Beruflich Dokumente

Kultur Dokumente

Some Aspects of Numerical Simulation of Control Valves For Steam Turbines

Hochgeladen von

Sharat ChandraOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Some Aspects of Numerical Simulation of Control Valves For Steam Turbines

Hochgeladen von

Sharat ChandraCopyright:

Verfügbare Formate

SOME ASPECTS OF NUMERICAL SIMULATION OF CONTROL VALVES FOR STEAM TURBINES

Martin HAJMAN, Dana KOVANDOV, Richard MATAS

The contribution deals with the numerical simulation of air and steam flow through the model of control valve for steam turbines. Numerical simulations were compared with experimental measurements for the award of the same boundary conditions. Valve characteristics have been computed for individual travel heights and pressure ratios of two variants of seat inflow angle (90and 60 ). Some other aspects are discussed in th e article - comparison of the axisymmetric and 3D modelling, influence of the computational domain size, comparison of characteristics for two flow media, experimental model of the valve etc. The mentioned results are important for engineering simulations and also for design of the control valves for steam turbines of the large output.

Abstract:

INTRODUCTION

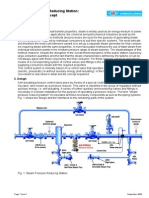

The control valve in a steam turbine is a main component included in the turbine set. This system comprises control fittings (i.e. valves, screens or control partitions) that control the flow of steam into the turbine. The system includes valve control (i.e. servos or HP hydraulic system) which sets the valves and screens to the required flow rate and pressure of the steam. It also contains an electronic system with control software which enables setting the valves, i.e. changing the steam flow into the turbine and thus changing the turbo-set output, from the control centre. The control valve should reliably regulate the amount of steam flow and thus the turbine set output. The actual regulation is achieved by a change of the flow area between the plug and the valve seat. The control valve design is outlined in Figure 1. These valves are produced in many versions with various arrangements and plugs. The development of a reliable valve is not easy; it involves a combination of numerical and experimental methods. It is a topical problem of the applied research and is performed to obtain data for design of reliable control valves. More information you can find e.g. in engineering oriented article [1] or in contribution summarizing the CFD solution of problem [2]. The target of this work is accuracy verification of a CFD simulation of the flow characteristics, to explain away some questions from work [3] and evaluating an effect of the inflow angle of the valve seat (and some other parameters) on the flow characteristics to compare the results with the older [4] and new experimental results.

BALANCED-PLUG AND UNBALANCED-PLUG VALVES

2 1 2 2 1 2

Fig. 1: Chart of the control valve

The control valves are divided into balanced and unbalanced valves according to the force necessary to change the position of the plug from the OFF position into the ON position. If the force equals force corresponding with the product of the annular area and the difference of pressures before and behind the valve, as shown in equation F = (d d ) ( p p ) , the valve is unbalanced. If the force controlling the plug is lower, the valve is balanced. 4 Valve balancing is a constructional adaptation of the valve that reduces the drive force of the valve; it involves insertion of a smaller valve into the plug of the main valve so that initially the smaller plug is moved during the opening, thus reducing the difference of pressures before and behind the valve, and only then the main plug is opened. The force necessary for lifting the small plug is low enough because the annular area is small. The force necessary for lifting the main plug is reduced because the difference of pressures is reduced. Operations described in this work concern an experimental model valve located in the koda Power s.r.o. laboratory. Unlike the real steam valves, the flow medium for this valve is air. The results are transferred by means of dimensionless quantities. Valves of large performance turbines are usually designed as balanced; this balancing system and its adjustment is a subject of further research. Also the researched valve is balanced, but the balancing was ignored in the calculations and the valve was considered unbalanced. The reason is that in the simulated higher travel of the tested valve, the flow through the balancing system has practically no effect on the overall flow and the research concentrated on comparison of the flow characteristics in higher travels. The balancing of the experimental valve can be manually closed and it can be operated as an unbalanced valve.

THE MAIN VALUES AND CHARACTERISTIC

The flow through a control valve can be comprehended as a flow through a nozzle. In terms of thermodynamics, the applicable laws and principles are identical, but the geometry of the nozzle is1 much simpler than the geometry of 1 .Dh2 & kr = [2 (i1C ikr )]2 kr p 2 1 2 . the control valve. The theoretical critical mass flow, which is determined by the formula m , is an important value; for ideal gas, it can be replaced with the formula m & kr = S * 0 4 & m v0 + 1 +1 The proportional mass flow is determined by the formula q = m & kr ; it relates the instantaneous mass flow to the critical mass flow. p The pressure ratio is a ratio between the static pressure on the outlet from the control valve and the total pressure on the valve inlet. It is determined by the formula = p2 . 0 H The proportional travel height is a real travel of the valve plug related to the critical diameter of the nozzle. It is determined by the equation h = D . The above mentioned formulas and values are used for determination of the flow characteristics of the valve the dependence q on , i.e. a basic characteristic of the valve. The valve characteristics can be supplemented with the turbine's operational characteristics.

