Beruflich Dokumente

Kultur Dokumente

Guidelines On Slaughter in Small Scale Chicken SH E

Hochgeladen von

NOVASTAR222Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Guidelines On Slaughter in Small Scale Chicken SH E

Hochgeladen von

NOVASTAR222Copyright:

Verfügbare Formate

GUIDELINES ON CHICKEN SLAUGHTERING AND CHICKEN MEAT HANDLING IN SMALL SCALE CHICKEN SLAUGHTERHOUSES

DIRECTORATE OF VETERINARY PUBLIC HEALTH DIRECTORATE GENERAL OF LIVESTOCK SERVICES MINISTRY OF AGRICULTURE 2006

FOREWORD Chicken meat in Indonesia is produced by big and small scale chicken slaughterhouses (RPA). Most chicken slaughterhouses in Indonesia have not met hygienic-sanitation requirements yet. Chicken meat is categorized as perishable and potentially harmful food (containing bacteria, virus, parasite, etc) which affect human health. Improper condition and handling procedure, which do not fulfill hygiene-sanitation requirements, will affect the quality and safety of chicken meat produced in slaughterhouses. It is necessary to issue a guideline on chicken slaughtering and chicken meat handling procedure in small scale slaughterhouses in order to improve the quality of chicken meat consumed by community. This guidance includes procedure on handling chicken before slaughtering, halal and good slaughtering, carcass and chicken meat handling as well as distribution process. Hopefully, this guidance will be useful for all stakeholders in producing safe, healthy, pure and halal (ASUH) chicken meat.

Jakarta, October 2006 Directorate of Veterinary Public Heath

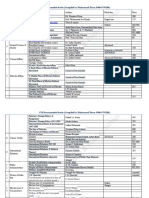

CONTENT Page DEFINITION INTRODUCTION. CHICKEN SLAUGHTERING PROCEDURE CHICKEN HANDLING PRIOR TO SLAUGHTERING Chicken Handling in Farm Chicken Transportation from Farm to Slaughterhouse . Chicken Handling in Slaughterhouse ANTEMORTEM EXAMINATION . CHICKEN HANDLING RIGHT BEFORE SLAUGHTERING ... Chicken Slaughtering with Stunning . Chicken Slaughtering without Stunning HALAL SLAUGHTERING PROCEDURE Slaughtering Requirements .. Slaughtering Procedure with Stunning .. Slaughtering Procedure without Stunning CHICKEN HANDLING AFTER SLAUGHTERING Scalding in Hot Water Plucking . Evisceration POSTMORTEM EXAMINATION CARCASS HANDLING . Carcass Washing and Chilling/Rinsing .... Carcass Packaging and Transporting SANITATION OF BUILDING, EQUIPMENTS AND ENVIRONMENT AROUND SLAUGHTERHOUSE . Requirements of Hygiene and Sanitation ... Method of Cleaning and Sanitation ... PERSONAL HYGIENE

PICTURE Page Chicken Slaughtering Procedure in Slaughterhouse .... Basket Piling in the Truck . Refreshing Chicken before Slaughtering Chicken Isolation Basket for Chicken which may not be slaughtered .... Machine Stunner for Chicken Slaughterhouse using carousel system ... Manual Chicken Stunner...

1. 2. 3. 4. 5. 6.

DEFINITION Slaughterhouse, a building area with special design and construction which meets certain techniques and hygiene requirements, is used as a chicken slaughterhouse for public consumptions purpose. Carcass is part of chickens body after slaughtering, plucking, and eviscerating, either with or without head-neck, and/or feet starting from tarsus and/or air sack and kidney. Chicken Meat is the slaughtered part of chicken that is edible for human, including the skin. Viscera are the chickens liver (after the gallstone is removed), heart, colon and other organs located in chest and stomach abdominal which are edible after passing the cleaning and washing procedure. Dirty Zone is a place with high level of biological, chemical and physical pollution. Clean Zone is a place with low level of biological, chemical and physical pollution. Animal Welfare is humans effort to raise animal with proper farming practice and protection. Antemortem examination is an examination on chickens health before slaughtering, which is done by a veterinarian or an authorized official of animal health under the supervision of an authorized veterinarian. Postmortem examination is an examination on chickens health after slaughtering, which is done by a veterinarian or an authorized official of animal health under the supervision of an authorized veterinarian. Sanitizer is a chemical used to decrease/eliminate microorganism. Disinfection is the act of reducing microorganism by using chemical materials and/or physical method, which to some extent does not harm the safety and edibility of the food. Hygiene is a condition or practice to raise and improve the health status as well as to prevent disease. Sanitation is a disease prevention measure that is done by eliminating or managing environmental factors related to the movement chain of the disease. Halal slaughtering is an animal slaughtering procedure which complies with Islamic Law. Chicken meat for human consumption should meet the ASUH requirements as follows:

Aman (safe) : it does not contain biological, chemical and physical danger causing risk to human health. Sehat (healthy) : it contains useful substances needed for health and bodys growth. Utuh (pure) : it is not mixed with other part of the animal or part of other animal. Halal : it is slaughtered and handled based on Islamic Law.

