Beruflich Dokumente

Kultur Dokumente

Ceramic Technology - 2 PDF

Hochgeladen von

FA AyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ceramic Technology - 2 PDF

Hochgeladen von

FA AyCopyright:

Verfügbare Formate

1

BANGLADESH TECHNICAL EDUCATION BOARD

4-YEAR DIPLOMA-IN-ENGINEERING PROGRAM

CERAMIC TECHNOLOGY

SYLLABUS FIFTH AND SIXTH SEMESTER

CERAMIC TECHNOLOGY

COURSE STRUCTURE

FIFTH SEMESTER SL. No 1. 2. 3. 4. 5. 6. 7. 8. 9. Subject Code 3650 3651 3656 3657 3658 3659 3033 1551 1552 Subject Name Ceramic Test and Calculation White Wares-I Enamel Glazes & Colors - l Ceramic Fabrication-Il Refractories-Il Instrumentation and Process Control Applied Mechanics Book Keeping and Accounting Business Organization T 2 2 2 2 2 2 2 2 2 18 P 3 3 3 3 3 3 3 0 0 21 C 3 3 3 3 3 3 3 2 2 23

SIX SEMESTER SL. Subject No Code 1. 3661 2. 3662 3. 3663 4. 3664 5. 3665 6. 3667 7. 3668 8. 2643 9. 1561 10. 1562

Subject Name White Wares-II Kilns and Furnaces-I Heavy Clay Products Ceramic Quality Control-I Enamel, Glazes and Colors-II Glass Manufacturing Fuels and Combustion Computer Aided Design (CAD) Business Communication Industrial Management-I

T 2 2 2 2 1 2 2 0 2 2 17

P 3 3 3 3 3 3 0 3 0 0 21

C 3 3 3 3 2 3 2 1 2 2 24

CONTENT

FIFTH SEMESTER SL. No 1. 2. 3. 4. 5. 6. 7. 8. 9. Subject Code 3650 3651 3656 3657 3658 3659 3033 1551 1552 Subject Name Ceramic Test and Calculation White Wares-I Enamel Glazes & Colors - l Ceramic Fabrication-Il Refractories-Il Instrumentation and Process Control Applied Mechanics Book Keeping and Accounting Business Organization Page 7 11 16 21 25 31 38 45 49

SIX SEMESTER SL. Subject No Code 1. 3661 2. 3662 3. 3663 4. 3664 5. 3665 6. 3667 7. 3668 8. 2643 9. 1561 10. 1562

Subject Name White Wares-II Kilns and Furnaces-I Heavy Clay Products Ceramic Quality Control-I Enamel, Glazes and Colors-II Glass Manufacturing Fuels and Combustion Computer Aided Design (CAD) Business Communication Industrial Management-I

Page 53 58 64 70 75 79 83 87 90 93

NUMBER DISTRIBUTION

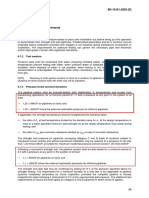

FIFTH SEMESTER

MARKS Sl. No Theory Subject code Name of the subject T P C

Cont. assess. Final exam.

Practical

Cont. assess. Final exam.

Total 150 150 150 150 150 150 150 100 100

1. 2. 3. 4. 5. 6. 7. 8. 9.

3650 3651 3656 3657 3658 3659 3033 1551 1552

Ceramic Test and Calculation White Wares-I Enamel Glazes & Colors - l Ceramic FabricationIl Refractories-Il Instrumentation and Process Control Applied Mechanics Book Keeping and Accounting Business Organization

2 2 2 2 2 2 2 2 2 18

3 3 3 3 3 3 3 0 0 21

3 3 3 3 3 3 3 2 2 23

50 50 50 50 50 50 50 50 50

50 50 50 50 50 50 50 50 50

30 30 30 30 30 30 30 -

20 20 20 20 20 20 20 -

450

450

210

140

1250

NUMBER DISTRIBUTION

SIXTH SEMESTER

MARKS Sl. No Theory Subject code Name of the subject T P C

Cont. assess. Final exam.

Practical

Cont. assess. Final exam.

Total 150 150 150 150 100 150 100 50 100 100

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

3661 3662 3663 3664 3665 3667 3668 2643 1561 1562

White Wares-II Kilns and Furnaces-I Heavy Clay Products Ceramic Quality Control-I Enamel, Glazes and Colors-II Glass Manufacturing Fuels and Combustion Computer Aided Design (CAD) Business Communication Industrial Management-I

2 2 2 2 1 2 2 0 2 2 17

3 3 3 3 3 3 0 3 0 0 21

3 3 3 3 2 3 2 1 2 2 24

50 50 50 50 25 50 50 50 50

50 50 50 50 25 50 50 50 50

30 30 30 30 30 30 30 -

20 20 20 20 20 20 20 -

425

425

210

140

1200

BANGLADESH TECHNICAL EDUCATION BOARD

4-YEAR DIPLOMA-IN-ENGINEERING PROGRAM

CERAMIC TECHNOLOGY

SYLLABUS FIFTH SEMESTER

3650

CERAMIC TEST AND CALCULATION 2 3

T P 3

AIMS To give the students basic concerts of physical properties of ceramic raw materials and body. To understand the quality of the ceramic raw materials and body. To develop skill to identify the quality materials and body. To develop knowledge and skill in ceramic test and calculation.

SHORT DESCRIPTION Moisture content and loss on ignition; Drying shrinkage and firing shrinkage; Water of plasticity; Density and specific gravity; Porosity; Density of a slip and Brongniarts formula; Body calculation; Empirical and molecular Formula; Oxides and their molecular weights; Describe Moh's scale of hardness determination of deflocculant demand; DETAIL DESCRIPTION : 1 Understand the empirical and molecular formula. 1.1 Define empirical and molecular formula. 1.2 Distinguish between empirical and molecular formula. 1.3 Discuss the procedure of calculating empirical formula of a compound from its chemical composition. 1.4 Describe the calculating process of molecular formula of a compound from its empirical formula. 1.5 Solve the problem on chemical composition, empirical formula and molecular formula. 2 Understand the oxide and their molecular weight. 2.1 Define oxides. 2.2 Classify the oxide in view of ceramic. 2.3 Describe the different type of oxides with example. 2.4 Calculate the molecular weight of oxides. 3 Understand the moisture content. 3.1 Define moisture content. 3.2 Explain the reason to know the moisture content. 3.3 Determine the moisture content. 3.4 Solve the problem on moisture content. 3.5 Explain the terms physical water, chemical water, and water of crystallization crystal amorphous and volatile materials. 4 Understand the Loss on Ignition. 4.1 Explain the Loss on Ignition.

Explain the reason the Loss on Ignition. Describe the procedure of determination of loss on Ignition of Ceramic materials. 4.4 Solve the problem on loss on Ignition. Understand drying shrinkage and firing shrinkage. 5.1 Define shrinkage drying , shrinkage and firing shrinkage. 5.2 Determine the drying shrinkage and firing shrinkage of ceramic body and clay materials by drying method. 5.3 Explain liner and volume shrinkage. 5.4 Describe the relation between linear and volume shrinkage. 5.5 Determine the volume shrinkage by suspended method. 5.6 Explain the necessity of measuring drying and firing shrinkage of ceramic body. 5.7 Describe the relation between moisture content (dry basis) and volume shrinkage. 5.8 Solve the problems on drying and firing shrinkage. Understand the water of plasticity. 6.1 Define water of plasticity. 6.2 Determine the water of plasticity of plastic cake. 6.3 Describe the necessity of water of plasticity. 6.4 Explain shrinkage water and pore water. 6.5 Solve the problem on water of plasticity, shrinkage water and pore water. Understand the density and specific gravity. 7.1 Define density and specific gravity. 7.2 Explain bulk density, apparent density, and true density. 7.3 Determine the bulk density of a porous body by suspended method. 7.4 Solve the problem on bulk density and true density. Understand the porosity. 8.1 Define porosity, apparent porosity, true porosity, apparent volume and true volume. 8.2 Determine the apparent porosity by suspended method. 8.3 Describe the effect of porosity on fired body. 8.4 Prove that percentage of porosity = (1-Da/Dt) 100 8.5 Solve the problem on porosity.

4.2 4.3

10

11

12

Understand the density of slip and Brongniarts formula. 9.1 Define the density of slip. 9.2 Determined the density of slip by specific gravity measuring flask. 9.3 Explain the necessity to know the density of slip. 9.4 State Brongniarts formula. 9.5 State the standard slop peck. 9.6 Describe how to prepare Standard slop peck. 9.7 Solve the problem on density of slip and Brongniarts formula and Standard slop peck. 9.8 Define the process of deflocculant demand. Understand the body calculation. 10.1 Define body. 10.2 Describe body preparation by dry and wet process. 10.3 Explain the dry measurement and wet measurement. 10.4 Describe the effect of specific gravity in body calculation. Understand the calculation of formula weight equivalent weight and formula batch weight. 11.1 Define formula weight equivalent weight and formula batch weight. 11.2 Describe the procedure to find out the molecular weight, equivalent weight and formula batch weight. 11.3 Solve the problems on molecular formula equivalent weight and formula batch weight. 11.4 Solve the problem on body calculation. Understand the measurement of moh's scale hardness of glaze. 12.1 Define the hardness. 12.2 Describe the necessity of hardness. 12.3 Describe the different types of hardness. 12.4 Describe the measurement process of moh's scale hardness. 12.5 Describe the factors of hardness.

