Beruflich Dokumente

Kultur Dokumente

BYK Additives

Hochgeladen von

tahera aqeelCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BYK Additives

Hochgeladen von

tahera aqeelCopyright:

Verfügbare Formate

Substance for Success.

Product Guide L-G 1

Paint Additives

February 2009

February 2009

Product Guide L-G 1

Paint Additives

Content

Wetting and Dispersing Additives (deflocculating) Wetting and Dispersing Additives (controlled flocculating) Wetting and Dispersing Additives for Universal Pigment Concentrates Pigment Synergists Silicone Surface Additives Acrylate Leveling Additives, liquid Acrylate Leveling Additives, powder form Nano Surface Additives Wax Emulsions and Dispersions in Water Wax Dispersions in Organic Solvents Micronized Wax Additives Silicone Defoamers Polymer Defoamers (silicone-free) Mineral Oil Defoamers Rheology Additives (liquid) Inorganic UV Absorbers Adhesion Promoters Other Additives Page 4-5

Page 6 Page 7

Page 8 Page 9 Page 10 Page 11 Page 12

Page 13 Page 14

Page 15

Product Guide L-G 1

February 2009

Wetting and Dispersing Additives (deflocculating)

for Wetting and Stabilization of Pigments and to avoid Flooding/Floating

Additive Composition NonSolvents volatile matter (%) Acid value (mg KOH/g) Amine Recommended for value Aqueous systems (mg KOH/g) Emulsions Amine neutralized 19 30 35 44 48 19 85 14 74 64 71 140 ca. 36 25 65 190 76 43 71 12 11 13 10

Solvent-borne systems Nonpolar Medium- Polar polar

Solventfree

ANTI-TERRA-U ANTI-TERRA-U 80 ANTI-TERRA-U 100 BYK-151 BYK-155/50 BYK-156 BYK-220 S BYK-9076 BYK-9077 BYK-W 966 DISPERBYK DISPERBYK-101 DISPERBYK-102 DISPERBYK-103 DISPERBYK-106 DISPERBYK-107 DISPERBYK-108 DISPERBYK-109 DISPERBYK-110 DISPERBYK-111 DISPERBYK-112 DISPERBYK-115 DISPERBYK-116 DISPERBYK-130 DISPERBYK-140 DISPERBYK-142 DISPERBYK-145 DISPERBYK-160 DISPERBYK-161 DISPERBYK-162 DISPERBYK-163

Salt of polyamine amides and acidic polyesters Salt of polyamine amides and acidic polyesters Salt of polyamine amides and acidic polyesters Alkylolammonium salt of a polymer Sodium salt of an acrylate copolymer Ammonium salt of an acrylate copolymer Polycarboxylic acid polyester Alkylolammonium salt of a copolymer Block copolymer with basic pigment affinic groups Salt of polyamine amides and acidic polyesters Alkylolammonium salt of a polycarboxylic acid polymer Salt of polyamine amides and an ester Copolymer with acidic groups Copolymer Salt of a polymer with acidic groups Hydroxyfunctional carboxylic acid ester Hydroxyfunctional carboxylic acid ester High molecular weight alkylolamino amide Copolymer with acidic groups Copolymer with acidic groups Acrylate copolymer with basic pigment affinic groups Block copolymer with pigment affinic groups Acrylate copolymer with basic pigment affinic groups Polyamine amides of unsaturated polycarboxylic acids Alkylolamonium salt of an acidic polymer Phosphoric acid ester salt of a copolymer Phosphoric acid ester salt of a copolymer Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups

50 80 >95 40 50 51 52 96 98 52 50 52 99 40 91 90 >97 >98 52 >90 60 52 >98 51 52 60 >95 29 30 38 45

Xylene/Isobutanol 8/1 Butylglycol Water/Dipropyleneglycol monomethylether 11/1 Water Water Alkylbenzenes Hydrocarbons Water White spirit/Butylglycol 8/1 Methoxypropylacetate Isoparaffinic hydrocarbons Methoxypropylacetate/ Alkylbenzenes 1/1 Methoxypropylacetate

24 40 50 100 38 26 85 30 101 132 53 129

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

X X X

X X X X

X X X X X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

Xylene/Butylacetate/ Methoxypropylacetate 5/1/1 Alkylbenzenes/Butylglycol 5/1 Methoxypropylacetate Methoxypropylacetate Xylene/Butylacetate 6/1 Methoxypropylacetate/ Butylacetate 6/1 Methoxypropylacetate/ Xylene/Butylacetate 5/4/2 <3 73 46 76

Xylene/Butylacetate/ Methoxypropylacetate 3/1/1

February 2009

Product Guide L-G 1

Additive

Composition

Nonvolatile matter (%)

Solvents

Acid value (mg KOH/g)

Amine Recommended for value Aqueous systems (mg KOH/g) Emulsions Amine neutralized 18 14 20 13 11 18 94 33

Solvent-borne systems Nonpolar Medium- Polar polar

Solventfree

DISPERBYK-164 DISPERBYK-165 DISPERBYK-166 DISPERBYK-167 DISPERBYK-168 DISPERBYK-169 DISPERBYK-170 DISPERBYK-171 DISPERBYK-174 DISPERBYK-180 DISPERBYK-181

Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Alkylolammonium salt of a copolymer with acidic groups Alkylolammonium salt of a polymer Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Block copolymer with pigment affinic groups Alkylolammonium salt of a polymer Block copolymer with pigment affinic groups Acrylate copolymer Copolymer Copolymer Acrylate blockcopolymer Acrylate blockcopolymer

60 40 29.5 52 30 29.5 30 39.5 52.5 81 65

Butylacetate

X X X X X

X X X X X X

X X X X X X X X X X X X X X

Butylacetate/Methoxypropyl- acetate/Isobutanol 3/2/1 Butylacetate/ Methoxypropylacetate 4/1 Methoxypropylacetate/ Butylacetate 2/1 Dicarboxylic acid ester Butylacetate Methoxypropylacetate/ Butylacetate 6/1 Methoxypropylacetate/ Butylacetate 4/1 Xylene/Methoxypropylacetate/Butylacetate 3/2/1 Methoxypropylacetate/ Propyleneglycol/ Methoxypropanol 5/3/2 Methoxypropylacetate/ Methoxypropoxypropanol/ Butylacetate 7/4/4 11 13 22 94 33