INTRODUCTION Year by year, the increasing chicken meat demand for consumption has indicated that people are very interested in this animal food commodity. They are interested in this commodity because it is relatively affordable for all community levels as well as its continuous supply is adequate and easy to get. The phenomenon of this high demand also becomes a chance to trigger the interest of small scale entrepreneurs in downstream sectors to play a part in this business. The quantity of this business group even develops rapidly so that most product supplies can fulfill the communitys needs. Ironically, this rapid development is not followed by quality improvement. Based on the observation made, the main aspect of customers need (that is the need to have safe and edible food) is likely to be ignored. The development of small scale chicken meat business is getting more uncontrolled, and the business quality is overlooked. This issue is indicated in a bad practice, which is against business ethic, such as formaldehyde-preserved carcasses, meat from chickens which died right before being slaughtered (TIREN or DUREN chickens), water injection to carcass, etc. This bad practice, caused by the entrepreneurs incomprehension and ignorance, is an implication of the governments weak guidance and monitoring that have made the technical aspects of hygiene-sanitation for customer protection not optimally implemented. Given to these issues, this book is developed to provide field technical officers with a practical guideline for their community development activities so that the food safety aspect, particularly chicken meat, in small scale business is gradually improved.

CHICKEN SLAUGHTERING PROCESS Having a halal and good chicken slaughtering (halalan thoyyiban) process, which also fulfills hygienic-sanitation requirements, results in ASUH (aman/safe, sehat/healthy, utuh/pure and halal) complete or cut carcasses. It is also important to consider about animal welfare while handling life chicken before it is slaughtered. This animal welfare should be applied both in the farm and in the slaughtered house where the animals are slaughtered. The animal welfare covers 5 (five) basic principles, also known as five freedoms to fulfill animals basic need, so that the animals have their: (1) Freedom from hunger and thirst, (2) Freedom from discomfort, (3) Freedom from pain, injury and disease, (4) Freedom to express normal behavior, (5) Freedom from fear and distress. In general, the chicken slaughtering process consists of (1) chicken handling before slaughtering, (2) antemortem examination, (3) chicken slaughtering, (4) postmortem examination and (5) carcass/chicken meat handling. Below is the flow of chicken slaughtering process at a small scale chicken slaughterhouse:

Life Chicken Handling

Antemortem Examination

Stunning

Halal Slaughtering

Scalding in Hot Water

Plucking

Evisceration

Postmortem Examination

Carcass Washing and Chilling

Carcass Packaging

This step may be skipped due to the availability of stunning device.

Picture 1 Chicken Slaughtering Procedure in Slaughterhouse (see picture 1 in original text)

CHICKEN HANDLING PRIOR TO SLAUGHTERING Chicken Handling in Farm The slaughtered chicken must be healthy and slaughtered properly in order to get a good quality chicken meat. Chickens to be sent to a slaughterhouse should be healthy and come from a Salmonella and Avian Influenza-free area or farm. It is recommended that the chicken is accompanied by Chicken Health Certificate from veterinarian in the farm. If the chicken comes from backyard farming which has no veterinarian, make sure that all chickens in the farm are healthy. The health status is indicated with no high mortality in a short period of time and the statement that the area is not infected by AI. The process of catching penned chickens affects the quality of chicken meat produced. Before catching the chickens, it is suggested to herd them to one side of the pen. After they are gathered in one side of the pen, the chickens then can be caught. Catching is conducted by holding the thighs using one hand while the other hand holds the chickens body. Afterwards, the chickens are put inside a plastic basket. It is better to avoid using a bamboo basket because bamboo fragments are relatively sharper than plastic which can cause scars on the chickens during transportation. It is necessary to count the number of chickens in one basket. The basket should not be too dense or too scarce. If the basket is too dense, it can cause suffocation to the chickens that may lead to a high mortality. On the other hand, it is economically unfavorable if the basket is too scarce. Chicken Transportation from Farm to Slaughterhouse The baskets full of chickens inside are transported by a truck or pick up car; if there are not many baskets, the transportation can be done by using a motorcycle. The trucks or pick up cars used should have open wall box so that the chickens inside the baskets can get sufficient air supply. It is necessary to pay attention to the height of the basket stack. The maximum stack for one truck is 6 baskets and 4 baskets for one pick up car. If the stack is too high, it can cause: 1. Lack of air supply for the chickens in the middle part of the stacks, which will lead to the death of chickens 2. Difficulty in unloading the baskets from the vehicle, that tends to cause a careless handling.

Picture 2 Basket Piling in the Truck (see the original text) During chicken transportation, it is better not to hang the chickens on a motorcycle or pile them on a pedicab as it can cause stress, bluish, or fracture on the chicken. Chicken Handling in Slaughterhouse Chicken handling in slaughterhouse will affect the quality of chicken meat. Improper chicken handling will create threat on the chicken such as stress, bluish, fracture or even death before slaughtering. It also decreases the meat quality and causes perishable and slimy meat. In addition to that, if the chicken is dead before slaughtering, its meat is considered as nonhalal one. Once the chickens arrived in the slaughterhouse, they are weighed and counted. It is important to find out the decrease of chicken number or to figure out the chicken weight reduction during transportation. Then, the chickens are refreshed in a particular place covered with roof and equipped with fans at a minimum of 2 hours before slaughtering. It is aimed to recover the chickens condition, as well as to omit their stress after catching and transportation process.