PRACTICAL 1. 2. 3. 4. 5. 6. 7. 8. Show skill to determine the moisture content of plastic cake. Show skill to determine the loss on ignition of ball clay supplied sample. Show skill to determine the water of plasticity of ceramic body. Show skill to find the linear drying and firing shrinkage. Show skill to find the volume shrinkage of ceramic body by suspended method. Show skill to find the ball density of fired ceramic body. Show skill to find the porosity of fired ceramic body by boiling method. Show skill to find density of the casting slip by specific gravity measuring flask.

10

9.

Show skill to mix the different densitys body and glaze slip to get the required density.

REFERENCE BOOKS :1. 2. 3. 4. 5. Ceramic test and calculation - by Andrew S. A. Apottery Science - by Dinsdale A. Hand book of ceramic calculations - by Heath A.A. The chemistry of ceramic by Aisao yamada. Ceramic powder preparation a hand book - by Ganguli, Dibyendu.

11

3651

WHITE WARES I

T 3

P 3

C 4

AIMS To be able to understand the white wares. To be enable to understand the basic concepts of raw materials for white wares. To be able to develop skill in preparing different white wares. To be able to acquire technical know-how to explore and exploit the material resources of Bangladesh to develop white ware industries. SHORT DESCRIPTION Basic concept of white wares; Raw materials of white ware body; White ware body and body composition; Transparent, translucent, opaque, porous and dense bodies; Firing range, particle size and plasticity of white ware body; Impurities and foreign materials of white ware body; Earthen wares; Manufacturing process of earthenware products; Stone wares; Manufacturing process of stone ware; Bone china; Manufacturing process of Bone china; Fritted porcelain; Manufacturing process of fritted porcelain; Porcelain; Manufacturing process of porcelain; Vitreous products; Traditional method of shaping; Advance method of shaping; Drying and finishing of white ware products. DETAIL DESCRIPTION Theory : 1 Understand the basic concept of white wares. 1.1 Define white wares. 1.2 Classify the white wares on structure basis. 1.3 Classify the white wares on ASTM basis. 1.4 Explain vitreous and semi vitreous body. 1.5 Distinguish between vitreous and semi virtuous body. 1.6 Mention the causes of vitreous ness and semi vitreous ness. 1.7 List the name of 5 vitreous and 5 semi vitreous bodies. 1.8 Classify the vitreous and semi vitreous products. 2 Understand the raw materials of white ware body. 2.1 List the name of major and minor raw materials of white ware body. 2.2 Describe the properties of raw materials of white ware body. 2.3 Describe function of raw materials in the white ware body. 3 Understand the white ware body and body composition. 3.1 Define white ware body and body composition. 3.2 Describe the body composition of white ware. 3.3 Explain trixial white wares. 3.4 Draw a trixial diagram and place different bodies on it. 3.5 Explain the trixial diagram with example. 4 Understand the impurities and foreign materials of white ware body.

12

10

Define impurities of white ware body. List the impurities of white wares body. Explain the effect of impurities on white ware body. Explain foreign materials present in the white ware body. Describe the advantages and disadvantages of foreign materials used in white ware body. Understand the earthenware body. 5.1 Define earthenware. 5.2 Classify the earthenware. 5.3 Describe the different types of earthenware bodies. 5.4 Distinguish between red and white earthenware. 5.5 Describe characteristics of red and white earthenware. Understand the Coarse/ Red earthenware body. 6.1 Define red earthenware body. 6.2 Mention the composition of red earthenware body. 6.3 Describe the properties of red earthenware body. 6.4 Describe the use of red earthenware body. 6.5 Mention the biscuit and glaze firing temperature of earthenware body. Understand the Fine earthenware. 7.1 Define the fine earthenware body. 7.2 Mention the list of fine earthenware body raw materials. 7.3 Mention the composition of fine earthenware body. 7.4 Describe the properties of fine earthenware body. 7.5 Mention the biscuit and glaze firing temperature of fine earthenware body. Understand the manufacturing process of earthenware products. 8.1 List the forming processes of earthenware products. 8.2 Give the composition of different types of earthenware body. 8.3 List the names of ten products used in table service. 8.4 Describe the jollying and jiggering process of manufacture of earthenware products. 8.5 Describe the casting process of manufacture of earthenware products. 8.6 Describe the plastic pressing process to make a shape of earthenware products. 8.7 Describe throwing and turning process to make a shape of earthenware products. Understand the stoneware. 9.1 Define stoneware. 9.2 Classify the stoneware. 9.3 Describe the raw materials of stoneware body, 9.4 Describe the characteristics of stoneware body, 9.5 Describe the use of stoneware body, Understand the coarse / red stoneware body. 10.1 Define coarse stoneware.

4.1 4.2 4.3 4.4 4.5

13

11

12

13

14

15

16

Mention the composition of coarse stoneware body. Describe the properties of coarse stoneware body, Describe the biscuit and glaze firing temperature of coarse stoneware body, 10.5 Describe the use of coarse stoneware body, Understand the fine stoneware body. 11.1 Define fine stoneware body. 11.2 Mention the composition of fine stoneware body. 11.3 Describe the properties of fine stoneware body, 11.4 Describe the biscuit and glaze firing temperature of fine stoneware body, Understand the manufacturing process of stoneware. 12.1 List different names of forming processes of stoneware products. 12.2 Describe the different forming processes of stoneware products. 12.3 Describe the defect in forming process and their remedy. 12.4 Describe drying, firing and glazing of stoneware products. Understand the porcelain. 13.1 Define porcelain. 13.2 Classify the porcelain. 13.3 Describe the development of porcelain. 13.4 Describe the characteristic of hard porcelain. 13.5 Distinguish between earthenware and porcelain. 13.6 Distinguish between stoneware and porcelain. Understand the soft porcelain. 14.1 Define soft porcelain. 14.2 Mention the raw materials of soft porcelain body, 14.3 Mention the composition of soft porcelain body, 14.4 Describe the properties of soft porcelain body, 14.5 Describe the biscuit and glaze firing temperature of soft porcelain body, 14.6 Explain the use of soft porcelain body, Understand the hard porcelain body. 15.1 Define hard porcelain body. 15.2 Mention the raw materials of hard porcelain body. 15.3 Mention the composition of hard porcelain body, 15.4 Describe the list of hard porcelain body composition, 15.5 Describe the properties of hard porcelain body, 15.6 Describe the biscuit and glaze firing temperature of hard porcelain body, 15.7 Explain the use of hard porcelain body. Understand the bone China. 16.1 Define bone China. 16.2 Describe the main materials of bone China and its quality. 16.3 Describe the characteristics of bone China. 16.4 Mention the composition of bone China body.

10.2 10.3 10.4

14

17

18

19

20

21

Calculate the batch composition on bone China body from empirical formula. Understand the manufacturing process of bone China. 17.1 List the name of forming process of bone China ware. 17.2 Describe the difficulties of bone China in firing process. 17.3 Describe the different forming process on bone china products. 17.4 Describe drying and firing procedure of bone china products. 17.5 Describe biscuit firing, glazing and glost firing of bone China products. Understand the fritted porcelain. 18.1 Define fritted porcelain. 18.2 Describe the characteristics of fritted porcelain. 18.3 Mention the composition of fritted porcelain body. Understand the manufacturing process of fritted porcelain. 19.1 Describe the manufacturing process of fritted porcelain. 19.2 Describe the difficulty of fritted porcelain in forming process. 19.3 Describe drying, biscuit firing, glazing and glost firing of fritted porcelain. Understand the manufacturing process of porcelain. 20.1 List different names of forming processes of porcelain products. 20.2 Describe the different forming processes of porcelain products. 20.3 Discuss the drying process of porcelain products. 20.4 Describe the method of biscuit firing of porcelain products. 20.5 Describe the method of glazing of porcelain products. 20.6 Describe the method of post firing of porcelain products. Understand the vitreous products. 21.1 Define vitrification. 21.2 Mention the dependence of degree of vitrification. 21.3 Describe the vitritication mechanism of porcelain body. 21.4 Calculate the body composition of porcelain product. 21.5 List the Ten vitreous products. 21.6 Describe the nasacity of vitrification of white ware body.

16.5

Practical : 1. Prepare fine earthenware products. 2. Prepare fine stoneware products. 3. Prepare bone china products. 4. Prepare fritted porcelain products. 5. Prepare hard porcelain products. 6. Prepare a spark plug.

REFERENCE BOOKS 1. Science of White wares Victoria E. Henkes, George, Y. Onada.

15

2. 3. 4. 5. 6. 7. 8. 9. 10.