X X X X X X X X X X X X X X X X X X X X

X X X X X X X

DISPERBYK-182

43

13

DISPERBYK-183

52

Tripropyleneglycol monome- thylether/Dipropyleneglycol monomethylether 5/2 Dipropyleneglycol monome- thylether/ Propyleneglycol 2/1 Propyleneglycol/ Methoxypropanol 1/1 Water Water Methoxypropylacetate/ Butylglycol 1/1 Methoxypropylacetate/ Butylglycol/ Methoxypropanol 2/2/1 Butylglycol/ Methoxypropylacetate 1/1 Water Water Methoxypropylacetate Methoxypropylacetate Methoxypropylacetate Methoxypropylacetate Methoxypropylacetate 35 10 30 19

17

DISPERBYK-184 DISPERBYK-185 DISPERBYK-187 DISPERBYK-190 DISPERBYK-191 DISPERBYK-192 DISPERBYK-194 DISPERBYK-2000 DISPERBYK-2001

52 >90 70 40 98 >98 53 40 46

15 17 35 20 4 29

X X

X X

X X X X X X X X X X X X X X X X X X X X X X X X X X

X X X X X X

DISPERBYK-2008 DISPERBYK-2009 DISPERBYK-2010 DISPERBYK-2015 DISPERBYK-2020 DISPERBYK-2025 DISPERBYK-2050 DISPERBYK-2070 DISPERBYK-2150 DISPERBYK-2155 DISPERBYK-2163 DISPERBYK-2164 LACTIMON LACTIMON-WS

Structured acrylic copolymer Structured acrylic copolymer Structured acrylic copolymer Structured acrylic copolymer Structured acrylic copolymer Structured acrylic copolymer Acrylate copolymer with basic pigment affinic groups Acrylate copolymer with pigment affinic groups Block copolymer with basic pigment affinic groups Block copolymer with pigmentaffinic groups Block copolymer with pigmentaffinic groups Block copolymer with pigmentaffinic groups Polycarboxylic acid polymer Polycarboxylic acid polymer

100 44 40 40 70 70 52 52 52 >99 45 60 50 50

20 10 37 38 40

66 4 20 36 37 30 20 57 48 10 13 13 23

X X X X X X X X X X

Xylene/Butylacetate/ Methoxypropylacetate 3/1/1 Butylacetate/Methoxypropyl- acetate 2/3 Xylene/Isobutanol Butylglycol/Isobutanol/ Water 5/4/1 60 43

Product Guide L-G 1

February 2009

Wetting and Dispersing Additives (controlled flocculating)

for Wetting and Stabilization of Pigments and to avoid Settling, Sagging, and Flooding/Floating

Additive Composition NonSolvents volatile matter (%) Acid value (mg KOH/g) Amine Recommended for value Aqueous systems (mg KOH/g) Emulsions Amine neutralized 51 37 37 100 100

Solvent-borne systems Nonpolar Medium- Polar polar

Solventfree

ANTI-TERRA-202 ANTI-TERRA-204 ANTI-TERRA-205 ANTI-TERRA-207 ANTI-TERRA-P BYK-P 104 BYK-P 104 S BYK-P 105 BYKUMEN

Alkylolammonium salt of a polycarboxylic acid Polycarboxylic acid salt of polyamine amides Polycarboxylic acid salt of polyamine amides Alkylolammonium salt of a polycarboxylic acid Phosphoric acid salt of polyamine amides Polycarboxylic acid polymer Polycarboxylic acid polymer Polycarboxylic acid polymer Polycarboxylic acid polyester

50 52 52 80 42 50 50 98.5 46

Stoddard solvent/ Butoxyethanol 9/1 Methoxypropanol/ Alkylbenzenes 3/2

51 41

X X X X X X X X X X X X X X X X X X X

Methoxypropanol/Isoparaffinic 40 hydrocarbons 3/2 Isobutanol/Methoxymethylethoxypropanol 3/2 100

Isobutanol/Xylene/Water 3/1/1 170 Xylene/Diisobutylketone 9/1 Xylene/Diisobutylketone 9/1 White spirit/Isobutanol 3/2 180 150 365 35

X X

Wetting and Dispersing Additives for Universal Pigment Concentrates

Additive Composition NonSolvents volatile matter (%) 81 55 >98 99 Water Water Acid value Recommended for (mg Glycol pastes KOH/g) 61 15 36 40 Properties VOC free pigment concentrates DISPERBYK-2090 DISPERBYK-2091 DISPERBYK-2095 DISPERBYK-2096 Modified polyalkoxylate with acidic groups in a star like structure Modified polyalkoxylate with neutral groups in a star like structure Salt of polyamineamides and acidic polyesters Polar acidic esters of high molecular weight alcohols Stabilization of basic carbon blacks Stabilization of organic and inorganic pigments Viscosity reduction in combination with DISPERBYK-2091 To improve compatibility in non-polar coatings

X X X X

X X X X

Pigment Synergists

to Support Pigment Dispersion

Additive Composition Non-volatile matter (%) 100 100 Properties For phthalocyanine pigments, violet pigments, and carbon blacks. Use always in combination with high molecular weight wetting and dispersing additives. For organic red, yellow, and orange pigments. Use always in combination with high molecular weight wetting and dispersing additives.

BYK-SYNERGIST 2100 Insoluble pigment complex BYK-SYNERGIST 2105 Insoluble pigment complex

February 2009

Product Guide L-G 1

Silicone Surface Additives

to Improve Substrate Wetting and Surface Slip

Additive Composition Reactive group Nonvolatile matter (%) Active substance (%) Solvents Recommended for Aqueous systems Emulsions Amine neutralized Xylene/Isobutanol 4/1 Butylglycol Xylene/ Monophenylglycol 7/2 Xylene Methoxypropylacetate/ Phenoxyethanol 1/1 White spirit/Methoxypropylacetate 9/1 Butoxyethanol Alkylbenzenes/ Butyrolacton 1/1 Methoxypropylacetate Methoxypropanol acetate/Xylene 8/1 Dipropyleneglycol monomethylether Butylglycol Xylene/Isobutanol 4/1 Dipropyleneglycol monomethylether Xylene/Alkylbenzenes/ Cyclohexanone/Monophenylglycol 75/11/7/7 Xylene Methoxypropanol Dipropyleneglycol monomethylether Methoxypropylacetate Methoxypropanol 100 100 >96 70 PONPGDA* Solvent-borne systems Nonpolar Medium- Polar polar Solventfree

BYK-300 BYK-301 BYK-302 BYK-306 BYK-307 BYK-310 BYK-315 BYK-320 BYK-321 BYK-322 BYK-323 BYK-325 BYK-330 BYK-331 BYK-332 BYK-333 BYK-336 BYK-337 BYK-341 BYK-344 BYK-345 BYK-346 BYK-347 BYK-348 BYK-349 BYK-370

Polyether modified polydimethylsiloxane Polyether modified polydimethylsiloxane Polyether modified polydimethylsiloxane Polyether modified polydimethylsiloxane Polyether modified polydimethylsiloxane Polyester modified polydimethylsiloxane Polyester modified polymethylalkylsiloxane Polyether modified polymethylalkylsiloxane Polyether modified polymethylalkylsiloxane Aralkyl modified polymethylalkylsiloxane Aralkyl modified polymethylalkylsiloxane Polyether modified polymethylalkylsiloxane Polyether modified polydimethylsiloxane Polyether modified polydimethylsiloxane Polyether modified polydimethylsiloxane Polyether modified polydimethylsiloxane Polyether modified polydimethylsiloxane Polyether modified polydimethylsiloxane Polyether modified polydimethylsiloxane Polyether modified polydimethylsiloxane Silicone surfactant Silicone surfactant Silicone surfactant Silicone surfactant Silicone surfactant Polyester modified polydimethylsiloxane OH

52 52 >95 12.5 >97 25 25 52 51 >98 >96 52 51 >98 >97 >97 25 15 51.5 52 87.5 45 85 >96 >94 25

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X

X X

X X

X X

X X X

X X X X X X X X X

X X X X X X X X X X X X X X

BYK-371 BYK-373 BYK-375 BYK-377 BYK-378

Polyester modified polydimethylsiloxane Polyether-polyester modified polydimethylsiloxane Polyether modified polydimethylsiloxane

Acrylic OH

40 52 25 >96 >96 25 >96 25 >96 >97

Polyether modified polydimethylsiloxane OH

Polyether modified polydimethylsiloxane OH OH

BYK-SILCLEAN 3700 Silicone modified polyacrylate

BYK-SILCLEAN 3710 Polyether modified polydimethylsiloxane Acrylic BYK-SILCLEAN 3720 Polyether modified polydimethylsiloxane OH BYK-UV 3500 BYK-UV 3510 BYK-3520 BYK-3521 BYK-UV 3530 BYK-UV 3570 Polyether modified polydimethylsiloxane Acrylic Polyether modified polydimethylsiloxane Organically modified polydimethylsiloxane Organically modified polydimethylsiloxane Polyether modified polydimethylsiloxane Acrylic Polyester modified polydimethylsiloxane Acrylic

X X

* Propoxylated Neopentylglycoldiacrylate

Product Guide L-G 1

February 2009

Acrylate Leveling Additives, liquid

Additive Composition NonSolvents volatile matter (%) Leveling Air release, Defoaming Antipopping Substrate wetting, Anticrater effect Recommended for Aqueous systems Solventborne systems Solventfree systems Masterbatch resins for powder coatings Remarks

BYK-340 BYK-350 BYK-352 BYK-354

Polymeric fluoro surfactant Polyacrylate Polyacrylate Polyacrylate

10 100 80 51

Dipropyleneglycol monomethylether Methoxypropanol Alkylbenzenes/ Diisobutylketone 9/1 Methoxypropylacetate Alkylbenzenes Dipropyleneglycol monomethylether Dipropyleneglycol monomethylether Dipropyleneglycol monomethylether Xylene Methoxypropylacetate Dipropyleneglycol monomethylether

X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X

Solvent-free version of BYK-358 N Solvent-free version of BYK-355

BYK-355 BYK-356 BYK-358 N BYK-359 BYK-361 N BYK-380 N BYK-381 BYK-388 BYK-390 BYK-392 BYK-394

Polyacrylate Polyacrylate Polyacrylate Polyacrylate Polyacrylate

52 >98 52 >99 >98

Acrylate copolymer 52 Polyacrylate, ionic Fluoro modified polyacrylate Polyacrylate Polyacrylate Polyacrylate 52 70 52 52 80

X X

Foil release

Acrylate Leveling Additives, powder form

Additive Composition Residue Acrylate Leveling after calcin- content ing (%) (%) 57 60 63 63 63 63 Anticrater effect Pigment wetting Recommended for Remarks Powder coatings BYK-360 P BYK-364 P BYK-366 P BYK-368 P BYK-3900 P BYK-3931 P Polyacrylate, adsorbed on silicon dioxide 39 Polyacrylate, adsorbed on silicon dioxide 37 Polyacrylate, adsorbed on silicon dioxide 34 Polyacrylate, adsorbed on silicon dioxide 34 Polyacrylate, adsorbed on silicon dioxide 34 Polyacrylate, adsorbed on silicon dioxide 34

X X X X X

X X X X X X

X X X X X X

OH reactive

Enhanced acceptance of impurities Synergist, Used in combination with standard leveling additives

Nano Surface Additives

for Improved Scratch Resistance

Additive Composition NonParticle Carrier volatile content matter (%) (%) 55 97 97 50 30 30 30 25 Water TPGDA HDDA Methoxypropyl-acetate Particle Recommended for Application areas size UV systems Conventional D50 systems, (nm) Aqueous Solvent-free solvent-borne 40 40 40 20

NANOBYK-3600* Aluminium oxide nanoparticles NANOBYK-3601* Aluminium oxide nanoparticles NANOBYK-3602* Aluminium oxide nanoparticles NANOBYK-3610 NANOBYK-3650

X X X X X X X X

TPGDA = Tripropyleneglycoldiacrylate

Parquet and furniture coatings Parquet/furniture and industrial coatings Parquet/furniture and industrial coatings Wood and furniture coatings, industrial coatings, plastic coatings Wood and furniture coatings, industrial coatings, automotive refinish coatings Wood and furniture coatings, industrial coatings, automotive coatings Wood and furniture coatings, industrial coatings, automotive coatings HDDA = Hexanedioldiacrylate

Aluminium oxide nanoparticles, 37 surface-modified with polysiloxane Silica nanoparticles, 31 surface-modified with polysiloxane Silica nanoparticles, 34 surface-modified with polysiloxane Silica nanoparticles, 31 surface-modified with polysiloxane

Methoxypropyl-acetate/ 20 Methoxy-propanol 6/1 Methoxypropylacetate/ Methoxypropanol 6/1 Methoxypropylacetate/ Methoxypropanol 6/1 20

NANOBYK-3651

20

NANOBYK-3652

25

20

* For enhanced effectivity the combination with standard silicone surface additives is recommended.