Picture 3 Refreshing Chicken before Slaughtering (see the original text)

Before slaughtering, the chickens should not be fed, but should be given water to drink, 8-12 hours at the minimum. It is aimed to empty the chickens crop before slaughtering to prevent the possibility of the excretion of crops or intestines content.

ANTEMORTEM EXAMINATION At the refreshing stage, ante-mortem examination, i.e. an examination of chickens health before slaughtering, can be done. Ideally, antemortem examination is conducted by a veterinarian. However, when there is no veterinarian or their availability is limited, the examination can be done by an animal health paramedic (paravet) who has skill, knowledge, and experience in poultry. The paravet should also work under supervision of an authorized veterinarian. The purposes of antemortem examination are: (1) To get chickens which have adequate rest. (2) To avoid slaughtering sick chickens in order to prevent the slaughterhouse along with its tools and employees from being contaminated. (3) To give initial information for the postmortem examination. (4) To ensure that there is no deviation to chickens condition, even though the chicken is already accompanied by a health certificate.

10

Antemortem examination is conducted by inspecting all chickens belonging to the same basket group or when necessary inspecting each chicken randomly in different baskets. Antemortem examination toward chickens includes: 1) Active movement of chicken; 2) Cleanliness of feather; 3) Cleanliness of mouth, nose, eyes, and cloacae; 4) Color of comb; 5) Respiration; 6) Movement of head. Recommendations of antemortem examination result include: (1) Slaughtering without any treatments, when the antemortem examination confirms that the chicken is healthy. (2) Delay of slaughtering, when antemortem examination indicates chicken suffers from respiratory problem (CRD, snot, etc). Apart from the delay of slaughtering, additional treatment or handling should be given during washing the carcass, such as adding sanitizer (using chlorine with a maximum required concentration of 50 ppm). (3) Refusal of slaughtering, when antemortem examination result is compatible with HPAI and Salmonellosis. The rejected chicken should be put in a separate basket with a special label/sign for further examination.

Picture 4 Chicken Isolation Basket for Chicken which may not be slaughtered (see the original text)

CHICKEN HANDLING RIGHT BEFORE SLAUGHTERING Chicken Slaughtering With Stunning Chicken stunning is done by submerging the chicken to electrified water at 15-25 volt, 0.1-0.3 ampere, for 5-10 seconds to the about-to-be-slaughtered chicken. The purposes of stunning are: (1) To make the chicken unconscious before slaughtering, so as to reduce pain (animal welfare aspect). (2) To simplify slaughtering procedure. (3) To minimize struggling seconds after slaughtering to reduce blood spots on the carcass. (4) To speed up bleeding process. There are several types of stunner: (1) Machine stunner, which uses electrified water medium with certain voltage, ampere and timeline. This type of stunner is generally used in Chicken

11

Slaughterhouses (RPA) employing carousel, by hanging chicken on its feet so the head is upside down. Workers whose job is to hang chickens on the carousel have to possess certain skill, i.e catching chickens, taking out chickens from the crate, and hanging them on the carousel. The contact duration of chicken head inside the electrified water must be counted according to the voltage size. Once chickens are stunned, they are expected to be unconscious but not dead yet. Picture 5: Machine Stunner for Chicken Slaughterhouse using carousel system (see the original text) (2) Manual stunner. This stunner is used in small to mid-scaled slaughterhouses not owning carousel. There are several types of manual stunner, which is basically operated by touching the chicken head with a metal electrified with certain voltage and ampere, to stun the chicken. Generally before stunning the chickens are hanged carefully on the carousel (capacity 10 chickens) with their head on the bottom. After they are hanged, in turn the chicken heads are touched by the stunner within a certain period of time to stun the chickens. Right after they are stunned, the slaughtering process should be immediately conducted . A matter of concern in stunning is that the chicken is not dead yet before slaughtering. The recovering period after stunning is approximately 45 seconds, which means if after 45 seconds of unconsciousness the chicken is not slaughtered, it would become conscious again. The benefits of stunning are: (1) To minimize struggling after slaughtering, so as to reduce blood spots on the wing area. (2) To ease the butcher in the slaughtering process. (3) To speed up bleeding process. An improper stunning process, for example from lack of monitoring towards voltage use, will cause loss. Those losses are: (1) If the stunners voltage is too high, the chicken would be dead before slaughtering. This will cause the chicken meat to be haram (forbidden to be eaten by Islamic law). Moreover, chickens which are dead before slaughtering would cause the bleeding process to be imperfect, which will cause the chicken meat to change color. Picture 6: Manual Chicken Stunner (see the original text) (2) If the stunners voltage is too low, the chicken is still conscious, thus complicating the slaughtering process.