Fig. 2: Chart of an experimental control valve

q = m/mKR [-] 1 0,9 2. travel height 15mm 0,8 0,7 5. travel height 27.4mm 0,6 0,5 0,4 0,3 0,2 0,1 = p2/p0 [-] 0 0,84 0,85 0,86 0,87 0,88 0,89 0,9 0,91 0,92 0,93 0,94 0,95 0,96 0,97 0,98 0,99 1 6. travel height 34mm 3. travel height 20mm 4. travel height 25mm

EXPERIMENTAL AIR TUNNEL

The model valve is located in an air tunnel of the KODA POWER experimental laboratory. The air tunnel has an open cycle and the air is supplied by a radial compressor with regulation. The design and the most important parts of the air tunnel are illustrated in Figure 3. The equipment is used for measuring flow characteristics; its design allows measurement of force characteristics, i.e. load on the plug or the shaft. The travel height of the plug is adjusted manually by control screw positioned above the valve chamber. The control screw is coupled with a nut whose thread is screwed on the subsequent plug shaft. Turning the control screw by 360 corresponds to 1 mm of the plug travel. Pressures in the air tunnel in selected areas by the help of static taps are measured. Static pressures on axially symmetrical parts of the valve, such as the inlet piping, the nozzle sleeve or the valve seat are taken four times in 90 on the same cross section. The pressures taken from one measuring point only are subsequently merged and a hose with the resulting pressure is conducted into a pressure converter whose electric signal is processed by computer software. The mass flow of the working medium is measured by a nozzle inserted in the inlet piping. Other values related to the measurement are monitored during the experimental measurement. The current pressure in the inlet chamber of the valve and the current temperature of the inlet air are registered in each record of the measured outputs. The current critical mass flow and the pressure ratio are subsequently calculated from these values for each recorded measuring point. The measurements were performed for a great range of operational parameters. For now, only values from = 0.84 were used for comparison with characteristics obtained via CFD. Each cycle is recorded three or four times during the measurement. This method made the measurement more accurate and eliminated random errors in the measurements. The measured data were used in a graphic chart of the flow characteristics (Figure 4). The curves corresponding to the individual travel heights illustrate the anticipated shape, i.e. a part of ellipse. The individual characteristics maintain the trend of increased proportional flow when the travel is changed to a higher level. On the other side there is a decreased trend of the proportional flow when the pressure ratio is increased.

Flow characteristics - seat inflow angle 90

experimental measurement koda Power s.r.o. turbine's char. 1. travel height 10mm

Fig. 4: Chart of the flow characteristics obtained by experimental measurement

Fig. 3: Air tunnel

NUMERICAL SIMULATIONS OF THE VALVE

The geometry of the control valve for the simulation was adapted from 3D models of the aggregate and individual CAD elements in the Catia V5 program. The geometry was further adapted and simplified with this program. The main software tool for performing the numerical simulation of the flow was the ANSYS/FLUENT 13.0 program, the details of simulations are described in the thesis [5]. All the mathematical models were conceived without a balancing system. The desired geometry of the valve was simplified to an axially symmetrical model in the first phase. Simplification of the task into axial symmetry facilitated acquiring methodology of the calculations and testing their applicability for engineering applications, i.e. a quick check of the valve design and acquisition of flow characteristics. The 3D task represents a mathematical model based on a measured physical model. The only important difference was usage of a screen in the inlet section of the valve which was inserted into the model during the measurement. Due to the relatively complicated geometry and flow field, the solution was complicated and frequently not very stable. The third and fourth travel heights displayed a low stability at high values (pressure ratio), so a partially different calculation model had to be used. To allow comparison of results, identical setting was used for all the tasks, i.e. a model of ideal gas, marginal pressure conditions and a "density based implicit" solver with adjusted second degree of accuracy. Two equation turbulence models RNG k- and "realizable" k- models were used. The computation grids were non-structured, in a axisymmetric task quad cells with a refining in the wall area for better modelling of the boundary layer, for 3D tasks tetrahedrals with prisms in the wall area. The number of cells oscillated around 20 - 25 thousand in axisymmetrical tasks and around 2 million in 3D tasks. The geometry of the numerical model and illustration of the computational grids are given in Figure 5. A method applicable for general as well as batch processing of the simulation was debugged for the tasks. The calculation of the given travel height started with a low and, after stabilization of the flow pattern, the pressure ratio gradually increased. There was used a standard initialization; convergence for the selected conditions occurred after approximately 4000 iterations.

Flow characteristics - seat inflow angle 90

results of axisymmetric and 3D simulations, experimental results q = m/mKR [-] 1 0,9 0,8 0,7 0,6 0,5 0,4 0,3 0,2 0,1 0 0,84 0,85 0,86 0,87 0,88 0,89 = p2/p0 [-] 1 1. tr. h. 10 mm axi 2. tr. h. 15 mm axi 3. tr. h. 20 mm axi 4. tr. h. 27.4 mm axi 5. tr. h. 35 mm axi 1. tr. h. 10 mm 3D 2. tr. h. 15 mm 3D 3. tr. h. 20 mm 3D 4. tr. h. 27.4 mm 3D 5. tr. h. 35 mm 3D turbine's char. 1. tr. h. 10 mm EXPER 2. tr. h. 15 mm EXPER 3. tr. h. 20 mm EXPER 4. tr. h. 25 mm EXPER

