Beruflich Dokumente

Kultur Dokumente

Appendix 3 HRSG Water Quality R1

Hochgeladen von

yuchakrOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Appendix 3 HRSG Water Quality R1

Hochgeladen von

yuchakrCopyright:

Verfügbare Formate

Appendix-3

Information This document is related only to HRSG side guideline. For more detailed information and procedure, please refer to ST and Common side OMM documents. HRSG WATER QUALITY

Combined cycle feed water shall be treated with hydrazine & ammonia while boiler water with sodium phosphate as per Mitsubishi recommended criteria mentioned in Table-1. More preservation criteria mentioned in Table-2.

The criteria are base from the following items.

a.

Boiler Drum pressure for silica limitation of boiler water. Maximum allowable limit of silica in the boiler water varies in accordance with the Steam drum pressure. Specially, at higher drum pressure silica limitation must strictly observe. Because silica carry over ratio to the steam at higher steam drum pressure is high. (Refer to Fig.-1 Operating limit of Silica in Steam Drum.)

b. pH limitation for condenser cooling tube materials. When copper alloy material is applied, pH should be lower to the range of 8.8 ~ 9.2 in order to prevent copper corrosion by ammonia attack. In the case of copper free material, pH can be set higher around 9.3 ~ 9.6 in order to minimize the corrosion rate of carbon steel which is the main material cycle. Particularly, feed water pH can be control at higher range such as 9.3 ~ 9.6, because titanium material is use for the condenser cooling tubes in this plant, and these material are tolerable for higher pH.

c.

Boiler water treatment Low pH coordinated treatment is recommended for the boiler water by the following reasons. c.1. Scale growth rate inside the evaporator tubes may be reduced, and this will prolong the boiler acid cleaning interval. In addition, this treatment will not produce a thicker, low density and porous scale that may develop over heat to the evaporator tubes. c.2. Caustic corrosion caused by free caustic soda can be prevented, because disodium phosphate will make a reverse hydrolysis reaction with trisodium phosphate.

Na3PO4 + H2O

Na2HPO4 +

NaOH

Mitsubishi recommend the mixing ratio as Na / PO4 = 2.8.

MITSUBISHI HEAVY INDUSTRIES, LTD.

-1-

Appendix-3

TABLE- 1

Sampling Point Condensate pump discharge

MITSUBISHI RECOMMENDED CRITERIA

Unit S/cm mg O/l at 25C S/cm S/cm mg O/l mg Fe/l mg Cu/l mg N2H4/l mg/l at 25C S/cm mg Cl/l mg SiO2/l mg PO4/l at 25C S/cm mg Cl/l mg SiO2/l mg PO4/l at 25C S/cm mg Cl/l mg SiO2/l mg PO4/l mg SiO2/l S/cm Criteria (Target) 1.0(< 0.5) (< 0.015 8.5 ~ 9.6 (9.3 ~ 9.5) 5.5 ~ 12( 3.0 ~ 8.5 ) < 0.5 < 0.007 (< 0.02) (< 0.01) (above 0.01) To keep nearly 0 10.0 ~ 10.5(9.8 ~ 10.8) 150 (< 2) (< 2) 10 ~ 30 10.0 ~ 10.5(9.4 ~ 10.5) 150 (< 2) (< 2) 10 ~ 30 9.2 ~ 9.8(8.5 ~ 9.8) 60 (< 2) (< 0.2) 1 ~ 10 < 0.02 < 0.3 see Note *(1) see Note *(3) Set at 6.2, see Note *(2) see Note *(1) Remarks see Note *(1)

Description Electric Conductivity Dissolved Oxygen pH Electric Conductivity Electric Conductivity Dissolved Oxygen

Feed Water Total Iron Total Copper Hydrazine Oil pH LP Drum Electric Conductivity Chloride Silica Phosphate pH IP Drum Electric Conductivity Chloride Silica Phosphate HP Drum pH Electric Conductivity Chloride Silica Phosphate Saturated Steam Silica Electric Conductivity

Note

*(1) : Conductivity passed through strong cation exchange resin *(2) : Conductivity given corresponding to pH range such as 9.0 ~ 9.5. *(3) : Na/PO4 = 2.8

MITSUBISHI HEAVY INDUSTRIES, LTD.