Science of White Wares- II Victoria E. Kenkes and Wilian M. Corty. Ceramic White Wares S. Sen. Ceramic White Ware New Comber. Materials and Equipment White Ware William M. Carty. Ceramics Vol- l, II & lll Komolel. Stoneware and Porcelain Daniel Rhodes. Industrial Ceramic Singer. Test Book on Ceramic Engineering Komolel Ceramic Test and Calculation by Andrews A. I.0

16

3656

ENAMEL GLAZES AND COLORS I

T 2 3

P 3

AIMS

To be able to understand basic concepts of enamels. To be able to understand the basic concepts of fritting process. To be able to understand the basic concepts of ceramic glazes and color. To be able to perform experiment of the preparation of glaze.

SHORT DESCRIPTION Enamels; Raw materials for enamels; Base metal; Enamels coating; Applying process of enamels; Enamels firing; Decoration of enamels; Frit; Manufacturing process of enamels; Glazes; Types of glaze; Raw materials of glaze; Glaze calculation. Lead glaze; Porcelain glaze; Stoneware glaze; Manufacturing process of glaze; glaze firing; Decoration of glazes; DETAIL DESCRIPTION Theory: 1 Understand the enamels. 1.1 Describe the history of enamels. 1.2 Define enamels. 1.3 Classify the enamels. 1.4 Describe the physical and chemical characteristics of different types of enamels. 2 Understand the raw materials of enamels. 2.1 Make a list of enamels raw materials with chemical formula. 2.2 Classify the raw materials of enamels. 2.3 Describe the properties of enamel raw materials. 2.4 Describe the uses of enamel raw materials. 3 Understand the frit. 3.1 Define frit. 3.2 Describe the raw materials of frit. 3.3 Describe the fruiting rules. 3.4 Describe the fritting process. 3.5 Describe the advantages and disadvantages of fritting. 4 Understand the manufacturing process of enamels. 4.1 Describe the mixing of enamels by the use of mixture. 4.2 Describe the screening process of enamels slip by the use of different types of screen. 4.3 Describe proportion of water in the enamels slip. 5 Understand the base metal. 5.1 Define base metal. 5.2 Describe base metal preparation.

17

10

11

12

Describe the method of shaping the base metal plate. Describe the method of trimming the base metal. Describe the method of cleaning the base metal by using acid and alkali. Understand the enamel coating. 6.1 Define enamel coating. 6.2 Classify the enamel coating. 6.3 Define the ground coat and cover coat. 6.4 Describe the counter enameling. 6.5 Describe the composition of ground coat and cover coat enamel. Understand the process of enamel application. 7.1 Classify the enamel applying process. 7.2 Describe the dipping process of enamels. 7.3 Describe the spraying process of enamels. 7.4 Describe the pouring process of enamels. 7.5 Describe the brushing process of enamels. 7.6 Describe the advantages and disadvantages of wet and dry spraying. Understand the enamels firing. 8.1 Describe the different process of enamel firing. 8.2 Describe the different types of tools for enamels firing. 8.3 Describe the setting method of enamels production into the furnace. Understand the enamels decoration. 9.1 Define decoration. 9.2 Describe the classification of decoration. 9.3 Describe the spatula method of decoration. 9.4 Describe the dusting method of decoration. 9.5 Describe the deep bowls methods of decoration. 9.6 Describe the working method of decoration. 9.7 Describe the decoration firing of enamels. Understand the glazes. 10.1 Define glaze. 10.2 Describe the antiquity of glaze. 10.3 Describe the purpose of glaze. 10.4 Distinguish between enamels and glaze. Understand the glaze raw materials. 11.1 Mention the raw materials of glaze. 11.2 Describe the classification of glaze raw materials. 11.3 Describe the refractoriness of materials of glaze. 11.4 Describe the fluxing materials of glaze. 11.5 Describe the opaque fire materials of glaze. 11.6 Describe the coloring materials glaze. 11.7 Describe the floating materials of glaze. 11.8 Describe the properties of glaze raw materials. Understand the glaze calculation.

5.3 5.4 5.5

18

13

14

15

16

17

Define molecular formula or sager formula. Describe the calculating process of molecular formula from batch composition. 12.3 Describe the calculating process of batch composition from molecular formula. 12.4 Discuss and solve the problems of chemical composition of glaze. Understand the different types of glaze. 13.1 Describe the classification of glaze. 13.2 Describe soft glaze. 13.3 Describe medium glaze. 13.4 Describe hard glaze. 13.5 Describe the opaque glaze. 13.6 Describe the transparent glaze. 13.7 Describe the translucent glaze. Understand the Lead Glaze. 14.1 Define lead glaze. 14.2 Describe the sources of raw materials for lead glaze. 14.3 Describe the composition of lead glaze. 14.4 Describe the preparation of lead glaze. 14.5 Describe the application of lead glaze. 14.6 Describe the properties of lead glaze. 14.7 Describe the advantages and disadvantages of lead glaze. 14.8 Describe the use of lead glaze. Understand the porcelain glaze. 15.1 Describe the porcelain glaze. 15.2 Describe the classification of porcelain glaze. 15.3 Describe opaque glaze, transparent glaze and translucent glaze. 15.4 Describe the composition of different types of porcelain glaze. 15.5 Describe the preparation of different type of porcelain glaze. 15.6 Describe the application of different types of porcelain glaze. 15.7 Describe the properties of different types of porcelain glaze. 15.8 Describe the uses of different type of porcelain glaze. Understand the stoneware glaze. 16.1 Explain stoneware glaze. 16.2 Describe the composition of stoneware glaze. 16.3 Describe the preparation of stoneware glaze. 16.4 Describe the application of stoneware glaze. 16.5 Describe the properties of stoneware glaze. 16.6 Describe the advantages and disadvantages of stoneware glaze. 16.7 Describe the uses of stoneware glaze. Understand the manufacturing process of glaze. 17.1 Describe the glaze mixing by the use of ball. 17.2 Describe the screening of glaze by the use of different type of screen. 17.3 Describe the iron separation of glaze by the use of magnetic separator.

12.1 12.2

19

17.4 Describe the properties of water of glaze. 17.5 Describe the density of glaze. 17.6 Describe the viscosity of glaze. 18 Understand the glaze firing. 18.1 Describe the ideal firing condition for glaze firing. 18.2 Explain the controlling system of oxidation and reduction in glaze firing. 18.3 Describe the firing temperature in glaze firing. 18.4 Describe the uneven temperature in glaze firing. 18.5 Compared between gas and electric firing. 19 Understand the decoration of glazes. 19.1 Define the decoration of glaze. 19.2 Classify the decoration on their position. 19.3 Describe under glaze colors and decoration. 19.4 Describe the method of application of different types of decoration. Practical: 1. Identify the raw materials of enamels. 2. Make the base metal shaping and prepare the base metal for enamels. 3. Apply the ground coat and cover coat over the base metal for enamels. 4. Make fire for the enamels. 5. Decorate the enamels. 6. Prepare the frit. 7. Identify the raw materials for glaze. 8. Prepare glaze and apply it on earthenware (Low temperature). 9. Prepare red lead glaze. 10. Prepare while lead glaze. 11. Prepare fritted glaze. 12. Prepare porcelain transparent glaze and apply it. 13. Prepare porcelain opaque glaze and apply it. 14. Prepare porcelain translucent glaze and apply it. 15. Prepare stoneware glaze and apply it. REFERENCE BOOK 1. Ceramic Glazes Par melee C M. 2. Ceramic Color Show Know Marla 3. Handbook of Ceramic Calculation Heath Ah. 4. A Text Book of Ceramic Engineering Komolel. 5. Clay and Glazes for the Potter Daniel Rhodes. 6. Ceramic Glazes Felekia. 7. Understanding Potter Glazes

20

8.

Enamels

David Green. Andrews A. E.

21

3657

CERAMIC FABRICATION II

T 2 3

P 3

AIMS To be able to understand the advanced method of ceramic fabrication. To be able to understand forming defects, joining defects and handing defects. To be able to understand the preparation of ceramic body for glazing. To be able to prepare different ceramic wares.

SHORT DESCRIPTION Advanced method of shaping ceramic ware in the plastic state; Stiff mud process of making ceramic ware; Formation of ceramic ware in the roller machine; Ram pressing of ceramic ware; Impact forming and injection molding process; Pressure casting by electrophoresis and microwave casting; Granulation and binder; Semi-dry press process and dry press process; Forming defects; Casting joint of ceramic ware; Finishing of ceramic fabrication. DETAIL DESCRIPTION Theory: 1 Understand the advanced method of shaping ceramic ware in the plastic state. 1.1 Explain the shaping of ceramic ware in the plastic state. 1.2 Mention different types of advanced method of shaping ceramic ware in the plastic state. 1.3 Describe different types of advanced method of shaping ceramic ware in the plastic state. 2 Understand the stiff mud process of making ceramic ware. 2.1 Describe the stiff mud process of making ceramic ware. 2.2 Explain the advantage of stiff mud process of making ceramic ware. 2.3 Draw the flow sheet of the stiff mud process of making ceramic wares. 2.4 Describe the stiff mud process of making ceramic ware. 3 Understand the formation of ceramic ware in the roller machine. 3.1 Describe roller machine. 3.2 Describe the method of forming ceramic ware by roller machine. 3.3 Describe the method of formation of ceramic ware by roller machine. 3.4 Describe the operating process of roller machine. 3.5 Explain the forming defects of ceramic ware due to roller machine. 3.6 Mention the necessity of roller machine for forming ceramic ware. 4 Understand the ram pressing of ceramic ware. 4.1 Explain ram pressing or plastic pressing of ceramic ware.

