Beruflich Dokumente

Kultur Dokumente

T-BEAM & Rectangular Beam (3sections) - Final

Hochgeladen von

nsureshbabuOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

T-BEAM & Rectangular Beam (3sections) - Final

Hochgeladen von

nsureshbabuCopyright:

Verfügbare Formate

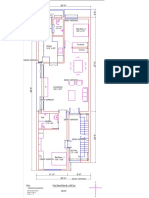

Design of Beams

Grade of concrete = M 25 = F1 - Modification Factor for Tension Reinforcement F2 - Modification Factor for Compression Reinforcement

Clear Cover (cc) =32 mm = 3.1 N/mm

2

Grade of Steel =Fe 415 pt & pc,max =

Moment Shear t

v t

c

Mu Vu Leff bw D bf Df d Pt Pc Pt Pc

N/ N/ dia Spacing

kN m kN mm mm mm mm mm mm mm mm mm kN m % % No dia No dia No dia No dia No dia No dia % % mm2 mm2 mm mm F1 F2 F3

200.00

Size of beam

Factors

1.383

450 750

Actual < Allowable, Hence Safe 2 300 c/c

1 B1 Simply 10000

Support 750.00 230.00

800.00

1.048 0.071 0.72 0.65 OK 8 0 12 0 16 2 16 0 16 2 12 1.127 0.000 6 25 32 40.0 710.0 782.62 Singly 3.306

16 3 16 0 25 4 20 0 12 0 16 1.315

0.992 6 25 2 12 0.071 OK 8 0.64 0.63 14.08 0.80 1.01

t

c,max =

Dia

of

bar

cc

pt,min

Type of

Section

Mu,lim

Mu/bd

2

N/mm

2

% of Steel

Provided

16

16 1200 100

450

16

pt,limit

450 100

% of Steel

Requried

Tension

Reinforcement Details

Compression

Reinforcement Details

S.

No

Beam Section

Design Forces

Type of

Beam

Type3

40.0 710.0 0.981 3.527 0 16 Singly

215.00 100 Support

Span

900.00

Type2

6 40.0 Doubly 3.967

0.000

1.346 0.160

32

32 710.0

1339.49

782.62 2 200 c/c 0.67 0.71 OK 8 0.189

Leff/d

Allowa

ble

Actual

2

Actual < Allowable, Hence Safe

200 c/c 22.33

Check for Deflection

Leg

Stirrups

Check for Shear

check

2 12

Type1 Type2

0 12 0 16

TITLE

DOC. NO.

Type3

1.194%

0.205%

4.000%

d'

Eff.

depth

Type1

PREPARED

CHECKED

DATE

DATE

PROJECT

REVISION DESIGN OF T & RECTANGULAR BEAMS

1.0 Example 1 :

Design the T-Beam for the following parameters :

b

f

= D

f

=

b

w

= d =

f

ck

=

N/mm

2

f

y

=

N/mm

2

M

u =

D

f

/d

= 100/300 =

3x

umax

/7d < < x

umax

/d

M

ulim

= 0.3616 f

ck

b

w

x

umax

(d - 0.416x

umax

) + 0.4467 f

ck

(b

f

- b

w

) y

f

(d - y

f

/2 )

x

umax = 0.5313 d = 0.5313 x 300 = mm

y

f

= 0.15 x

umax

+ 0.65 D

f

= 88.9085 mm

M

ulim = kNm

M

u

< M

ulim Hence designed as singly reinforced section.

Location of N.A

When x

u

= D

f

, Moment of Resistance M

u1

= 0.3616 f

ck

b

f

D

f

(d -0.416 D

f

)

M

u1 = kNm

M

u

< M

u1

, N.A lies within the flange .( x

u

< D

f

)

Hence designed as a rectangular beam of width b =b

f

Method - 1 :

Area of tension reinforcement ( A

st

)

A

st

= =

mm

2

Method - 2 :

Depth of N.A (x

u

) M

u

= 0.3616 f

ck

b

f

x

u

(d - 0.416x

u

)

x

u

= = 87.33 mm < D

f

A

st

= 0.3616 x f

ck

x b

f

x x

u

x 1.15 =

mm

2

2.0

Example 2 :

Design the T-Beam for the following parameters

0.2277

3489.45

CL. NO. T - BEAM DESIGN CALCULATIONS

250

kNm

200

mm 100 mm

300 mm

DATE CHECKED

REFERENCES

Yugasoft

PROJECT

TITLE REVISION

DESIGNED

MP

DOCUMENT. NO.

1200

20

200

mm

DATE

0.33

Df/d

f

y

0.5313

3488.26

256.8583

224.2498

159.39

(

(

2

6 . 4

1 1 202 . 1

d b f

M

d

f ck

u

d b

d b f

M 4.6

1 1

f

f 0.5

f

2

f ck

u

y

ck

(

(

CL. NO. T - BEAM DESIGN CALCULATIONS

DATE CHECKED

REFERENCES

Yugasoft

PROJECT

TITLE REVISION

DESIGNED

MP

DOCUMENT. NO. DATE

b

f

= mm D

f

=

b

w

= mm d = mm

f

ck

=

N/mm

2

f

y

=

N/mm

2

M

u = kNm d' = mm

D

f

/d = 100/200 = 0.5 > x

umax

/d

M

ulim

= 0.3616 f

ck

b

f

x

umax

(d - 0.416x

umax

) x

umax

= 0.456 d

= kNm =

M

u

> M

ulim Hence designed as doubly reinforced section.

Depth & location of N.A :

x

u

= x

umax

= 91.2 mm < D

f

N.A lies within the flange.

Area of tension reinforcement ( A

st

)

= +

f

y

(d-d')

= mm

2

Area of compression reinforcement ( A

sc

)

= c

sc

= 0.0035 ( 1 - d'/x

umax

)

= 0.0035 ( 1 - 30/91.2 )

=

=

mm

2

f

sc

=

N/mm

2

f

cc

=

N/mm

2

3.0

Example 3 :

Design the T-Beam for the following parameters

b

f

= D

f

=

b

w

= d =

f

ck

=

N/mm

2

f

y

=

N/mm

2

M

u =

1200 100

310 kNm

500 20

200 200

30 135

1200 mm 100

(M

u

- M

ulim

) x 1.15

(0.456)

91.2mm

M

u

- M

ulim

(f

sc

-f

cc

)(d-d')

25 415

A

st

1911.48

0.3616 x f

ck

x b

f

x x

umax

x 1.15

f

y

102.56

200 mm

A

sc

395.13

8.92

0.00235

mm

300 mm

mm

128.266

CL. NO. T - BEAM DESIGN CALCULATIONS

DATE CHECKED

REFERENCES

Yugasoft

PROJECT

TITLE REVISION

DESIGNED

MP

DOCUMENT. NO. DATE

D

f

/d

= 100/300 =

3x

umax

/7d < Df/d < x

umax

/d

M

ulim

= 0.3616 f

ck

b

w

x

umax

(d - 0.416x

umax

) + 0.4467 f

ck

(b

f

- b

w

) y

f

(d - y

f

/2 )

x

umax = 0.4791 d = 0.4719 x 300 = mm

y

f

= 0.15 x

umax

+ 0.65 D

f

= mm

M

ulim = kNm

M

u

< M

ulim Hence designed as singly reinforced section.