Fig. 5: Geometry of the CFD model and illustration of computational grids

COMPARISON OF NUMERICAL SIMULATIONS WITH EXPERIMENTAL MEASUREMENTS

This comparison was performed in order to evaluate the accuracy of the numerical simulation results because, as it was discovered, reliable comparison of flow characteristics obtained by measurements and simulations is not available despite the existing large amount of numerical simulations and experimental measurements [2, 3]. The numerical simulations were performed with regard to the experimental measurement and with the same marginal conditions, if possible. Although the simulation and the measurement were performed simultaneously, it was not possible to maintain absolutely identical conditions, but they were identical enough for most of the modes. The complex comparison results of experimental measurements and numerical simulations are illustrated in Figure 6. An analysis of this chart suggests that numerical simulations can simulate the characteristics with satisfactory accuracy. The first simulated travel height corresponds with the results most accurately as its characteristics are virtually identical. In higher pressure ratios, where the simulation is more demanding, the values slightly differ from the measurements. Even an experimental measurement is demanding in this sphere; it was performed for the maximum pressure ratio = 0.98. However, this sphere lies beyond the presumed characteristic of the turbine. The second travel height shows relatively low differences between the proportional mass flow of the numerical simulation curves and the curve of the experiment. In principle, the values of the individual modes in the second travel height do not differ; the curve representing the experiment shows higher mass flows than the simulation. The third travel height shows approximately identical deviations as the second; the curve representing the experiment, however, shows lower values of the mass flow. Nevertheless, the proportional deviations fluctuate within 3 5 % in the first, second and third travel height. At first sight, the fourth compared travel shows the largest differences of the characteristics curves. Here, however, the travel adjustment of the valve plug is not identical. The experimental measurement was performed at the travel of 25 mm, while the simulation in the fourth travel was adjusted to the critical travel which corresponds to 27.4 mm. With regard to this fact it is clear that the curve representing the experiment shows lower values of the mass flow than the simulation curve.

Flow characteristics - seat inflow angles 90 and 60

q = m/mKR [-] 1 0,9 0,8 0,7 0,6 0,5 0,4 0,3 0,2 0,1 0 results of axisymmetric simulations 1. tr.h. 14 mm 60 2. tr.h. 21 mm 60 3. tr.h. 28 mm 60 4. tr.h. 38 mm 60 5. tr.h. 48 mm 60 1. tr. h. 10 mm 90 2. tr. h. 15mm 90 3. tr. h. 20 mm 90 4. tr. h. 27.4 mm 90 5. tr. h. 35 mm 90 turbine's char.

0,9

0,91 0,92 0,93 0,94 0,95 0,96 0,97 0,98 0,99

Fig. 6: Flow characteristics - comparison of the simulation with the experiment

Flow characteristics - seat inflow angles 90 and 60

q = m/mKR [-] 1 0,9 0,8 0,7 0,6 0,5 0,4 0,3 0,2 0,1 0 results of 3D simulations

1.tr. h. 14 mm 60 2. tr. h. 21 mm 60 3. tr. h. 28 mm 60 4. tr. h. 38 mm 60 5. tr. h. 48 mm 60 1. tr. h. 10 mm 90 2. tr. h. 15 mm 90 3. tr. h. 20 mm 90 4. tr. h. 27.4 mm 90 5. tr. h. 35 mm 90 turbine's char.

NUMERICAL SIMULATIONS OF THE SEAT INFLOW ANGLE

One of the important geometry parameters of the valve is the inflow angle of the valve seat. Currently, the geometry of the inflow angle in KODA POWER s.r.o. is 90. Some of the earlier works suggest that lowering this angle might produce changing of the valve losses [1]. Thus a study, in which the inflow angle was modified to 60, has been performed; it was to compare efficiency of both versions as regards the mass flow of liquid through the valve while maintaining identical marginal circumstances. These were formed by inlet and outlet pressure and an identical clear area in the adjustment of individual travels of the plug. The simulations of the inflow angle effects were performed as axially symmetrical and 3D models. The results of the simulations are relatively similar; they are illustrated in Figure 7 for the axisymmetric model and Figure 8 for the 3D model. The simulations proved the effect of different geometry in both versions; it affects the resulting mass flow through the valve in all travel heights. The obtained characteristics curves correspond for the axisymmetric case as well as the 3D case. Both types of calculations proved an effect of different geometry in both versions which results in a different mass flow through the valve in all the travel heights. Comparison of the mass flow in the 60 and 90 inflow angle proved that the mathematical model with 60 produces a higher flow rate. The differences in values fluctuated within 3 5 % again. In some cases, the calculation resulted in separation of the liquid flow from the wall in the sleeve area which caused a crash or instability of the calculation. This extensive separation of the flow was removed by application of a different turbulence model; the k- RNG model was replaced with the "realizable" k- model where these problems did not occur. This issue has to be tackled independently and the simulations should be confronted with experimental results in detail. It is also necessary to include the influence of equalizing of the inlet flow through the screen, which has been omitted in the 3D models so far; this work is under preparation, just as experimental verification of the 60 inflow angle.

Flow characteristics - seat inflow angle 90

CFD simulations for medium air and steam

= p2/p0 [-] 0,84 0,85 0,86 0,87 0,88 0,89 0,90 0,91 0,92 0,93 0,94 0,95 0,96 0,97 0,98 0,99 1,00

= p2/p0 [-] 0,84 0,85 0,86 0,87 0,88 0,89 0,90 0,91 0,92 0,93 0,94 0,95 0,96 0,97 0,98 0,99 1,00

Fig. 7: Comparison of characteristics of axisymmetric simulations for inflow angles 90and 60

Fig. 8: Comparison of characteristics of 3D simulations for inflow angles 90and 60

EFFECTS OF SELECTED PARAMETERS ON RESULTS OF NUMERICAL SIMULATIONS

Further results were reached in verification of certain parameters on the results of the simulations. It particularly concerns an effect of the flowing medium and the size of the numerical area on the outlet. Ideal gas representing steam with realistic parameters for an 800 MW turbine was used as the flowing medium for the comparison. The parameters of the medium were prepared according to the methodology for replacement of steam with ideal gas in numerical calculations where a calculation of substitute parameters of the gas from the inlet and the anticipated outlet condition was performed. Also the marginal conditions were changed to conditions of the real performance. Although the flowing media and the marginal conditions are very different, they can be easily compared via the dimensionless quantities and q. The comparative simulations were performed for selected lifts and proportional pressures. It is clear from the chart in Figure 9 that the flow characteristics of the steam as a flow medium in the first travel height virtually do not differ from the flow characteristic in the third travel height, but a certain deviation is evident. This deviation, however, is not great and the simulations satisfactorily confirm justification of modelling with the selected medium and the transfer of values via dimensionless coefficients to different conditions. Although the simulations correspond with each other as regards mass flows, differences in the flow pattern are ) Fig. 10: Characteristics of a model with visible. In simulations with steam, the steam flow is separated from the diffuser wall in certain modes. This fact was also verified by a change of the numerical model Fig. 9: Comparison of characteristics (90 for two various flow media prolonged piping which did not disprove the separation of the flow. In simulations of identical modes on 3D mathematical models, the separation of the flow did not occur, but the mass flow was virtually identical, see Figure 9. This fact led to adaptation of the geometrical model and prolongation of its outlet section behind the diffuser with piping. This modification was to determine the effect of the prolonged piping on the flow characteristics, or on the flow pattern. Comparison of characteristics for air in Figure 10 shows that they are identical; the extent of the outlet area has no effect on the flow characteristics. The characteristics for alternate steam produced the same mass flows and the characteristics are mutually approximating. A small increase of the mass flow is evident in the 3D model. The characteristics are not much different from the others, the deviations fluctuated around 5 8 %.

1

1

results of CFD simulations

q = m/mKR [-]

q = m/mKR [-]

Flow characteristics - prolonged piping, angle 90

3. tr. h. 20 mm air 3D

1. tr. h. 10 mm air axi 3. tr. h. 20 mm air axi 3. tr. h. 20 mm air 3D

0,9 0,8 0,7 0,6 0,5 0,4 0,3 0,2 0,1

1. tr. h. 10 mm steam axi

0,9 0,8 0,7 0,6 0,5 0,4 0,3 0,2 0,1

3. tr. h. 20 mm long air 3D

3. tr. h. 20 mm long steam 3D

3. tr. h. 20 mm steam axi 3. tr. h. 20 mm steam 3D turbine's char.

3 .tr. h. 20 mm long steam axi turbine's char.

= p2/p0 [-]

0 0,84

0,85

0,86

0,87

0,88

0,89

0,90

0,91

0,92

0,93

0,94

0,95

0,96

0,97

0,98

0,99

1,00

0 0,84 0,85 0,86 0,87

0,88 0,89

0,9

0,91 0,92 0,93 0,94 0,95

0,96 0,97 0,98 0,99

= p2/p0 [-]

CONCLUSIONS

The contribution summarizes results of existing works on a model of the new type of control valve for steam turbines. In the initial phase, the works concentrated on comparison of flow characteristics obtained by experiments and numerical methods. Then an effect of the seat angle on the flow characteristic and secondarily an effect of the flow medium within the calculation area of the numerical model were numerically verified. The results imply the following conclusions: The experimental valve of a modular design allows measurement of characteristics in a broad range of parameters; it can be operated as an unbalanced as well as balanced valve. In addition, it allows measuring pressures in the balancing system and force effects on the plug and shaft, thus significantly extending the spectrum of tasks for the actual development of the valve and for comparisons with CFD simulations. Comparison of flow characteristics with the experiment produced satisfactory results. The results are quite unique in their scope of comparisons of characteristics because they map a great extent of modes under known conditions. The results suggest that relatively accurate characteristics for unbalanced valves can be obtained by means of axially symmetrical models whose creations and calculations are now very simple. The 3D effects in the flow, e.g. its separation in the diffuser area, are more complicated. These effects are hard to predict by calculations (they depend on a correct selection of a number of parameters including a turbulence model) and their measurement is also complicated. The study also suggests that to a certain extent, they need not affect the flow characteristics, but can affect force impacts on the valve. The results of the simulations and produced curves proved that a change of geometry in the flow part of the valve to a newly suggested 60 version can increase the flow through the valve while keeping the same flow area. The increase of the mass flow rate was approximately 3 5 %. These results negate outcomes of an earlier report; although it contains experimentally measured flow characteristics of both versions of the inflow angle in the nozzle, it lacked a necessary detailed description of the measured conditions. Increase of the flow amount through the valve brings about reduction of thermodynamic loss of the valve, which affects the efficiency of the entire turbine set. Should the new version be put into practice, it would be necessary (besides further measurements) to adapt it to higher demands on the control equipment, i.e. the servo drive which must allow a broader extent of axial displacement. Testing of the effects of the flow medium confirmed an assumption regarding similarity of the valve behaviour for various flow media and the marginal conditions corresponding to conditions of a real operation of a steam turbine set with parameters of admission steam; the resulting characteristics are in line with the anticipations. Nevertheless, the simulations discovered changes in the character of the flow pattern in the diffuser. The output area showed practically no impact on the characteristics; partial deviations were in the flow pattern again. The work confirmed that numerical simulations of valves that have already been performed in large numbers are difficult to solve due to the complicated geometry and the flow patterns; no general methodology for the solution can be determined, so that a suitable mathematical model and methodology for calculation must be specified for each researched mode of the valve. The work produced a number of interesting findings applicable in development of control valves. The study of this issue by means of physical as well as mathematical models will continue and concentrate on a balancing system of the valve including its numerical model. Its correct adjustment is essential for the valve control equipment because it fundamentally affects its force load.

REFERENCES

[1] [2] [3] [4] [5] Yong H. Y., Kune Y. S.: Engineering analysis of mass flow rate for turbine system control and design, In Nuclear Engineering and Design 241, Elsevier, 2011, pp. 4061-4078. Matas R., Bedn L., Taj L.: Numerical Simulations and Experiments as Modern Tools for Research of Control Valvesfor Steam Turbines. In Experimental Fluid Mechanics 2010. Liberec: Technick univerzita, 2010, pp. 398-409. ISBN: 978-80-7372-670-6. Jirka L., Matas R., Taj L.: CFD simulace proudn pry o nadkritickch parametrech regulanm ventilem. In Power System Engineering, Thermodynamics & Fluid Flow, Plze, Zpadoesk univerzita v Plzni, 2007, pp. 65-72. ISBN 978-80-7043-542-7. Zarjankin A. J.: Issledovanie merenia sdruenogo regulirujuego klapana firmy koda turbiny, Research report MEI, Moscow, 1994 Hajman, M.: Vpoet prtokov charakteristiky ventilu s rznmi vstupnmi prmry sedla, diploma thesis, Zpadoesk univerzita v Plzni, 2011.

Acknowledgement These results were achieved in the framework of 1M06059 project of the Vyzkumna centra MMT programme (Research Centres, Ministry of Education, Youth, and Sports of the Czech Republic) and in specific research (project ZCU SGS-2010-040). The access to the MetaCentrum computing facilities provided under the programme "Projects of Large Infrastructure for Research, Development, and Innovations" LM2010005 funded by the Ministry of Education, Youth, and Sports of the Czech Republic is acknowledged.

Richard MATAS, University of West Bohemia, Univerzitn 2732/8, 306 14 Plze, mata@ntc.zcu.cz; Dana KOVANDOV, KODA POWER a.s., Tylova 1/57, 301 28 Plze, dana.kovandova@doosan.com; Martin HAJMAN, KODA POWER a.s., Tylova 1/57, 301 28 Plze, martin.hajsman@doosan.com

Das könnte Ihnen auch gefallen

- Modeling 6.1 Development of Non-Linear Model: Tuning of Injection Molding MachineDokument19 SeitenModeling 6.1 Development of Non-Linear Model: Tuning of Injection Molding Machinegoldy243usNoch keine Bewertungen

- REPORTpp 1Dokument16 SeitenREPORTpp 1gajulavamshikrishna02Noch keine Bewertungen

- Control Valves - Modeling and Simulation: Cpatrascioiu@upg-Ploiesti - Ro C.panaitescu@gmail - Ro Nparaschiv@upg-PloiestiDokument6 SeitenControl Valves - Modeling and Simulation: Cpatrascioiu@upg-Ploiesti - Ro C.panaitescu@gmail - Ro Nparaschiv@upg-PloiestiTimothy FieldsNoch keine Bewertungen

- Valve Model ExpansionDokument8 SeitenValve Model Expansionsaeed65Noch keine Bewertungen

- Articulo Sobre El Modelado de Un Sistema NeumaticoDokument27 SeitenArticulo Sobre El Modelado de Un Sistema NeumaticoLuis HerreraNoch keine Bewertungen

- Guidelines For Selecting The Proper Valve CharacteristicDokument6 SeitenGuidelines For Selecting The Proper Valve CharacteristicIamPedroNoch keine Bewertungen

- Air Flow and Charge Motion Study of Engine Intake PortDokument9 SeitenAir Flow and Charge Motion Study of Engine Intake PortAshokNoch keine Bewertungen

- Theoretical and Experimental Study of Hydraulic Actuators Synchronization by Using Flow Divider ValveDokument12 SeitenTheoretical and Experimental Study of Hydraulic Actuators Synchronization by Using Flow Divider ValverezaNoch keine Bewertungen

- Analysis and Optimization of A Butterfly Valve DiscDokument10 SeitenAnalysis and Optimization of A Butterfly Valve DiscAsiff RazifNoch keine Bewertungen

- Dynamic Analysis of Proportional Solenoid Controlled Piloted Relief Valve by BondgraphDokument18 SeitenDynamic Analysis of Proportional Solenoid Controlled Piloted Relief Valve by BondgraphmilligatorNoch keine Bewertungen