22

10

11

Describe the method of forming ceramic wares by ram pressing process. 4.3 Describe different shape of ceramic wares by ram pressing process. 4.4 List the name of ceramic wares making by ram pressing. Understand the impact forming and injection molding process. 5.1 Describe the impact forming process of ceramic fabrication. 5.2 Describe the making of wares by impact forming process. 5.3 Mention the advantage of impact forming process. 5.4 Explain injection moulding process of fabrication of ceramic ware. 5.5 Describe the disadvantages of making ceramic wares by injection moulding process. Understand the granulation and binder. 6.1 Define granulation and binder. 6.2 Describe the granulation process. 6.3 Explain the necessity of granulation process in dry press body. 6.4 Describe different kinds of binder. 6.5 Explain the necessity of binder for forming by dry press process. Understand the forming defects. 7.1 Explain forming defects of ceramic ware. 7.2 Describe different types of forming defects. 7.3 Explain the method of remedy of forming defects. Understand the casting joint of ceramic ware. 8.1 Describe the method casting joint. 8.2 Describe the handle and line joining process. 8.3 Describe different types joining defects. 8.4 Explain the method of removal of joining defects. Understand the concept of finishing of ceramic fabrication. 9.1 Explain the finishing of ceramic fabrication. 9.2 Describe different types of finishing process. 9.3 Describe finishing process of flat and hollow wares. 9.4 Describe the finishing defects. 9.5 Explain the necessity of finishing of fabrication for ceramic wares. Understand the Advanced methods of shaping in the Liquid state. 10.1 Define the advanced methods of shaping in the Liquid state. 10.2 Mention the classification of advanced methods of shaping in the liquid state. 10.3 Explain the necessity of advanced methods of shaping in the liquid state. 10.4 Describe the advantage and disadvantage of advanced methods of shaping in the liquid state. Understand the pressure casting. 11.1 Define the pressure casting. 11.2 Describe the making process of tableware by pressure casting. 11.3 Describe the making process of sanitary ware by pressure casting.

4.2

23

11.4 Explain the necessity of pressure casting process. 11.5 Describe the advantage of pressure casting process. 11.6 Describe isostaticma chine. 12 Understand the casting by Electrophoresis. 12.1 Explain the concepts of casting by Electrophoresis. 12.2 Describe the making of ceramic ware by Electrophoresis process. 12.3 Describe the advantage of Electrophoresis process. 12.4 Describe the disadvantage of Electrophoresis process. 13 Understand the Micro wave Casting. 13.1 Define the Microwave casting process. 13.2 Describe the making process of ceramic ware by Microwave casting. 13.3 Describe the advantage of Microwave casting. 13.4 Explain the necessity of Microwave casting process. 14 Understand the shaping in the dry state. 14.1 Define the Shaping of dry state. 14.2 Classify the Shaping of dry process. 14.3 Define the semidry process. 14.4 Describe the semidry forming press process of ceramic ware. 14.5 Mention the advantage of semidry press process. 14.6 Draw the flow sheet of semidry press process. 15 Understand the dust pressing process. 15.1 Define the concept of dust pressing process. 15.2 Describe the dust pressing process of forming ceramic tiles. 15.3 Mention the advantage of dust pressing process. 15.4 Draw the flow sheet of dust pressing process. 15.5 Describe the hydraulic automatic dry press process of forming ceramic tiles. Practical: 1. Make ceramic ware by roller machine. 2. Shape the ceramic ware in the plastic state. 3. Make ceramic ware by stift mud process. 4. Make ceramic ware by pressure casting process. 5. Make ceramic ware by semi-dry press process. 6. Make ceramic ware by dry-press process. 7. Make a jug and joint its handle by casting joint. 8. Make a tea cup and joint its handle. 9. Make a hallow ware and qive its finishing. REFERENCE BOOKS 1. 2. Industrial ceramic by Singer & SInger. Refractories Hand Book.

24

by Hosokawa. 3. Stoneware and Porcelain

Takamiya

and

by Daniel Rhodes. 4. 5. 6. Ceramic Hank Book by Robison Jim Ceramic Hand Boook by Fraser Hary Ceramic Hand Book by Gregorg Lan.

25

3658

REFRACTORIES II

T 2

P 3

C 3

AIMS To be able to understand the basic concept of basic refractories. To be able to understand magnesite brick, lime refractories, dotomiite brick, chrome brick, crhrome magnesite brick and graphite refractories. To be able to prepare different refractory products.

SHORT DESCRIPTION Use of sic in ceramic factories; Basic refractories; Magnesite refractories; Dolomite brick; Zirconia refractories brick; Bauxite refractories brick; Haematile refractories brick; Chromites refractories brick; Graphite refractories brick; Carborundum refractories brick; Cordierite refractories brick and saggar. DETAIL DESCRIPTION Theory: 1 Understand the basic refractories. 1.1 Explain basic refractory. 1.2 Describe the properties of basic refractory. 1.3 Describe the uses of basic refractories. 2 Understand the acid refractories. 2.1 Explain the acid refractory. 2.2 Describe the properties of acid refractory. 2.3 Describe the use of acid refractory. 2.4 Explain the necessity of acid refractory. 2.5 Distinguish between basic and acid refractory. 3 Understand the neutral refractories. 3.1 Explain the neutral refractory. 3.2 Describe the properties of neutral refractory. 3.3 Describe the use of neutral refractory. 3.4 Explain the necessity of neutral refractory. 4 Understand the low heat duty refractories. 4.1 Explain the low heat duty refractory. 4.2 Describe the composition of low heat duty refractory. 4.3 Describe the properties of low heat duty refractory. 4.4 List the name of low heat duty refractory raw materials. 4.5 Explain the importance of the low heat duty refractory. 5 Understand the medium heat duty refractories. 5.1 Explain the medium heat duty refractory. 5.2 List the name of medium heat duty refractory raw materials.

26

10

5.3 Describe the composition of medium heat duty refractory. 5.4 Describe the temperature determination of medium heat duty refractory. 5.5 Describe the properties of medium heat duty refractory. Understand the supper heat duty refractories. 6.1 Explain the supper heat duty refractory. 6.2 List the name of supper heat duty refractory raw materials. 6.3 Describe the composition of supper heat duty refractory. 6.4 Describe the properties of supper heat duty refractory. 6.5 Explain the necessity of supper heat duty refractory. Understand the Grog. 7.1 Explain the Grog. 7.2 Describe the preparation of Grog manufacturing process. 7.3 Describe the properties of Grog. 7.4 Describe the use of Grog. 7.5 Explain the necessity of Grog manufacturing for refractory brick and Sager. Understand the supper duty Silica brick. 8.1 Explain the supper duty Silica brick. 8.2 Describe the raw materials of supper duty Silica brick. 8.3 Describe the composition of supper duty Silica brick. 8.4 Describe the characteristics of supper duty Silica brick. 8.5 Describe the properties of supper duty Silica brick. 8.6 Describe the use of supper duty Silica brick. 8.7 Describe the temperature determination of supper duty Silica brick. Understand the Semi silica bricks. 9.1 Define the semi Silica brick. 9.2 Describe the raw materials of semi Silica brick. 9.3 Describe the composition of semi Silica brick. 9.4 Describe the properties of semi Silica brick. 9.5 Explain the use of semi Silica brick. Understand the High Alumina Bricks. 10.1 Explain the high alumina brick. 10.2 Describe the raw materials of high alumina brick. 10.3 Describe the composition of high alumina brick. 10.4 Describe the properties of high alumina brick. 10.5 Explain the use of high alumina brick. Understand the Supper duty fire bricks. 11.1 Explain the supper duty fire brick. 11.2 Describe the composition of supper duty fire brick. 11.3 Describe the properties of supper duty fire brick. 11.4 Explain the use of supper duty fire brick. Understand the mullite refractories Bricks. 12.1 Explain the mullite refractory bricks.

11

12

27

13

14

15

16

17

12.2 List the name of mullite refractory bricks raw materials. 12.3 Describe the composition of mullite refractory bricks. 12.4 Describe the properties of mullite refractory bricks. 12.5 Describe the use of mullite refractory bricks. Understand the low alumina refractory bricks. 13.1 Explain the low alumina refractory bricks. 13.2 List the name of low alumina refractory bricks. 13.3 Describe the composition of low alumina refractory bricks. 13.4 Describe the properties of low alumina refractory bricks. 13.5 Explain the use of low alumina refractory bricks. Understand the magnesite refractories. 14.1 Explain magnesite refractory bricks. 14.2 Describe the manufacturing process of maghesite refractory bricks. 14.3 Describe the properties of magnesite refractory brick. 14.4 Describe the uses of magnesite refractory brick. Understand the dolomite brick. 15.1 Explain dolomite refractories. 15.2 Describe the manufacturing process of dolomite brick. 15.3 Describe the properties of dolomite refractories. 15.4 Describe the raw materials of dolomite refractor bricks. 15.5 Describe the uses of dolomite refractroy brick. Understand the zirconia refractory brick. 16.1 Explain zirconia refractory brick. 16.2 Describe the manufacturing process of zirconia refractory brick. 16.3 Describe the properties of zirconia refractory brick. 16.4 Describe the raw materials required for zirconia refractory brick. 16.5 Describe the uses of zirconia refractory brick. Understand the bauxite refractories brick. 17.1 Describe the bauxite refractories brick. 17.2 Describe the properties of bauxite refractory brick. 17.3 list the raw materials of bauxite refractory brick. 17.4 Describe the manufacturing process of bauxite refractory brick. 17.5 Describe the uses of bauxite refractory brick. Understand the haematic refractories brick. 18.1 Define Hematite refractories brick. 18.2 Describe the properties of haematite brick. 18.3 List the raw materials of haematite brick. 18.4 Describe the manufacturing process of hematite refractory brick. 18.5 Describe the uses of haematite brick. Understand the chromite refractory brick. 19.1 Define the chromite refractory brick. 19.2 Describe the properties of chromite refractory brick. 19.3 List the raw materials of chromite refractory brick.