Location of N.A

When x

u

= D

f

, Moment of Resistance M

u1

= 0.3616 f

ck

b

f

D

f

(d -0.416 D

f

)

M

u1 = kNm

M

u

> M

u1

, N.A lies outside the flange . x

u

> D

f

When x

u

= 7D

f

/ 3 ,

Moment of Resistance M

u2

= 0.3616 fck bf (7Df/3) d-0.416 (7Df/3)

M

u2 = kNm > 310 kNm

Mu < Mu2 Non Uniform stress block in flange. x

u

< 7D

f

/3

( Rectangular cum parabolic stress block )

Depth of N.A ( X

u

)

M

u

= 0.3616 x f

ck

x b

w

x x

u

x (d-0.416x

u

)

+ 0.4467 x f

ck

x (b

f

- b

w

) x y

f

x (d - y

f

/ 2)

a = 0.416 + 0.0225 k k = (21/34) * ((b

f

/b

w

) -1) = 3.088

b = - (1+ 0.3 k - 0.195 (D

f

/d) )

c = M_k + 0.4225 k (D

f

/d)

2

- 1.3 k (D

f

/d)

M_k = =

x

u

/d = =

x

u = 142.8956 mm < 143.73 mm

(x

umax

)

y

f

= 0.15 x

u

+ 0.65 D

f

= mm < D

f

Hence O.K

Area of tension reinforcement ( A

st

)

= ( 0.3616 f

ck

b

w

x

u

+ 0.4467 f

ck

(b

f

- b

w

)

y

f

) 1.15

= mm

2

4.0

Example 4 :

Design the T-Beam for the following parameters

b

f

= mm D

f

=

b

w

= mm d = mm

f

ck

=

N/mm

2

f

y

=

N/mm

2

M

u = kNm d' = mm

D

f

/d

= 100/300 =

0.33

(0.4791)

310.581

86.5595

0.3616 x f

ck

x b

w

x d

2

1.905 Mu

A

st

86.434

(0.2053)

1200 100

50

200 300

20 250

258

0.33

mm

143.73

364.798

280.3123

0.476319

f

y

3390.729

a

ac b b

2

4

2

CL. NO. T - BEAM DESIGN CALCULATIONS

DATE CHECKED

REFERENCES

Yugasoft

PROJECT

TITLE REVISION

DESIGNED

MP

DOCUMENT. NO. DATE

3x

umax

/7d < Df/d < x

umax

/d

Limiting Moment of Resistance : ( M

ulim

)

M

ulim

= 0.3616 f

ck

b

w

x

umax

(d - 0.416x

umax

) + 0.4467 f

ck

(b

f

- b

w

) y

f

(d - y

f

/2)

x

umax = 0.5313 d = 0.5313 x 200 = mm

y

f

= 0.15 x

umax

+ 0.65 D

f

= mm

= kNm

M

u

> M

ulim

Hence designed as doubly reinforced section.

Depth of N.A location

x

u

= x

umax

= 159.39 mm > D

f

N.A lies outside the flange. ( x

u,max

< 7D

f

/3 )

Area of tension reinforcement ( A

st

)

= ( 0.3616 f

ck

b

w

x

u,max

+ 0.4467 f

ck

(b

f

- b

w

)

y

f

) 1.15

= mm

2

Area of compression reinforcement ( A

sc

)

= c

sc

= 0.0035 ( 1 - d' /x

umax

)

= 0.0035 ( 1 - 50/159.39 )

=

=

mm

2

f

sc

=

N/mm

2

f

cc

=

N/mm

2

5.0

Example 5 :

Design the T-Beam for the following parameters

b

f

= D

f

=

b

w

= d =

f

ck

=

N/mm

2

f

y

=

N/mm

2

M

u =

D

f

/d

= 90/450 = <

3x

umax

/ 7d

Limiting Moment of Resistance : ( M

ulim

)

A

st

4735.32

A

sc

M

u

- M

ulim

1200 mm

8.92

0.2277 0.5313

253.858

f

y

(f

sc

-f

cc

)(d-d')

0.0024

21.906 217.39

90 mm

200 mm 450 mm

(0.2053 )

30 415

654.5 kNm

0.2

88.9085

159.39

CL. NO. T - BEAM DESIGN CALCULATIONS

DATE CHECKED

REFERENCES

Yugasoft

PROJECT

TITLE REVISION

DESIGNED

MP

DOCUMENT. NO. DATE

M

ulim

= 0.3616 f

ck

b

w

x

umax

(d - 0.416x

umax

) + 0.4467 f

ck

(b

f

- b

w

) D

f

(d - D

f

/2)

x

umax = 0.4791 d = 0.4719 x 450 = mm

M

ulim = kNm

M

u

< M

ulim Hence designed as singly reinforced section.