-2-

Appendix-3

3.6 3.2

pH > 10.3

Silica in Steam Drum (mg/l)

2.8 2.4 2.0 1.6 1.2 0.8 0.4 0.0 90 100 110 120 130 140 150 160

2

pH 9.3 pH 9.0

170

180

190

Boiler Drum Pressure (kg/cm g)

Fig.-1

Operating Limit of Silica in Steam Drum

[Explanation] When the boiler drum operating pressure is 130kg/cm2g, maximum limit of silica in the steam drum water is approx. 0.8mg/l from the above curve based on the pH in boiler water of 9.3, because maximum limit is also depending upon its pH. [Continuous blow valve Operation] The steam drum continuous blow valve opening determined by the water quality and the operator shall coordinate with the chemist for the related analysis results and the recommended valve opening positions. Normally small amount of the drum water is always blows down to keep a good water quality. Initial opening of the continuous blow valve recommended position around 10%. Refer to Fig-2 Steam Drum Continuous Blow Valve Performance Curve.

MITSUBISHI HEAVY INDUSTRIES, LTD.

-3-

Appendix-3

PHOSHATE(PO4) INJECTION PROCEDURE

On-line conductivity meter for the steam drum water sample shall be in service prior to the start of phosphate injection. Phosphate is injected to HP, IP, & LP steam drum in order thru the separate pump based on each on-line conductivity meter readings. For example, if the IP Drum conductivity is still above the start condition, phosphate pump will be started to inject phosphate solution into the IP Drum first, then next into the LP Drum for each duration set in AUTO mode.

PO4 Target mg/l LP Drum IP Drum HP Drum min. max. min. max. min. max. 10 30 10 30 1 10 < 8 S/cm < 50S/cm PO4 injection Start Duration condition < 55S/cm 100% stroke x 25min. 100% stroke x 15min. 40% stroke x 5min.

100% x 5min. HP DRUM

30min. Timer

100% x 15min.

25min. Timer

Re-injection If conductivity still low

IP DRUM

100% x 25min.

25min. Timer

LP DRUM STAND-BY

MITSUBISHI HEAVY INDUSTRIES, LTD.

-4-

Appendix-3

TABEL-2

PRESERVATION GUIDE LINE

Duration Section CONDENSER HOTWELL 1 to 3 Days 4 to 7 Days 8 to 30 Days N2H4 50mg/l x (Week) Over 30 Days N2H4 50mg/l x (Week) <Upper Limit 500mg/l> ECO, EVAPOORAT OR & STEAM DRUM

N2H4 50mg/l N2H4 50mg/l X (Week) and N2 Pressurized Prezervation N2H4 50mg/l X (Week) < Upper Limit 500mg/l> and N2 Pressurized Prezervation

Preservation under unit stop condition

N2H4 50mg/l

Hot Banking

and N2 Pressurized Prezervation

SH & MS PIPE

Valve Shutting under unit stop condition

N2 Pressurized Prezervation

N2 Pressurized Prezervation

N2 Pressurized Prezervation

RH, LTR & HTR PIPE

Valve Shutting under unit stop condition

Drying-out

Drying-out

Drying-out

MITSUBISHI HEAVY INDUSTRIES, LTD.

-5-

Appendix-3

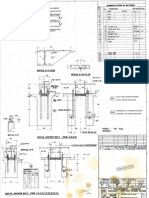

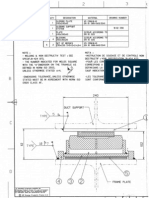

Fig.-2 Steam Drum Continuous Blow Valve Performance Curve

MITSUBISHI HEAVY INDUSTRIES, LTD.

-6-

Appendix-3

Fig.-2 Steam Drum Continuous Blow Valve Performance Curve

MITSUBISHI HEAVY INDUSTRIES, LTD.