February 2009

Product Guide L-G 1

Wax Emulsions and Dispersions in Water

Additive Wax base NonCarrier volatile matter (%) 50 35 35 Water Water Water Emulsifier Melting Mechanical Surface Anti- AntiAntiSoftsystem point (wax resistance slip Slip blocking, settling feelcomponent) Water Effect C repellence Non-ionic Anionic Non-ionic 60 130 135 Gloss OrienApplication areas reduc- tation of tion effect pigments Printing inks, architectural coatings

AQUACER 498 AQUACER 507 AQUACER 513

Paraffin wax Oxidized HDPE wax Oxidized HDPE wax Oxidized HDPE wax Modified EVA copolymerwax Modified PE wax

X X X X

X X

Automotive coatings Printing inks, wood, architectural and industrial coatings Printing inks, wood, architectural and industrial coatings Automotive coatings

AQUACER 515

35

Water

Non-ionic

135

AQUACER 526

30

Water

Anionic

105

X

45 Water Water Water Non-ionic Anionic Non-ionic 130 95 105

AQUACER 531 AQUACER 533 AQUACER 535

X X X X X X X

X X X X X

Printing inks Architectural coatings Wood, architectural and industrial coatings Wood, architectural and industrial coatings Printing inks, wood, architectural and industrial coatings Printing inks For wax stains to enhance the color difference between sap and heart wood Wood coatings, printing inks

Modified 40 paraffin wax Modified 30 paraffin wax Modified 30 paraffin wax Modified 35 paraffin wax Oxidized HDPE wax Modified bees wax 35 15

AQUACER 537

Water

Anionic

110

AQUACER 539

Water

Non-ionic

90

AQUACER 552 AQUACER 560

Water Water

Non-ionic

130 70

X

30 30 35 35 35 Water Water Water Water Non-ionic Cationic Anionic 160 135 125 135 130

AQUACER 593 AQUACER 840

Modified PP wax Oxidized HDPE wax

X X X X X X X X

EVA = Ethylene-Vinylacetate

Automotive and industrial coatings Can coatings

AQUACER 1547 Oxidized HDPE wax AQUAMAT 208 Oxidized HDPE wax AQUAMAT 263 Oxidized HDPE wax

X X X

X X X X

Wood, and architectural coatings Printing inks

Water/Dipro- pyleneglycol monometyl ether 12/1 Water

AQUAMAT 270 Modified PE wax AQUATIX 8421

55

125

Wood, architectural and industrial coatings Automotive coatings, industrial coatings

Modified EVA 20 copolymer wax PP = Polypropylene

Water

Non-ionic

105

PE = Polyethylene

HDPE = High Density Polyethylene

Product Guide L-G 1

February 2009

Wax Dispersions in Organic Solvents

Additive Wax base NonSolvents volatile matter (%) 40 20 20 20 Ethanol Dipropyleneglycol monomethylether Methoxypropylacetate Dipropyleneglycol monomethylether Butylglycol Butylglycol Butyldiglycolacetate/ Butyldiglycol/Aromatic hydrocarbons Melting Mechanical Surface point (wax resistance slip component) C 105 90 100 90 100 85 105 AntiAntiSoft- Gloss blocking, settling feel reducWater effect tion repellence OrienApplication areas tation of effect pigments Printing inks Can coatings Coil coatings Can/Coil coatings Can coatings Can coatings Can/Coil coatings

CERACOL 39 CERACOL 79 CERACOL 600 CERACOL 601 CERACOL 603 CERACOL 604 CERACOL 607

PE wax Carnauba wax Modified hydrocarbon wax Carnauba wax

X X X X X X X X X X X X X X X

Polymer/PTFE mixture 20 Carnauba wax PTFE-modified PE wax 11,5 35

CERACOL 609N Wax modified Lanolin 20 CERAFAK 100 CERAFAK 103 CERAFAK 106 CERAFAK 110 CERAFAK 111 CERAFAK 116 EVA Copolymer wax EAA Copolymer wax EVA Copolymer wax EVA Copolymer wax PE wax Modfied FT wax 10 6 6 6 12.5 25 15

Aromatic hydrocarbons/ 85 Isopropanol 1/1 Xylene/Butylacetate 1/1 105 Xylene/Butylacetate/ Butanol 7/8/1 Xylene/Butylacetate/ Butanol 7/8/1 Butylacetate/Butanol 15/1 Butylacetate Aromatic-free white spirit 110 105 100 110 110

Can/Coil coatings

X X X X X X X X X X X X X X X X X X X X X X X

FT = Fischer-Tropsch

X X X X X

Industrial coatings Automotive coatings Automotive coatings Automotive and industrial coatings Automotive and industrial coatings Architectural coatings Can/Coil coatings, architectural and industrial coatings

CERAFAK 127N FT wax

Aromatic hydrocarbons 120

X X X X X

X X

CERAFAK 131

PE wax

12.5 15 20 13.5 15 22 20 40 17.5 4.7 4.4 4.7 90 >98

Xylene Isobutanol/Aromatic hydrocarbons 13/4 Butanol/White spirit 1/1

115 90

Wood coatings Can coatings Industrial coatings Can coatings Industrial coatings

CERAFAK 140N Carnauba wax CERAFAK 180N Carnauba wax CERAFAK 184 Modified hydrocarbon wax Oxidized HDPE wax PE wax PE wax Oxidized HDPE wax EVA Copolymer wax EVA/EAA Copolymer wax mixture EVA Copolymer wax PE wax PE wax

Aromatic hydrocarbons 85 100

CERAFAK 186N Hydrocarbon wax CERAMAT 241 CERAMAT 248 CERAMAT 250 CERAMAT 258 CERATIX 8461 CERATIX 8463 CERATIX 8466 MINERPOL 220 MINERPOL 221 PE = Polyethylene

Aromatic hydrocarbons 95 Xylene/Butylacetate 1/1 135 Aromatic-free white spirit Butylacetate Butylacetate Xylene/Butylacetate/ Butanol 3/6/1 Xylene/Butylacetate/ Butanol 3/6/1 110 120 135 105 110

X X X

X X X X

Wood coatings Architectural coatings Wood coatings Can coatings, wood and industrial coatings

X X X

Automotive, wood and industrial coatings Automotive coatings Automotive, wood and industrial coatings Offset printing inks Offset printing inks