Location of N.A

When x

u

= D

f

, Moment of Resistance M

u1

= 0.3616 f

ck

b

f

D

f

(d -0.416 D

f

)

M

u1 = kNm

M

u

> M

u1

, N.A lies outside the flange . x

u

> D

f

When x

u

= 7D

f

/3 ,

Moment of Resistance M

u2

= 0.3616 f

ck

b

w

(7D

f

/3) x

(d - 0.416 (7D

f

/3)

)

+ 0.4467 x f

ck

x (b

f

- b

w

) x D

f

x (d - D

f

/2)

= kNm > 654.5 kNm ( M

u

)

Mu > Mu2 Uniform stress block in the flange. x

u

> 7D

f

/3

Area of tension reinforcement ( A

st

)

Method - 1:

A

st

=

= mm

2

Method - 2:

M

u,flange

= 0.4467 x f

ck

x (b

f

- b

w

) x D

f

x (d - D

f

/ 2)

= kNm

M

u,web

= M

u

- M

uflange

= kNm

A

st

=

= mm

2

Method - 3:

653.69

483.35

4612.731

657

488.467

166.034

215.6

4612.7308

) 2 / (

15 . 1

6 . 4

1 1

5 . 0

2

f y

uflange

w

w

uweb

ck y

ck

D d f

M

d b

d b

M

f f

f

+

(

(

y

f w f ck

w

f f

w

f

w

u

ck y

ck

f

D b b f

d b

d

D

d

D

b

b

f

d b

M

f f

f

ck

15 . 1 ) ( 4467 . 0

2 1

2

4467 . 0 6 . 4

1 1

5 . 0

2

+

(

(

(

(

|

|

.

|

\

|

|

|

.

|

\

|

|

|

.

|

\

|

CL. NO. T - BEAM DESIGN CALCULATIONS

DATE CHECKED

REFERENCES

Yugasoft

PROJECT

TITLE REVISION

DESIGNED

MP

DOCUMENT. NO. DATE

Depth of N.A ( X

u

)

M

u

= 0.3616 f

ck

b

w

x

u

(d - 0.416x

u

)

+ 0.4467 f

ck

(b

f

- b

w

) D

f

(d - D

f

/ 2)

x

u

=

x

u

= mm > 7D

f

/3 ( 210mm )

Uniform stress block in the flange & xu > 7Df/3

= + 0.4467 f

ck

(b

f

- b

w)

D

f

) 1.15

= mm

2

6.0

Example 6 :

Design the T-Beam for the following parameters

b

f

= mm D

f

= mm

b

w

= mm d = mm

f

ck

=

N/mm

2

f

y

=

N/mm

2

M

u = kNm d' = mm

D

f

/d

= 90/450 = <

3x

umax

/7d

Limiting Moment of Resistance : ( M

ulim

)

M

ulim

= 0.3616 f

ck

b

w

x

umax

(d - 0.416x

umax

)

+ 0.4467 f

ck

(b

f

- b

w

) D

f

(d - D

f

/2 )

x

umax = 0.479 d = 0.479 x 200 = mm

M

ulim = kNm

M

u

> M

ulim Hence designed as doubly reinforced section.

(0.2053)

215.6

700 50

0.2

90

200 450

30 415

211.403

A

st

4613.16

657.01

f

y

( 0.3616 f

ck

b

w

x

u

1200

(

(

|

|

.

|

\

|

|

|

.

|

\

|

|

|

.

|

\

|

d

D

d

D

b

b

d b f

M

d

f f

w

f

w ck

u

2 1

34

21

3616 . 0

664 . 1 1 1 202 . 1

2

CL. NO. T - BEAM DESIGN CALCULATIONS

DATE CHECKED

REFERENCES

Yugasoft

PROJECT

TITLE REVISION

DESIGNED

MP

DOCUMENT. NO. DATE

Depth of N.A location

x

u

= x

umax

= 215.6 mm > D

f

N.A lies outside the flange. ( x

u,max

> 7D

f

/3 )

Area of tension reinforcement ( A

st

)

= ( 0.3616f

ck

b

w

x

umax

+ 0.4467 f

ck

(b

f

- b

w

)

D

f

) 1.15

+

=

mm

2

Area of compression reinforcement ( A

sc

)

= c

sc

= 0.0035 ( 1 - d'/x

umax

)

= 0.0035 ( 1 - 50/215.6 )

=

=

mm

2

f

sc

=

N/mm

2

f

cc

=

N/mm

2

A

sc

4936.236 A

st

A

st

f

y

0.002688

319.32 349.95

13.38

A

sc

M

u

-M

ulim

(f

sc

-f

cc

)(d-d')

(M

u

-M

ulim

) X 1.15

fy(d-d')

DATE CHECKED

REFERENCES

DESIGNED

06-Oct-09

DATE

MP

DATE CHECKED

REFERENCES

DESIGNED

06-Oct-09

DATE

MP

DATE CHECKED

REFERENCES

DESIGNED

06-Oct-09

DATE

MP

DATE CHECKED

REFERENCES

DESIGNED

06-Oct-09

DATE

MP

DATE CHECKED

REFERENCES

DESIGNED

06-Oct-09

DATE

MP

DATE CHECKED

REFERENCES

DESIGNED

06-Oct-09

DATE

MP

DATE CHECKED

REFERENCES

DESIGNED

06-Oct-09

DATE

MP

General

The slab portion deforming with the rectangular portion of the beam increases the moment

resisting capacity of the beam where it is in compression.where it is in tension along with

the beam,such as at supports in continuous beams,it cracks and only tensile reinforcement

provided are effective in tension and compressive force is taken by web(rectangular portion)

reducing the beam to a rectangular one.

Structurally,flanged beams may be of two types- T beams & L beams.If slab is

extending on both sides of a beam it is called a T-beam;but if the slab is only on one side

it is an L-beam.

Which portion of the slab will work with the beam depends on span of beam,

width of slab on adjacent sides,breadth of beam,thickness of slab and slab reinforcement at the

junction of beam and slab.

For ready reference the code defines the effective width of flange (slab) as follows:

a)

i) For T-beam, b

f

= l

0

+ b

w

+ 6D

f

6

ii) For L-beam, b

f

= l

0

+ b

w

+ 3D

f

12

b

f

= Effective width of flange for T or L-beam

l

0

= distance between sections of zero moments in a beam

b

w

= breadth of web,and

D

f

= Thickness of slab

b) If the beam is an isolated one,i.e,only one beam has been provided in the floor/roof

system,the effectve width of flange shall be as follows:

i) For T-beam, b

f

= + b

w

ii) For L-beam, b

f

= + b

w

Note: l

o

= 0.7 l

eff

In case,if the main reinforcement of a slab is parallel to the beam,the transverse reinforcement

of slab at the junction shall not be less than 60% of the main reinforcement at midspan of the

slab extending into it upto atleast quarter span of beam,to have monolithic behaviour.

