Beruflich Dokumente

Kultur Dokumente

ED3600

Hochgeladen von

Mohamed TahounOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ED3600

Hochgeladen von

Mohamed TahounCopyright:

Verfügbare Formate

Information and Recommendations for the Engineer

ED-3600

ENGINEERING DATA

Aerovent Twin City Fan & Blower Clarage

Turning Gear and Component Selection Guidelines

Turning Gear Selection

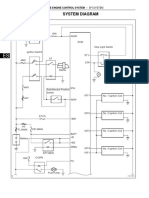

The main purpose of a turning gear is to alleviate the ill effects due to thermal stratification when a hot gas fan is shut down. During a hot shutdown of the fan, there will be a temperature gradient across the fan rotor because of the migration of warmer gas to the top portion of the fan housing and cooler gas to the bottom portion of the fan housing. This causes a temporary set in the fan shaft and on a re-start the fan will experience higher vibration levels. The following fans are typically good candidates to have a turning gear: Induced Draft fans over 120 in diameter and with large shafts and are subject to frequent start/ stops and or hot shut downs. All Gas Recirculation fans Hot Gas fans with high system sensitivity or fans operating close to the installed resonant speed All high temperature process fans in Cement, Sintering and Pelletizing etc. There are basically three types of turning gears. The first has the capability of being able to start the fan from a dead rest. The second type engages only on coast down and the size of the turning gear unit is much smaller as compared to the one that can start from a dead rest. The third type of turning gear is employed for fans with hydrodynamic bearings, which are fitted with hydrostatic lift. For starting from a dead rest, typically the turning gear size ranges from 5 HP to 150 HP for fan applications. A smaller turning gear is possible for smaller fans. High starting torque motors, typically NEMA C, are used with units that start from a dead rest. Sometimes with a marginal main drive motor, turning gear with the starting capability from a dead rest would be helpful to take away some burden from the main motor. Instead of starting from a dead rest, the main motor will accelerate from the turning gear speed. For units engaging on coast down, the motor may range up to 100 HP and could utilize a standard NEMA B as opposed to a NEMA C motor. Turning gear systems employed with fans that have bearings fitted with hydrostatic lift provide more compact units. This is because these units can run at a very low speed due to the fact that there is no minimum speed required for the bearings to develop the oil film since the oil film is provided by the hydrostatic lift. The size of the unit with hydrostatic lift may range up to 25 HP. A typical arrangement of a turning gear in a fan application is given below:

BRAKE MOTOR

SPEED REDUCER

COUPLING OVER RUNNING CLUTCH

FAN OUTBOARD BEARING

SOLE PLATE FOR SPEED REDUCER

CONCRETE FOUNDATION

Components

To make the turning gear unit compact for units starting from a dead rest, usually NEMA C motors are used. This is done to utilize the high starting torque characteristics of a NEMA C motor to help overcome the high breakaway torque of the fan and drive motor. For units engaging during coast down and for units with hydrostatic lift, standard NEMA B motors are adequate since high breakaway torque is not involved. Most applications use 1800 rpm motors, but 1200 rpm motors are used in certain situations. With a certain speed reducer combination, a brake motor or a separate brake may be required.

Motor

Usually right-angled speed reducers or in line speed reducers are used to rotate the fan at the required turning gear speed. A brake might be necessary depending on the type of speed reducer used and if the back drive resistance of the reducer is not adequate to overcome the drag torque of the clutch. The brake is wired to disengage while the turning gear motor is energized and engage while the turning gear motor is de-energized.

Speed Reducer

2006 Twin City Fan Companies, Ltd.

The speed reducer must have adequate torque carrying capability to handle the maximum torque and peak torque of the turning gear system. Thermal rating of the speed reducer is important to handle the normal operating torque without overheating the reducer for reliable operation. Output speed of the turning gear system is to be determined based on the minimum speed required to develop oil film when used with hydrodynamic bearings. This is usually dependent on the Sommerfeld number, which again depends on the oil viscosity, radial load, size of the bearing, bearing clearance etc. Fans with anti-friction bearings do not typically have a minimum speed requirement.

Selection and Sizing of Components

The first step is to calculate the breakaway torque of the fan rotor as a dead load and the breakaway torque of the drive motor. The next step is to determine the turning gear speed, which is a function of the type of bearing and whether or not the bearings are equipped with hydrostatic lift. All components have to be adequately sized for the duty requirements and the peak load requirements of the turning gear system.