Butylacetate/Butanol 9/1 100 Linseed oil/Mineral oil Linseed oil 120 120

X X

EVA = Ethylene-Vinylacetate

HDPE = High Density Polyethylene

PTFE = Polytetrafluorethylene

EAA = Ethylene-Acrylic acid

10

February 2009

Product Guide L-G 1

Micronized Wax Additives

Additive Wax base Particle size (m) Melting point D10 D50 D90 (wax component) 1 6 14 115 C 160 160 160 135 Mecha- Surface Anti- Soft- Gloss Sand- Structure/ Outgassing reduc- ability Texture slip Slip feel nical of effect tion resistpowder ance coatings Pigment wetting in powder coatings Coating systems AquePow- Solder vent- ous coat- borne ings Application areas

AQUAFLOUR 400 Modified PE wax/polymer mixture CERAFLOUR 913 PP wax CERAFLOUR 914 PP wax CERAFLOUR 915 PP wax CERAFLOUR 916 Modified HDPE wax/ polymer mixture CERAFLOUR 920 Organic polymer

X X X X X

X X X X X X X X X X X X

X X X X X X

7 12 14 17

18 24 34 46

31 36 57 82

Wood, archi tectural, industrial coatings Wood and industrial coatings Wood and industrial coatings Wood and industrial coatings Wood and industrial coatings

13

X

2 8 15 115

CERAFLOUR 928 Modified PE wax

X

2 2 6 9 12 15 115 135

X X

CERAFLOUR 940 FT wax CERAFLOUR 950 Modified HDPE wax CERAFLOUR 960 Modified amide wax CERAFLOUR 961 Modified PE wax CERAFLOUR 962 Modified PE wax CERAFLOUR 965 PTFE CERAFLOUR 967 Synthetic polymer CERAFLOUR 968 PTFE modified PE wax CERAFLOUR 969 PTFE modified PE wax CERAFLOUR 970 PP wax CERAFLOUR 981 PTFE

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

Printing inks, wood, architectural, industrial coatings Wood and industrial coatings, Can coatings, overprint varnishes Printing inks Printing inks, wood, industrial coatings Powder coatings Powder coatings Powder coatings Powder coatings Powder coatings Powder coatings Powder coatings

1 2 2 8 2 2 2 1

4 5 9 31 6 6 9 3

11 10 24 80

145 140 140

300 11 14 14 8 115 115 160

X X X X X X X X X

CERAFLOUR 988 Amide modified PE wax CERAFLOUR 990 PE wax CERAFLOUR 991 PE wax

13

140

3 2

6 5

12 9

115 115

CERAFLOUR 993 Amide wax CERAFLOUR 994 Amide wax

3 1

13 5

31 10

145 145

CERAFLOUR 995 PE wax/Amide 2 wax mixture CERAFLOUR 996 PTFE modified 2 PE wax

11

140

11

115

CERAFLOUR 997 PTFE modified 2 PE wax

13

115

X

5 9 115

CERAFLOUR 998 PTFE modified 2 PE wax

X

PTFE = Polytetrafluorethylene FT = Fischer-Tropsch

Wood and industrial coatings Can/Coil coatings, wood and industrial coatings Wood and industrial coatings Architectural and industrial coatings Can/Coil coatings, wood and industrial coatings Wood and industrial coatings Can coatings, wood and industrial coatings Wood, architectural, industrial coatings Can/Coil coatings, wood, architectural, industrial coatings Can/Coil coa tings, wood coatings, archi tectural coatings, industrial coatings Coil/Can coatings, wood, architectural, industrial coatings

PE = Polyethylene

HDPE = High Density Polyethylene PP = Polypropylene

11

Product Guide L-G 1

February 2009

Silicone Defoamers

Additive Composition PolyHydro- Polymers Solvents/Carrier siloxane phobic particles BYK-017 BYK-018 BYK-019 BYK-020 BYK-021 BYK-022 BYK-023 BYK-024 BYK-025 BYK-028 BYK-044 BYK-045 BYK-060 N BYK-065 BYK-066 N BYK-067 A BYK-070 BYK-071 BYK-072 BYK-077 BYK-080 A BYK-085 BYK-088 BYK-093 BYK-094 BYK-141 BYK-1610 BYK-1615 BYK-1650 BYK-1660 BYK-1730 BYK-1770 BYK-A 530 Dipropyleneglycol monomethylether Butylglycol/Ethylhexanol/ White spirit 6/2/1 NonRecommended for volatile Aqueous systems Solvent-borne systems matter (%) Emulsions Amine- NonMedium- Polar neutral- polar polar ized >98 >97 60 10 >97 >97 18.5 >96 18.5 >98 57 8.5 2.8 0.7 0.7 89 Properties/Application areas Solventfree

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

X X

X X X

Millbase defoamer for glycol pastes and aqueous pigment concentrates Specifically for emulsion lacquers with low PVC For PU and PU/Acrylate systems

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

Also for aqueous UV systems PVC 18-25, also for airless application PVC 18-25, highly effective against micro foam PVC 30-50 PVC 0-25 Very easy incorporation (specifically for curtain coaters) Standard silicone defoamer for aqueous systems Millbase defoamer for glycol pastes and aqueous pigment concentrates For plasters and non-pigmented systems Broad effectivity in solvent-borne systems Standard silicone defoamer for solvent-borne systems Solvent-free and odor-free version of BYK-066 N For solvent-borne systems with medium to high polarity Specifically for low polar wood coatings Complies with FDA 175.300 Gives also good leveling

X X X X X X X X

Polyglycol Polyglycol Water Polyglycol Dipropyleneglycol monomethylether Polyglycol Water Water Diisobutylketone Cyclohexanone Diisoutylketone Propyleneglycol

Xylene/Methoxypropylacetate/ 9 Butylacetate 10/2/1 Xylene Xylene/Butanol/ Methylisobutylketone 2/1/1 Alkylbenzenes Propyleneglycol 3.5 1 52 87.5 >98 3.3 >98 >96 17 12.5 27.5 27.8 99.2 >96 5

Solvent-free version of BYK-077 Complies with FDA 175.300 Excellent effectivity and broad compatibility

X X X X X X X X

Isoparaffine Polyglycol Polyglycol Water Water Water Water Polyglycol Mixture of hydrocarbons

Alkylbenzenes/Isobutanol 11/2 3.2

Emulsion paints with medium PVC, also emulsion plasters Highly filled emulsion paints Emulsions paints with medium PVC (35-70) High gloss emulsion systems (PVK 20-50) VOC free High build systems (joinery) Specifically for epoxy systems

12

February 2009

Product Guide L-G 1

Polymer Defoamers (silicone-free)

