Beruflich Dokumente

Kultur Dokumente

Wps

Hochgeladen von

naseema1Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Wps

Hochgeladen von

naseema1Copyright:

Verfügbare Formate

-----------

- - -

L

P.O.Box 8817, Building # DY34 Tel: +971 4 324 3888

Inside Dubai Ship Docking Yard Fax: +971 4 324 3682

AI Jadaf, Dubai

Email: testing@l onestar-lab.com

United Arab Emirates

Websit e: www.lonestar-Iab.com

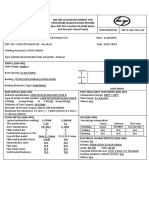

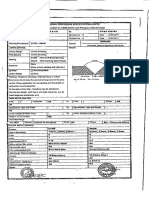

WELDING PROCEDURE SPECIFICATION - WPS

Compan y Name Stars Line Metallic Ind. L.L.C Prepared by Mr. K. Kalimuthu

Welding Procedure Specificati on # SLMIWPS/005/09 Date: 01-12-2009 Supporting PQR # SLM/PQRl005/09

Revision # : 0 Date : Cogniz ant Code AWS D1.1

Welding Process (es) FCAW Type (s) Semi Automatic

Joint Design : Sinql e V' Groove

60

0

5

Backing/Back weld :

0

No

-.

/

'

Backing Material (type) EN 10025, S275JR

.

Retainer

Root Gap

Groo ve Angle

Root Face

N/A

2. 5mm

60(5)

2mm

1

t,ofm

Edge prepara tion Machin ing & Grinding (Bevel)

Plate Thickness 2Qmm

2.5 mm

Base Metals

F-No.:

Pi Group No 1 F-No .: Group No.: 1

-

Type EN 10025 EN 10025

ST' Type

Specification re;: peci ication

Grade S275JR Grade S275JR

Qualification Range

Base metal: 5mm to Unlimited Plate: All Thi ckness

Th ickness Groove Fillet

Weld met al: Base Mel al + Reinforcement Pipe: N/A

Pipe Dia Groove : N/A Fill et : All

Other:

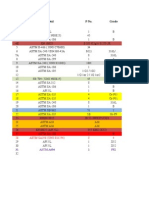

Filler Metals Root Hot Pass Fill ICap

...

Spec No. A 5.20 A 5.20 A 5.20

AWS No. Classification E 71T E 71T E 71T

..

F-No. F6 F6 F6

A-No . 1 1 1

Size of Filler Metals 01.2mm 01 .2mm 01.2mm

-. _.

Electrode-Trade Name N/A N/A N/A

Flux Trade Name N/A N/A N/A

Consumable Insert N/A N/A N/A

Process FCAW FCAW FCAW

NDT-RPT-254-WPS-Stars Lin e Metallic Page I of2

UKAS. Commer cial & Legal ter ms and conditions on the reverse of uus sheet

Other Locations: Abu Dhaol Aiman Oman Qatar

P.O.Box 8817, Build ing # DY34 Tel: +971 4 324 3888

Inside Dubai Ship Dock ing Yard Fax: +971 4 324 3682

AI Jadaf, Dubai Email: testing@lonestar-l ab.com

Unit ed Arab Emirates

Website: www.lonestar-Iab.com

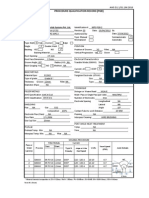

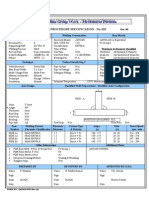

I Company Name : Stars Line Metallic Ind. L.L.C I WPS # . SLMIWPSJOOSJ09 I Rev. # a

Position Post Weld Heat Treatment

Position (s) Groove 3G Temperature Range N/A

Welding Progression: G Uphill D Downhill D Horizontal Time Range N/A

Heating Rate N/A

Position (s) of Fillet N/A Cooling Rate N/A

Preheat Gas

50C if ambient less % Composition

Gas (es) Flow Rate

(Mixture)