18

19

28

19.4 Describe the manufacturing process of chromite refractory brick. 19.5 Describe the uses of chromite brick. 20 Understand the graphite refractory brick. 20.1 Understand the graphite refractory brick. 20.2 Describe the properties of graphite refractories. 20.3 List the raw materials of graphite refractories. 20.4 Describe the manufacturing process of graphite refractory brick. 20.5 Describe the uses of graphite refractories. 21 Understand the carborundum refractory brick. 21.1 Explain carborundum refractory brick. 21.2 Describe the properties of carborundum brick. 21.3 List the raw materials of carborundum refractories. 21.4 Describe the manufacturing process of carborundum refractories brick. 21.5 Describe the uses of carborundum refractories brick. 22 Understand the cordierite refractories brick. 22.1 Explain cordierite refractories brick. 22.2 Describe the properties of cordierite refractory brick. 22.3 List the raw materials of cordierite refractories. 22.4 Describe the manufacturing process of cordierite refractories. 22.5 Describe the uses of cordierite refractory brick. 23 Understand the sager. 23.1 Define sager. 23.2 Describe different method of preparation of saggar. 23.3 Describe the firing process of saggar. 23.4 Describe the properties of saggar. 23.5 Describe the molding defects of saggar. 23.6 Describe the uses of saggar. 24 Understand the SiC refractory. 24.1 Describe the SiC refractory. 24.2 Describe the uses of sic in ceramic factory. 24.3 Describe the melting point of SiC. Practical: 1 Perform the preparation of magnesite brick. 1.1 Draw the working procedure preparing magnesite brick. 1.2 Calculate the temperature. 1.3 Fire the brick. 2 Perform the preparation of dolomite refractories bricks. 2.1 Prepare dolomite refractory brick following the working procedure. 2.2 Calculate the temperature. 2.3 Fire the refractories brick. 2.4 Write down the decision. 3 Perform the preparation of zirconia refractories brick. 3.1 Follow the working procedure of preparing ziconia bricks. 3.2 Calculate the temperature.

29

3.3 Fire the refractory brick. 3.4 Write down the decision. Perform the preparation of Bauxite refractories. 4.1 Make baxite refractory brick following the working procedure. 4.2 Calculate the temperature. 4.3 Fire the refractories brick. 4.4 Write down the decision. Perform the preparation of chromate brick. 5.1 Prepare chroomite brick following the working procedure. 5.2 Calculate the temperature. 5.3 Fire the refractory brick. 5.4 Write down the decision. Perform the preparation of graphite refractories brick. 6.1 Prepare graphite refractory brick following working procedure. 6.2 Calculate the temperature. 6.3 Fire the refractories brick. 6.4 Write down the decision. Perform the preparation of carborundum refractory brick. 7.1 Prepare the coardierete refractory brick follow the working procedure. 7.2 Calculate the temperature. 7.3 Fire the refractories brick. 7.4 Write down the decision. Perform the preparation of cordierite refractories brick. 8.1 Prepare the cordierite refractory brick following the working procedure. 8.2 Calculate the temperature. 8.3 Fire the brick. 8.4 Write down the decision. Perform the preparation of seggar. 9.1 Calculate the temperature. 9.2 Fire the seggar. 9.3 Write down the decision.

REFERENCE BOOKS 1. Refractories Hand Book. by Tokaniya & Hosokawa. 2. Refractories Materials by Shear. 3. 4. 5. Ceramic Hand Book. by Robinson. Silicon Carbide Ceramic by Somlyas. Advanced Ceramic Materials

30

by Hamid Mostagaeli.

31

3659

INSTRUMENTATION AND PROCESS CONTROL T 2 P 3 C 3

AIMS To be able to understand the basic concepts of industrial instrumentation and process control. To be able to understand the basic concepts of transducers. To be able to understand the basic concepts of temperature measurement and temperature measuring devices. To be able to understand the basic concepts of pressure measurement and pressure measuring devices. To be able to understand the basic concepts of level measurement and level measuring devices. To be able to understand the basic concepts of flow measurement and flow measuring devices. To be able to understand the basic concepts of humidity measurement and humidity measuring devices. To be able to understand the basic concepts of signal conditioning. To be able to calibrate, operate and maintain the different instruments & transducers.

SHORT DESCRIPTION Measurement systems; Transducers; Temperature measurement and temperature measuring devices; Thermistors, thermoconples and bimetalic thermometer; Gas thermometer, vapor pressure thermometer, liquid expansion thermometer and integrated circuit temperature transducers; Optical devices; Pressure measurement; Pressure elements, capsules, bellows, c-type Bourdon tube pressure gauge and other pressure measuring devices; Level measurement and level measuring devices; Flow measurement and flow measuring devices; Humidity measurement and humidity measuring devices; Signal conditioning systems; Controller principles; Display devices and recorders. DETAIL DESCRIPTION Theory : 1 Understand the concepts of measurement systems. 1.1 Define temperature measurement instrument. 1.2 Explain measurement systems. 1.3 Describe the basic block diagram of a generalized measurements system.

32

Explain the following elements of a generalized measurement systems: (i) Primary sensing elements. (ii) Variable conversion elements. (iii) Data processing elements. 1.5 Explain the following terms with examples: (i) Transducer. (ii) Signal conditioning. (iii) Display. 1.6 Describe the spring elements with diagrams which are used for sensing force (F) or torque (T) in engineering instrumentation. 1.7 Describe the following pressure sensitive primary devices with neat diagrams: (i) Bourdon tubes. (ii) Bellows. (iii) Diaphragms. (iv) Capsules. 1.8 Describe the flow sensing elements with diagrams. Understand the transducers. 2.1 Make a list of transducers with their uses. 2.2 Describe the classification of transducers with examples. 2.3 Differentiate between the following terms. (i) Transducers and inverse transducers. (ii) Active and passive transducers. (iii) Primary and secondary transducers. (iv) Analog and digital transducers. (v) Output and inverse transducers. 2.4 Describe the following characteristics of transducers. (i) Input characteristics (ii) Transfer characteristics (iii) Transducer response (iv) Output characteristics 2.5 Describe the different criteria for selection of transducers for particular application. 2.6 Explain the following terms: Accuracy, Sensitivity, Reproducibility or repeatability, Drift, Error, Dead zone, Resolution, Percentage error, Zero error, Tolerance, Stability, Constancy, Full Scale Deflection (f.s.d), Secular changer, Calibration, Hysteresis, Step input, Range, Response time, Capacity, Precision, Linearity, Primary and secondary standard. Understand the temperature measurement and the temperature measuring device. 3.1 Describe the scales of temperature measurement. 3.2 Mention the relative temperature scales. 3.3 Explain the relation between temperature and thermal energy.

1.4

33

Explain the relation of temperature to metal resistance. Make a list of temperature measuring instruments. Explain the term thermal transducers. Explain the principle of Resistance-Temperature Detectors (RTD) and its construction & operation. Understand the thermistors, thermocouples and bimetallic thermometers. 4.1 Explain the principle, constructional detail and operation of thermistors. 4.2 Explain the principle, construction and operation of thermo-couples. 4.3 Make a list of six couples of materials of wire used in making thermocouples with range of temperature in each case. 4.4 Discuss the advantages and disadvantage of thermo couples. 4.5 Explain the principle, construction and working principle of a bimetallic thermometer. Understand the gas thermometer, vapor pressure thermometer, liquid expansion thermometer and integrated circuit temperature transducers. 5.1 Explain the working principle of gas thermometer. 5.2 Explain the working principle of vapor-pressure thermometer 5.3 Explain the working principle of liquid expansions thermometer 5.4 Explain the integrated circuit temperature transducer and its application in the temperature measurement. Understand the optical devices for temperature measurement. 6.1 Mention the electromagnetic radiation (EMR) in terms of frequency wavelengths, speed of propagation and spectrum. 6.2 Explain the energy of electro-magnetic radiation in terms of power, intensity and the effects of divergence. 6.3 Describe photo-conductive, photo-voltaic and photo-emissive type photo detectors (Non-mathematical description only). 6.4 Describe the principle and construction of a radiation pyrometer. 6.5 Describe the principle and construction of optical pyrometer. 6.6 Distinguish between incandescent atomic and laser light sources by the characteristics of their light.