Additive Composition Hydro- Polymers Solvents phobc particles BYK-011 BYK-012 BYK-016 BYK-051 BYK-052 Hydrocarbons/Ethylhexanol 21/1 NonRecommended for volatile Aqueous systems Solvent-borne systems matter (%) Emulsions Amine NonMedium- Polar neutral- polar polar ized 29 >96 >99 Properties/Application areas Solventfree

X X X

X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X X X X X X X X

Excellent effectivity in aqueous 2-pack PU systems Emulsion paints and plasters with a PVC of 30-85 Industrial coatings and printing inks Better compatibility than BYK-052, reduced effectivity Standard defoamer for industrial and architectural coatings (also available without aromatic solvents as BYK-1752) Less compatible than BYK-052, better effectivity Especially for 2-pack PU and epoxy systems Version of BYK-052 without aromatic solvents Specifically for solvent-free radiation curing systems Especially for polyester systems (wood and furniture coatings) Also for air release and better leveling Especially for 2-pack PU and epoxy systems

White spirit/Glycolic acid 20 butylester/Butylglycol 71/8/1 White spirit/Glycolic acid 20 butylester/Butylglycol 71/8/1 White spirit/Glycolic acid 20 butylester/Butylglycol 71/8/1 Isoparaffine Isoparaffine Alkylbenzenes/Methoxypropylacetate 12/1 Alkylbenzenes/Methoxypropylacetate 8/1 25 20 100 6.5 44 > 99

BYK-053 BYK-054 BYK-1752 BYK-1790 BYK-A 500 BYK-A 501 BYK-A 535

Mineral Oil Defoamers

Additive Composition Paraffin based mineral oils BYK-031 BYK-033 BYK-034 BYK-035 BYK-037 BYK-038 Hydrophobic particles Water Polysiloxane Alkylphenolethoxylate NonRecommended for volatile Emulsion Emulsion matter paints, plasters (%) exterior wall paints 53 >97 >97 >97 53.5 >96 Emulsion adhesives Industrial emulsions Emulsion lacquers Recommended Production PVC range of emulsion binders 50-85

X X X X X X

X X X X X X

X X X X X X X

X X X X

X X X

X X X

35-70

X X X

X X X

20-70 20-40 50-85 20-70

13

Product Guide L-G 1

February 2009

Rheology Additives (liquid)

Additive Composition NonActive Solvents volatile substance matter (%) (%) 52 52 Xylene/Alkylbenzenes/ Isobutanol 5/4/1 N-Methylpyrrolidone Recommended for Aqueous systems Solvent-borne systems Nonpolar Medium- Polar polar Properties/Application areas

BYK-405 BYK-410

Polyhydroxycarboxylic acid amides Modified urea

X X

X X

Enhances thixotropy in systems that contain pyrogenic silica Creates thixotropy. Avoids settling/sagging while maintaining good leveling and air release Creates thixotropy. Avoids settling/sagging while maintaining good leveling and air release Creates thixotropy. Especially useful to avoid settling in aqueous pigment slurries Creates pseudoplasticity; fast viscosity recovery after shearing gives excellent sag resistance High shear thickener Creates pseudoplasticity; fast viscosity recovery after shearing gives excellent sag resistance Creates pseudoplasticity; fast viscosity recovery after shearing gives excellent sag resistance

BYK-411

Modified urea

27

N-Methylpyrrolidone

X X X X

BYK-420 BYK-425 BYK-428 BYK-430 BYK-431 BYK-E 410 BYK-E 411 BYK-E 420

Modified urea Urea modified polyurethane Highly branched polyurethane

52 50 25

N-Methylpyrrolidone Polypropylene glycol 600 Water/Ethoxylates Isobutanol/Solvent naphtha 9/1 Isobutanol/ Monophenylglycol 9/1 N-Ethylpyrrolidone N-Ethylpyrrolidone N-Ethylpyrrolidone

High molecular urea modified 30 medium polar polyamide High molecular urea modified 25 non polar polyamide Modified urea Modified urea Modified urea 52 27 52

X X X X X X X

NMP free version of BYK-410 NMP free version of BYK-411 NMP free version of BYK-420

14

February 2009

Product Guide L-G 1

Inorganic UV Absorbers

Additive Composition NonCarrier volatile matter (%) 22 47 45 44 44 44 47 55 Water Aromatic-free white spirits Water Methoxypropylacetate Water Methoxypropylacetate Aromatic-free white spirits Water Particle content (%) 18 30 40 40 40 40 40 50 Particle size D50 (nm) 10 10 20 20 40 40 40 60 Recommended for Aqueous systems Solvent-borne systems Application areas

NANOBYK-3810 NANOBYK-3812 NANOBYK-3820 NANOBYK-3821 NANOBYK-3840 NANOBYK-3841 NANOBYK-3842 NANOBYK-3860

Cerium oxide nanoparticles Cerium oxide nanoparticles Zinc oxide nanoparticles Zinc oxide nanoparticles Zinc oxide nanoparticles Zinc oxide nanoparticles Zinc oxide nanoparticles Zinc oxide nanoparticles

X X X X X X X X

Wood care Wood care Transparent wood and furniture coatings, Transparent architectural coatings (wood care) Solvent-borne wood and industrial coatings Transparent wood and furniture coatings, Transparent architectural coatings (wood care) Wood care Wood care Pigmented systems, Thin transparent architectural coatings (wood care)

All UV absorbers can be used in combination with radical scavengers (HALS).

Adhesion Promoters

Additive Composition Acid value (mg KOH/g) Nonvolatile matter (%) Solvents Recommended for Aqueous systems Emulsions Amine neutralized 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate Methoxypropanol Solventborne baking systems Aqueous decorative coatings that are applied onto aged pigmented alkyd paints Application areas

BYK-4500 BYK-4510

High molecular weight block copolymer Copolymer with acidic groups

30

40 80

X X X

Baking systems for metallic substrates

Other Additives

Additive Composition Nonvolatile matter (%) Acid content (%) 20 Solvents Acid value (mg KOH/g) Amine value (mg KOH/g) 10 Recommended for Aqueous systems Solvent-borne systems Nonpolar Medium- Polar polar Powder coatings Processing additive Processing additive Blocked acid catalyst Properties

BYK-3950 P BYK-3951 P BYK-CATALYST 450

Copolymer with 100 pigment affinic groups Copolymer with 100 pigment affinic groups Amine salt of para-toluene sulfonic acid Amine salt of para-toluene sulfonic acid 26.5

X X X X X X X X X X X X X X X

Methoxypropanol/ 60 Propylene glycol/ Water 64/5/3 Propanol/ Methanol/ Water 58/10/2 Isobutanol 60

