Beruflich Dokumente

Kultur Dokumente

Plasticizing Range

Hochgeladen von

hermenegilsonOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Plasticizing Range

Hochgeladen von

hermenegilsonCopyright:

Verfügbare Formate

Netstal-Maschinen AG

Plasticizing range

Netstal solution expertise

Netstal Support Concept

Plasticizing range

Increasing cost pressure and higher quality standards for moulded parts necessitate the application of an injection moulding machine optimally tailored to the respective product. Netstal original plasticizing components provide you with the decisive edge in meeting high qualitative standards in terms of the melt and plasticizing performance. Fast, precise, reliable ! Three outstanding features of a Netstal machine to enable the manufacture of complex moulded parts in extremely short cycle times. The primary factor in the moulded part manufacturing process is the plasticizing process the transformation of plastic granules into a processible melt form. The development of a variety of new plastics, particularly in the technical sector, also necessitates continual adaptation and modification of the plasticizing system. Increased wear as a result of abrasion, adhesion and corrosion due to additives in the materials, as well as constantly increasing material throughput rates and higher processing temperatures, all require maximum performance from all the plasticizing components such as cylinders, screws and back-flow stops. Netstal is not only a supplier of plasticizing components, but is also a partner that offers solutions that are precisely tailored to the outstanding performance of Netstal machines. Research and development R & D plays a major role at NetstalMaschinen AG and our specialists have longstanding experience in the design of plasticizing components. The production-based development environment allows our team to realise optimised application solutions for screws, cylinders and back-flow stops and make these available to our partners, the Netstal machine users. Application technology Product-specific specialists are on hand to help you select the best possible Netstal component application.

Uncompromising quality :

Your choice :

Uncompromising quality is the benchmark for our plasticizing component manufacturing process.

Netstal original plasticizing components ( screws, cylinders and back-flow stops ) !

Netstal Support Concept

Our product managers in the business units Caps and Closures, Packaging, Medical, PET and our optical and technical component product managers are technical specialists with in-depth knowledge of their respective areas of responsibility. The benefits to be gained from this specialisation are clearly apparent: competent and comprehensive consulting that is tailored to your product range. Spiralling demands on production in terms of cost-efficiency and quality necessitate the application of appropriate machine equipment, whereby plasticizing and specifically screw geometry plays a major role. Depending on the application, ultra-fast, mild, highly accurate or energy-optimised metering may be required, and frequently, all of these requirements are called for. Regardless of the type of thermoplastics your company processes polyolefins, technical plastics or high temperature plastics we have the optimal equipment for you. Benefit from all the advantages of our consulting service and use original plasticizing components ! Customer service Netstal offers you excellent availability in terms of original plasticizing

components delivered direct from our warehouse. As such, we achieve our principal priority by ensuring that the right part is in the right place at the right time. Noone knows your machines better than Netstal. All original plasticizing components are tailored and optimised to meet the performance of Netstal injection moulding machines. For this reason, it is understandable that Netstal can only guarantee the achievement of agreed performance data if original Netstal plasticizing components are used. Similarly, our application technology consulting and scope of guarantee can only be provided for our original parts. Machines, consulting and spare parts all from a single source providing you with the decisive edge when it comes to plasticizing !

Application technology consulting is a central focus of our support concept.

Targeted product service

Netstal quality at the heart of our product lines.

Fast, precise, reliable:

Pro Original for the success of original technology :

The three outstanding features of a Netstal machine.

All from a single source benefit from this decisive advantage.

www.vdma.org/original

3

Netstal Support Concept

The plasticizing range for any situation

A decisive factor when it comes to first-rate plasticizing performance is the right choice of plasticizing system. The comprehensive requirements encompass the following : Outstanding plasticizing performance Excellent thermal and material homogeny in terms of the melt Efficient, but mild melt preparation without material damage High level of wear and corrosion protection for an enhanced service life Excellent reproducibility Highest possible range of application Requirements are weighted differently depending on the respective application area. Consequently, the shear stress rate is the most important factor when processing PC / ABS blends in order to achieve the highest possible impact resistance, such as that required for thin-walled housings. The manufacture of caps and packaging requires an extremely high standard of plasticizing performance, while high plasticizing performance at a low shear stress rate forms the focus in the production of PET preforms. Complete homogeny in terms of the melt is, of course, a prerequisite for all the applications. Netstal provides you with the optimum plasticizing system for your application to consequently meet the most stringent requirements.

Geometrical layout Screws Cylinders Back-flow stops

Plasticizing performance

Outstanding plasticizing performance Quality melt and moulded part Process reliability/reproducibility Long service life

Material selection Material quality Material friction pairing Protection against corrosion

Coatings Surface structure Non-stick feature Rapid colour changing

Process management

Choice of plasticizing system :

Optimal performance:

A decisive factor when it comes to excellent plasticizing performance.

The ideal coordination of geometric design, material selection, optional coatings and process management.