3.4 3.5 3.6 3.7

Understand the basic concepts of pressure measurement and pressure measuring device. 7.1 Mention the relations of atmospheric pressure, gauge pressure and absolute pressure by equations. 7.2 Make a list of different pressure measuring instruments. 7.3 Describe the principle of U-tube manometer in measuring differential pressure. 7.4 Describe the principle of inclined tube manometer in measuring differential pressure. 7.5 Describe the principle of measurements of pressure by direct reading well-type manometer.

34

10

11

7.6 Mention four commonly used manometric liquids. 7.7 Mention the important characteristics of manometric liquids. Understand pressure elements, capsules, bellows, C-type Bourdon tube pressure gage and other pressure measuring devices. 8.1 Make a list of six elastic deformation pressure elements. 8.2 Explain the functions of elastic deformation pressure elements. 8.3 Describe the function of pressure capsules in measuring pressure. 8.4 Describe the function of bellows as a pressure measuring device. 8.5 Describe the constructional detail of C-type Bourdon tube pressure gauge and its operation. 8.6 Explain the working principle of diaphragms as pressure measuring devices. 8.7 Explain the working principle of following electronic devices for the measurement of pressure (non-mathematical description only): (a) Potentionmetric device. (b) Linear variable differential transformer (LVDT). (c) Inductive devices. 8.8 Describe the following pressure measuring devices: (a) Pirani gauge. (b) lionization gauge. Understand the basic concepts of level measurement and level measuring devices. 9.1 Mention the importance of measurement of level in the industries. 9.2 Make a list of level measuring devices. 9.3 Describe the measurement of level by sight glass. 9.4 Describe the measurement of level by float with cable pulley and weight. 9.5 Describe the method of measurement of level by doughnut shaped float with magnet. 9.6 Describe the method of measurement of level by air trap. 9.7 Describe the method of measurement of level by bubbler pipe. 9.8 Describe the method of measurement of level by ultrasonic method. Understand the flow measurement and flow measuring device. 10.1 Make a list of flow measuring devices. 10.2 Describe the measurement of flow of fluids and solids. 10.3 Explain the method of measurement of flow-rate of a fluid by orifice plate. 10.4 Describe the method of measurement of flow-rate of a fluid by using venturimeter. 10.5 Describe the method of measurement of flow rate of a fluid by using rotameter. 10.6 Describe the method of measurement of flow rate by turbine meter. 10.7 Explain how pitot-tube can be used for measurement of flow of liquid. Understand the humidity measurement and humidity measuring devices. 11.1 Explain the terms absolute humidity and relative humidity.

35

11.2 11.3 11.4 11.5 11.6 11.7

Explain humidity chart. Make a list of humidity measuring devices. Describe with neat sketch the construction and working principle of a hydrometer. Discuss the working principle of a sling psychrometer with diagram. Describe the method of measurement of dew point by a continuous dew point recorder. Describe the method of measurement of moisture by using moisture balance.

PRACTICAL 1 (a) Measure the temperature of a furnace/oven by a thermo-couple. (b) Measure the temperature of a fluid by using a liquid expansion thermometer. (c) Measure the temperature of an oven by using a platinum resistance thermometer. (d) Measure the temperature of a furnace by using a radiation pyrometer. 2 (a) (b) (c) 3 (a) (b) (c) Measure the temperature of steam/hot water by using a bimetallic thermometer. Determine the temperature co-efficient of a thermistor. Measure the temperature of red-hot metal by using an optical pyrometer. Determine the temperature of an oven by a pressure spring thermometer. Practice the temperature control by using a temperature control apparatus. Practice the temperature control loop using a temperature regulation control unit. Measure the pressure of a flowing fluid in a pipe by using an open U- tube manometer. Practice the pressure control and flow control by using a pressure / flow control apparatus. Study the regulation loap necessary to control the pressure in a tank. Measure the pressure of a compressible fluid in vessel by a C-type Bourdon tube pressure gauge. Draw the neat sketch of a Bourdon tube pressure gauge. Measure the pressure of a flowing fluid in a pipe by using an inclined manometer. Practice the process control system e.g study of positive and negative feed back dynamic response, stability, gain linear and non linear behavior etc. using a Demonstration control Apparatus. Measure the strain or torgue by a strain gauge.

4 (a) (b) (c) 5 (a) (b) 6 (a) (b)

(c)

36

7 (a) (b) 8 (a) (b) (c) (d) 9 (a) (b) 10 (a) (b) 11 (a) 12 (a) (d)

Measure the absolute humidity and relative humidity of air by using a sling psychrometer. Operate the photoelectric transducer for the measurement of intensity of light. Measure the level of a vessel using a suitable level measuring instrument available in the laboratory. Control the level of a vessel/container using a level control apparatus. Study the liquid level control regulation loop using a level regulation control unit. Operate a liquid level and pressure control Test stand. Measure the flow rate of a flowing liquid by using an orifice meter. Operate and study a process trainer unit. Measure the flow rate of a liquid flowing in a pipe using a venturi meter. Operate and study an ElectroHydraulic servo in process control system. Determine the flowrate by using a rotameter. Determine the pH value of a solution using a suitable instrument. Control the pH control mechanism using a pH control system unit.

13 Record the temperature of an oven in a circular recorder.

REFERENCE BOOKS 1 2 3 4 5 6 7 8 9 10 Electrical and Electronics measurement and instrumentation A. K. Sawhney. Engineering Instrumentation Technology D. C. Ramsay; Process control Instrumentation Technology C. D. Jahnson; Industrial Instrumentation D. P Eckman; Principles of Industrial Process Control D. P. Eckman; Instrumentation F. M Kirk and K. N. R Rimboi; Electrical Measurement and Measuring Instruments J. B Gupta; Electrical Transducers for Industrial Measurement P. H. Mansfield; Industrial Instrumentation Fundamentals Austin E. Fribance; Chemical Instrumentation and Process Control A. Suryanarayan;

37

3033

APPLIED MECHANICS

T 2

P 3

C 3

AIMS To provide the understanding of the composition and resolution of forces and computing the resultant forces. To provide the ability of computing moments of inertia of different simple sections and solid bodies. To enable to understand the laws of friction and the co-efficient of friction. To provide the understanding of deriving support reactions and types of loading on simple beams and structures. To enable to understand the concept and principle of motion and simple harmonic motion. To facilitate the understanding of work-power-energy, projectiles and gear trains.

SHORT DESCRIPTION Composition and resolution of forces; Moments and their applications; Equilibrium of forces; Center of gravity; Moment of inertia; Friction; Support reaction; Simple harmonic motion; Projectiles; Work, power and energy; Gear trains. DETAIL DESCRIPTION Theory : 1 Understand the composition and resolution of forces. 1.1 State the effect of forces. 1.2 Mention the characteristics of a force. 1.3 Define resultant force and composition of forces. 1.4 Find the resultant force graphically and analytically. 1.5 Write the laws of forces. 1.6 Define resolution of a force. 1.7 State the principle of resolution of force. 2 Understand the principles of resultant force. 2.1 Express the deduction of the formula for finding the resolved part of a component. 2.2 Find the position of the resultant force graphically and analytically. 2.3 Solve problems related to resultant force. 3 Understand the aspects of moment of forces. 3.1 Define moment of force. 3.2 Represent the moment of a force geometrically. 3.3 Mention the units of moment. 3.4 Identify the clockwise and anticlockwise moment.

38

3.5 State the Varignons principle of moments. 3.6 State the laws of moments. 3.7 State what is meant by the lever. 3.8 Identify the types of lever. 3.9 Solve problems related to moment of forces. Understand the aspects of equilibrium of forces. 4.1 Mention different system of forces. 4.2 State the principles of equilibrium of forces. 4.3 State the Lamis theorem. 4.4 Express the derivation of Lamis theorem. 4.5 Describe different methods of the equilibrium of coplanar forces and non-coplanar forces. 4.6 Explain the conditions of equilibrium. 4.7 Mention the various types of equilibrium of forces. 4.8 Solve problems related to equilibrium of forces. Understand the concept of center of gravity. 5.1 Define center of gravity and centroid. 5.2 Distinguish between center of gravity and centroid. 5.3 Explain the methods of finding out center of gravity of simple geometrical figure. 5.4 Determine the center of gravity of simple geometrical figure geometrically and by integration. 5.5 Identify the axis of reference and axis of symmetry. 5.6 Determine the center of gravity of plain geometrical figure by first principle of moments. 5.7 Calculate the center of gravity of compound geometrical figure or areas by moments. 5.8 Calculate the center of gravity of solid bodies. Understand the application of moment of inertia. 6.1 Explain the term moment of inertia. 6.2 Mention the units of moment of inertia. 6.3 Express the derivation of the formulae for moment of inertia of an area. 6.4 Describe the methods for finding out the moment of inertia. 6.5 Find the moment of inertia of simple areas by the method of integration. 6.6 State the theorem of perpendicular axis as applied to moment of inertia. 6.7 Show the proof of the theorem of perpendicular as applied to moment of inertia. 6.8 State the parallel axis theorem in the determination of moment of inertia of areas. 6.9 Explain the radius of gyration and section modulus. 6.10 Calculate the moment of inertia and section modulus of composite sections and simple solid bodies. Understand the principles of mass moment of inertia. 7.1 Explain the mass moment of inertia