Location of Neutral Axis

For a Singly Reinforced Section: (Mu<Mulim)

Case 1: x

u

D

f

(Neutral Axis lies within the Flange)

When x

u

= D

f ,

the moment of resistance is given by

M

u1

= 0.3616 x f

ck

x b

f

x D

f

(d - 0.416 D

f

)

M

u

M

u1

Case 2: Assume x

u

=7D

f

/3 : x

u

<7D

f

/3

The Moment of Resistance is given by

M

u2

= 0.3616 x f

ck

x b

w

x (7D

f

/3) x

(d - 0.416 (7D

f

/3)

)

+ 0.446 x f

ck

x (b

f

-b

w)

x D

f

) x (d - D

f

/2)

Case 3: Assume x

u

=7D

f

/3 : x

u

<7D

f

/3

< M

u2

Non Uniform stress block in the Flange.(N.A lies outside the Flange) (3/7 ) x

u

< Df

M

u2

Uniform rectangular stress block in the Flange.(N.A lies outside the Flange) (3/7 ) x

u

Df

0.5 l

0

(l

0

/ b) + 4

l

0

(l

0

/ b) + 4

DOCUMENT. NO. DATE DESIGNED DATE

MP

Yugasoft

PROJECT

Design of T- Beam Technical Notes TITLE REVISION

CL. NO. DESIGN CALCULATIONS

DATE DATE CHECKED

REFERENCES

M

u

M

u

Page 16 of 23

DOCUMENT. NO. DATE DESIGNED DATE

MP

Yugasoft

PROJECT

Design of T- Beam Technical Notes TITLE REVISION

CL. NO. DESIGN CALCULATIONS

DATE DATE CHECKED

REFERENCES

415

x

umax

(TABLE B of SP16)

Case 1: When the Neutral Axis (N.A) lies within the flange (x

u

<=D

f

)

In this case Flanged beam can be considered as a rectangular beam of width b =bf and

experssion for x

u

,M

UR

and A

st

for singly reinforced beam can be used by replacing b by b

f

m = 0.416 x

umax

Z = d - 0.416 x

umax

C

u

= 0.3616 x f

ck

x b

f

x x

umax

T

u

= 0.87 x f

y

x A

st,lim

M

ulim

= C

u

x z or T

u

x z

M

ulim

= 0.361 x f

ck

x b

f

x x

umax

(d - 0.416 x

umax

)

= 0.3616

x (x

umax

/d)

x

(1 - 0.416 (x

umax

/d)) x (b

f

/b

w

)

f

ck

x b

w

x d

2

= 0.87 x f

y

x A

stlim

x

(d - 0.416 x

umax

)

=

At Limiting condition Equating T

u

= C

u

0.87 x f

y

x A

stlim

= 0.3616 x f

ck

x b

f

x x

umax

= 0.3616 x f

ck

x b

f

x x

umax

0.87 x f

y

= 0.3616 x f

ck

x b

f

x x

u

(d - 0.416 x

u

)

=

=

=

0.87 x f

y

= 0.87 x f

y

x A

st

x

(d - 0.416 x

u )

M

UR

0.479 0.456

d d

x

umax

500

M

ulim

A

st,lim

M

ulim

0.87 x f

y

x

(d - 0.416 x

umax

)

Df

M

ulim

X

u

d

A

st

A

st,lim

d

f

y

250

0.531

A

st

M

UR

0.361 x f

ck

x b

f

x x

u

(

(

2

f

u

d b fck

M 4.6

1 1 1.202

d b

d b f

M 4.6

1 1

f

f 0.5

f

2

f ck

u

y

ck

(

(

Page 17 of 23

DOCUMENT. NO. DATE DESIGNED DATE

MP

Yugasoft

PROJECT

Design of T- Beam Technical Notes TITLE REVISION

CL. NO. DESIGN CALCULATIONS

DATE DATE CHECKED

REFERENCES

=

= Pt,lim x bf x d +

100

=

415

3 x x

umax

Case 2: When the Neutral Axis (N.A) lies outside the flange

& 3/7 xu lies within the flange

Rectangular cum Parabolic portion of stress block is acting on the flange.Non Uniform

stress block is acting on the flange.

3 x x

umax

=

+

C

uw

= 0.361 x f

ck

x b

w

x x

umax

y

fmax

= 0.15 x

umax

+0.65 D

f

C

uf

= 0.446 x f

ck

x (bf - b

w)

x y

f

C

u

= 0.361 x f

ck

x b

w

x x

umax

+ 0.446 x f

ck

x (b

f

- b

w)

x y

f

T

u

= 0.87 x f

y

x A

st,w

+ 0.87 x f

y

x A

st,f

M

ulim

= M

uw

+ M

uw

M

ulim

= C

uw

x z

w

+ C

uf

x

z

f

= 0.361 x f

ck

x b

w

x x

umax

x (d-0.446x

umax

)

+ 0.446 x fck x (bf - bw) x yf

.

A

st

Df

d 7d

f

y

M

u

0.87 x f

y

x

(d - 0.416 x

u

)

A

sc

M

u -

M

ulim

(fsc - f

cc)

x

(d - d')

For Doubly Reinforced Section

A

st

M

u -

M

ulim

0.87 x f

y

x

(d - d')

250 500

0.2276 0.2053 0.1954

7

Page 18 of 23

DOCUMENT. NO. DATE DESIGNED DATE

MP

Yugasoft

PROJECT

Design of T- Beam Technical Notes TITLE REVISION

CL. NO. DESIGN CALCULATIONS

DATE DATE CHECKED

REFERENCES

M

ulim

= 0.361 x f

ck

x b

w

x x

u

x (d-0.446x

umax)

+ 0.446 x fck x (bf - bw) x yf

= 0.361 x x

umax

/d x (1- 0.416 x x

umax

/d)

f

ck

x b

w

x d

2

+ 0.223 x (bf/bw-1) x (yf/d) x (2-(yf/d))

M

ur

= C

uw

x z

w

+ C

uf

x

z

f

= 0.361 x f

ck

x b

w

x x

u

x (d-0.446x

umax

)

+ 0.446 x fck x (bf - bw) x yf x (d-yf/2)

Equating T

u

= C

u

0.87 x f

y

x A

st

= 0.361 x f

ck

x b

w

x x

u

+ 0.446 x f

ck

x (b

f

- b

w)

x y

f

= 0.361 x f

ck

x b

w

x x

u

+

0.446 fck (bf - bw)yf

0.87 x f

y

0.361 x f

ck

x b

w

x x

umax

+ 0.446 x f

ck

x (b

f

- b

w)

x y

f

= 0.87 x f

y

0.87 x f

y

+

= 0.87 x f

y

0.87 x f

y

x (d - y

f

/2)

a = 0.416 + 0.0225 k

b = 1+ 0.3 k- 0.195 (D

f

/d)

c = M_k + 0.4225 k (D

f

/d)

2

- 1.3 k (D

f

/d)

x

u

/d =

k = (21/34) * ((b

f

/b

w

) -1)

M_k =

Case3: When the Neutrl Axis (N.A) lies outside the flange

& 3/7 x

u

lies outside the flange

Uniform stress block in flange.