-7-

Appendix-3

Fig.-2 Steam Drum Continuous Blow Valve Performance Curve

MITSUBISHI HEAVY INDUSTRIES, LTD.

-8-

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- ABQ - Stack Silencer Lower Braket Revised DrawingDokument2 SeitenABQ - Stack Silencer Lower Braket Revised DrawingyuchakrNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- ABQ, RTR Site Stack Silencer Lower Braket RepairDokument2 SeitenABQ, RTR Site Stack Silencer Lower Braket RepairyuchakrNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Sliding Support PDFDokument6 SeitenSliding Support PDFyuchakrNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- 2.support Leg Detail PDFDokument4 Seiten2.support Leg Detail PDFyuchakrNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Support Frame PDFDokument1 SeiteSupport Frame PDFyuchakrNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Dummy Duct Plan Rev.3 PDFDokument5 SeitenDummy Duct Plan Rev.3 PDFyuchakrNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- TPM01 Attachment #2 EXHAUST DUCT On GT SIDE-New PDFDokument2 SeitenTPM01 Attachment #2 EXHAUST DUCT On GT SIDE-New PDFyuchakrNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Support Frame PDFDokument1 SeiteSupport Frame PDFyuchakrNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Slidding Support PDFDokument1 SeiteSlidding Support PDFyuchakrNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- 11 - Acoustics DBD - Baseline PDFDokument36 Seiten11 - Acoustics DBD - Baseline PDFyuchakrNoch keine Bewertungen

- Khabat Thermal Power Plant Appendices Flow DiagramsDokument70 SeitenKhabat Thermal Power Plant Appendices Flow Diagramsyuchakr100% (2)

- Boillngout - ' - """"""""""""""": Care of Boiler Out of ServiceDokument20 SeitenBoillngout - ' - """"""""""""""": Care of Boiler Out of ServicesellappanNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Part 3 Power Plant Volume I PDFDokument850 SeitenPart 3 Power Plant Volume I PDFyuchakr100% (5)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Design of Compact Plate Fin Heat ExchangerDokument61 SeitenDesign of Compact Plate Fin Heat ExchangerIndra Uchiha100% (3)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Circulation of BoilerDokument5 SeitenCirculation of BoilerMuralikrishna ArigondaNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Steam Plant OperationDokument794 SeitenSteam Plant Operationgladiatork00793% (14)

- EnvironmentDokument6 SeitenEnvironmentyuchakrNoch keine Bewertungen

- Internal Circulation CFB Boiler PDFDokument11 SeitenInternal Circulation CFB Boiler PDFAkhilesh Kumar0% (1)

- Thermal Insulation Calculation SoftwareDokument2 SeitenThermal Insulation Calculation Softwareyuchakr100% (3)

- Dec - 2011Dokument20 SeitenDec - 2011Raktim DekaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Composition of Exhaust Gases From Diesel Gasoline and Propane Powered Motor CoachesDokument7 SeitenThe Composition of Exhaust Gases From Diesel Gasoline and Propane Powered Motor CoachesAhmad BilaalNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- New Sample Prep and Data Analysis For Analyzing Pesticides in FoodsDokument42 SeitenNew Sample Prep and Data Analysis For Analyzing Pesticides in FoodsdonkixNoch keine Bewertungen

- Stability of Food Emulsions (2) : David Julian McclementsDokument37 SeitenStability of Food Emulsions (2) : David Julian McclementsscribdGMMEGANoch keine Bewertungen

- Organic Chemistry Some Basic Principles and Techniques - WatermarkDokument29 SeitenOrganic Chemistry Some Basic Principles and Techniques - WatermarkPrathviraj SinghNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Seimens PS 555Dokument26 SeitenSeimens PS 555HoangNoch keine Bewertungen

- Assignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Dokument8 SeitenAssignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Andaradhi NararyaNoch keine Bewertungen