Controls

Clutch

For turning gear applications, overrunning clutches are required and are either shaft-mounted type or foot mounted type with input and output shafts. It must be noted that the clutches are assembled either for clockwise rotation or counter-clockwise rotation. Clutch rotation must match the normal fan rotation. Shaft mounted type clutches are available with inner race over-running or outer race over-running. Clutches with inner race over-running are mounted on the fan shaft and clutches with the outer race over-running are mounted on the output shaft of the reducer. Often times special output shafts for the speed reducer are required and this increases the cost and lead-time of the speed reducer.

When the fan motor is de-energized, the turning gear motor is energized and when both speeds match, the clutch automatically engages. If there is a brake in the turning gear system, it should disengage on energizing the turning gear motor. Bearings equipped with hydrostatic lift and/or circulating oil must continue to operate while the turning gear is operating and rotating the fan rotor and motor rotor.

Turning Gear Motor Inertia Verification

For turning gear units starting from a dead rest, it is necessary to make sure that the turning gear motor has adequate inertia capability to accelerate the load without overheating. Inertia seen by the turning gear motor must be lower than the inertia capability of the turning gear motor.

There are usually three couplings in a turning gear assembly. One between the fan and the clutch, the second between the clutch and the speed reducer and the third between the speed reducer and the turning gear motor. Typically all the couplings are gear couplings and the one between the fan and the clutch has to accommodate thermal expansion of the shaft. For smaller units and with different arrangements, the number of couplings can be reduced to one or two.

Couplings

TM

3MSS01/06

Das könnte Ihnen auch gefallen

- ERG100Dokument12 SeitenERG100Mohamed TahounNoch keine Bewertungen

- ED3900Dokument8 SeitenED3900Mohamed TahounNoch keine Bewertungen

- Ngineering ATA: Topics in AcousticsDokument4 SeitenNgineering ATA: Topics in AcousticsMohamed TahounNoch keine Bewertungen

- ED2900Dokument2 SeitenED2900Mohamed TahounNoch keine Bewertungen

- ED2500Dokument6 SeitenED2500Mohamed TahounNoch keine Bewertungen

- ED3700Dokument4 SeitenED3700Mohamed TahounNoch keine Bewertungen

- ED3500Dokument2 SeitenED3500Mohamed TahounNoch keine Bewertungen

- ED3000Dokument4 SeitenED3000Mohamed TahounNoch keine Bewertungen

- ED3300Dokument4 SeitenED3300Mohamed Tahoun100% (1)

- ED3100Dokument6 SeitenED3100Mohamed TahounNoch keine Bewertungen

- Ngineering ATA: Fan Damper SelectionDokument4 SeitenNgineering ATA: Fan Damper SelectionMohamed TahounNoch keine Bewertungen

- ED2700Dokument4 SeitenED2700Mohamed TahounNoch keine Bewertungen

- ED1800Dokument8 SeitenED1800kapilnandwanaNoch keine Bewertungen

- ED2200Dokument2 SeitenED2200Mohamed TahounNoch keine Bewertungen

- Fan Performance Characteristics of Centrifugal FansDokument4 SeitenFan Performance Characteristics of Centrifugal FansJan Willem de Ruyter100% (1)

- Types of Single PhaseDokument10 SeitenTypes of Single PhaseKifayat MsdNoch keine Bewertungen

- Ed 2300Dokument4 SeitenEd 2300rlam17Noch keine Bewertungen

- ED2100Dokument6 SeitenED2100Mohamed TahounNoch keine Bewertungen

- Ngineering ATA: Fan Bearing Maintenance & TroubleshootingDokument6 SeitenNgineering ATA: Fan Bearing Maintenance & TroubleshootingRavi DeshmukhNoch keine Bewertungen

- Fan Vibration Isolation ED1900 PDFDokument4 SeitenFan Vibration Isolation ED1900 PDFsivajirao70Noch keine Bewertungen

- ED1700Dokument4 SeitenED1700Mohamed TahounNoch keine Bewertungen

- ED2000Dokument4 SeitenED2000Mohamed TahounNoch keine Bewertungen

- Ngineering ATA: Temperature & Altitude Effects On FansDokument3 SeitenNgineering ATA: Temperature & Altitude Effects On FansMohamed TahounNoch keine Bewertungen

- ED1200Dokument4 SeitenED1200Mohamed TahounNoch keine Bewertungen

- ED1500Dokument3 SeitenED1500Mohamed TahounNoch keine Bewertungen

- ED1000Dokument4 SeitenED1000Mohamed TahounNoch keine Bewertungen

- Fan Belt DriveDokument6 SeitenFan Belt DriveRavi DeshmukhNoch keine Bewertungen

- Ngineering ATA: Field Testing of FansDokument5 SeitenNgineering ATA: Field Testing of FansMohamed TahounNoch keine Bewertungen

- ED800Dokument8 SeitenED800Mohamed TahounNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Brake Booster 1Dokument3 SeitenBrake Booster 1Sagar ChoubeyNoch keine Bewertungen