Preheat Temperature, minimum than 10 C

lnterpass Temperature, maximum 250C Shieldi ng : CO2 99.9% 15/20CFH

Temperature Measurement Temple Stick Trailing N/A N/A N/A

Purgi ng N/A N/A N/A

Electrical Characteristics

Current Type D.C Tungsten Electrode Size and type N/A

Pol arity DCEP (Reverse) Mode of Metal Transfer GMAW N/A

Volt age (Range) 20 - 30 Electrode Wire Feed Speed Range

100 1 PM

Current (Range) 150 - 250 Others N/A

Technique

String or Weave Bead Both Multiple or Single Pass (per side) Multi Pass

Orifice or Gas Cup Size o 9.5mm to 019mm Max weld Thickness (Any pass) N/A

Initial and Interpass Cleaning Grindi ng and Wire Brushing Multiple or Single Electrode Single

Met hod or Back Gouging Grinding Travel Speed (Range) As Below

Oscillation N/A Peening N/A

Contact Tube to Work Distance Minimum Electrode Dia Other N/A

Filler Metal Current Max Heat

Volt Travel Speed

Weld Layers Process Type Input

Cl ass Di a,mm Amp Range Rang e Range , mm/min

Polarity K.J/lnch

Root FCAW E 71T 0 1.2mm DCEP 150 - 200 20 - 30 1.12 1.90

Hot Pass FCAW E 71T 0 1.2mm DCEP 180 - 250 20 - 30 1.24 2.50

Fill / Cap FCAW E 71T 0 1.2mm DCEP 180 - 250 20 - 30 1.24 2.50

Prepftre<;f'by - , Accepted By

Name Mr. K. KalimuthiJ Name

Lonestar Technical Se-rvices,

.

Company Company Stars :a-Ui

Dubai.

"

,

.J, PO ,

[l IJ ,

:0 d\. . . 1,

Signature @

,

Signature 6 E'" J

u?; 't1 "

"

I .

/' .;} j;

I-- - , .

. r" ."

Date 01- D 2Q09: - Date 01 -

NDT-RPT-254-WPS-Stars Li ne Metallic Page 2 of 2

UKAS. Commercial & Legal t erms and conditions on the reverse of this sheet

Other Locat i ons : Abu Dhab< Arman Oman Qatar

Das könnte Ihnen auch gefallen

- GATE Solved Question Papers For Production Industrial Engineering PI by AglaSem Com PDFDokument56 SeitenGATE Solved Question Papers For Production Industrial Engineering PI by AglaSem Com PDFSudhagar KingNoch keine Bewertungen

- WPS - 024Dokument4 SeitenWPS - 024MAT-LIONNoch keine Bewertungen

- (AL Shabab) : Painting Procedure P-04Dokument12 Seiten(AL Shabab) : Painting Procedure P-04Omar Nabil80% (5)

- I-963 Welder Certificate Smaw-Gtaw-1Dokument1 SeiteI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- PQR-WPS-WPQR XXX Rev 0Dokument6 SeitenPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- ASME Action Check ListDokument3 SeitenASME Action Check Listarunrad100% (1)

- PQR With-PwhtDokument2 SeitenPQR With-PwhtKarthikNoch keine Bewertungen

- The Australian Welding Guide 2012Dokument220 SeitenThe Australian Welding Guide 2012notsofar100% (2)

- Weld Joint 1Dokument81 SeitenWeld Joint 1rajibali27100% (1)

- For Fillet Weld Joint Project:Production ManifoldDokument1 SeiteFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Dokument2 SeitenASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- WPS PQR ProcedureDokument31 SeitenWPS PQR Proceduresudeesh kumarNoch keine Bewertungen

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Dokument3 SeitenWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- Welder Qualification CertificateDokument2 SeitenWelder Qualification CertificateLuttpi100% (1)

- WPS PQR As Per IsDokument3 SeitenWPS PQR As Per Istarun kaushalNoch keine Bewertungen

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDokument2 SeitenWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabNoch keine Bewertungen

- Welder CertificateDokument6 SeitenWelder CertificateA. ΒρατσισταNoch keine Bewertungen

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Dokument1 SeiteWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNoch keine Bewertungen

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDokument2 SeitenBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNoch keine Bewertungen

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDokument1 SeiteWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNoch keine Bewertungen

- WPS Fcaw PDFDokument1 SeiteWPS Fcaw PDFErik Huang100% (3)

- Viewing and Interpretation of RadiographsDokument30 SeitenViewing and Interpretation of RadiographsNatrajiNoch keine Bewertungen

- Asme PQRDokument4 SeitenAsme PQRHong Dae Yoon100% (2)

