Beruflich Dokumente

Kultur Dokumente

PPE BS ENs Guide PDF

Hochgeladen von

srijubasu1121Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PPE BS ENs Guide PDF

Hochgeladen von

srijubasu1121Copyright:

Verfügbare Formate

Appendix 1 RESPIRATOR TYPES AND RESPIRATOR STANDARDS This appendix concentrates on dust and aerosol filtering respirators as this

type is the most likely to be used. Where chemical filtration is required, then suitable disposable half-mask respirators will be needed, or chemical cartridges fitted to half- or full-face masks, or to powered respirators. The appropriate cartridge must be chosen for the contaminant and this must be changed in line with manufacturers recommendations. Generally speaking, a satisfactory (and consistently satisfactory) fit is more likely to be achieved with a half mask respirator than with a disposable respirator and this type is more economical if long term use is needed. If disposable dust respirators are chosen, note that they are generally described as single shift respirators they are designed to be used for a continuous 8 hour shift and should not be used for longer than this. Users should note that it is unlikely that a satisfactory fit can be achieved with a disposable respirator that has been donned and removed several times throughout a day. Three categories of dust filtration are available (a) (b) (c) low efficiency, FFPI (Protection Factor1 4) medium efficiency, FFP2 (Protection Factor 10) high efficiency, FFP3 (Protection Factor 20)

Only FFP2 and FFP3 respirators are recommended as these give the highest levels of protection. Surgical masks and nuisance dust masks are not classed as RPE: they give no protection against inhalation of fine particulates and must not be used as a control measure. Disposable respirators may be obtained with or without exhalation valves: those with valves help to avoid heat and moisture build up in the mask and are more comfortable for longer term use. The Safety Office, or your Area Safety Officer, should be consulted where there is doubt over the most appropriate type of RPE to choose for a particular individual or task.

1.

Disposable dust respirators, with or without exhalation valve Standard: Protection: EN 149:2001 FFP2 or FFP3 Protection Factors of 10 (FFP2) or 20 (FFP3) are available. Although FFP3 respirators provide significantly better protection than FFP2, they also cost significantly more. None required. Dispose of them after each shift. Follow the manufacturers instructions and especially check the respirator is in good order before use use both straps, fitted one below and one above the ears adjust the nose bridge for a correct fit do not allow the inside to become contaminated dispose of it after a single shift

Maintenance: Precautions:

Protection factor (PF): concentration of contaminant in breathing zone = ambient concentration /PF

Page 1 of 3 UPS S7/09 (Appendix 1) July 2009

2.

Disposable half-mask respirators Standard: Protection: EN405 Protection Factors of 10 (FFP2) or 20 (FFP3) are available in combination with protection against organic vapours and/or inorganic gases. P3 filters provide significantly better protection than P2 filters but at modest increased cost. P3 filters for the 3M 7500 mask are available with added activated charcoal, giving some protection against odours as well. None required. These should be disposed of within one month, in which case there are no maintenance requirements under COSHH. Care must be taken over storage if the inside is to remain uncontaminated during their one-month lifetime. Follow the manufacturers instructions and especially check the respirator is in good order before use wear the straps as indicated by the manufacturer clean the mask after use pay special attention to the valve(s) do not allow the inside to become contaminated dispose of it after one month of use.

Maintenance:

Precautions:

3.

Half-mask respirators with disposable filters Standard: EN 140 (mask). Filter standards are EN 141 (gas filters of Class 1, 2, or 3), EN 143 (particle filters of class P1, P2, or P3) and EN 371 (Class Ax, for certain low boiling point organic chemicals) For particulate filtration, Protection Factors of 10 (P2) or 20 (P3) are available. EN 143 P3 filters are normally used and excellent face seals may be achieved with this type of mask. The preferred respirator for protection against aeroallergens is the 3M 7500, which is generally fitted with two P3 filters, but may alternatively be fitted with P3 filters that give additional protection against odours by incorporating activated charcoal. Gas filters may be fitted to half-mask respirators, giving protection against organic vapours and/or inorganic gases. Required. Under COSHH, non-disposable RPE has stringent maintenance, examination, and test requirements. Unless a commitment can be made to comply with these requirements, the use of half-mask respirators is likely to contravene the COSHH Regulations. Because the mask is reused care must be taken over storage if the inside is to remain uncontaminated. Follow the manufacturers instructions and especially check the respirator is in good order before use wear the straps as indicated by the manufacturer clean the mask after use pay special attention to the valve(s) do not allow the inside to become contaminated.

Protection:

Maintenance:

Precautions:

Page 2 of 3 UPS S7/09 (Appendix 1) July 2009

4.