12

Chicken Slaughtering Without Stunning Immediately after chickens are taken out of the crate, the butcher then conduct slaughtering using a certain technique. This treatment is actually very effective, particularly from the manpower usage perspective and time needed. However, there are several matters of concern: (1) The worker has to have advanced skill in catching and slaughtering chicken. (2) The treatment starting from catching to slaughtering must be done carefully to avoid bruising, blood spots and fractures. (3) During slaughtering, we must make sure that the three pipes are cut (artery, trachea and esophagus). HALAL SLAUGHTERING PROCESS Basically, the halal slaughtering process in Indonesia must fulfill both technical and animal welfare requirements, including aspects of slaughtered chicken, butcher (person who slaughters chicken) and slaughtering process. Slaughtering Requirements General Requirements The general requirements for halal chicken slaughtering are: (1) The butcher (male or female) has to be a Moslem, adult (baligh) and has a sound mind. (2) Say basmalah (bismillahi allahu akbar) before slaughtering. (3) The knife used for slaughtering has to be sharp and clean. (4) Slaughtering is done on the base point of the neck by cutting the trachea, esophagus and two neck arteries (arteries on the right and on the left side of the neck) with one incision. Requirements for Butcher Butchers have to fulfill the following requirements: (1) During slaughtering it is advisable (sunnah, Islamic Law) to read a short prayer for the Prophet of Muhammad (Allahumma shollii wa sallum ala sayyidinaa Muhammad) and recite laudation (Allahu akbar) three times as well as basmalah. (2) Having knowledge on which chicken is halal or haram to be slaughtered, and how to slaughter the halal way.

13

Requirements for Chicken Chickens to be slaughtered should be alive, healthy and clean. Requirements for Slaughtering Process Moreover, we need to pay a close attention to animal slaughtering process, which are: 1. To position the to-be-slaughtered chicken facing the Kiblat (Mecca) as recommended by Islamic Law. 2. To avoid actions which cause stress to chickens prior to slaughtering. 3. To allow the chickens blood to flow freely, after slaughtering, until it stops bleeding before conducting subsequent process. 4. To conduct a proper and hygienic slaughtering, and to maintain the environments sanitation. Slaughtering Process With Stunning Slaughtering Slaughtering is conducted by using a sharp and clean knife, so that one incision is enough to cut the three pipes (trachea, esophagus and artery). The butcher should have more than one knife; a spare of sharp and clean knife should always be available. To maintain the sharpness and cleanliness of the knives, a steamer/boiler for soaking the knives and a knife sharpener should be available. Slaughtering must be done immediately right after the chicken is stunned. A stunned chicken is marked by a tetany (convulsion/spasm) on its neck and head, normal wings (not dropped) and the conjunctiva is not completely closed. Whereas a dead chicken after stunning is marked by a dropping head without any tetany, a fully closed conjunctiva, and a slightly dropped wings. Bleeding Thorough bleeding has a significant effect on chicken meat produced. Chicken ought to be slaughtered in an upside down position (hanged), so the blood can flow out and dries up. Slaughterhouses using carousel system must accurately calculate the timeline between slaughtering to scalding (the average time for chicken to bleed completely is 3-5 minutes). For slaughterhouses using suspension rack, the removal of chickens from the rack is done at a minimum of 3-5 minutes after slaughtering or until the chicken has stopped moving altogether and there is no blood coming out of its neck.

14

Chicken Slaughtering without Stunning Slaughtering Slaughtering chicken without stunning is much more difficult than slaughtering stunned chicken. The chicken has to be handled properly without hurting it. The chicken has to be taken out from the basket by holding the thighs and wings. Then the chicken is hold with one hand while the other hand holds a knife to slaughter. Similar to the procedure of chicken slaughtering with stunning, in this procedure the butcher must have spare knifes to ensure the sharpness and cleanliness. Bleeding After slaughtering, the chicken is placed into a basket or specific container (box) which is easy to clean up. In this procedure it is necessary to ensure that the blood flows perfectly (around 3-5 minutes) or until the chicken completely die.

CHICKEN HANDLING AFTER SLAUGHTERING Scalding Scalding is aimed to ease the plucking procedure. To have a quality carcass or good chicken meat, it is recommended to avoid still alive chicken submersion into hot water as it causes incomplete bleeding resulting reddish carcass. The submersion procedure can be done in 3 ways: 1. Submersion in hot water with temperature 52-55C for 90-120 seconds. This procedure is usually applied to young chicken or broiler. 2. Submersion in hot water with temperature 52-60C for 90-120 seconds. This procedure is usually applied to old chicken. This submersion produces drier skin carcass. 3. Submersion in hot water with temperature 65-80C for 30-45 seconds then followed with submersion in cold water for 10 seconds to prevent skin damage. This procedure is usually applied to old non-native chicken and native chicken. Scalder in a modern slaughterhouse uses stem/boiler system. In this system chicken is hanged in the carousel and automatically will enter the scalder of which temperature and time have been set according to the chicken average weight. For small-middle scale slaughterhouse the scalder can be modified as efficient as possible. The important thing is to control the submersion temperature and timeline. Water in the scalder has to be changed regularly in order to have clean water.

