Beruflich Dokumente

Kultur Dokumente

Kinetics of Coal Drying in Bubbling Fluidized Beds

Hochgeladen von

Kin Wai CheahOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Kinetics of Coal Drying in Bubbling Fluidized Beds

Hochgeladen von

Kin Wai CheahCopyright:

Verfügbare Formate

1

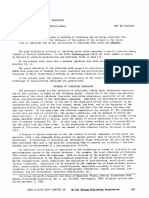

KINETICS OF COAL DRYING IN BUBBLING FLUIDIZED BEDS

Edward K. Levy, Hugo S. Caram, Zheng Yao, Zhang Wei and Nenad Sarunac

Energy Research Center

Lehigh University

117 ATLSS Drive

Bethlehem, Pennsylvania 18015, USA

ABSTRACT

Some coals used in U.S. coal fired power plants have unusually high moisture levels.

High fuel moisture leads to low power plant thermal efficiency, increased stack emissions of

pollutants and maintenance and operational problems. One solution is to dry the coal before

burning it, and if this is done using power plant waste heat, it can result in significant efficiency

improvements.

This paper describes laboratory experiments, to determine the kinetics of coal drying in a

bubbling fluidized bed, and a simple theoretical model of coal drying. The experiments were

performed with coal which had been crushed to minus 6 mm and fluidized with air with

temperatures ranging up to 66C and with velocities of 0.9 to 1.7 m/s. In-bed electrical heaters,

used to simulate an in-bed tube bundle, provided additional thermal energy for drying. The

experiments determined the effects of superficial air velocity, drying temperature and inlet air

humidity level on rate of drying.

A theoretical model of the drying process was developed in which the air and coal

particles are assumed to be at the same temperature and the airwater vapor mixture leaving the

bed at the free surface is in equilibrium with the local values of particle moisture. This model is

in good agreement with laboratory data, showing that for this application, the drying rates do not

depend on fluidized bed bubble behavior or on particle- gas contact, but are controlled by in-bed

heat transfer, flow rate, moisture content and temperature of the feed air, and the equilibrium

moisture content of the coal.

KEYWORDS: Particle Drying, Bubbling Fluidization

____________________

Proceedings Fifth World Congress on Particle Technology, Orlando, Florida, April 2006.

2

I. BACKGROUND

Low rank fuels such as subbituminous coals and lignites contain relatively large amounts

of moisture compared to higher rank coals. When these fuels are used in coal- fired power plants,

the high fuel moisture affects the operation of the power plant, resulting in fuel handling

problems, decreased power plant efficiency, and increased stack gas emissions and station

service power. Recently completed theoretical analyses and coal test burns performed at a U.S.

lignite- fired power plant showed that by reducing the fuel moisture, it is possible to improve

boiler performance and generation efficiency and reduce stack emissions and water consumption

by evaporative cooling towers (Reference 1). The economic viability of the approach and the

actual impact of the drying system on efficiency, stack emissions and water consumption will

depend critically on the design and operating conditions of the drying system. This paper

describes laboratory drying studies performed by the authors to gather data and develop models

on the drying kinetics of high moisture coals.

II. LABORATORY DRYING STUDIES

The drying experiments were performed in a 152 mm diameter, 1372 mm high fluidized

bed column with a sintered powder- metal distributor plate. The compressed air used in the

experiments flowed though a rotameter and air heater before entering the plenum. A submerged

horizontal bundle of 13 mm diameter electric heating elements, instrument ed with thermocouples

to indicate heater surface temperature, provided in-bed heating. Thermocouples inserted through

the bed wall were used to measure vertical distribution of bed temperature. Small samples of

coal were removed from the bed and coal moisture was measured at various time intervals during

the batch bed drying tests.

The experiments were carried out with two coals, a North Dakota lignite and a

subbituminous coal from the Powder River Basin (PRB). The as-received moisture content of

the lignite varied slightly from sample-to-sample, usually ranging from 54 to 58 percent

(expressed as mass of moisture/mass dry fuel) and the PRB coal had a moisture content of

approximately 37 percent. During the first minute or two of each test, fines were elutriated from

the bed. The drying rate presented here is based on the dry coal which remained in the bed after

elutriation had occurred and after coal samples had been removed for analysis.

The drying tests were performed with coal having a wide size distribution, in most cases

with the top size in the 2 to 4 mm range and mean particle sizes from 300 to 400 microns. The

tests were performed with inlet air and heater surface temperatures up to 66C, with superficial

air velocities ranging from 0.9 to 1.7 m/s and with settled bed depths of 0.39 m. The drying

curves for two of the tests are given in Figure 1, where the numerical values for drying rate were

obtained by fitting straight lines to the drying data over the first portions of the tests. Drying rate

results for lignite are summarized in Figure 2, which shows the drying rate as a function of

velocity, for four different particle sizes. The results show that the drying rate increased with air

velocity, but that, within the accuracy of the data, the data for all four particle size distributions

are on the same curve. Thus, the larger drying rates associated with the larger particles, are due

to higher air velocities and not to any inherently higher rates of drying due to particle size. This

suggests that, in this particle size range, drying rate is controlled by the internal pore structure of

the coal, but not by particle size.

3

DRYING RATE VERSUS VELOCITY

0.004

0.005

0.006

0.007

0.008

0.009

0.01

0.011

0.8 0.9 1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8

Velocity (m/s)

D

r

y

i

n

g

R

a

t

e

(

d

G

/

d

t

)

(

k

g

w

t

r

/

k

g

d

r

y

c

o

a

l

*

m

i

n

)

2.82 mm top size

2 mm top size

9.53 mm top size

6.35 mm top size

DRYING RATE VERSUS TEMPERATURE

0

0.002

0.004

0.006

0.008

0.01

0.012

0.014

0.016

0.018

30 35 40 45 50 55 60 65 70

Temperature (C)

D

r

y

i

n

g

R

a

t

e

(

k

g

/

(

k

g

d

r

y

c

o

a

l

*

m

i

n

)

)

Lignite

PRB Coal

U0 = 1.55m/s

Tlog(F) VERSUS G

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

-450 -400 -350 -300 -250 -200 -150 -100 -50 0

Tlog(F)

G

MOISTURE CONTENT VERSUS TIME

0

0.1

0.2

0.3

0.4

0.5

0.6

0 1 0 20 30 40 50 60 70 80 90 100

Time (min)

M

o

i

s

t

u

r

e

C

o

n

t

e

n

t

(

k

g

m

a

s

s

/

k

g

d

r

y

m

a

s

s

)

Tests 39 and 63

U0 = 1.58m/s

Tair,in = 66C

ho = 0.39m

Tube bundle: 2D spacing

6.35 mm top size

Lignite

PRB

As to be expected, drying rate is also a strong function of temperature. Figure 3

compares drying rates for bed and inlet air temperatures ranging from 43 to 66C.

III. FIRST PRINCIPLE DRYING MODEL

The relative humidity of air in equilibrium with coal can be expressed as a function of the

coal moisture content, . