Beruflich Dokumente

Kultur Dokumente

TUBE-To-TUBESHEET - Welding Before or After Expanding

Hochgeladen von

Dries VandezandeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TUBE-To-TUBESHEET - Welding Before or After Expanding

Hochgeladen von

Dries VandezandeCopyright:

Verfügbare Formate

Tube to tube sheet joint (Heat Exchanger) -> Welding prior to or after expanding?

Please describe what is feasible if joint for tube to tube sheet is expanded and strength welded. (Consider fixed tubesheet heat exchanger) 1-Welding after expanding 2-Welding before expanding

There are certain merits and demerits of both the sequences you mentioned. Codes including ASME Sec. VIII Div. 1 and TEMA do not say anything regarding the recommended sequence to be followed. But the preferred and recommended sequence is 2, that is welding before expanding based upon following reasons: 1. Welding shall be performed in an atmosphere where welding gases can escape; welding after expansion will surely result in bad tube-to-tubesheet joints having porosity or weld inclusions by lubricants (if cleaning not done properly) 2. Welding after expansion would cause adverse effects on expansion (can get loosened) due to welding heat. Such tubes would be requiring re-rolling. On the other hand, the de-merits of above mentioned recommended solution include: a. No foolproof check would be in place for leak tightness of expansion done b. Chance of welding getting damaged during expansion process. The later can be overcome by increasing the starting distance of expansion towards shell side (recommended is > 15 mm from the toe of the weld joint, used by manufacturers)

The leak tightness of expansion generally done only through Mock-up test.After mock-up test the test piece is cross sectioned and leak path is measured under microscope. The % of expansion is strictly done as per TEMA Rules and it is measure by GO and NOGO gauge and Bore dial gauges. To carryout full expansion after welding also induce more stresses into the tube to tubesheet weld joint. Generally initial rolling i.e 25% to 50% expansion done initially to make sure that the tube is in position and does not move inward or outward during welding and complete the final expansion after welding and this will reduce stress on the tube to tubesheet weld joint.

Specification for the Tube to Tubesheet welding you may find in ASME SEC III indetail. I have followed both section III and Nuclear Power Corporation of India specification which

will be more stringent.

Das könnte Ihnen auch gefallen

- Tube To Tubesheet Joint TypeDokument2 SeitenTube To Tubesheet Joint TypeExsan Othman100% (1)

- Heat treatment SS clad CS to prevent sensitisationDokument3 SeitenHeat treatment SS clad CS to prevent sensitisationarifhonNoch keine Bewertungen

- Tube To Tubesheet Weld Joint Design & Welding Qualifications MicroDokument21 SeitenTube To Tubesheet Weld Joint Design & Welding Qualifications MicroSiva baalanNoch keine Bewertungen

- Detecting Susceptibility to Intergranular Attack in Austenitic Stainless SteelsDokument38 SeitenDetecting Susceptibility to Intergranular Attack in Austenitic Stainless SteelsNest Necture100% (5)

- Minimum Leak Path For TTJDokument3 SeitenMinimum Leak Path For TTJparikshitpadture100% (2)

- Gasket Seating Face Tolerance PDFDokument5 SeitenGasket Seating Face Tolerance PDFAdrian RogersNoch keine Bewertungen

- Proposed New ASMEB31P Standard On Preheat & PWHT PDFDokument34 SeitenProposed New ASMEB31P Standard On Preheat & PWHT PDFWitchfinder General100% (1)

- Tube To Tube Sheet Mock UpDokument5 SeitenTube To Tube Sheet Mock UpKushalNoch keine Bewertungen

- Tube-to-tubesheet weldingDokument8 SeitenTube-to-tubesheet weldingManjadi Maverick100% (1)

- Hastelloy C-276 WeldingDokument4 SeitenHastelloy C-276 WeldingClaudia MmsNoch keine Bewertungen

- ASME Impact Test RequirementDokument3 SeitenASME Impact Test Requirementapply19842371100% (4)

- VESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedDokument6 SeitenVESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedMuhammad Farukh ManzoorNoch keine Bewertungen

- Heat Exchanger Inspection PDFDokument8 SeitenHeat Exchanger Inspection PDFreezmanNoch keine Bewertungen

- P91 Welding and PWHT ProcedureDokument4 SeitenP91 Welding and PWHT ProcedureHatem Ragab100% (2)

- Tube To Tube-Sheet Expansion ProcedureDokument4 SeitenTube To Tube-Sheet Expansion ProcedureMuhammadShabbirNoch keine Bewertungen

- What Is PWHTDokument2 SeitenWhat Is PWHTShaik ShahNoch keine Bewertungen

- A1084-15a Standard Test Method For Detecting Detrimental Phases in Lean Duplex Austenitic - Ferritic Stainless SteelsDokument18 SeitenA1084-15a Standard Test Method For Detecting Detrimental Phases in Lean Duplex Austenitic - Ferritic Stainless Steelstjt4779Noch keine Bewertungen

- ASME Pressure Vessel Joint EfficienciesDokument4 SeitenASME Pressure Vessel Joint EfficienciesliamcsNoch keine Bewertungen

- TEMA Standards Inquiries 2020Dokument24 SeitenTEMA Standards Inquiries 2020Nisarg Patel100% (1)

- Titanium FormingDokument5 SeitenTitanium FormingSiavash IraniNoch keine Bewertungen

- ASTM F1545 Plastic Lined Pipe 0803 PDFDokument6 SeitenASTM F1545 Plastic Lined Pipe 0803 PDFdavi rodriguesNoch keine Bewertungen

- Work Instruction On Tube ExpansionDokument40 SeitenWork Instruction On Tube Expansionjayaarnav100% (1)

- Lining, Weld Overlay and CladdingDokument1 SeiteLining, Weld Overlay and Claddingalokbdas100% (1)

- Tube To Tube Sheet Mockup Qualification NewDokument5 SeitenTube To Tube Sheet Mockup Qualification NewalokbdasNoch keine Bewertungen

- Asme Pcc-1 App O - 411-E-103 - Ch. Cover FLGDokument12 SeitenAsme Pcc-1 App O - 411-E-103 - Ch. Cover FLGVilas AndhaleNoch keine Bewertungen

- Tube To Tube Sheet WeldingDokument5 SeitenTube To Tube Sheet WeldingGowrish Kumar100% (2)

- Tube-to-Tubesheet Joints - BaherDokument51 SeitenTube-to-Tubesheet Joints - BaherNAMO100% (3)

- Basic Points of P91Dokument4 SeitenBasic Points of P91Asad Bin Ala Qatari100% (1)

- 6-12-0002 Rev 8 Supplementary Specification For Carbon Steel VesselsDokument7 Seiten6-12-0002 Rev 8 Supplementary Specification For Carbon Steel Vesselsravi2007Noch keine Bewertungen

- API 660 Vs TEMADokument5 SeitenAPI 660 Vs TEMAALONSO GOMEZNoch keine Bewertungen

- Diaphragm Elimination Using Taper-Lok - NPRADokument11 SeitenDiaphragm Elimination Using Taper-Lok - NPRAN. S. PanditNoch keine Bewertungen

- AD 2000 Shell Under External PressureDokument3 SeitenAD 2000 Shell Under External Pressuremechengg01100% (1)

- ASTM A193 and A194 Quick Reference GuideDokument5 SeitenASTM A193 and A194 Quick Reference GuidegarrybieberNoch keine Bewertungen

- Assessment of Delta Ferrite For SA 240 Type 304L Austenitic Weld Metal Using Different Filler MaterialsDokument6 SeitenAssessment of Delta Ferrite For SA 240 Type 304L Austenitic Weld Metal Using Different Filler Materialsafnene1Noch keine Bewertungen

- Design Consideration For Internal Welding Attachments in Clad Pressure VesselsDokument6 SeitenDesign Consideration For Internal Welding Attachments in Clad Pressure VesselsJose ManuelNoch keine Bewertungen

- Astm A 450Dokument10 SeitenAstm A 450Telmo VianaNoch keine Bewertungen

- Tube-Tubesheet Mockup Test ProcedureDokument2 SeitenTube-Tubesheet Mockup Test Procedurefizanlamin100% (9)

- PWHT For Shell Nozzle of Steel Storage Tanks-21Dokument27 SeitenPWHT For Shell Nozzle of Steel Storage Tanks-21الGINIRAL FREE FIRE100% (1)

- Static Equipment Group-Facebook Posts Binder Format-eBook-1st EditionDokument397 SeitenStatic Equipment Group-Facebook Posts Binder Format-eBook-1st EditionDivyesh PatelNoch keine Bewertungen

- Optional Integral With Hub Type Body Flange CalculationDokument13 SeitenOptional Integral With Hub Type Body Flange Calculation9913489806Noch keine Bewertungen

- Section II A SA-20 - SA-20M PDFDokument45 SeitenSection II A SA-20 - SA-20M PDFSocrates MoralesNoch keine Bewertungen

- Tube To Tube SheetDokument59 SeitenTube To Tube Sheet0101100175% (12)

- API 660 Checklist Basic - PreliminaryDokument1 SeiteAPI 660 Checklist Basic - Preliminaryvm153748763100% (1)

- INSPECT HEAT EXCHANGERDokument82 SeitenINSPECT HEAT EXCHANGERBalaji VenkatesanNoch keine Bewertungen

- Asme b16.25 Buttwelding EndsDokument22 SeitenAsme b16.25 Buttwelding Endsgst ajahNoch keine Bewertungen

- Clad RestorationDokument48 SeitenClad RestorationsalunkheclNoch keine Bewertungen

- Post Weld Heat TreatmentDokument51 SeitenPost Weld Heat Treatmenttbmari97% (32)

- Definition of Buttering From ASME Section IXDokument2 SeitenDefinition of Buttering From ASME Section IXsanket100% (3)

- Metallurgical Analysis of Cracks in Induction Hardened CrankshaftsDokument10 SeitenMetallurgical Analysis of Cracks in Induction Hardened Crankshaftsmans2014100% (1)

- Weld Joint EfficienciesDokument5 SeitenWeld Joint EfficienciesMohd Idris MohiuddinNoch keine Bewertungen

- Shell and Tube Heat Exchangers (API 660 vsTEMA)Dokument3 SeitenShell and Tube Heat Exchangers (API 660 vsTEMA)Aravind MadhuNoch keine Bewertungen

- Technical Specification Carbon Steel Heat Exchangers: Project No: 338033Dokument14 SeitenTechnical Specification Carbon Steel Heat Exchangers: Project No: 338033jdgh1986Noch keine Bewertungen

- KochDokument181 SeitenKochRichard FelipNoch keine Bewertungen

- Tube Roller ExpansionDokument12 SeitenTube Roller ExpansionTejaswiNoch keine Bewertungen

- Tube Tubesheet Joints TypesDokument2 SeitenTube Tubesheet Joints TypesMuhammadShabbirNoch keine Bewertungen

- A Simple Approach To Hot Tap and Repair Sleeve Welding - tcm153-574205Dokument13 SeitenA Simple Approach To Hot Tap and Repair Sleeve Welding - tcm153-574205Charly RiveraNoch keine Bewertungen

- Saej 356 V 002Dokument7 SeitenSaej 356 V 002Evandro Luis GomesNoch keine Bewertungen

- Tube To Tube SheetDokument9 SeitenTube To Tube Sheetcmpatel_00100% (2)

- HVAC Handbook Part 3 Piping DesignDokument122 SeitenHVAC Handbook Part 3 Piping DesignTanveer100% (7)

- Design of Repair Clamp For Online Elimination of Leakage From Bolted Flanged JointsDokument7 SeitenDesign of Repair Clamp For Online Elimination of Leakage From Bolted Flanged JointsAlberto Fernando Leon Arismendy100% (1)