Powered Respirators Standard: Protection: EN 12941 TH2 or TH3 (older respirators to EN 146 may still be used). They are available with hoods (TH3 or TH2), or visors or helmets (TH2). Protection Factors of 20 (TH2) or 40 (TH3). Powered respirators using hoods to EN 12941 TH3 provide the highest level of protection, and respirators to this standard incorporate a low flow warning device (those to EN 146 do not). Required. Under COSHH, examination, testing, and maintenance are required at least monthly. The manufacturers instructions should be followed and a record of the tests should be kept for at least five years. The use of powered respirators is necessary where individuals cannot wear fitted RPE (e.g. they have beards or heavy facial stubble). The University Safety Office should be consulted for assistance in the choice of respirator. Precautions: Follow the manufacturers instructions and especially check that all parts of the device are in good order before use check that the fan is providing enough airflow before use charge or change the battery after use do not use the device if it is dirty, damaged, incomplete or not providing sufficient airflow

Maintenance:

5.

Full-face respirators Standard: Protection: BS EN 136, of Classes 1, 2, or 3 (mask). Filter standards are as described above, to EN 141, 143, or 371 Protection Factor of 40 when EN 143 P3 filters are used these filters give excellent protection, the highest standard of face seal may be achieved with this type of mask, and it also protects the eyes. Combination filters may be fitted giving protection against organic vapours and/or inorganic gases. These respirators are cumbersome and uncomfortable to wear and are generally suitable only for use with chemical cartridges in emergencies (e.g. for cleaning up spillages), not for routine protection against allergenic dusts. They are not suitable for spectacle wearers unless prescription inserts are used in the mask. Maintenance: Required. Under COSHH, non-disposable RPE has stringent maintenance, examination, and test requirements. Unless a commitment can be made to comply with these requirements, the use of half-mask respirators is likely to contravene the COSHH Regulations. Care must be taken over storage if the inside is to remain uncontaminated. Follow the manufacturers instructions and especially check the respirator is in good order before use wear the straps as indicated by the manufacturer clean the mask after use pay special attention to the valves do not allow the inside to become contaminated.

Page 3 of 3 UPS S7/09 (Appendix 1) July 2009

Precautions:

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Is 2720 4 1985Dokument1 SeiteIs 2720 4 1985srijubasu1121Noch keine Bewertungen

- FMS BHU - How To ReachDokument3 SeitenFMS BHU - How To Reachsrijubasu1121Noch keine Bewertungen

- ShodharthiDokument8 SeitenShodharthisrijubasu1121Noch keine Bewertungen

- Utilization NotesDokument3 SeitenUtilization Notessrijubasu1121Noch keine Bewertungen

- L-T - L Mraft-L (T-F-T-L: PublicDokument2 SeitenL-T - L Mraft-L (T-F-T-L: Publicsrijubasu1121Noch keine Bewertungen

- In Favour of The " Member Secretary, GSET" Payable at Vadodara, On or Before 10th October 2016. TheDokument1 SeiteIn Favour of The " Member Secretary, GSET" Payable at Vadodara, On or Before 10th October 2016. Thesrijubasu1121Noch keine Bewertungen

- Category Minimum Qualifying Marks Paper - II 50 Marks Paper - II 50 Marks Aggregate Paper - I + Paper - II 100 Marks General Sebc/Obc ST/ ST/ PH/ VHDokument2 SeitenCategory Minimum Qualifying Marks Paper - II 50 Marks Paper - II 50 Marks Aggregate Paper - I + Paper - II 100 Marks General Sebc/Obc ST/ ST/ PH/ VHsrijubasu1121Noch keine Bewertungen

- Admission Form LU OptDokument2 SeitenAdmission Form LU Optsrijubasu1121Noch keine Bewertungen

- India Is Best WorldDokument7 SeitenIndia Is Best Worldsrijubasu1121Noch keine Bewertungen

- Safety Health ProgramDokument6 SeitenSafety Health Programsrijubasu1121Noch keine Bewertungen

- DRP Oct Nov 2013Dokument32 SeitenDRP Oct Nov 2013srijubasu1121Noch keine Bewertungen

- B.Ed Syllabus PDFDokument64 SeitenB.Ed Syllabus PDFsrijubasu11210% (1)

- IBall Service CentresDokument17 SeitenIBall Service Centressrijubasu1121Noch keine Bewertungen

- Akhilesh Yadav Introduces Barcoding & E-Filing For Speedy Disposal of Public ComplaintsDokument3 SeitenAkhilesh Yadav Introduces Barcoding & E-Filing For Speedy Disposal of Public Complaintssrijubasu1121Noch keine Bewertungen

- Ugc Net SolvedDokument38 SeitenUgc Net Solvedsrijubasu1121Noch keine Bewertungen

- Diary For All YearsDokument367 SeitenDiary For All Yearssrijubasu1121Noch keine Bewertungen