- Smaw Wps FinalDokument3 SeitenSmaw Wps FinalsheikmoinNoch keine Bewertungen

- PQR Gmaw3gDokument4 SeitenPQR Gmaw3gdevendrasingh2021100% (3)

- Gta+sma PQRDokument3 SeitenGta+sma PQRRahul MoottolikandyNoch keine Bewertungen

- WPS 2014-002 006 - 6G PipeDokument3 SeitenWPS 2014-002 006 - 6G PipejeswinNoch keine Bewertungen

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Dokument8 SeitenQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNoch keine Bewertungen

- WPS PQR PDFDokument23 SeitenWPS PQR PDFtomj9104Noch keine Bewertungen

- P-WPS 135 - MAG (GR 316)Dokument9 SeitenP-WPS 135 - MAG (GR 316)Tarun PatelNoch keine Bewertungen

- WPQR6Dokument3 SeitenWPQR6Dimitris NikouNoch keine Bewertungen

- Wps & PQR and Weld Map and Test PlanDokument67 SeitenWps & PQR and Weld Map and Test PlanmarghoobNoch keine Bewertungen

- What's New in ISO 15614-12017Dokument13 SeitenWhat's New in ISO 15614-12017alevent100% (1)

- 03 WPS PQR For FCAWDokument3 Seiten03 WPS PQR For FCAWBrijesh Yadav100% (1)

- Madina Group WPS 025 GuideDokument4 SeitenMadina Group WPS 025 GuideMAT-LIONNoch keine Bewertungen

- Joints (Qw-402) DetailsDokument3 SeitenJoints (Qw-402) DetailsNaqqash SajidNoch keine Bewertungen

- 2.5 Technical Specifications For Hydro Mechanical WorksDokument62 Seiten2.5 Technical Specifications For Hydro Mechanical WorksAbhishek PandeyNoch keine Bewertungen

- AWS ELECTRODE CLASSIFICATION GUIDEDokument8 SeitenAWS ELECTRODE CLASSIFICATION GUIDEFuaz Sukarya Abu Fatih100% (1)

- Wps Mma PipeDokument2 SeitenWps Mma PipeDimitris NikouNoch keine Bewertungen

- PQRDokument2 SeitenPQRnaseema1100% (1)

- Norsok L-004-CR Ror OgDokument29 SeitenNorsok L-004-CR Ror OgWissam Jarmak100% (2)

- WPQR Welding Procedure Qualification RecordsDokument3 SeitenWPQR Welding Procedure Qualification Recordsramesh rajaNoch keine Bewertungen

- WPS PQR CompressedDokument5 SeitenWPS PQR CompressedBalaje MantravadiNoch keine Bewertungen

- Fcaw 16 THKDokument5 SeitenFcaw 16 THKparesh2387Noch keine Bewertungen

- Fcaw 16 THKDokument5 SeitenFcaw 16 THKparesh2387Noch keine Bewertungen

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDokument4 Seiten163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNoch keine Bewertungen

- STT Pipe Welding Reduces Spatter & SmokeDokument3 SeitenSTT Pipe Welding Reduces Spatter & SmokeahmedNoch keine Bewertungen

- PT. MITRA KARYA SARANA Aluminum Welding ProcedureDokument1 SeitePT. MITRA KARYA SARANA Aluminum Welding ProcedureAbu Zahid100% (1)

- CIGWELDDokument244 SeitenCIGWELDrodastrid5653100% (1)

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Dokument1 SeiteWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- Base Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4Dokument3 SeitenBase Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4MAT-LIONNoch keine Bewertungen

- 004 Gtaw P5aDokument16 Seiten004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- W-55 PLATE ID CARDDokument6 SeitenW-55 PLATE ID CARDKrishnan TnNoch keine Bewertungen

- WPSPQRDokument11 SeitenWPSPQR0502raviNoch keine Bewertungen

- Welding IiwDokument6 SeitenWelding IiwletsmakeithappenNoch keine Bewertungen

- Welder Operators Qualification TestDokument2 SeitenWelder Operators Qualification Testlokifarad100% (1)

- WPS 316 L PDFDokument4 SeitenWPS 316 L PDFIrinaNoch keine Bewertungen

- WPQDokument1 SeiteWPQChava TejaNoch keine Bewertungen

- 6GR RequirementsDokument1 Seite6GR Requirementswalitedison100% (1)