15

Plucking Plucking, generally, can be done in two ways, namely by using machine and by using hand (manual). In fact manual plucking is not applicable anymore as it consumes long time and needs more workers. There are two kinds of plucking machines: 1. Automatic plucker 2. Semi-automatic plucker Small and middle scale slaughterhouses can modify semi-automatic machine. Usually this machine is in the form of drum plucking with various capacities. While there is a machine that can handle one chicken only, there is one that can handle up to ten chickens per operation. This machine is made of aluminum or stainless steel with rubber fingers. The machine must use clean water during its operation. Both the automatic plucker and the semi-automatic one should always be clean. The rubber fingers need to be changed regularly, and if one of the fingers is broken after use then it has to be replaced immediately. The machines need to be washed and disinfected after use in order to prevent contamination. Evisceration Evisceration can be done by using machine or manually. Manual Manual evisceration is done with the following steps: 1. The chicken has to be slaughtered properly up to the neck so that the respiratory and esophagus are cut. 2. The incision around the vent and sternum should be big enough to allow the entrance of a hand or evisceration tool to the lung 3. Removal of sebaceous glands in the tail area to reduce the smell 4. Evisceration can be done by hand or using evisceration tool 5. Washing all viscera in stomach and breast and removing unused viscera including lung, head, crop and trachea Evisceration using machine In a modern slaughterhouse, evisceration is done by using machine. The evisceration consists of: 1. Perforating the area around cloacae. 2. Evisceration. 3. Cleaning of abdomen using vacuum. 4. Washing of abdomen using compressed water. 5. Washing of carcass using compressed water.

16

POSTMORTEM EXAMINATION The evisceration procedure is continued with postmortem examination on the chickens viscera and carcass. The purpose of this examination is to confirm antemortem diagnose, to detect and eliminate unusual things on carcass in order to have a safe and edible carcass. This examination should be conducted by a veterinarian or paravet who has skill and knowledge to differentiate between a normal and abnormal carcass, and it should be conducted under authorized veterinarian supervision. In the small-middle scale slaughterhouse, the postmortem examination can be conducted by someone who does the evisceration and has been trained before. The viscera that have passed the postmortem examination should be separated from carcass and collected in a specific place for washing procedure. The abnormal viscera cannot be consumed by people. It is necessary to notice that all equipments used during evisceration should be washed and disinfected before used to handle carcass.

CARCASS HANDLING Carcass Washing and Chilling/Rinsing Carcass washing can be done by conducting the following steps: 1. Spraying the carcass using compressed clean water, the objective is to clean any dirt that sticks to the chicken skin. 2. Soaking the carcass in the stainless / porcelain / plastic basin which contains clean water for several minutes (10 minutes). At this stage, sanitizer with certain concentration (50 ppm maximum) can be added to the water. 3. Chilling the carcass in the stainless / porcelain / plastic basin which contains cool water (ice made from clean water) with 5-100C for 30 minutes. The objective of chilling is to decrease the carcasss temperature, so that the microorganism growth and enzyme activities in carcass/meat can be obstructed, so the storage period can be longer. For a modern slaughterhouse, washing and chilling of carcass are conducted directly using a spin/chiller machine operated automatically. Adding cool water and chlorine can be done automatically using a dosing pump. Carcass Packaging and Transporting After chilling process, the carcasses should be dried by putting them in a crate/box. The crate or box must not touch the floor directly. Do not dry the carcasses on the floor even though it is covered with plastic. Cool temperature should be maintained by adding blocks of ice to the topmost of carcass stack to avoid the growth of microorganism.

17

Transporting carcass must be done using a closed vehicle, preferably refrigerator truck. When using an opened car, carcass should be kept inside box and the topmost part of the carcass should be covered with blocks of ice. Then, cover all outer side of the boxs surface using plastic, to prevent pollution of dust during the travel. The closed vehicle and transportation box must be clean and in good condition.

Sanitation of Building, Equipment, and Environment around Slaughterhouse In the poultry slaughtering business, sanitation requirement is very important and obligatory because the final product constitutes food that has highly demand on the ASUH requirements.

Hygiene and Sanitation Requirements Building Sanitation Some points to be considered related to the success of building sanitation program are: Design and construction of the building have to suit the purpose of the building and should be easy to maintain, clean and sanitize. Building lay out is properly designed according to each operation process so that it could perform well and easy to clean, sanitize, and the building is protected from pollution/crossed pollution. The size of the building has to suit the capacity of production so that tools arrangement will not disturb production process, and the building is able to accommodate workers movement. Separation of clean and dirty area. Floor should meet this condition: waterproof, not slippery, flat, no holes, no crack, strong to bear the burden, slope slightly into waste disposal as well as easy to clean and disinfect. Door should be made from non-corrosive, waterproof and antitoxic material, and able to prevent entrance of pest. Have good ventilation and air circulation, and the air flows should be arranged to come from the clean area and running to the dirty area.