- Controllers and Final Control Elements: 24/12/2016 Dr. Arkan Jasim Hadi 1Dokument27 SeitenControllers and Final Control Elements: 24/12/2016 Dr. Arkan Jasim Hadi 1کبری ادریس رسولNoch keine Bewertungen

- t000005801 PDFDokument7 Seitent000005801 PDFMohammed Hassan B KorainaNoch keine Bewertungen

- J. David Powell, N.: P. Fekete, and Chen-Fang ChangDokument12 SeitenJ. David Powell, N.: P. Fekete, and Chen-Fang Changdimoi6640Noch keine Bewertungen

- Instrumentation Process 2014.12.31 PDFDokument14 SeitenInstrumentation Process 2014.12.31 PDFFadlul RamadhanNoch keine Bewertungen

- PrdsDokument0 SeitenPrdssandi1111Noch keine Bewertungen

- Volume (10) Issue (2) 160-173Dokument14 SeitenVolume (10) Issue (2) 160-173abhisek haldarNoch keine Bewertungen

- Piping SystemsDokument5 SeitenPiping SystemsDesislavNoch keine Bewertungen

- Variable Trim Compressor - A New Approach To Variable Compressor GeometryDokument10 SeitenVariable Trim Compressor - A New Approach To Variable Compressor GeometryAlbert CalderonNoch keine Bewertungen

- 9.0 Field Testing MethodsDokument4 Seiten9.0 Field Testing Methodsghgh140Noch keine Bewertungen

- Influence of Axial Compressor Flow Passage Geometry Changes On Gas Turbine Engine Work ParametersDokument10 SeitenInfluence of Axial Compressor Flow Passage Geometry Changes On Gas Turbine Engine Work ParametersDyahSeptiWidhayatiNoch keine Bewertungen

- Stability Improvement of High-Pressure-Ratio Turbocharger Centrifugal Compressor by Asymmetric Flow Control-Part I Non-Axisymmetrical Flow in Centrifugal CompressorDokument9 SeitenStability Improvement of High-Pressure-Ratio Turbocharger Centrifugal Compressor by Asymmetric Flow Control-Part I Non-Axisymmetrical Flow in Centrifugal CompressorjswxieNoch keine Bewertungen

- Control Valve Selection For Hydraulic SystemsDokument7 SeitenControl Valve Selection For Hydraulic SystemszodedNoch keine Bewertungen

- Objective of Experiment. Equipment Set-Up. Theory of Experiment. Procedure. Results & Calculations. Discussion of The Results. ConclusionDokument11 SeitenObjective of Experiment. Equipment Set-Up. Theory of Experiment. Procedure. Results & Calculations. Discussion of The Results. ConclusionAmmar Al-AghbariNoch keine Bewertungen

- International Journal of Pressure Vessels and Piping: ArticleinfoDokument10 SeitenInternational Journal of Pressure Vessels and Piping: ArticleinfoMahdiNoch keine Bewertungen

- Butterfly Valve and FlowDokument5 SeitenButterfly Valve and FlowMurugan RangarajanNoch keine Bewertungen

- Graph Installed Flow and Gain PI Mag 03 21Dokument11 SeitenGraph Installed Flow and Gain PI Mag 03 21FabioSalaNoch keine Bewertungen

- Flowmeter DemonstrationDokument24 SeitenFlowmeter DemonstrationNajwa Ghazali100% (16)

- Experiment No 7Dokument7 SeitenExperiment No 7Faizan Ahmed67% (3)

- HydraulicsDokument65 SeitenHydraulicsMohsin EhsanNoch keine Bewertungen

- Lab 5 - Operating Characteristics of A Centrifugal PumpDokument9 SeitenLab 5 - Operating Characteristics of A Centrifugal PumpGianne Nigelle DoriaNoch keine Bewertungen

- Control Valve SizingDokument7 SeitenControl Valve SizingJojolasNoch keine Bewertungen

- محمد السيد عبد العزيز حسن سكشن 7 PDFDokument12 Seitenمحمد السيد عبد العزيز حسن سكشن 7 PDFZezo HassanNoch keine Bewertungen

- Lab Manuals Fluid Mechanics-IIDokument30 SeitenLab Manuals Fluid Mechanics-IISri E.Maheswar Reddy Assistant ProfessorNoch keine Bewertungen

- Control Valve OcrDokument14 SeitenControl Valve OcrpathakshashankNoch keine Bewertungen

- Control Valve SelectionDokument7 SeitenControl Valve SelectionatiqulaNoch keine Bewertungen

- Ijet V2i2p15Dokument4 SeitenIjet V2i2p15International Journal of Engineering and TechniquesNoch keine Bewertungen

- Journal of EEA, Vol. 28, 2011: Keywords: Centrifugal Pump, FLUENTDokument7 SeitenJournal of EEA, Vol. 28, 2011: Keywords: Centrifugal Pump, FLUENTMohammed El-ShahatNoch keine Bewertungen

- Pressure Observer-Controller Design For Pneumatic Cylinder ActuatorsDokument10 SeitenPressure Observer-Controller Design For Pneumatic Cylinder ActuatorsSähilDhånkhårNoch keine Bewertungen