BYK-CATALYST 451

26.5

20

10

BYK-ES 80

Alkylolammonium salt of an unsaturated acidic carboxylic acid ester Alkylolammonium salt 8.5 of acidic phosphoric acid esters + ketoxime 4 Combination of surface active low molecular weight polymers Combination of high boiling solvents Modified urea <1

140

140

Increases conductivity for electrostatic application Anti-gelling additive and viscosity stabilizer Avoids surface defects in aqueous systems Avoids surface defects in architectural and industrial coatings Reduces drying and caking of aqueous pigment concentrates

BYKANOL-N

Isobutanol/ Xylene/Water 10/6/1

16

17

X X X X X

BYKETOL-AQ

Methoxypropanol

BYKETOL-OK

Alkylbenzenes/ Diisobutylketone/ Dipentene Water

BYKETOL-PC

90

BYKETOL-Special

Combination of high boiling solvents

<1

Alkylbenzenes/ Diisobutylketone

Avoids surface defects in architectural and industrial coatings; contains silicone Avoids surface defects in aqueous systems

BYKETOL-WS

Cobination of surface active low molecular weights polymers

Butylglycol

15

Product Guide L-G 1

Products and Applications

BYK Additives

Additives are used during the production of coatings, printing inks and plastics to optimize the production process and to improve the quality of the final product. Product Range Additives Additives to improve surface slip, leveling and substrate wetting Adhesion promoters Defoamers and air release agents Foam stabilizers Processing additives Rheological additives UV-absorbers Viscosity depressants Waxes Wetting and dispersing additives for pigments and extenders Application Areas Ambient curing resins (FRP) Architectural coatings Automotive OEM Automotive refinishes Can coatings Coil coatings Color masterbatches Industrial coatings Leather coatings Marine paints Molding compounds Paper coatings Pigment concentrates Polyurethane foams Powder coatings Printing inks Protective coatings PVC plastisols Thermoplastics Wood and furniture coatings

BYK Instruments

BYK offers a complete line of testing instruments to meet your needs in many application areas: Gloss/Appearance Color Portable or stationary laboratory equipment including easy to use quality control software. BYK instruments the complete solution for the coatings and plastics industry.

BYK USA Inc. 524 South Cherry Street P.O. Box 5670 Wallingford, CT 06492 USA Tel 203 265-2086 Fax 203 284-9158 cs.usa@byk.com www.byk.com/additives

BYK-Gardner USA 9104 Guilford Road Columbia, MD 21046 USA Tel 800 343-7721 301 483-6500 Fax 800 394-8215 301 483-6555 custserv.byk.gardnerusa@altana.com www.byk.com/instruments

ANTI-TERRA, BYK, BYK-DYNWET, BYK-SILCLEAN, BYKANOL, BYKETOL, BYKOPLAST, BYKUMEN, DISPERBYK, DISPERPLAST, LACTIMON, NANOBYK, SILBYK and VISCOBYK are registered trademarks of BYK-Chemie. AQUACER, AQUAFLOUR, AQUAMAT, CERACOL, CERAFAK, CERAFLOUR, CERAMAT, CERATIX and MINERPOL are registered trademarks of BYK-Cera. This information is given to the best of our knowledge. Because of the multitude of formulations, production, and application conditions, all the above-mentioned statements have to be adjusted to the circumstances of the processor. No liabilities, including those for patent rights, can be derived from this fact for individual cases. This brochure replaces all previous issues printed in the USA.

02/2009

Das könnte Ihnen auch gefallen

- LuDokument15 SeitenLutahera aqeelNoch keine Bewertungen

- PDFDokument30 SeitenPDFtahera aqeelNoch keine Bewertungen

- Pen Rchive Oulouse Rchive Uverte : O A T A O OataoDokument32 SeitenPen Rchive Oulouse Rchive Uverte : O A T A O Oataotahera aqeelNoch keine Bewertungen

- BET Explains How Blade Design Impacts Helicopter PerformanceDokument33 SeitenBET Explains How Blade Design Impacts Helicopter PerformanceAnonymous Da8GxwVNoch keine Bewertungen

- 5 1033 PDFDokument12 Seiten5 1033 PDFtahera aqeelNoch keine Bewertungen

- E-Mail Corresponding Author: Vroemen@dtinnovations - NLDokument7 SeitenE-Mail Corresponding Author: Vroemen@dtinnovations - NLtahera aqeelNoch keine Bewertungen

- 01 08 2017Rs.7500Dokument6 Seiten01 08 2017Rs.7500tahera aqeelNoch keine Bewertungen

- IPST05 Paper162Dokument6 SeitenIPST05 Paper162mohamedahmedmouradNoch keine Bewertungen

- 8.31 Mercury in Water: S. Nishi B. G. LiptákDokument7 Seiten8.31 Mercury in Water: S. Nishi B. G. Liptáktahera aqeelNoch keine Bewertungen

- 1083fm PDFDokument46 Seiten1083fm PDFMohamed NaserNoch keine Bewertungen

- Frankovic 4Dokument14 SeitenFrankovic 4tahera aqeelNoch keine Bewertungen

- Electric Mqchine Martinez JasminDokument71 SeitenElectric Mqchine Martinez JasminShradhaSharmaNoch keine Bewertungen

- User Manual: FDTD & Code BasicsDokument37 SeitenUser Manual: FDTD & Code Basicstahera aqeelNoch keine Bewertungen

- CVF PGDokument867 SeitenCVF PGThiago VelosoNoch keine Bewertungen

- Discussion Forum - Solarwaterheaters2Dokument32 SeitenDiscussion Forum - Solarwaterheaters2tahera aqeelNoch keine Bewertungen

- National Income, Saving and Investment: Handbook of Statistics On Pakistan EconomyDokument10 SeitenNational Income, Saving and Investment: Handbook of Statistics On Pakistan Economytahera aqeelNoch keine Bewertungen

- STL Radm 89Dokument39 SeitenSTL Radm 89tahera aqeelNoch keine Bewertungen

- n9415 PDFDokument9 Seitenn9415 PDFtahera aqeelNoch keine Bewertungen

- Radiation Intensities and Heat-Transfer in Boiler FurnacesDokument33 SeitenRadiation Intensities and Heat-Transfer in Boiler Furnacestahera aqeelNoch keine Bewertungen

- IndustrialEngineering 2011 12Dokument62 SeitenIndustrialEngineering 2011 12syedamiriqbalNoch keine Bewertungen

- Brand-Product RelationshipDokument17 SeitenBrand-Product Relationshiptahera aqeelNoch keine Bewertungen