Tools and Machine Sanitation Some points to be considered relating to the success of tools and machine sanitation program are: The tools design is made to comply with their purposes, easy to clean and disinfect. The tools material that has direct contact with the product should be made from anti-toxic and non-corrosive material. Tools in the dirty area should not be used to handle other products in clean area. 18

Environment Sanitation Sanitation program will also succeed when the location and environment of a slaughterhouse meet these requirements: Flood-free with well-maintained road facility available. Free from chemical pollution source. Water supply meets the requirements of clean water, and is available at any time. Has a good system of liquid waste disposal that will not pollute the surrounding environment. Well-maintained and clean; no stack of garbage. Cleaning and Sanitation Method Cleaning Cleaning of building, devices, and tools should be done on a regular basis and in a proper way to remove any physically seen dirt. Points to be considered relating to cleaning are: Cleaning Method Cleaning can be done by physical measure (for example: scratching), chemical measure (for example using detergent and substance combining with acid and alkaline), or combination of both measures. Heating may help the cleaning using physical and chemical measures. However, choosing the temperature should be done carefully, according to the detergents type, the nature of dirt, and the nature of surface to be clean. A certain synthetic organic material can absorb components of chicken meat. When the temperature is increased, the amount of components that will be absorbed will be higher. Choosing Detergent Some points to be considered relating to the success of choosing detergent are: 1. Detergent used must be able to damp, to clean any dirt from the surface and to disperse particles from the dirt/suspension; 2. Detergent used must have a nature that easy to rinse so that it would be easy to wash off any remaining dirt and detergent from the tools; 3. Detergents type, concentration and temperature have to suit the type of dirt; 4. Detergent used should be non-corrosive and suits other materials, including disinfection used for sanitation program. 5. Cold detergent solution can be used for certain purpose. However, hot detergent solution should be used to remove remaining fat. The remaining fat and protein still clinging on tools will form crust of salt. This layer constitutes source of pollution, which is mostly missed from our sight, but easily detected by ultra violet. To remove this hard layer (crust), an acid or alkaline detergent, or both combinations, can be used in sequence.

19

Cleaning procedure Cleaning procedure includes: 1. Disposal of any solid waste from the surface by brushing, sucking, scratching or others means. If necessary waste disposal should be followed by pouring clean water thoroughly. Water temperature used for this measure is determined by the wastes type. This procedure is usually applicable for cleaning floor, wall, evisceration desk, carcasses submersion container, plucking machine, etc. 2. Cleaning process should use a kind of detergent solution to disperse/suspense any waste and microorganism particles. This procedure is usually applied in the beginning of the process such as when cleaning small equipments: knives, cutting board, carcasses crate, etc. The duration for submersion depends on type of detergent used and the quantity of waste stick in the equipment. Later, the submersion process should then be followed by brushing or scratching and finished with washing off. 3. Cleaning process should use cleanser material that would not harm the equipments surface. 4. Rinsing aimed to washed out of dirt and leftover detergent should be done by using clean water. If the abovementioned procedures are already applied, the disinfection process can then be applied.

Sanitation Sanitation procedure includes process of cleaning by using any detergent and disinfection materials. Disinfection aims to decrease numbers of living microorganism, but generally it could not kill bacteria spore. Active disinfectant will not kill the whole microorganism, only lessen their amount to the level which would not harm the consumer. Cleaning and disinfection phase could be conducted jointly by using mixture of detergent and disinfectant. Cleaning and disinfection procedures have to suit the process and the type of product output. Disinfectant and detergent should be used carefully because any mistake could harm the entire process. For example hypochlorite solution, if it is mixed with any acid chemicals, it can create chlorine gas that is corrosive and toxicant. The worker, who deals with acid and alkaline chemicals, should wear working clothes and special protection glasses. Apart from that, there should be an operational guideline/manual explaining the details of technical matters. Disinfectant container should be labeled and kept away from food and packaging materials. Disinfectants that could be used in a chicken slaughterhouse are: Chlorine and chlorine compound, including hypochlorite compound

20

Chlorine and chlorine compound are best use in processing unit and when transporting chicken, including in the slaughterihouses itself. This compound is available within cheap price. This particular disinfectant works effectively against some microorganism, but it is corrosive especially when in touch with metal materials and it also has a whitening effect. Therefore, soon after being used, all equipments have to be washed off. Furthermore, chlorine disinfectant will loose its efficacy if there is a presence of organic waste, excluding chlorine dioxide, in the area.

Iodofor Iodofor is always mixed with detergent that contains acid compound. Therefore iodofor is best used during waste disposal of any chemicals that contain acid compound. Iodofor has good efficacy especially when dealing with microorganism. The efficacy of iodofor could be seen through its color. The color will be faded if the amount of iodium decreased down to ineffective level. This compound has weakness that it could give color to foodstuff if mixed with any kind of food. In addition to that, iodofor could also give off an odor and affecting taste. Iodofor is corrosive especially when in touch with metal and the level of corrosiveness depends on the formulation and the characteristic of the surface that need to be disinfected. Therefore, it is best to rinse of all equipments after disinfection measures.