Netstal Support Concept

Netstal LP screw : The high performance screw for maximum plasticizing performance and superlative melt quality. Through its special geometric design, the LP barrier screw combines first-rate plasticizing performance with mild material preparation and optimal mixing attributes that are guaranteed even at high throughput rates. Used in standard applications and high speed packaging applications, the LP screw can achieve superlative polyolefin throughput performance, with excellent quality melt homogeny and exceptional temperature management.

Benefits for you

Outstanding plasticizing performance Excellent material homogeny Superb pressure-throughput ratio Low-wear Material conserving melting concept

In addition, a high melting capability at low pressure within the barriers enables perfect cap production using extremely high viscosity HDPE. Moreover, non-reinforced technical plastics such as ABS, PBT or POM can be processed at higher rotational speeds and with greater homogeny in comparison to a standard screw.

LP operating principle

Barrier flight CylinderScrew

Direction of flow Screw Melt channel Solids channel Feed section

LP screw :

The right choice where a high standard of melt quality and maximal plasticizing performance is called for.

Netstal Support Concept

Netstal standard screw: Impressive in the melt preparation for numerous conventional applications, the standard screw has proved itself as a versatile and costefficient solution. The standard screw really comes to the fore with a broad range of materials when implemented for technical and medical applications with medium and low rotational speeds. A balanced geometry ensures exceptional temperature management and homogeny within a

Benefits for you

Universally deployable for a broad range of materials with medium plasticizing requirements Exceptional temperature management and homogeny for technical and medical applications. Excellent reproducibility and process reliability within a broad process latitude

broad process latitude when processing materials such as PA, ABS, PC, PMMA or POM.

Netstal PET screws: To ensure the optimal melt quality, Netstal supplies special high-performance plasticizing units for PET processing. Mild material preparation not least thanks to the intrusion principle patented by Netstal and an excellent standard of homogeny guarantee top product quality. High throughput rates up to 1,500 kg / h and a focus on maximum energy efficiency provide for maximum productivity. Netstal is also an excellent partner in terms of special applications, such

Benefits for you

Outstanding plasticizing performance Mild material preparation providing minimum AA values thanks to the intrusion principle and special screw geometry Excellent material homogeny Energy-efficient plasticizing The optimal solution for all PET applications

as hot-fill or recycled flakes, and is always able to provide the optimal screw concept.

Standard screw :

PET screw:

The right choice for a wide range of technical plastics.

Netstal supplies high-performance plasticizing units for the manufacture of PET preforms.

Netstal Support Concept

Protection against wear + +++ +++

Protection against corrosion + ++ +++

Screw Nitriding steel optional coating Hardened steel optional coating Powder steel

Cylinder Nitriding steel Bi-metal plating Bi-metal plating

Application area Non-reinforced plastics, standard packaging applications Reinforced plastics with low or high filling ratio Non-reinforced or reinforced technical plastics with corrosive additives

Coordinated plasticizing components We supply you with just the right cylinders, back-flow stops and locking systems all specifically tailored to our range of screws and their respective applications. Protection against wear Plasticizing components are subjected to exceptionally high stress loads. A variety of additives such as glass fibre, fillers and colourings call for targeted measures to avoid adhesive and abrasive wear. Netstals range of products features high quality materials that are coordinated to produce favourable friction conditions and thereby optimally protect the components against surface wear. In addition to the appropriate choice of materials, through intelligent

geometric design Netstal focuses on ensuring that no unnecessary stress is exerted on the plasticizing components. In barrier screws, for example, the friction resulting from ring backflow stops or melt pressures is reduced, thereby achieving an exceptionally long service life even where great demands are placed on the plasticizing process. Protection against corrosion Above all, the rapid development of new technical plastics frequently calls for additional protection of the plasticizing components against corrosion. Solution-orientated materials, coated where necessary, are also used in this case to largely prevent the complex processes of oxygen-related and intercrystaline corrosion, which also often occurs in combination with additives.

Coatings On the one hand, coatings are applied to improve wear and corrosion protection, but on the other hand also to optimise the non-stick attributes and prevent adhesion to screws and back-flow stops. Longstanding experience has taught our engineers which coatings will have the specific effects required to optimise plasticizing systems. As a consequence, the appropriate coatings can, for example, practically eliminate optical defects in the manufacture of lenses and other transparent products. Adhesion, pitted and degraded plastic parts as well as black spots are largely prevented, while colour changing is accelerated and product quality assurance largely secured.

Coordinated plasticizing components :

Coatings:

Your application our cylinders, back-flow stops and locking systems.

To enhance wear and corrosion protection or optimise non-stick characteristics.

For a su successful future.

Boasting 60 years of experience, Netstal is one of the pioneers of injection moulding technology. Machines and production systems from Netstal are characterised by their reliability, precision, speed, user-friendliness and efficiency. Thanks to our worldwide sales and service network, we can guarantee a future-oriented partnership.