- Ajme 4 2 1Dokument8 SeitenAjme 4 2 1tahera aqeelNoch keine Bewertungen

- 5 Polyester Resins PDFDokument7 Seiten5 Polyester Resins PDFSakti Arss0% (1)

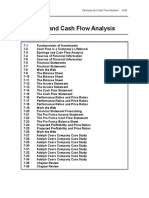

- Earnings and Cash Flow Analysis: SlidesDokument6 SeitenEarnings and Cash Flow Analysis: Slidestahera aqeelNoch keine Bewertungen

- 08 ProgrammersGuideDokument131 Seiten08 ProgrammersGuidelanforex90522Noch keine Bewertungen

- Troubleshoot Higher Voltages ATX Power SupplyDokument0 SeitenTroubleshoot Higher Voltages ATX Power SupplyTim Willform100% (3)

- Engineering EconomicsDokument13 SeitenEngineering Economicstahera aqeelNoch keine Bewertungen

- Research Article: Synthesis and Thermal Degradation Studies of Melamine Formaldehyde ResinsDokument7 SeitenResearch Article: Synthesis and Thermal Degradation Studies of Melamine Formaldehyde Resinstahera aqeelNoch keine Bewertungen

- United States Patent (191 ': HoracekDokument5 SeitenUnited States Patent (191 ': Horacektahera aqeelNoch keine Bewertungen

- Melamine Formaldehyde Curing Studies andDokument7 SeitenMelamine Formaldehyde Curing Studies andtahera aqeelNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Cyanoacrylate Fuming Method For Detection of LatenDokument8 SeitenCyanoacrylate Fuming Method For Detection of LatenRozalia PiperNoch keine Bewertungen

- Im 440.600aa Chemad-ADokument69 SeitenIm 440.600aa Chemad-AAlejandro VerdugoNoch keine Bewertungen

- A Report On Brinjal Shoot and Fruit Borer and Its ManagementDokument15 SeitenA Report On Brinjal Shoot and Fruit Borer and Its Managementapi-522184233Noch keine Bewertungen

- Journal of Environmental ManagementDokument8 SeitenJournal of Environmental ManagementsadsdaNoch keine Bewertungen

- What Is Organic Compound?Dokument3 SeitenWhat Is Organic Compound?Mark Joseph LatadeNoch keine Bewertungen

- ORG 3 Palladium Catalysis The Suzuki Reaction LMDokument6 SeitenORG 3 Palladium Catalysis The Suzuki Reaction LMVictor OdoyoNoch keine Bewertungen

- ReviewerDokument7 SeitenReviewerTristan BaceraNoch keine Bewertungen

- Lai2002 PDFDokument10 SeitenLai2002 PDFHimanshuNoch keine Bewertungen

- NITRIC ACID 68-70%: Safety Data SheetDokument9 SeitenNITRIC ACID 68-70%: Safety Data Sheetduong nguyenNoch keine Bewertungen

- Food ChemistryDokument10 SeitenFood ChemistryDaniela RamosNoch keine Bewertungen

- Evs AssignmentDokument8 SeitenEvs AssignmentBhavya PandeyNoch keine Bewertungen

- A Comprehensive Review On Kenaf Seeds and Leaves For MedicineDokument8 SeitenA Comprehensive Review On Kenaf Seeds and Leaves For Medicineportracer.idNoch keine Bewertungen

- Sewage Treatment TechniquesDokument208 SeitenSewage Treatment TechniquesBarecha HailuNoch keine Bewertungen

- Ap Bio Review Unit 1 BiochemistryDokument8 SeitenAp Bio Review Unit 1 Biochemistryapi-210373179Noch keine Bewertungen

- Automated Sample Preparation For Fame Analysis in Edible Oils Using An Agilent 7696A Sample Prep WorkbenchDokument8 SeitenAutomated Sample Preparation For Fame Analysis in Edible Oils Using An Agilent 7696A Sample Prep WorkbenchGiang Nguyễn Thị HươngNoch keine Bewertungen

- Physiological Basis For Mid Storage CorrectionDokument11 SeitenPhysiological Basis For Mid Storage CorrectionsathishsstNoch keine Bewertungen

- Grain Crop and ProductsDokument73 SeitenGrain Crop and ProductsMohamed Ali AtigNoch keine Bewertungen

- Lican CellsDokument2 SeitenLican CellsGillian HuangNoch keine Bewertungen

- Chemical Properties of CarbohydratesDokument2 SeitenChemical Properties of CarbohydratesD K SRIVASTAVA75% (8)

- PCOG LEC - Assignment 5 (Volatile Oils)Dokument4 SeitenPCOG LEC - Assignment 5 (Volatile Oils)sadburgerNoch keine Bewertungen

- Use of Whey in Controlling Calf DiarrhoeaDokument27 SeitenUse of Whey in Controlling Calf DiarrhoeanaturalamirNoch keine Bewertungen

- Syllabus - Name ReactionDokument4 SeitenSyllabus - Name ReactionVASUNDHRA DNoch keine Bewertungen

- Chapter 8Dokument59 SeitenChapter 8ashenafiNoch keine Bewertungen

- SSC CGL 2023 26th July (Shift-4) All GK QuestionsDokument2 SeitenSSC CGL 2023 26th July (Shift-4) All GK QuestionsBADUGU AKSHAY STUDENT - B.A PPENoch keine Bewertungen

- Investigating The Caffeine Content (MG) in Different Brands of Black Tea (Tetley Black Tea, AmericaDokument15 SeitenInvestigating The Caffeine Content (MG) in Different Brands of Black Tea (Tetley Black Tea, AmericaMM DomìN8RNoch keine Bewertungen

- CHEM 210 Karty Exam 2Dokument19 SeitenCHEM 210 Karty Exam 2nm100% (1)

- Formula of 105 DEG C PVC (Polyvinyl Chloride) Cable SheathDokument2 SeitenFormula of 105 DEG C PVC (Polyvinyl Chloride) Cable SheathPVC XANH QDNoch keine Bewertungen

- Identification of Biochemicals in Pure Form and in Food SamplesDokument2 SeitenIdentification of Biochemicals in Pure Form and in Food SamplesNick MillerNoch keine Bewertungen

- Fluoroplastic: Ptfe Semifinished Products and Finished PartsDokument10 SeitenFluoroplastic: Ptfe Semifinished Products and Finished PartsJohnNoch keine Bewertungen

- OperationDokument11 SeitenOperationmahboobiqbal09Noch keine Bewertungen