- Industrial Process Control ValvesDokument36 SeitenIndustrial Process Control Valvesffown100% (1)

- Wilo. Caracteristici TehniceDokument104 SeitenWilo. Caracteristici TehniceIoan Octavian StanciuNoch keine Bewertungen

- 302-Exp7 S13Dokument10 Seiten302-Exp7 S13Anurag KashyapNoch keine Bewertungen

- Control Valve Characteristics PDFDokument20 SeitenControl Valve Characteristics PDFPrem SagarNoch keine Bewertungen

- Ejector Pump CFDDokument24 SeitenEjector Pump CFDSyed Qasim ZaheerNoch keine Bewertungen

- Fluid Flow Measurement and Analysis ExperimentDokument11 SeitenFluid Flow Measurement and Analysis ExperimentJohn TomlinsonNoch keine Bewertungen

- SS 09Dokument3 SeitenSS 09Ajaykumar TiwariNoch keine Bewertungen

- Flow Analysis of Butterfly Valve Using CFDDokument7 SeitenFlow Analysis of Butterfly Valve Using CFDIJMERNoch keine Bewertungen

- Vana Seçimi Control Valve Selection Practical GuideDokument7 SeitenVana Seçimi Control Valve Selection Practical GuideÖmer EmelNoch keine Bewertungen

- Modeling Press Brake Machine PDFDokument88 SeitenModeling Press Brake Machine PDFLê Duy MinhNoch keine Bewertungen

- CFD Course Work 3rd Year Sam MailerDokument12 SeitenCFD Course Work 3rd Year Sam MailerSam MailerNoch keine Bewertungen

- Cavitation Measurement in A Centrifugal PumpDokument15 SeitenCavitation Measurement in A Centrifugal PumpBE GokuNoch keine Bewertungen

- Lab 4 (Flowmeter Demonstration)Dokument23 SeitenLab 4 (Flowmeter Demonstration)Muhamad Baihakhi ShamsudinNoch keine Bewertungen

- Performance Test On Single Stage Axial Flow FanDokument3 SeitenPerformance Test On Single Stage Axial Flow FanAkhil Jaiswal100% (1)

- Designand Modelingof Ball Valve Final VersionDokument27 SeitenDesignand Modelingof Ball Valve Final VersionBreno PenaNoch keine Bewertungen

- Moog Hydraulic Servo Valve Construction Plus Moog PDFDokument13 SeitenMoog Hydraulic Servo Valve Construction Plus Moog PDFJean DesingermainNoch keine Bewertungen

- Performance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningDokument3 SeitenPerformance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningIjsrnet Editorial100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- Control of DC Motor Using Different Control StrategiesVon EverandControl of DC Motor Using Different Control StrategiesNoch keine Bewertungen

- Prevention of Actuator Emissions in the Oil and Gas IndustryVon EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNoch keine Bewertungen

- Bring Quality Near Perfection With Six Sigma: Inspiring Business ConfidenceDokument4 SeitenBring Quality Near Perfection With Six Sigma: Inspiring Business ConfidenceSharat ChandraNoch keine Bewertungen

- Ultrasonic Measurements of Solid Propellant Burning Rates in Nozzleless Rocket MotorsDokument8 SeitenUltrasonic Measurements of Solid Propellant Burning Rates in Nozzleless Rocket MotorsSharat ChandraNoch keine Bewertungen

- Technical Notes.: Determination of Thermal Transport Properties in Ammonium PerchlorateDokument3 SeitenTechnical Notes.: Determination of Thermal Transport Properties in Ammonium PerchlorateSharat ChandraNoch keine Bewertungen

- Bring Quality Near Perfection With Six Sigma: Inspiring Business ConfidenceDokument4 SeitenBring Quality Near Perfection With Six Sigma: Inspiring Business ConfidenceSharat ChandraNoch keine Bewertungen

- Developments in and Implementation of Gas Generators For Fire SuppressionDokument16 SeitenDevelopments in and Implementation of Gas Generators For Fire SuppressionSharat ChandraNoch keine Bewertungen

- Phillip: Stochl, Joseph E. Maloy, Masters, A D Richard LDokument63 SeitenPhillip: Stochl, Joseph E. Maloy, Masters, A D Richard LSharat ChandraNoch keine Bewertungen

- Simulation of A Cold Gas Thruster System and Test Data CorrelationDokument20 SeitenSimulation of A Cold Gas Thruster System and Test Data CorrelationSharat ChandraNoch keine Bewertungen

- Home Tech Support Gauge CalibrationDokument1 SeiteHome Tech Support Gauge CalibrationSharat ChandraNoch keine Bewertungen

- Richard Nakka's Experimental Rocketry Web Site: Solid Rocket Motor Theory - GUIPEPDokument8 SeitenRichard Nakka's Experimental Rocketry Web Site: Solid Rocket Motor Theory - GUIPEPSharat ChandraNoch keine Bewertungen

- AWS R I C P: Adiographic Nterpreter Ertification RogramDokument4 SeitenAWS R I C P: Adiographic Nterpreter Ertification RogramSharat Chandra100% (1)

- Review On Comparative Study Between Helical Coil and Straight Tube Heat ExchangerDokument5 SeitenReview On Comparative Study Between Helical Coil and Straight Tube Heat ExchangerSharat ChandraNoch keine Bewertungen