- GMAWDokument12 SeitenGMAWsushant47Noch keine Bewertungen

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Dokument4 SeitenProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNoch keine Bewertungen

- P. WpsDokument14 SeitenP. WpsIsmiArdyNoch keine Bewertungen

- Welding Procedure Specification For GTAW & GMAWDokument4 SeitenWelding Procedure Specification For GTAW & GMAWanh thoNoch keine Bewertungen

- PQR - 152Dokument3 SeitenPQR - 152MAT-LIONNoch keine Bewertungen

- WPQ Sample PrintoutDokument1 SeiteWPQ Sample PrintoutKannan VelNoch keine Bewertungen

- WPS for Welding SA-335 P11 to SA-234 WP11Dokument3 SeitenWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNoch keine Bewertungen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- Wps ExampleDokument2 SeitenWps ExampleAnonymous stV08Js44VNoch keine Bewertungen

- Maxi-Jolly Chain Length CalculationDokument3 SeitenMaxi-Jolly Chain Length Calculationnaseema1Noch keine Bewertungen

- Weld Fitting DimensionsDokument5 SeitenWeld Fitting DimensionsteguheafNoch keine Bewertungen

- Buttweld FittingsDokument3 SeitenButtweld FittingsAshok Kumar100% (1)

- Sproule WR 1200 Perlite TDSDokument2 SeitenSproule WR 1200 Perlite TDSnaseema1Noch keine Bewertungen

- Seamless Welding Fittings-DataDokument24 SeitenSeamless Welding Fittings-DataeASMENoch keine Bewertungen

- Itp For Storge TankDokument23 SeitenItp For Storge Tanknaseema1Noch keine Bewertungen

- InsulationDokument4 SeitenInsulationnaseema1Noch keine Bewertungen

- Piping System Installation Page 4 Thru 8Dokument5 SeitenPiping System Installation Page 4 Thru 8naseema1Noch keine Bewertungen

- Pittsburgh Corning Foamglass Cold Process Piping Installation GuidelineDokument7 SeitenPittsburgh Corning Foamglass Cold Process Piping Installation Guidelinenaseema1Noch keine Bewertungen

- Insulation InspectionsDokument1 SeiteInsulation Inspectionsnaseema1Noch keine Bewertungen

- Kaiflex Specification DomesticDokument5 SeitenKaiflex Specification Domesticnaseema1Noch keine Bewertungen

- Travel Speed Calculator: Calculate Welding Speed in mm/minDokument2 SeitenTravel Speed Calculator: Calculate Welding Speed in mm/minMohammad ElhedabyNoch keine Bewertungen

- Kaiflex MasterSpecificationDokument8 SeitenKaiflex MasterSpecificationnaseema1Noch keine Bewertungen

- Insulation InspectionsDokument1 SeiteInsulation Inspectionsnaseema1Noch keine Bewertungen

- Kooltherm PipeDokument8 SeitenKooltherm Pipenaseema1Noch keine Bewertungen

- ProcedureDokument11 SeitenProcedurePoonam AshwinNoch keine Bewertungen

- Pipe, Duct and Equipment InsulationDokument6 SeitenPipe, Duct and Equipment Insulationnaseema1Noch keine Bewertungen

- Pipe and Equipment Insulation 0910Dokument14 SeitenPipe and Equipment Insulation 0910naseema1Noch keine Bewertungen

- B - 8.8 - ZSS006 STD Spec For Piping Flushing Testing InspectionDokument9 SeitenB - 8.8 - ZSS006 STD Spec For Piping Flushing Testing Inspectionnaseema1Noch keine Bewertungen

- r1Dokument3 Seitenr1naseema1Noch keine Bewertungen

- U.I.P. System: Submittal DataDokument2 SeitenU.I.P. System: Submittal Datanaseema1Noch keine Bewertungen

- Kooltherm PipeDokument8 SeitenKooltherm Pipenaseema1Noch keine Bewertungen

- UAS Engineering & Ship Repair ServicesDokument1 SeiteUAS Engineering & Ship Repair Servicesnaseema1Noch keine Bewertungen

- Materials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding FittingsDokument1 SeiteMaterials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding Fittingsnaseema1Noch keine Bewertungen