- Team-Teaching:: Creating Individualized Attention and Personal Learning EnvironmentsDokument10 SeitenTeam-Teaching:: Creating Individualized Attention and Personal Learning Environmentssrijubasu1121Noch keine Bewertungen

- Permit - To - Work - Procedure1 NOV 08Dokument123 SeitenPermit - To - Work - Procedure1 NOV 08srijubasu1121Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Esteem 1999 2000 1.3L 1.6LDokument45 SeitenEsteem 1999 2000 1.3L 1.6LArnold Hernández CarvajalNoch keine Bewertungen

- Contemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceDokument25 SeitenContemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceGrace06 Labin100% (7)

- Immigrant Italian Stone CarversDokument56 SeitenImmigrant Italian Stone Carversglis7100% (2)

- TreesDokument69 SeitenTreesADITYA GEHLAWATNoch keine Bewertungen

- Solutions GoldsteinDokument10 SeitenSolutions GoldsteinAnyiNoch keine Bewertungen

- Stalthon Rib and InfillDokument2 SeitenStalthon Rib and InfillAndrea GibsonNoch keine Bewertungen

- Effects of Climate ChangeDokument3 SeitenEffects of Climate Changejiofjij100% (1)

- Biology Accel Syllabus 2011-2012Dokument3 SeitenBiology Accel Syllabus 2011-2012Mike DeleonNoch keine Bewertungen

- Bảng giá FLUKEDokument18 SeitenBảng giá FLUKEVăn Long NguyênNoch keine Bewertungen

- Dawn of Solar PV CookingDokument5 SeitenDawn of Solar PV CookingAbhinav AgrawalNoch keine Bewertungen

- Arduino Oscilloscope ProjectDokument12 SeitenArduino Oscilloscope ProjectSathya Narayan100% (1)

- Fines Reduction Project at Wendling Bowser QuarryDokument2 SeitenFines Reduction Project at Wendling Bowser QuarryMarcos Antonio ParoliniNoch keine Bewertungen

- Fyp-Hydraulic Brakes CompleteDokument32 SeitenFyp-Hydraulic Brakes CompleteRishabh JainNoch keine Bewertungen

- A Year On A FarmDokument368 SeitenA Year On A FarmvehapkolaNoch keine Bewertungen

- Scanner and Xcal Comperative Analysis v2Dokument22 SeitenScanner and Xcal Comperative Analysis v2Ziya2009Noch keine Bewertungen

- Recipes From The Perfect Scoop by David LebovitzDokument10 SeitenRecipes From The Perfect Scoop by David LebovitzThe Recipe Club100% (7)

- Surface TensionDokument13 SeitenSurface TensionElizebeth GNoch keine Bewertungen

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingDokument47 SeitenColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanNoch keine Bewertungen

- Chapter 3.c (Centroid by Intergration)Dokument15 SeitenChapter 3.c (Centroid by Intergration)Ariff AziziNoch keine Bewertungen

- EXP4 The Diels Alder ReactionsDokument3 SeitenEXP4 The Diels Alder ReactionsLaura GuidoNoch keine Bewertungen

- American BreakfastDokument4 SeitenAmerican BreakfastHamilton Valenzuela ChipongianNoch keine Bewertungen

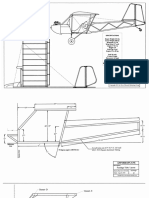

- Plans PDFDokument49 SeitenPlans PDFEstevam Gomes de Azevedo85% (34)

- AssessmentDokument9 SeitenAssessmentJuan Miguel Sapad AlpañoNoch keine Bewertungen

- Dusta ManaDokument16 SeitenDusta ManamahaphalaNoch keine Bewertungen

- Faa Registry: N-Number Inquiry ResultsDokument3 SeitenFaa Registry: N-Number Inquiry Resultsolga duqueNoch keine Bewertungen

- Cynosure Starlux 500 Palomar Technical Service ManualDokument47 SeitenCynosure Starlux 500 Palomar Technical Service ManualJF SilvaNoch keine Bewertungen

- Design and Development of Automatic Pneumatic Jack in Four Wheeler Ijariie5374Dokument5 SeitenDesign and Development of Automatic Pneumatic Jack in Four Wheeler Ijariie5374Saravanan ViswakarmaNoch keine Bewertungen

- EN Manual Lenovo Ideapad S130-14igm S130-11igmDokument33 SeitenEN Manual Lenovo Ideapad S130-14igm S130-11igmDolgoffNoch keine Bewertungen

- NF en Iso 5167-6-2019Dokument22 SeitenNF en Iso 5167-6-2019Rem FgtNoch keine Bewertungen

- Implicit Explicit SignalsDokument8 SeitenImplicit Explicit SignalsVersoza Nel100% (2)