Quaternary Ammonium Compound All quaternary ammonium compounds are effective detergent, colorless, relatively non corrosive to metal, non poisoned, but they have bitter taste and could not be mixed with soap or any anionic detergent. The tolerance of quaternary ammonium especially when handling gram-negative bacteria is not as good as chlorine, chlorine compound and iodofor compound. The compound has a tendency to stick to the surface material. Therefore it is best to washing off all equipment after disinfection measures. Strong Acid and Alkaline Aside having the characteristic as a detergent, strong acid and alkaline are also active anti-microbe. Nevertheless, it is best to take prevention measures when using these chemicals so that it would not contaminate the carcass or the poultry meat. Once disinfection was conducted, the entire equipment surfaces have to be rinsed. Drying To avoid the growth of microorganism, all equipments have to be dried up soon once the cleaning was done, . Equipments such as knives, cutting block, grindings have to be washed, disinfected, rinsed and then placed in the dryer board.

21

Personal Hygiene Some requirements for workers that have to be fulfilled in term of personal hygiene practice: 1) Healthy, they do not have contagious diseases (salmonella, tuberculosis, hepatitis, skin disease in hand, diarrhea, vomited, fever, laryngitis followed by fever). 2) They should always practice personal hygiene when handling poultry/carcass by doing: a) Hand washing before and after working, after leaving the toilet, after covering their mouths while coughing and sneezing, after touching polluted material, etc b) Hand washing procedure that should be applied: - soak hands using clean water - use soap or cleanser and brush the hands for 15 seconds - also brush the hands palm, between fingers and nails - wash hand using clean stream water - do not use the clean hands when turning off the tap 3) wear clean clothes 4) avoid bad working habits such as: a) smoking b) spitting c) eating d) sneezing and coughing in front of the products e) putting fingers inside the mouth f) biting nails or licking hands g) put off all accessories (necklace, ring, watch) h) using excessive make up and perfume i) sitting or leaning on equipments j) touching nose, face, ear and hair during working 5) behave and work according to the rule 6) all workers at the slaughtering house should have a training on personnel hygiene

22

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Personal ResponsesDokument1 SeitePersonal ResponsesNOVASTAR222Noch keine Bewertungen

- Social Sudies: School Base Assement (Sba)Dokument1 SeiteSocial Sudies: School Base Assement (Sba)NOVASTAR222Noch keine Bewertungen

- Personal ResponsesDokument1 SeitePersonal ResponsesNOVASTAR222Noch keine Bewertungen

- Power of AttorneyDokument2 SeitenPower of AttorneyTresha GayeNoch keine Bewertungen

- Vitamin and Mineral TableDokument5 SeitenVitamin and Mineral TableNOVASTAR222Noch keine Bewertungen

- Area and Volume MeasurementsDokument1 SeiteArea and Volume MeasurementsNOVASTAR222Noch keine Bewertungen

- Geometric Shapes ChartDokument1 SeiteGeometric Shapes ChartFriendVamp0% (1)

- January 2011Dokument11 SeitenJanuary 2011dggoodeNoch keine Bewertungen

- January 2012Dokument12 SeitenJanuary 2012NOVASTAR222Noch keine Bewertungen

- TeamBrain User GuideDokument20 SeitenTeamBrain User Guidezoranle2363Noch keine Bewertungen

- Density and Relative Density of A SubstanceDokument1 SeiteDensity and Relative Density of A SubstanceNOVASTAR222Noch keine Bewertungen

- What Is Rainwater HarvestingDokument10 SeitenWhat Is Rainwater HarvestingNOVASTAR222Noch keine Bewertungen

- Howtoread PDFDokument11 SeitenHowtoread PDFCon Mua Ngang QuaNoch keine Bewertungen

- Practice Problems Density and Specific GravityDokument2 SeitenPractice Problems Density and Specific GravityNOVASTAR222100% (1)

- Information Technology Study NotesDokument6 SeitenInformation Technology Study NotesNOVASTAR22250% (2)

- Chicken Butchering BasicsDokument5 SeitenChicken Butchering BasicsNOVASTAR222Noch keine Bewertungen

- Caribbean Examinations Council: Timetable May-June 2013Dokument12 SeitenCaribbean Examinations Council: Timetable May-June 2013Ashley Maxwell0% (1)

- 5096 w09 QP 1Dokument20 Seiten5096 w09 QP 1Asiff MohammedNoch keine Bewertungen

- Social Sudies Sba Cover PageDokument8 SeitenSocial Sudies Sba Cover PageNOVASTAR222Noch keine Bewertungen

- Pastry MakingDokument20 SeitenPastry MakingNOVASTAR222Noch keine Bewertungen

- 5096 w08 QP 1Dokument20 Seiten5096 w08 QP 1Asiff MohammedNoch keine Bewertungen