Netstal-Maschinen AG CH -8752 Nfels /Switzerland Phine +41 55 618 6111 Fax +41 55 618 66 04 Internet www.netstal.com E-mail nsc @ netstal.com

No. 1 / 09.2009 / 1000 / D, E

SynErgy

EVOS

ELION

e-Jet

PET-LINE

NSC

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Finite Element Analysis in Solid WorksDokument6 SeitenFinite Element Analysis in Solid WorksMarco Mejia RuízNoch keine Bewertungen

- Brittleness IndexDokument3 SeitenBrittleness IndexViviRachmawatiNoch keine Bewertungen

- Stiffness An Unknown World of Mechanical Science 2000 InjuryDokument14 SeitenStiffness An Unknown World of Mechanical Science 2000 InjuryAdam Taylor100% (1)

- Exercises Problems Answers Chapter 6Dokument9 SeitenExercises Problems Answers Chapter 6A Sibiescu100% (1)

- Questions 1Dokument15 SeitenQuestions 1Har AhmadNoch keine Bewertungen

- Mechanisms of Heat Transfer: Pre-Reading 17.7Dokument22 SeitenMechanisms of Heat Transfer: Pre-Reading 17.7goharNoch keine Bewertungen

- Common Mistakes in Fatigue AnalysisDokument14 SeitenCommon Mistakes in Fatigue AnalysismuhannedNoch keine Bewertungen

- Chapter 82 Advanced Theories of Covalent BondingDokument94 SeitenChapter 82 Advanced Theories of Covalent BondingcheruNoch keine Bewertungen

- CH 01Dokument72 SeitenCH 01Shashi ShekharNoch keine Bewertungen

- Hydrodynamic Effects During Earthquakes On Dams and Retaining WallsDokument6 SeitenHydrodynamic Effects During Earthquakes On Dams and Retaining WallsAndres CaroNoch keine Bewertungen

- Bucyrus OGL Lubrication SD 4713Dokument8 SeitenBucyrus OGL Lubrication SD 4713dpomahNoch keine Bewertungen

- Gamma Titanium Aluminide Alloys Science andDokument5 SeitenGamma Titanium Aluminide Alloys Science andkorkmazmailNoch keine Bewertungen

- Properties of Pure SubstanceDokument21 SeitenProperties of Pure SubstancemalarvizhiNoch keine Bewertungen

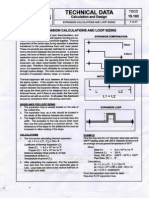

- Expansion Calculation and Loop Sizing001Dokument2 SeitenExpansion Calculation and Loop Sizing001Joseph R. F. DavidNoch keine Bewertungen

- Dental Composite Resin. A ReviewDokument7 SeitenDental Composite Resin. A ReviewDan MPNoch keine Bewertungen

- Spray Dryer Modeling in Theory and Practice PDFDokument34 SeitenSpray Dryer Modeling in Theory and Practice PDFmarmaduke32Noch keine Bewertungen

- Group 3 Heat Exchanger Problems:: The Log Mean Temperature Difference IsDokument6 SeitenGroup 3 Heat Exchanger Problems:: The Log Mean Temperature Difference IsKen MaglinteNoch keine Bewertungen

- Controversial Electro ProblemDokument16 SeitenControversial Electro ProblemJorge AlcarazNoch keine Bewertungen

- Sheet 3 Solution 2012Dokument35 SeitenSheet 3 Solution 2012jp2away68Noch keine Bewertungen

- Prestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 12Dokument44 SeitenPrestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 12Carlos Alberto Pacheco SierraNoch keine Bewertungen

- Discovery of Sub Atomic ParticlesDokument4 SeitenDiscovery of Sub Atomic ParticlesManasvi SharmaNoch keine Bewertungen

- UPS Neuttral EarthingDokument11 SeitenUPS Neuttral Earthingarun kumarNoch keine Bewertungen

- Electric Generator Project FileDokument27 SeitenElectric Generator Project Filegudias375Noch keine Bewertungen

- Temperature Field Analysis of Tunnel Kiln For Brick ProductionDokument6 SeitenTemperature Field Analysis of Tunnel Kiln For Brick ProductionDWWillsonNoch keine Bewertungen

- ThAnalysis Catalogue enDokument44 SeitenThAnalysis Catalogue enHanLe DuyNoch keine Bewertungen

- DSFfilmDokument4 SeitenDSFfilmGagandeep BhatiaNoch keine Bewertungen

- Purolite® A500Mb: Strong Base Anion MacroporousDokument2 SeitenPurolite® A500Mb: Strong Base Anion MacroporousKewl DudzNoch keine Bewertungen

- Chapter Viii: The Nano WorldDokument2 SeitenChapter Viii: The Nano WorldCherry Ann OlasimanNoch keine Bewertungen

- Fluid Mechanics Lab 1Dokument18 SeitenFluid Mechanics Lab 1Billu RocxNoch keine Bewertungen