39

10

11

Mention the units of mass moment of inertia. State the formulae for finding out the mass moment of inertia of uniform rod, circular ring, circular lamina and solid sphere. 7.4 Calculate the mass moment of inertia of simple solid bodies and flywheel. Understand the principles of friction. 8.1 Define friction. 8.2 State the laws of static and dynamic friction. 8.3 Identify the types of friction. 8.4 Explain the angle of friction. 8.5 Explain coefficient of friction. Understand the application of friction. 9.1 Determine the frictional force of a body lying on an inclined plane. 9.2 Identify the ladder and wedge. 9.3 Identify the methods of solving the problems on wedge and ladder friction. 9.4 Describe the screw friction. 9.5 Determine the efficiency of a screw jack. 9.6 Solve problems relating to the application of friction. Understand the fundamentals of support reaction. 10.1 Define beam. 10.2 Identify the types of beam. 10.3 Identify the types of loading on beam. 10.4 Determine the support reactions of different types of beam under different loading conditions. 10.5 Identify the frames and trusses with their end supports. 10.6 State the methods of finding support reactions and force on the member of the frame. 10.7 Outline the assumptions made in finding force in the member of the frame or truss. 10.8 Calculate the support reactions and forces on different end supports of simple truss by graphical, joint and section methods. 10.9 Identify the nature of the force on the members of the frame or truss graphically and analytically. Understand the principle of simple harmonic motion. 11.1 Describe simple harmonic motion (S.H.M.). 11.2 State the general condition of simple harmonic motion. 11.3 Describe the terms relating to S. H. M. such as (a) amplitude (b) oscillation (c) beat (d) periodic time and (e) frequency. 11.4 Express the derivation of velocity and acceleration of a particle moving with S. H. M. 11.5 Express the derivation of maximum velocity and acceleration of a particle moving with S. H. M. 11.6 Solve problems related to simple harmonic motion.

7.2 7.3

40

12

13

14

Understand the features of projectile. 12.1 Describe a projectile. 12.2 Give example of projectiles. 12.3 Describe the term relating to projectiles. 12.4 Identify the motion of a body thrown horizontally in the air. 12.5 Describe the motion of a projectile. Understand the principle of projectiles. 13.1 Express the derivation of the equation of the path of a projectile. 13.2 Express the derivation of the time of flight of a projectile on a horizontal plane. 13.3 Express the derivation of horizontal range of a projectile. 13.4 Express the derivation of the equation of maximum height of a projectile on a horizontal plane. 13.5 Express the derivation of velocity and direction of motion of a projectile after a given interval of time. 13.6 Solve problems related to projectiles. Understand the aspects of work, power and energy. 14.1 Define work, power and energy. 14.2 State the units of work, power and energy. 14.3 Explain the work done in rotation. 14.4 Mention the types of engine power. 14.5 State the meaning of the engine efficiency. 14.6 Mention the types of engine efficiency. 14.7 Mention types of energy. 14.8 Express the derivation of the equation of kinetic energy. 14.9 State the law of conservation of energy. 14.10 Solve problems related to work, power and energy.

15

Understand the various aspects of gear trains. 15.1 State what is meant by gear. 15.2 Identify the types of gears. 15.3 Identify the simple gear drive. 15.4 Express the derivation of the equation of velocity ratio of simple gear drive. 15.5 Identify the compound gear drive and gear train. 15.6 Identify the equation of power transmitted by simple and compound train. 15.7 Identify the epicyclic gear train. 15.8 Express the derivation of the velocity ratio of an epicylic gear train. 15.9 Solve problems related to gear trains.

Practical : 1 Determine the resultant force by using force board.

41

1.1 Set up the force board. 1.2 Set up the accessories on force board. 1.3 Find the resultant force. 1.4 Calculate the magnitude of resultant force. 1.5 Compare the calculated values with experimental values. Determine the compression load using crane boom. 2.1 Set up the crane boom. 2.2 Set up the accessories on crane boom. 2.3 Find the compression load on jib. 2.4 Calculate the compression analytically. 2.5 Compare the experimental values with analytical values. Determine the equilibrium force by using Kennon force table. 3.1 Set up the Kennon force table. 3.2 Set up the accessories on Kennon force table. 3.3 Find the magnitude and direction of a force establishing equilibrium. 3.4 Calculate the magnitude and direction of equilibrium force. 3.5 Compare the calculated values with experimental values. Determine the center of a triangular lamina. 4.1 Select a triangular lamina and a plumb bob. 4.2 Set up the plumb bob. 4.3 Find the center point of the triangular lamina. Determine the center of gravity of solid body. 5.1 Select solid bodies such as solid rod, step rod and body with cut out holes. 5.2 Select a fulcrum. 5.3 Set up the fulcrum. 5.4 Find the center point. 5.5 Compare the analytical values with experimental values. Determine the co-efficient of friction. 6.1 Set up the friction apparatus. 6.2 Select the materials of which coefficient of friction is to be determined. 6.3 Place the materials over each other. 6.4 Raise one end of the body until the other body slides down. 6.5 Find the angle of friction. 6.6 Find the of co-efficient friction. Determine the action of load on the member of simple frame or truss. 7.1 Select two members of which one end roller and other end pin point. 7.2 Select a tension spring. 7.3 Make a unit as a simple frame or truss. 7.4 Apply the load. 7.5 Read the tension load on spring. Determine the values of term related S. H. M. 8.1 Setup the simple pendulum.

42

10

Oscillate the pendulum. Find the value of amplitude, periodic time, oscillation, beat and frequency. 8.4 Calculate maximum velocity and acceleration. Determine the torque of engine by prony brake. 9.1 Set up the prony brake with the engine fly wheel . 9.2 Tighten the hand wheel of prony brake. 9.3 Measure the length of torque arm. 9.4 Start the engine. 9.5 Take the reading of spring scale. 9.6 Find the torque of engine. 9.7 Compare the calculated values with the manufacturers recommended values. Determine the BHP of an engine by chassis dynamometer. 10.1 Place the vehicle on chassis dynamometer. 10.2 Start the vehicle engine. 10.3 Transmit power at different gear position. 10.4 Find the B. H. P. of the engine by chassis dynamometer at different speeds. 10.5 Compare the experimental value with the manufactures recommended value.

8.2 8.3

REFERENCE BOOKS

1 2 3 4 5

Applied Mechanics Applied Mechanics Applied Mechanics Analytical Mechanics Mechanics of Materials

R. S. Khurmi R. K. Jain Fairries Faires & Nash Morgan

43

1551

BOOK KEEPING & ACCOUNTING 2

TP 0

C 2

AIMS To be able to understand the principles and practices of book keeping and accounting. To be able to understand the procedures of general accounting, financial accounting and their applications.

SHORT DESCRIPTION Concept of book keeping and accounting; Transactions; Entry systems; Accounts; Journal; Ledger; Cash book; Trial balance; Final accounts; Cost account & financial accounting; Depreciation; Public works accounts. DETAIL DESCRIPTION 1 Understand the concept of book keeping and accounting. 1.1 Define book keeping and accountancy. 1.2 State the objectives of book keeping. 1.3 State the advantages of book keeping. 1.4 Differentiate between book keeping and accounting. 1.5 State the necessity and scope of book keeping and accounting. Understand the transactions. 2.1 Define transactions and business transaction. 2.2 Explain the importance of transactions. 2.3 Describe the characteristic features of transactions. 2.4 Discuss the classification of transaction. 2.5 Identify the transaction from given statements stating reasons. Understand the entry system. 3.1 State the aspects of transactions. 3.2 Define single entry system. 3.3 State the objectives of single entry system. 3.4 Discuss the disadvantages of single entry system. 3.5 Define double entry system. 3.6 Discuss the principles of double entry system. 3.7 Justify whether double entry system is an improvement over the single entry system. 3.8 Distinguish between single entry and double entry system of book keeping. Understand the classification of accounts. 4.1 Define accounts.

44

State the objectives of accounts. Illustrate different type of accounts with example. Define Golden rules of Book keeping. State the rules for Debit and Credit in each class of accounts. Determine Debtor (Dr) and Creditor (Cr.) from given transactions applying golden rules. 4.7 Define accounting cycle. 4.8 State the different steps of accounting cycle. Understand the Journal. 5.1 Define Journal. 5.2 State the object of Journal. 5.3 State the functions of Journal. 5.4 Mention the various names of Journal. 5.5 Interpret the form of Journal. 5.6 Journalize from given transactions. Understand the ledger. 6.1 Define ledger. 6.2 Interpret the form of ledger. 6.3 State the functions of ledger. 6.4 Distinguish between Journal and Ledger. 6.5 Prepare ledger from given transactions. 6.6 Explain why ledger is called the king of all books of accounts. Understand the cash book. 7.1 Define cash book (single, double and triple column). 7.2 Explain cash book as both Journal and Ledger. 7.3 Prepare double column cash book from given transactions showing balances. 7.4 Prepare triple column cash book from given transaction and find out the balances. 7.5 Define petty cash book. 7.6 Prepare analytical and imprest system of cash book. 7.7 Define discount. 7.8 Explain the different types of discount. Understand the trial balance. 8.1 Define trial balance. 8.2 State the object of a trial balance. 8.3 Discuss the methods of preparation of a trial balance. 8.4 Explain the limitations of a trial balance. 8.5 Prepare trial balance from given balance. Understand the final accounts. 9.1 State the components of final account. 9.2 Distinguish between trial balance and balance sheet. 9.3 Identify the revenue expenditure and capital expenditure.