- H&sbionov 2007Dokument20 SeitenH&sbionov 2007NOVASTAR222Noch keine Bewertungen

- Gceh&sbionov 2006Dokument16 SeitenGceh&sbionov 2006NOVASTAR222Noch keine Bewertungen

- Gceh&sbionov 2006Dokument16 SeitenGceh&sbionov 2006NOVASTAR222Noch keine Bewertungen

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDokument16 SeitenUniversity of Cambridge International Examinations General Certificate of Education Ordinary LevelNOVASTAR222Noch keine Bewertungen

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDokument16 SeitenUniversity of Cambridge International Examinations General Certificate of Education Ordinary LevelNOVASTAR222Noch keine Bewertungen

- Gceh&Sbio Nov 2005Dokument16 SeitenGceh&Sbio Nov 2005NOVASTAR222Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- About Bosna Bank International (BBI)Dokument1 SeiteAbout Bosna Bank International (BBI)HasoNoch keine Bewertungen

- Nonverbal Communication in LibyaDokument5 SeitenNonverbal Communication in LibyaNatashaNoch keine Bewertungen

- Hadeeth Sunnah Resources UpdatedDokument1 SeiteHadeeth Sunnah Resources UpdatedMohammed NabeelNoch keine Bewertungen

- Homohalal Play Explores Love and IdentityDokument51 SeitenHomohalal Play Explores Love and IdentityLaura W. GedozNoch keine Bewertungen

- Good Practice Bulletin - Jan 2017Dokument2 SeitenGood Practice Bulletin - Jan 2017Alan SultanNoch keine Bewertungen

- CSS Recommended books (40 charactersDokument3 SeitenCSS Recommended books (40 charactersRaheela ShahNoch keine Bewertungen

- History of BhopalDokument12 SeitenHistory of BhopalAyushi JangalwaNoch keine Bewertungen

- Osama Bin Laden A BiographyDokument176 SeitenOsama Bin Laden A BiographyRohit Garg100% (2)

- Stories of Prophets - 2Dokument19 SeitenStories of Prophets - 2Hadis MusaNoch keine Bewertungen

- 2008 Mumbai AttacksDokument31 Seiten2008 Mumbai AttacksRyanNoch keine Bewertungen

- Ramadan Calendar 2019 - Dhaka: Ramadan Date Sehr IftarDokument1 SeiteRamadan Calendar 2019 - Dhaka: Ramadan Date Sehr IftartitassarkerNoch keine Bewertungen

- Understanding Deen - by Anjum K. AlviDokument138 SeitenUnderstanding Deen - by Anjum K. AlviAnjumNoch keine Bewertungen

- The Khilafah's AchievementsDokument6 SeitenThe Khilafah's AchievementsM Aamir SayeedNoch keine Bewertungen

- The Perfect Guide's Imperative KnowledgeDokument40 SeitenThe Perfect Guide's Imperative KnowledgeSalman Selamat100% (1)

- Senarai Semak Penerimaan Jadual Peperiksaan Upsr 2010Dokument2 SeitenSenarai Semak Penerimaan Jadual Peperiksaan Upsr 2010zfharulNoch keine Bewertungen

- TextileDokument50 SeitenTextileQasim Abbas BhattiNoch keine Bewertungen

- 2014-01-28 - en - IlahiSir Secret Is Inside Basmala SharifDokument2 Seiten2014-01-28 - en - IlahiSir Secret Is Inside Basmala Sharifjonny101Noch keine Bewertungen

- Student Learning Tracker: RAG (Red, Amber & Green)Dokument6 SeitenStudent Learning Tracker: RAG (Red, Amber & Green)sgmdhussainNoch keine Bewertungen

- Signature Et DéclarationDokument504 SeitenSignature Et DéclarationjawhersahmimNoch keine Bewertungen

- Pub253 Book Review ReportDokument59 SeitenPub253 Book Review Reportnurulba3syaNoch keine Bewertungen

- Wakalah (Agency)Dokument9 SeitenWakalah (Agency)Harizul RafiqNoch keine Bewertungen

- Other LessonsDokument88 SeitenOther Lessonsjholhambri maulanaNoch keine Bewertungen

- Asrar AlamDokument16 SeitenAsrar AlamMansoor AliNoch keine Bewertungen

- 08-21-2012 EditionDokument28 Seiten08-21-2012 EditionSan Mateo Daily JournalNoch keine Bewertungen

- Program Masturoh 2021Dokument2 SeitenProgram Masturoh 2021Suci RinaNoch keine Bewertungen

- Ethiopia Map BuildingDokument2 SeitenEthiopia Map BuildingksuphdcandiNoch keine Bewertungen

- YakuthbaDokument1 SeiteYakuthbaImt Qadiri100% (1)

- H2O Autumn Cup 2023 - Meet Program FridayDokument9 SeitenH2O Autumn Cup 2023 - Meet Program Fridayadib.jr08Noch keine Bewertungen

- HST 102Dokument75 SeitenHST 102Hani Haj SassiNoch keine Bewertungen

- Student projects data tableDokument3 SeitenStudent projects data tableqqqNoch keine Bewertungen