=

M

ulim

A

st,lim

A

st,lim

Mu_flange

Mu

A

st

Mu_web

0.3616 x f

ck

x b

w

x d

2

a

ac b b

2

4

2

Page 19 of 23

DOCUMENT. NO. DATE DESIGNED DATE

MP

Yugasoft

PROJECT

Design of T- Beam Technical Notes TITLE REVISION

CL. NO. DESIGN CALCULATIONS

DATE DATE CHECKED

REFERENCES

+

3 x x

umax

C

uw

= 0.361 x f

ck

x b

w

x x

umax

C

uf

= 0.446 x f

ck

x (b

f

- b

w)

x D

f

C

u

= 0.361 x f

ck

x b

w

x x

umax

+ 0.446 x f

ck

x (b

f

- b

w)

x D

f

T

u

= 0.87 x f

y

x A

st,w

+ 0.87 x f

y

x A

st,f

Equating C

u

= T

u

ie C

uw

+ C

uf

= T

uw

+ T

uf

xu = 0.87 x fy x Ast- 0.446 x fck(b

f

-b

w

) x Df

0.361 f

ck

b

w

or

xu =

M

ulim

= M

uw

+ M

uw

M

ulim

= C

uw

x z

w

+ C

uf

x

z

f

= 0.361 x f

ck

x b

w

x x

umax

x (d-0.446x

umax

)

+ 0.446 x fck x (bf - bw) x Df

.

M

ulim

= 0.361 x f

ck

x b

w

x x

u

x (d-0.446x

umax)

+ 0.446 x f

ck

x (b

f

- b

w

) x D

f

= 0.361 x x

umax

/d x (1- 0.416 x x

umax

/d) +

f

ck

x b

w

x d

2

0.223 x (b

f

/b

w

-1) x (D

f

/d) x (2-(D

f

/d))

M

ur

= C

uw

x z

w

+ C

uf

x

z

f

= 0.361 x f

ck

x b

w

x x

u

x (d-0.446x

umax

)

+ 0.446 x f

ck

x (b

f

- b

w

) x D

f

x (d-D

f

/2)

A

stf

=

0.87 x f

y

A

stw

=

A

st

=

Equating T

u

= C

u

0.87 x f

y

x A

st

= 0.361 x f

ck

x b

w

x x

u

+ 0.446 x f

ck

x (b

f

- b

w)

x y

f

Df

d d

M

ulim

0.446 f

ck

(b

f

-b

w

)D

f

0.87 x f

y

x A

stw

0.361 x f

ck

x b

w

y

f w f ck

w

f f

w

f

w

u

ck y

ck

xf

D b b f

d b

d

D

d

D

b

b

f

d b

M

f f

f

ck

87 . 0

) ( 446 . 0

2 1 223 . 0

6 . 4

1 1

5 . 0

2

+

(

(

(

(

(

(

|

|

.

|

\

|

|

|

.

|

\

|

|

|

.

|

\

|

d b

d b f

) M ( 4.6

1 1

f

f 0.5

w 2

ck

u

y

ck

(

(

w

uflange

M

Page 20 of 23

DOCUMENT. NO. DATE DESIGNED DATE

MP

Yugasoft

PROJECT

Design of T- Beam Technical Notes TITLE REVISION

CL. NO. DESIGN CALCULATIONS

DATE DATE CHECKED

REFERENCES

0.361 x f

ck

x b

w

x x

umax

+ 0.446 x f

ck

x (bf - b

w)

x D

f

= 0.87 x f

y

0.87 x f

y

+

= 0.87 x f

y

0.87 x f

y

x (d - D

f

/2)

Determination of f

sc

corresponding to strain (

sc

)

<0.00109 < 0.00144 < 0.00174

0.00109 Table A

Note : SP16:1980

0.87 x 250 =

0.8 x 0.87 x 415 = 0.00144

0.8 x 0.87 x 500 = 0.00174

Note:

Linear Interpolation shall be done for intermediate values.

Modulus of Elasticity of steel E

s

(for all grades) = 2 x 10^5 N/mm

2

Determination of f

cc

corresponding to strain

sc

(figure 21,IS 456:2000)

0

sc 0

f

cc

= 0.446f

ck

sc

446f

ck

(

sc

- 250

sc

2

)

0

sc

Note 0.446f

ck

f

cc

= 0.446f

ck

- g

cc

=

=

g

cc

x

f

cc

y

sc

f

sc

(N/mm

2

)

A

st,lim

A

st,lim

Mu_web Mu_flange

288.7 0.00174 347.8

Fe 250 Fe 415 Fe 500

sc

f

sc

(N/mm

2

)

sc

f

sc

(N/mm

2

)

391.3

0.00163 306.7 0.00195 369.6

x Es x Es x Es

217.39 0.00144

0.00109 0.00241 342.8 0.00277

0.00192 324.8 0.00226

0.00380 360.9 0.00417 434.8

413

2 x 10 ^5 0.00276 351.8 0.00312 423.9

0.0035

0.002 -

sc

2 x 10 ^5

2 x 10 ^5

0.002 0.0035

or

0

.

4

4

6

f

c

k

sc

0.002

0.002

0.002

(

(

|

.

|

\

|

|

.

|

\

|

2

002 . 0 002 . 0

2 446 . 0

sc sc

ck

f

c c

| |

2

250 446

sc sc ck

f c c

(

(

|

.

|

\

|

2

002 . 0

1 1 446 . 0

sc

ck

f

c

Page 21 of 23

DOCUMENT. NO. DATE DESIGNED DATE

MP

Yugasoft

PROJECT

Design of T- Beam Technical Notes TITLE REVISION

CL. NO. DESIGN CALCULATIONS

DATE DATE CHECKED

REFERENCES

Eqn of Parabola

@ x = 0.002 - c

sc

, y = g

cc

y =

x

2

or

Note

If the amount of tension reinforcement required to resist the Design moment Mu is less

than the minimum reinforcement,then the minimum reinforcement (A

st,min

) is provided for

creep,shrinkage,thermal and other environmental requirements irrespective of the

strength requirement.