- PaperDokument48 SeitenPaperAnonymous MHKrd6RNoch keine Bewertungen

- Coa - Argan Oil Organic PDFDokument1 SeiteCoa - Argan Oil Organic PDFDhaval SoniNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- TheSouthernWarPoetryoftheCivilWar 10134200Dokument195 SeitenTheSouthernWarPoetryoftheCivilWar 10134200Isaiah ThomasNoch keine Bewertungen

- NCSE 2013 Integrated ScienceDokument22 SeitenNCSE 2013 Integrated ScienceMicahNoch keine Bewertungen

- Shape Memory AlloysDokument16 SeitenShape Memory AlloysginejonathanNoch keine Bewertungen

- Chemistry Investigatory Project Efforts By: Yash Raj Singh Xii-DDokument15 SeitenChemistry Investigatory Project Efforts By: Yash Raj Singh Xii-DSatyam NegiNoch keine Bewertungen

- Jiacheng Yang, Tianbo Tang, Yu Jiang, Georgios Karavalakis, Thomas D. Durbin, J. Wayne Miller, David R. Cocker III, Kent C. JohnsonDokument9 SeitenJiacheng Yang, Tianbo Tang, Yu Jiang, Georgios Karavalakis, Thomas D. Durbin, J. Wayne Miller, David R. Cocker III, Kent C. JohnsonMohamed TaalbiNoch keine Bewertungen

- Composite Propellant 2 PDFDokument9 SeitenComposite Propellant 2 PDFAishwarya NNoch keine Bewertungen

- REDOX EQUILIBRIUM (Teacher's Copy)Dokument34 SeitenREDOX EQUILIBRIUM (Teacher's Copy)jiaNoch keine Bewertungen

- Neurotoxicologists urged consider effects safety healthDokument2 SeitenNeurotoxicologists urged consider effects safety healthpmp aspirantNoch keine Bewertungen

- ICIS Green ChemicalsDokument1 SeiteICIS Green ChemicalsstevierayoNoch keine Bewertungen

- Capitolo 15Dokument20 SeitenCapitolo 15Juan Pablo CorreaNoch keine Bewertungen

- Pacop Red Pharmaceutical ChemistryDokument109 SeitenPacop Red Pharmaceutical ChemistryAstherielle GalvezNoch keine Bewertungen

- Specification Data: Starquick® Self-Locking Pipe ClampDokument6 SeitenSpecification Data: Starquick® Self-Locking Pipe ClampأبومحمدالزياتNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Cambridge Secondary Two Science: Chapter 9: Material ChangesDokument28 SeitenCambridge Secondary Two Science: Chapter 9: Material ChangesarenestarNoch keine Bewertungen

- Bio Polishing EnzymeDokument3 SeitenBio Polishing Enzymefebry_yulindraNoch keine Bewertungen

- Mott - HyPulse Element FilterDokument12 SeitenMott - HyPulse Element FilterCristhian CuevaNoch keine Bewertungen

- Effect of PH On Corrosion RateDokument8 SeitenEffect of PH On Corrosion RateياسرشلالالحسنيNoch keine Bewertungen

- 45 - Miscible DisplacementDokument15 Seiten45 - Miscible Displacementrizal tri susilo67% (3)

- Sponge IronDokument11 SeitenSponge IronVenkatadurgarao VendraNoch keine Bewertungen

- Synthesis of PetrochemicalsDokument9 SeitenSynthesis of PetrochemicalsAnoop UchagawkarNoch keine Bewertungen

- Introduction To BiopharmaceuticsDokument106 SeitenIntroduction To BiopharmaceuticsHely Patel100% (1)

- Chloride 8113Dokument6 SeitenChloride 8113okgnosasNoch keine Bewertungen

- Why We Die: The New Science of Aging and the Quest for ImmortalityVon EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Summary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisVon EverandSummary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisBewertung: 5 von 5 Sternen5/5 (8)

- The Fabric of Civilization: How Textiles Made the WorldVon EverandThe Fabric of Civilization: How Textiles Made the WorldBewertung: 4.5 von 5 Sternen4.5/5 (57)