4.2 4.3 4.4 4.5 4.6

45

10

11

12

Select the items to be posted in the trading account, profit & loss account and the balance sheet. 9.5 State the adjustment to be made from the given information below or above the trial balance. 9.6 Prepare trading account, profit & loss account and balance sheet from the given trial balance & other information. Understand the cost and financial accounting. 10.1 Define financial accounting. 10.2 State the objectives of financial accounting. 10.3 Define cost accounting. 10.4 Discuss the relationship between financial Accounting and cost accounting. 10.5 State the elements of direct cost and indirect cost. 10.6 Prepare cost sheet showing prime cost, factory cost, cost of production, total cost and selling price. 10.7 Explain the following terms: a. Fixed cost b. Variable cost c. Factory cost d. Overhead cost e. Process cost f. Direct cost g. Operating cost h. Standard cost Understand the depreciation 11.1 Define depreciation. 11.2 State the objects of depreciation. 11.3 Discuss the necessity for charging depreciation. 11.4 Describe the different methods of determining depreciation. 11.5 Explain the relative merits and demerits of different method of depreciation. Understand the public works accounts. 12.1 State the important aspects of public works accounts. 12.2 Describe the main features of public works accounts. 12.3 Explain Revenue and Grant. 12.4 Define Value Added Tex (VAT) 12.5 State the merits and demerits of VAT. 12.6 Define Bill and Voucher.

9.4

46

1552

BUSINESS ORGANIZATION

T 2 0

P 2

AIMS To be able to understand the basic concepts and principles of business organization. To be able to understand the banking system and insurance policy in Bangladesh. To be able to understand the trade system and stock exchange activities in Bangladesh.

SHORT DESCRIPTION Principles and functions of business organization; Formation of business organization; Purchasing functions and systems; Banking system and its operation; Negotiable instrument; Stock Exchange; Home trade and foreign trade; Insurance; provident fund and benevolent fund. 1 Understand business organization. 1.1 Define business. 1.2 Mention the objects of business. 1.3 Define business organization. 1.4 State the principles of business organization. 1.5 State the function of business organization. 2 Understand the formation of business organization. 2.1 Define soletradership, partnership and joint stock company. 2.2 Describe the formation of soletradership, partnership and joint stock company. 2.3 Mention the advantages and disadvantages of soletradership, partnership and joint stock company. 2.4 Discuss the role of co-operative society (producers co-operative and consumers co-operative) in Bangladesh. 3 Understand the purchasing functions and system. 3.1 Define purchasing. 3.2 Describe the five R (right quantity, right quality, right time, right price & right source) of purchasing principles. 3.3 State the function of purchase. 3.4 Discuss the purchasing procedure. 4 Understand the banking system and its operations. 4.1 Define bank. 4.2 State the service rendered by bank. 4.3 Describe the classification of bank in Bangladesh. 4.4 State the functions of Bangladesh Bank in controlling money market.

47

Mention the various name of commercial Bank in Bangladesh and their functions. 4.6 Describe the role of Gramin Bank in assisting small scale industries. 4.7 Mention different types of account operated in a bank. 4.8 Mention how different types of bank accounts are opened and operated. Understand the negotiable instrument. 5.1 Define negotiable instrument. 5.2 Discuss the types of negotiable instrument. 5.3 Define cheque. 5.4 Describe different types of cheque. 5.5 Define bill of exchange. 5.6 Define hondi and letter of credit. Understand the stock exchange. 6.1 Define stock exchange. 6.2 State the objects of stock exchange. 6.3 Explain the functions of stock exchange. 6.4 Mention the procedure of membership of stock exchange. 6.5 Discuss the procedure of transaction in stock exchange. 6.6 Explain the stock exchange systems in Bangladesh. Understand the home trade. 7.1 Define home trade. 7.2 State the objects of home trade. 7.3 Define whole sale trade. 7.4 State the functions of whole sale trade. 7.5 Define retail trade. 7.6 State the advantages of retail trade. 7.7 Differentiate between whole sale trade and retail trade. Understand the foreign trade. 8.1 Define foreign trade. 8.2 Mention the advantages and disadvantages of foreign trade. 8.3 Mention the classification of foreign trade. 8.4 Discuss the importance of foreign trade in the economy of Bangladesh. Understand the insurance, pension compensation, provident fund and benevolent fund. 9.1 Define insurance. 9.2 Describe the essential conditions of insurance contract. 9.3 Describe life insurance, marine insurance, fire insurance, re-insurance and premium. 9.4 Discuss the types of insurance. 9.5 Distinguish between life insurance and general insurance. 9.6 State the pension policy of the government and autonomous bodies. 9.7 Explain the features of group insurance system and employees benevolent fund.

4.5

48

49

4-YEAR DIPLOMA-IN-ENGINEERING PROGRAM

CERAMIC TECHNOLOGY

SYLLABUS SIXTH SEMESTER

50

3661

WHITE WARES II

T 2

P 3

C 3

AIMS To be able to understand the pottery technology. To be able to understand the properties of white wares. To be able to prepare stoneware, porcelain, sanitary ware, products.

tile and allied

SHORT DESCRIPTION Vitreous sanitary wares; Manufacturing process of tiles; Electrical porcelain and its manufacturing process; Refractory porcelain and its manufacturing process; Manufacturing process of spark plug; Steatite body and its manufacturing process; Cordierite & rutile body and their manufacturing process; Titanate body and its manufacturing process; Zircon body and its manufacturing process; Lava bodies and its manufacturing process; Stone ware and their manufacturing process; Chemical porcelain and its manufacturing process; Laboratory ware; Engineering ware and their manufacturing process; Ceramic cutting tools and their manufacturing process; Ceramic crucibles and their manufacturing process; Saggar and kiln furniture; Biscuit firing and its controlling system; Glost firing and its controlling system; Decoration firing and its controlling system; Oxidation and reduction firing and their controlling system. DETAIL DESCRIPTION Theory: 1 Understand the sanitary wares. 1.1 Define sanitary ware. 1.2 List 10 (ten) sanitary ware products. 1.3 Describe the raw materials and their quality for sanitary wares. 1.4 Mention the composition of sanitary ware. 1.5 Discuss the production method of sanitary ware. 1.6 Describe the drying, glazing and firing of sanitary wares. 1.7 Describe the characteristics of sanitary ware. 1.8 Describe the properties of sanitary ware. 2 Understand the tiles. 2.1 Define tiles. 2.2 Classify tiles on the basis of uses and water absorption. 2.3 Describe the uses of tile. 2.4 Describe the raw materials of tiles and their quality. 2.5 Mention the composition of tiles. 2.6 Describe the tile forming Method of tile. 2.7 Describe the properties of tiles. 3 Understand the wall tile.

51

3.1 Define wall tile. 3.2 Mention the Raw materials of wall tile. 3.3 Describe the properties of wall tile. 3.4 Describe the forming process of wall tile. 3.5 Mention the composition of wall tile. 3.6 Describe the use of wall tile. Understand the Floor tile. 4.1 Define floor tile. 4.2 Mention the composition of floor tile. 4.3 Describe the forming process of floor tile. 4.4 Describe the properties of floor tile. 4.5 Describe the use of floor tile Understand the chemical porcelain. 5.1 Define chemical porcelain. 5.2 Mention the composition of chemical porcelain. 5.3 Mention the forming Method of chemical porcelain. 5.4 Describe the properties of chemical porcelain. 5.5 Explain the use of chemical porcelain. 5.6 Mention the biscuit and glaze firing temperature of chemical porcelain. Understand the chemical stoneware body. 6.1 Define chemical stoneware. 6.2 Mention the composition of chemical stoneware. 6.3 Mention the forming method of chemical stoneware. 6.4 Describe the properties of chemical stoneware. 6.5 Mention the biscuit and glaze firing temperature of chemical stoneware. Understand the electrical porcelain and its manufacturing process. 7.1 Define electrical porcelain. 7.2 Classify the electrical porcelain insulator. 7.3 Distinguish between low voltage and high voltage porcelain. 7.4 Mention the composition of low and high voltage porcelain. 7.5 Describe the characteristics of low voltage and high voltage porcelain. 7.6 Describe the forming process of electrical porcelain. 7.7 Describe drying, glazing and firing of electrical porcelain. 7.8 List the names of ten low voltages and high voltage porcelain and their uses. 7.9 Describe the high frequency insulator. Understand the refractory porcelain and its manufacturing process. 8.1 Define refractory porcelain. 8.2 Describe the characteristic of refractory porcelain. 8.3 Discuss the forming process of refractory porcelain products. 8.4 Describe the firing process of refractory porcelain. 8.5 Define the composition of refractory porcelain. 8.6 List the 6 (six) refractory porcelain products. Understand the manufacturing process of spark plug.

52

10

11

12

13

14

15

16