More over for singly reinforced sections P

t,provided

< p

t,limit

(under Reinforced Section)

For doubly Reinforced section,the area of tension and compression reinforcement Cl 26.5.1.1 b)

provided should be less than the maximum reinforcement to avoid practical difficulty 26.5.1.2 Note

in placing and compacting concrete. IS 456:2000

3 Transverse or Shear Reinforcement

Nominal Shear Stress t

v

= Cl 40.1

Under no circumstances even with shear reinforcement the nominal shear stress

in beams tv shall exceed maximum shear stress (t

c,max) given in Table 20 of

Cl 40.2.3

IS 456:2000 for different grades of concrete. IS 456:2000

Grade of concrete M15 Table 20

IS 456:2000

a) If t

v

> t

c,max

The section is to be redesigned by changing the value of b and d

b)If t

v

< t

c

given in Table 19 of IS 456:2000

Minimum shear reinforcement shall be provided in accordance with 26.5.1.6

Design shear strength of concrete

1

Table 19 Design Shear Strength of Concrete tc

N/mm

2

M15

0.28

0.35

0.46

0.54

0.6

0.64

0.68

0.71

0.71

0.71

0.71

0.71

0.71

M25 M30 M35

0.446f

ck

(0.002)

2

V

u

/ bd (N/mm

2

)

M40

tc,max

2.5 2.8 3.1 3.5 3.7 4

N/mm

2

M20

Grade of concrete

pt M20 M25 M30 M35 M40

0.25 0.36 0.36 0.37

0.15 0.28 0.29 0.29 0.29 0.3

0.37 0.38

0.5 0.51

0.59 0.6

0.50 0.48

0.75 0.56 0.57 0.59

0.49 0.5

1.25 0.67 0.7 0.71

1.00 0.62 0.64 0.66 0.67 0.68

0.73 0.74

0.78 0.79 1.50 0.72

1.75 0.75 0.78 0.8

0.74 0.76

2.25 0.81 0.85 0.88

0.82 0.84

0.86 0.88

0.9 0.92

0.93 0.95

0.96 0.98

2.50 0.82

2.75 0.82 0.9 0.94

0.88 0.91

0.99 1.01 3.00 0.82 0.92 0.96

2.00 0.79 0.82 0.84

2

2

) 002 . 0 (

) 002 . 0 (

446 . 0

sc

ck

cc

f

g c =

2

002 . 0

1 446 . 0 |

.

|

\

|

=

sc

ck cc

f g

c

| | t 6 / ) 1 5 1 ( 8 . 0 85 . 0 + =

ck c

f

t

ck

p

f

89 . 6

8 . 0

= |

Page 22 of 23

DOCUMENT. NO. DATE DESIGNED DATE

MP

Yugasoft

PROJECT

Design of T- Beam Technical Notes TITLE REVISION

CL. NO. DESIGN CALCULATIONS

DATE DATE CHECKED

REFERENCES

c) t

v

> t

c

given in Table 19 of IS 456:2000, Shear reinforcement

shall be provided to carry a stress equal to tv - tc

Spacing of Shear Reinforcement (S

v

)

Cl 26.5.1.6

When t

v

< t

c

S

v = IS 456:2000

t

v

> t

c

S

v = Cl 40.4 a

IS 456:2000

A

sv

- Total Cross Sectional area of stirrup legs(mm

2

)

f

y

- Characteristic strength of the stirrups

415 N/mm

2

Maximum Spacing of Shear Reinforcement (S

v

,

max

)

Cl 26.5.1.5 of IS 456:2000 stipulates that the maximum spacing of Shear reinforcement

measured along the axis of the member shall not be more than 0.75d or 300mm

whichever is less,where d is the effective depth of the section.

Provide Shear Reinforcement at a spacing in such a way that it should not exceed

the minimum of S

v

and S

v,max

4 Deflection Check

The Vertical deflection limits may generally be assumed to be satisfied ,provided Cl 23.2.1

that the span to depth ratio is not greater than the value obtained as below IS 456:2000

Allowable L/d = Basic Value x Span Factor x MF

t

x MF

c

a) Basic Values of L/d

Cantilever Simply Supported Continuous Cl 23.2.1 a

IS 456:2000

b) Span Factor = 1 Cl 23.2.1 b

IS 456:2000

c) Modification factor for Tension Reinforcement (MF

t

)

Cl 23.2.2c

MF

t

= 2 & Fig 4

IS 456:2000

Service stress in steel f

s

= 0.58f

y

Ast-Provided

d) Modification factor for Compression Reinforcement (MF

c

)

MF

c

= 1 + p

c

1.5 Cl 23.2.1 d

3 + p

c

& Fig 5

p

c

- % of Compression Reinforcement IS 456:2000

Note

For Spans (Cantilever ) above 10m the deflection calculation should be made.

e) Reduction factors for ratios of span to effective depth for flanged beams (F3) 0.8

F

3

= 0.8 + 2/7 (b

w

/ b

f

- 0.3)

The final span/depth ratio allowed is (Basic ratio) x (F1) x (F2) x (F3)

7 20 26

Ast-Required

10

Span (m)

1

0.225 + 0.00322 f

s

+ 0.625 log

10

(p

t

)

b

A f

sv y

4 . 0

87 . 0

b

A f

c v

sv y

) (

87 . 0

t t

Page 23 of 23

Das könnte Ihnen auch gefallen

- Curved+Beam+by+B C +punmiaDokument34 SeitenCurved+Beam+by+B C +punmiaHasanuzzaman PalashNoch keine Bewertungen

- Staircase DesignDokument45 SeitenStaircase DesignHenRy Ngu 旭67% (3)

- Sloped FootingDokument19 SeitenSloped FootingBala ChandarNoch keine Bewertungen

- 7 Slab Design 1503Dokument32 Seiten7 Slab Design 1503Er Mohd NoshadNoch keine Bewertungen

- Beam Design With RCCDokument24 SeitenBeam Design With RCCOsarieme Osakue100% (1)

- Wingwall Soil LoadsDokument4 SeitenWingwall Soil LoadsSharyn PolleyNoch keine Bewertungen

- Column DesignDokument6 SeitenColumn DesignKenneth CajefeNoch keine Bewertungen

- Slab DesignDokument6 SeitenSlab DesignJonasIrvinGallegoNoch keine Bewertungen

- Staircase Isolated Tread TypeDokument9 SeitenStaircase Isolated Tread TypeNishan GajurelNoch keine Bewertungen

- Footing ExcelDokument1 SeiteFooting ExcelchanakyaNoch keine Bewertungen

- Slab DesignDokument33 SeitenSlab Designchannajayamangala100% (2)