- ESAB ExtractPage34-35DDokument16 SeitenESAB ExtractPage34-35DDries VandezandeNoch keine Bewertungen

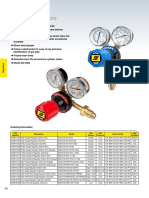

- Regulators Overall Offering Guide: Industrial Gas Cylinder RegulatorsDokument4 SeitenRegulators Overall Offering Guide: Industrial Gas Cylinder RegulatorsDries VandezandeNoch keine Bewertungen

- Interpass Temperature WeldingDokument2 SeitenInterpass Temperature Weldinghareesh13hNoch keine Bewertungen

- How Interpass Temp Affects Weld QualityDokument1 SeiteHow Interpass Temp Affects Weld QualityDries VandezandeNoch keine Bewertungen

- Regulators G Series Regulators: Number Description Model Gas Service Gas Pressure Inlet & Outlet Inlet PositionDokument1 SeiteRegulators G Series Regulators: Number Description Model Gas Service Gas Pressure Inlet & Outlet Inlet PositionDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage39-40DDokument17 SeitenESAB ExtractPage39-40DDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage32-33DDokument17 SeitenESAB ExtractPage32-33DDries VandezandeNoch keine Bewertungen

- Gas Safety Replacement RecommendationsDokument2 SeitenGas Safety Replacement RecommendationsDries VandezandeNoch keine Bewertungen

- ExtractPage35 36c PDFDokument8 SeitenExtractPage35 36c PDFDries VandezandeNoch keine Bewertungen

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDokument4 SeitenOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage35-36DDokument16 SeitenESAB ExtractPage35-36DDries VandezandeNoch keine Bewertungen

- Regulators G Series Regulators: Number Description Model Gas Service Gas Pressure Inlet & Outlet Inlet PositionDokument1 SeiteRegulators G Series Regulators: Number Description Model Gas Service Gas Pressure Inlet & Outlet Inlet PositionDries VandezandeNoch keine Bewertungen

- ExtractPage40 41D PDFDokument21 SeitenExtractPage40 41D PDFDries VandezandeNoch keine Bewertungen

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDokument2 SeitenOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage20-21cDokument8 SeitenESAB ExtractPage20-21cDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage15-16cDokument9 SeitenESAB ExtractPage15-16cDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage23-24cDokument8 SeitenESAB ExtractPage23-24cDries VandezandeNoch keine Bewertungen

- Order Propane Super Heating NozzlesDokument9 SeitenOrder Propane Super Heating NozzlesDries VandezandeNoch keine Bewertungen

- ExtractPage38 39c PDFDokument8 SeitenExtractPage38 39c PDFDries VandezandeNoch keine Bewertungen

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series KitsDokument1 SeiteOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series KitsDries VandezandeNoch keine Bewertungen

- ExtractPage23 24B PDFDokument4 SeitenExtractPage23 24B PDFDries VandezandeNoch keine Bewertungen

- ESAB ExtractPage29-30cDokument9 SeitenESAB ExtractPage29-30cDries VandezandeNoch keine Bewertungen

- Regulators Edge Series RegulatorsDokument4 SeitenRegulators Edge Series RegulatorsDries VandezandeNoch keine Bewertungen

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDokument2 SeitenOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandeNoch keine Bewertungen

- ExtractPage33 34c PDFDokument8 SeitenExtractPage33 34c PDFDries VandezandeNoch keine Bewertungen

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDokument4 SeitenOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandeNoch keine Bewertungen

- ExtractPage35 36c PDFDokument8 SeitenExtractPage35 36c PDFDries VandezandeNoch keine Bewertungen

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDokument2 SeitenOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandeNoch keine Bewertungen

- Gas Safety Replacement RecommendationsDokument2 SeitenGas Safety Replacement RecommendationsDries VandezandeNoch keine Bewertungen

- ExtractPage40 41c PDFDokument12 SeitenExtractPage40 41c PDFDries VandezandeNoch keine Bewertungen