- NL Master Specification Guide For Public Funded Buildings: Re-Issued 2009/10/01Dokument4 SeitenNL Master Specification Guide For Public Funded Buildings: Re-Issued 2009/10/01Sharat ChandraNoch keine Bewertungen

- Regulator Basics - To B EprintedDokument14 SeitenRegulator Basics - To B EprintedSharat ChandraNoch keine Bewertungen

- Study of Hydrodynamics of Horizontal Spiral Coil Tube: Research PaperDokument3 SeitenStudy of Hydrodynamics of Horizontal Spiral Coil Tube: Research PaperSharat ChandraNoch keine Bewertungen

- Fe Environmental EngineeringDokument24 SeitenFe Environmental Engineeringvzimak2355Noch keine Bewertungen

- Kepes Gyorgy 1967 Light and DesignDokument31 SeitenKepes Gyorgy 1967 Light and DesignAnonymous TOMo4s100% (1)

- Mitutoyo - Czujniki Linear Gage - PRE1474 (2) - 2018 ENDokument64 SeitenMitutoyo - Czujniki Linear Gage - PRE1474 (2) - 2018 END.T.100% (1)

- Sfa-5 10Dokument23 SeitenSfa-5 10Allen RosonNoch keine Bewertungen

- Get FileDokument45 SeitenGet FileJon-Leo K. SvendsenNoch keine Bewertungen

- Earth Electrode Resistance PDFDokument28 SeitenEarth Electrode Resistance PDFChathura PriyankaNoch keine Bewertungen

- Ultrasonic HC-SR04 PDFDokument4 SeitenUltrasonic HC-SR04 PDFDhany SSat0% (1)

- Mark Scheme (Results) January 2007: GCE Mathematics Core Mathematics C3 (6665)Dokument7 SeitenMark Scheme (Results) January 2007: GCE Mathematics Core Mathematics C3 (6665)Fahema ShafiNoch keine Bewertungen

- Kuliah 1 Skalar, Vektor Dan TensorDokument35 SeitenKuliah 1 Skalar, Vektor Dan TensorBatika KencanaNoch keine Bewertungen

- Lesson Plan Hess Law 90 - From MR - TonoDokument14 SeitenLesson Plan Hess Law 90 - From MR - TonoSiti Aminah Al-Hadi100% (2)

- Scientific Attitudes and ValuesDokument12 SeitenScientific Attitudes and ValuesSadik Khan83% (6)

- 00030316-Correlaciones PVT Crudo PesadoDokument16 Seiten00030316-Correlaciones PVT Crudo PesadoJohn Edinson Rodriguez FajardoNoch keine Bewertungen

- Cylinder Pressure Closed Loop ControlDokument11 SeitenCylinder Pressure Closed Loop ControlkhalihneNoch keine Bewertungen

- Cuk Control PDFDokument57 SeitenCuk Control PDFPraveen PJNoch keine Bewertungen

- OSA-06-Vibration Fatigue Analysis of Sheet Metal Mahindra2wheelerDokument11 SeitenOSA-06-Vibration Fatigue Analysis of Sheet Metal Mahindra2wheelerikramishereNoch keine Bewertungen

- Interzone 954 Antifungus ReportDokument10 SeitenInterzone 954 Antifungus Reportsteffy182100% (1)

- Chapt 6Dokument15 SeitenChapt 6morphos777Noch keine Bewertungen

- Electrophoresis TechniqueDokument47 SeitenElectrophoresis TechniqueHiroki PhạmNoch keine Bewertungen

- Cantilevered Beam Using 1d and 2d ElementsDokument40 SeitenCantilevered Beam Using 1d and 2d ElementsManasses juniorNoch keine Bewertungen

- Detonation N Pre-IgnitionDokument9 SeitenDetonation N Pre-IgnitionSanthosh RamananNoch keine Bewertungen

- AutoRecovery 1 Save of Lab Report Template With Grading Rubric (1) .AsdDokument5 SeitenAutoRecovery 1 Save of Lab Report Template With Grading Rubric (1) .AsdMohammed ElnaggarNoch keine Bewertungen

- 9709 s10 Ms 11Dokument6 Seiten9709 s10 Ms 11roukaiya_peerkhanNoch keine Bewertungen

- Mil HDBK 505 PDFDokument9 SeitenMil HDBK 505 PDFCORAL ALONSONoch keine Bewertungen

- Two Phase Vertical Separator SizingDokument4 SeitenTwo Phase Vertical Separator Sizingkamal100% (2)

- Large Deformation BeamDokument10 SeitenLarge Deformation BeamAdimasu AyeleNoch keine Bewertungen

- Lightings Columns Design and VerificationDokument32 SeitenLightings Columns Design and VerificationAlejandro Guardia Carrasco0% (1)

- FM Lab ManualDokument70 SeitenFM Lab ManualRishi PatilNoch keine Bewertungen

- Validated SheetDokument12 SeitenValidated SheetrohitkushNoch keine Bewertungen

- Tolerance Accumulation and Analysis (GD&T)Dokument80 SeitenTolerance Accumulation and Analysis (GD&T)Kishor kumar Bhatia50% (4)

- Escavadeira 350g Jonh DeereDokument652 SeitenEscavadeira 350g Jonh DeereBruno Leocadio67% (6)