ParambathNoch keine Bewertungen

- Bend Tooling's Tube Bending Tools Set-Up GuideDokument3 SeitenBend Tooling's Tube Bending Tools Set-Up GuideNigin ParambathNoch keine Bewertungen

- Ovr IbDokument27 SeitenOvr IbAriel CaresNoch keine Bewertungen

- Hydraulics Engineering Course OverviewDokument35 SeitenHydraulics Engineering Course Overviewahmad akramNoch keine Bewertungen

- Computer Networks Transmission Media: Dr. Mohammad AdlyDokument14 SeitenComputer Networks Transmission Media: Dr. Mohammad AdlyRichthofen Flies Bf109Noch keine Bewertungen

- Masteringphys 14Dokument20 SeitenMasteringphys 14CarlosGomez0% (3)

- 2021 Impact of Change Forecast Highlights: COVID-19 Recovery and Impact On Future UtilizationDokument17 Seiten2021 Impact of Change Forecast Highlights: COVID-19 Recovery and Impact On Future UtilizationwahidNoch keine Bewertungen

- Maxx 1657181198Dokument4 SeitenMaxx 1657181198Super UserNoch keine Bewertungen

- Evil Days of Luckless JohnDokument5 SeitenEvil Days of Luckless JohnadikressNoch keine Bewertungen

- CFO TagsDokument95 SeitenCFO Tagssatyagodfather0% (1)

- 4 Factor DoeDokument5 Seiten4 Factor Doeapi-516384896Noch keine Bewertungen

- Level 10 Halfling For DCCDokument1 SeiteLevel 10 Halfling For DCCQunariNoch keine Bewertungen

- Worksheet 5 Communications and Privacy: Unit 6 CommunicationDokument3 SeitenWorksheet 5 Communications and Privacy: Unit 6 Communicationwh45w45hw54Noch keine Bewertungen

- Joining Instruction 4 Years 22 23Dokument11 SeitenJoining Instruction 4 Years 22 23Salmini ShamteNoch keine Bewertungen

- Jesd8 15aDokument22 SeitenJesd8 15aSridhar PonnurangamNoch keine Bewertungen

- The Smith Generator BlueprintsDokument36 SeitenThe Smith Generator BlueprintsZoran AleksicNoch keine Bewertungen

- Human Rights Alert: Corrective Actions in Re: Litigation Involving Financial InstitutionsDokument3 SeitenHuman Rights Alert: Corrective Actions in Re: Litigation Involving Financial InstitutionsHuman Rights Alert - NGO (RA)Noch keine Bewertungen

- Mobile ApplicationDokument2 SeitenMobile Applicationdarebusi1Noch keine Bewertungen

- Hipotension 6Dokument16 SeitenHipotension 6arturo castilloNoch keine Bewertungen

- Qad Quick StartDokument534 SeitenQad Quick StartMahadev Subramani100% (1)

- Consumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaDokument16 SeitenConsumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaSundaravel ElangovanNoch keine Bewertungen

- Wheeled Loader L953F Specifications and DimensionsDokument1 SeiteWheeled Loader L953F Specifications and Dimensionssds khanhNoch keine Bewertungen

- Simba s7d Long Hole Drill RigDokument2 SeitenSimba s7d Long Hole Drill RigJaime Asis LopezNoch keine Bewertungen

- Extrajudicial Settlement of Estate Rule 74, Section 1 ChecklistDokument8 SeitenExtrajudicial Settlement of Estate Rule 74, Section 1 ChecklistMsyang Ann Corbo DiazNoch keine Bewertungen

- Guide To Raising Capital From Angel Investors Ebook From The Startup Garage PDFDokument20 SeitenGuide To Raising Capital From Angel Investors Ebook From The Startup Garage PDFLars VonTurboNoch keine Bewertungen

- Service Manual: Precision SeriesDokument32 SeitenService Manual: Precision SeriesMoises ShenteNoch keine Bewertungen

- Precision Machine Components: NSK Linear Guides Ball Screws MonocarriersDokument564 SeitenPrecision Machine Components: NSK Linear Guides Ball Screws MonocarriersDorian Cristian VatavuNoch keine Bewertungen

- Duca Industries March 2023 pay slip for Dipankar MondalDokument1 SeiteDuca Industries March 2023 pay slip for Dipankar MondalPritam GoswamiNoch keine Bewertungen

- The Dominant Regime Method - Hinloopen and Nijkamp PDFDokument20 SeitenThe Dominant Regime Method - Hinloopen and Nijkamp PDFLuiz Felipe GuaycuruNoch keine Bewertungen

- Critical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentDokument3 SeitenCritical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentJatin KaushikNoch keine Bewertungen