- BMW 5 Series 530i M Sport Specs and FeaturesDokument1 SeiteBMW 5 Series 530i M Sport Specs and FeaturesVinay RaoNoch keine Bewertungen

- MAN L21 31 PowerPlantDokument248 SeitenMAN L21 31 PowerPlantSmart Lau100% (4)

- Honda 9.9 - BABJDokument137 SeitenHonda 9.9 - BABJCraig Smith67% (3)

- Machinecard: Serial No. C20326 14064CNDokument3 SeitenMachinecard: Serial No. C20326 14064CNAbas AbasariNoch keine Bewertungen

- 1981 Miyata CatalogDokument12 Seiten1981 Miyata Catalogtharunkarra100% (1)

- Corolla 1.8 - 1Dokument4 SeitenCorolla 1.8 - 1Diego496Noch keine Bewertungen

- Driving and Controlling: Drive Controller Electric Transaxle Drive MotorDokument23 SeitenDriving and Controlling: Drive Controller Electric Transaxle Drive Motordgy24wntgcNoch keine Bewertungen

- Diesel Generator Set C Series: Specification SheetDokument4 SeitenDiesel Generator Set C Series: Specification Sheetrobinknit2009Noch keine Bewertungen

- Parts Book Hd785-7 Lepbh78703 J30001-UpDokument674 SeitenParts Book Hd785-7 Lepbh78703 J30001-UpMc MuklisNoch keine Bewertungen

- SSP 297 TouaregDokument56 SeitenSSP 297 Touaregภูเก็ต เป็นเกาะ100% (1)

- Manual de Usuario Stihl 009 (53 Páginas)Dokument1 SeiteManual de Usuario Stihl 009 (53 Páginas)toyioriginalNoch keine Bewertungen

- Service Bulletin - Pistons.: Normal CombustionDokument17 SeitenService Bulletin - Pistons.: Normal CombustionRasheed SiddiquiNoch keine Bewertungen

- CF MOTO Manual Taller 300NKDokument210 SeitenCF MOTO Manual Taller 300NKEvaColAra100% (5)

- System Diagram: 2Az-Fe Engine Control System - Sfi SystemDokument3 SeitenSystem Diagram: 2Az-Fe Engine Control System - Sfi SystemdennoNoch keine Bewertungen

- Toyota Starlet KP6 - Series Body Style Wiring DiagramsDokument13 SeitenToyota Starlet KP6 - Series Body Style Wiring Diagramscap67% (6)

- RadionDokument45 SeitenRadiontvsparavattani50% (2)

- Toyota Vios Ecu Wiring DiagramDokument4 SeitenToyota Vios Ecu Wiring DiagramSri Yuniati17% (6)

- C Loth Seat - OptionalDokument3 SeitenC Loth Seat - Optionalcrash2804Noch keine Bewertungen

- Isx Cpls Piston Overhaul Cross Ref PDFDokument1 SeiteIsx Cpls Piston Overhaul Cross Ref PDFAlex Renne ChambiNoch keine Bewertungen

- Chappter3 BirleştirildiDokument98 SeitenChappter3 Birleştirildikaybedenler kulübüNoch keine Bewertungen

- Design and Development of A Dry Sump Lubrication System For A Formula SAE Race CarDokument9 SeitenDesign and Development of A Dry Sump Lubrication System For A Formula SAE Race CarSunnyNoch keine Bewertungen

- Workshop ManualDokument52 SeitenWorkshop ManualMarko ZgNoch keine Bewertungen

- Inventory of Windshields (Inventario de ParabrisasDokument18 SeitenInventory of Windshields (Inventario de ParabrisasDomo StoreNoch keine Bewertungen

- Servoembrague 970 051: Clutch Servo UnitDokument5 SeitenServoembrague 970 051: Clutch Servo Unithoduart0620Noch keine Bewertungen

- Excavator Forest Mach Front Shovels Mat HNDLR Mini Hydraulic Wheeled ExDokument595 SeitenExcavator Forest Mach Front Shovels Mat HNDLR Mini Hydraulic Wheeled ExEder0% (1)

- Suntour XCM v3 Service Manual PDFDokument3 SeitenSuntour XCM v3 Service Manual PDFaleluja100% (1)

- 2013 Fault Codes PDFDokument286 Seiten2013 Fault Codes PDFAnguchamy Anguchamy89% (35)

- Massey Ferguson 50e Industrial Tractor Service ManualDokument38 SeitenMassey Ferguson 50e Industrial Tractor Service ManualAlexander Mugabe0% (2)

- Chainless Anchoring 2Dokument4 SeitenChainless Anchoring 2Santhosh RamananNoch keine Bewertungen