- Reinforcement: V, F: Project: Staircase Design - STC 1Dokument4 SeitenReinforcement: V, F: Project: Staircase Design - STC 1zzweirdozzNoch keine Bewertungen

- Single Isolated Square Footing FPSDokument8 SeitenSingle Isolated Square Footing FPSengmohamad19880% (1)

- Flat Slab DesignDokument6 SeitenFlat Slab DesignforbeskaNoch keine Bewertungen

- Appendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Dokument2 SeitenAppendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Md Nadeem Akhtar100% (1)

- RC Retaining WallDokument10 SeitenRC Retaining WallGertjan DuniceriNoch keine Bewertungen

- Wing WallDokument4 SeitenWing WallFaizal AryanovNoch keine Bewertungen

- Continuous BeamsDokument450 SeitenContinuous BeamssreenivasaeeNoch keine Bewertungen

- RCC72 Stairs & Landings - MultipleDokument5 SeitenRCC72 Stairs & Landings - Multiplemohamedadel100Noch keine Bewertungen

- RCC Beam Design Task-01Dokument29 SeitenRCC Beam Design Task-01Mohamed SaheelNoch keine Bewertungen

- Hetauda Raft DesignDokument92 SeitenHetauda Raft DesignSurendra MaharjanNoch keine Bewertungen

- Beam-Design-R CDokument123 SeitenBeam-Design-R CMarkNoch keine Bewertungen

- Two Way SlabDokument9 SeitenTwo Way SlabMehul Paþel100% (1)

- Slab Design ExcelDokument5 SeitenSlab Design ExcelVinod RevankarNoch keine Bewertungen

- Revised Pad Footing Rev.1 (10.7.2018)Dokument4 SeitenRevised Pad Footing Rev.1 (10.7.2018)Ally KhooNoch keine Bewertungen

- Rebar CalculatorDokument11 SeitenRebar CalculatorMahindaNoch keine Bewertungen

- Strap FootingDokument30 SeitenStrap Footinganon_140586866Noch keine Bewertungen

- Stair Case Design - at Design OfficeDokument14 SeitenStair Case Design - at Design OfficeShamen AmarasekaraNoch keine Bewertungen

- 2018 May 29 Circular Tank With WaterDokument4 Seiten2018 May 29 Circular Tank With WaterPRAKASHNoch keine Bewertungen

- Column Design 300x300Dokument7 SeitenColumn Design 300x3001234 1234Noch keine Bewertungen

- Continuous BeamsDokument324 SeitenContinuous BeamsKARTHIK SGNoch keine Bewertungen

- Made Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: RiyadhDokument6 SeitenMade Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: Riyadhsidiq7Noch keine Bewertungen

- RC BeamDokument77 SeitenRC BeamJvv GudboyNoch keine Bewertungen

- Squre Footing Design (WSD)Dokument3 SeitenSqure Footing Design (WSD)api-19753598Noch keine Bewertungen

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDokument1 SeiteChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNoch keine Bewertungen

- BridgeT BeamDokument23 SeitenBridgeT BeamMochammad Syafi UddinNoch keine Bewertungen

- Design of Critical Two-Way SlabDokument8 SeitenDesign of Critical Two-Way SlabBevelyn Manalo100% (1)

- Purlin DesignDokument6 SeitenPurlin DesignAnonymous mcHqIfbnV1Noch keine Bewertungen

- Slab CantileverDokument1 SeiteSlab CantileveramitkuknaNoch keine Bewertungen

- Design of Purlins Design Data: XX XX Yy IyyDokument6 SeitenDesign of Purlins Design Data: XX XX Yy IyyCorey CookNoch keine Bewertungen

- Continuous Beam Design ProgrammeDokument70 SeitenContinuous Beam Design ProgrammeNikhilNoch keine Bewertungen

- Cantilever Type BeamDokument42 SeitenCantilever Type BeamYer Oon100% (3)

- Design of BeamsDokument3 SeitenDesign of BeamsManoj Prabhahar100% (4)

- DESIGN CalculationDokument47 SeitenDESIGN CalculationZayyan Romjon100% (2)

- Design of Rectangular Water Tank (L/B 2)Dokument14 SeitenDesign of Rectangular Water Tank (L/B 2)Abhay ThakurNoch keine Bewertungen

- Retain Wall Counter FortDokument48 SeitenRetain Wall Counter FortSWADES RANJAN PAIRANoch keine Bewertungen

- Timber ExceDokument28 SeitenTimber ExceBryan MagparangalanNoch keine Bewertungen

- Basement WallDokument11 SeitenBasement WallrisrizNoch keine Bewertungen

- RC Shear Wall 1.2Dokument15 SeitenRC Shear Wall 1.2Balakrishnan100% (1)

- Isolated Footing Design Example and Excel SheetDokument8 SeitenIsolated Footing Design Example and Excel Sheetosama prog100% (1)

- T Beam DesignDokument6 SeitenT Beam Designkalpanaadhi0% (1)

- Linac ColumnsDokument143 SeitenLinac Columnsalbert_pathNoch keine Bewertungen

- A. Design of Flanged Beam SectionDokument7 SeitenA. Design of Flanged Beam SectionWilson PatyalNoch keine Bewertungen

- Auditorium Building DesignDokument28 SeitenAuditorium Building DesignChandra Sekar100% (1)

- Plate Girder DesignDokument8 SeitenPlate Girder Designkalpanaadhi100% (1)

- Design of FootingDokument31 SeitenDesign of FootingAbhinav100% (1)

- Strip FootingDokument10 SeitenStrip FootingKain Pasang Ruby IINoch keine Bewertungen

- Baseplate Biaxial MZDokument26 SeitenBaseplate Biaxial MZD SRINIVAS100% (1)

- Slab DesignDokument28 SeitenSlab DesignUlasi IfeanyiNoch keine Bewertungen

- Design of Wall Footing Project #Dokument3 SeitenDesign of Wall Footing Project #Raghad F Al-Zu'biNoch keine Bewertungen

- Base Slab & Crack Width Check - ACI CodeDokument6 SeitenBase Slab & Crack Width Check - ACI CodensureshbabuNoch keine Bewertungen

- Roarks BookDokument433 SeitenRoarks BooknsureshbabuNoch keine Bewertungen

- MSC SimufacDokument10 SeitenMSC SimufacnsureshbabuNoch keine Bewertungen

- Attachment 3 PDFDokument1 SeiteAttachment 3 PDFnsureshbabuNoch keine Bewertungen