- Post WeldDokument4 SeitenPost Weldnaseema1Noch keine Bewertungen

- Jhl1 5 RepairDokument2 SeitenJhl1 5 Repairnaseema1Noch keine Bewertungen

- SCIA Engineer - Advanced Training Aluminium 2010.1.0Dokument81 SeitenSCIA Engineer - Advanced Training Aluminium 2010.1.0Vlad MosNoch keine Bewertungen

- Fdot Design Standards: 18100 1 CCTV Pole PlacementDokument26 SeitenFdot Design Standards: 18100 1 CCTV Pole PlacementAlejandro MusepuNoch keine Bewertungen

- A Avesta-2507-P100 Ss en 5Dokument1 SeiteA Avesta-2507-P100 Ss en 5el_sharkawy2011Noch keine Bewertungen

- Interview Type Question Manufacturing PDFDokument4 SeitenInterview Type Question Manufacturing PDFSourav KayalNoch keine Bewertungen

- The Tara Handpump: Dhaka-BangladeshDokument178 SeitenThe Tara Handpump: Dhaka-BangladeshLovasoa Mbolamanana Joseph AndrianirianaNoch keine Bewertungen

- WHD250 Worldpoly Operation ManualDokument34 SeitenWHD250 Worldpoly Operation ManualalejandroNoch keine Bewertungen

- Safety Requirements For Welding Job at Confined SpacesDokument5 SeitenSafety Requirements For Welding Job at Confined SpacesHassane AmadouNoch keine Bewertungen

- How To Weld 316 Stainless SteelDokument3 SeitenHow To Weld 316 Stainless Steel10161016Noch keine Bewertungen

- Catálogo Rexnord IngenieríaDokument152 SeitenCatálogo Rexnord IngenieríaCésar VásquezNoch keine Bewertungen

- Updated Up To ACS 38 Dtd. 14.01.2020Dokument368 SeitenUpdated Up To ACS 38 Dtd. 14.01.2020Hermann LoweNoch keine Bewertungen

- Foroozan Offshore Complex Piping SpecificationDokument40 SeitenForoozan Offshore Complex Piping SpecificationshervinyNoch keine Bewertungen

- Specification For Pressure PartsDokument6 SeitenSpecification For Pressure PartsARUNNoch keine Bewertungen

- Arcelor Mittal HistarDokument32 SeitenArcelor Mittal HistarAnonymous uNhWGqNzNoch keine Bewertungen

- Iso 11666 2018 en PDFDokument8 SeitenIso 11666 2018 en PDFحسن عبدالهادي الصلويNoch keine Bewertungen

- Zacsil Potassium Silicate DataDokument5 SeitenZacsil Potassium Silicate DatadancercelNoch keine Bewertungen

- Air Handling UnitsDokument8 SeitenAir Handling UnitsmkmNoch keine Bewertungen

- Waterstop Catalog 0411Dokument12 SeitenWaterstop Catalog 0411hks1209Noch keine Bewertungen

- EurocodesDokument7 SeitenEurocodesSafet CemalovicNoch keine Bewertungen

- Burj Al Baher Curtain Wall SpecsDokument73 SeitenBurj Al Baher Curtain Wall SpecsmcbluedNoch keine Bewertungen

- Imo PSPCDokument14 SeitenImo PSPCFrancis VicencioNoch keine Bewertungen

- NG22 282 CST PSL 100011 - Revc0Dokument9 SeitenNG22 282 CST PSL 100011 - Revc0Theophilus OrupaboNoch keine Bewertungen

- Welding Inspection, AWS Bridging: Multi - Choice Question Paper (MSR-B-WI-2)Dokument7 SeitenWelding Inspection, AWS Bridging: Multi - Choice Question Paper (MSR-B-WI-2)Le Tuan100% (1)

- AS 4100/amdt 1/2012-02-29Dokument28 SeitenAS 4100/amdt 1/2012-02-29luiscr3806Noch keine Bewertungen

- DVS 2207-3Dokument12 SeitenDVS 2207-3gura9054Noch keine Bewertungen

- BN 1457Dokument2 SeitenBN 1457marijaaaaaaaaaaNoch keine Bewertungen

- Hard - Facing Welding - Electrodes PDFDokument3 SeitenHard - Facing Welding - Electrodes PDFreeet87Noch keine Bewertungen