- Attachment-6: 2306-P1-A 2306-P1-BDokument3 SeitenAttachment-6: 2306-P1-A 2306-P1-BnsureshbabuNoch keine Bewertungen

- Fibagel CC MsdsDokument6 SeitenFibagel CC MsdsnsureshbabuNoch keine Bewertungen

- Eurobeam Steel Beam CalculationDokument3 SeitenEurobeam Steel Beam CalculationnsureshbabuNoch keine Bewertungen

- 01 Model2Dokument1 Seite01 Model2nsureshbabuNoch keine Bewertungen

- GRP Cladding MaterialDokument3 SeitenGRP Cladding MaterialnsureshbabuNoch keine Bewertungen

- Fluor: Calculation SheetDokument1 SeiteFluor: Calculation SheetnsureshbabuNoch keine Bewertungen

- Resume of Subashchandrabose.R: +65 83031670 Dynamac Engineering Services PVT LTD 45 Gul Road, SingaporeDokument6 SeitenResume of Subashchandrabose.R: +65 83031670 Dynamac Engineering Services PVT LTD 45 Gul Road, SingaporensureshbabuNoch keine Bewertungen

- CCIP - 16167 Concrete Buildings Scheme Extract FINALDokument45 SeitenCCIP - 16167 Concrete Buildings Scheme Extract FINALDerek AngNoch keine Bewertungen

- K.P.S Nagar: by M.S. EstatesDokument6 SeitenK.P.S Nagar: by M.S. EstatesnsureshbabuNoch keine Bewertungen

- Final Proposal HELIOS JIPDokument18 SeitenFinal Proposal HELIOS JIPnsureshbabuNoch keine Bewertungen

- Chen 2015-Membrane Gas Separation Technologies For Biogas UpgradingDokument50 SeitenChen 2015-Membrane Gas Separation Technologies For Biogas UpgradingyenNoch keine Bewertungen

- Book Review-Quantitative Seismic Interpretation Applying Rock PhysicsDokument2 SeitenBook Review-Quantitative Seismic Interpretation Applying Rock PhysicsQazi Sohail ImranNoch keine Bewertungen

- Fiber-Optic Communication Is A Method of Transmitting InformationDokument19 SeitenFiber-Optic Communication Is A Method of Transmitting Informationpy thonNoch keine Bewertungen

- Microplate Washer User Manual LMW 9620Dokument16 SeitenMicroplate Washer User Manual LMW 9620AlexeyNoch keine Bewertungen

- QuickGuide CIRA Geocolor 20171019Dokument2 SeitenQuickGuide CIRA Geocolor 20171019Dardo Melgar RocaNoch keine Bewertungen

- Ch#17 Physics XiiDokument16 SeitenCh#17 Physics Xiinoor deenNoch keine Bewertungen

- CV - Tony BroccoliDokument25 SeitenCV - Tony BroccolitbroccoliNoch keine Bewertungen

- Chemical Plant Interview Book by Industrial GuideDokument14 SeitenChemical Plant Interview Book by Industrial GuideTom Jose KooduthottiyilNoch keine Bewertungen

- Condenser Vacuum Article From Power MagazineDokument7 SeitenCondenser Vacuum Article From Power MagazineUdhayakumar VenkataramanNoch keine Bewertungen

- Does Cloud Seeding Really Work? An Experiment Above Idaho Suggests Humans Can Turbocharge SnowfallDokument3 SeitenDoes Cloud Seeding Really Work? An Experiment Above Idaho Suggests Humans Can Turbocharge SnowfallAncaBotocNoch keine Bewertungen

- Oe671 Syl08Dokument3 SeitenOe671 Syl08ramoramoniNoch keine Bewertungen

- Materi MatrikulasiDokument72 SeitenMateri MatrikulasiAyziffyNoch keine Bewertungen

- CIP25-Corrosion of Steel in ConcreteDokument2 SeitenCIP25-Corrosion of Steel in Concrete7774R105Noch keine Bewertungen

- PARTES - TurbineMeterManual212FDokument16 SeitenPARTES - TurbineMeterManual212FronaldNoch keine Bewertungen

- Chapter 1 Introduction To Biochemistry and ThermodynamicsDokument4 SeitenChapter 1 Introduction To Biochemistry and ThermodynamicsMamamiaNoch keine Bewertungen

- Here: Muller Big Blue Welder Repair Manual PDFDokument5 SeitenHere: Muller Big Blue Welder Repair Manual PDFSIVARAMANJAGANATHAN0% (2)

- ESTCON ICG 2018 Complete ManuscriptDokument8 SeitenESTCON ICG 2018 Complete ManuscripttriwicakNoch keine Bewertungen

- Organic Chemistry - Chapter 15 Benzene & Aromatic CompoundsDokument9 SeitenOrganic Chemistry - Chapter 15 Benzene & Aromatic CompoundsSairille ManejaNoch keine Bewertungen

- N70F I3 R0 EnglishDokument1 SeiteN70F I3 R0 English阿康Noch keine Bewertungen

- Shi 2020Dokument11 SeitenShi 2020Ricardo Jose GuerreroNoch keine Bewertungen

- Wide Standard 01 enDokument2 SeitenWide Standard 01 enproftononNoch keine Bewertungen

- List of Textile Universities in USADokument3 SeitenList of Textile Universities in USAFazle RubbiNoch keine Bewertungen

- 2014 - Influence of Zn-Fe Molar Ratio On Optical andDokument7 Seiten2014 - Influence of Zn-Fe Molar Ratio On Optical andMoayad FlaifelNoch keine Bewertungen

- The Physics of Superfluid Helium: W. F. VinenDokument12 SeitenThe Physics of Superfluid Helium: W. F. VinenPaulo CesarNoch keine Bewertungen

- r20 - Me - II Year SyllabusDokument43 Seitenr20 - Me - II Year Syllabusdurga Prasad amuduriNoch keine Bewertungen

- 1603 03093Dokument51 Seiten1603 03093pippoNoch keine Bewertungen

- Construction: Close Coupled Centrifugal PumpsDokument11 SeitenConstruction: Close Coupled Centrifugal PumpsAhmed AbarchidNoch keine Bewertungen

- Pile DesignDokument9 SeitenPile DesignIndraHoedayaNoch keine Bewertungen

- 2.2 Density & Specic GrvityDokument14 Seiten2.2 Density & Specic Grvityurvish_soniNoch keine Bewertungen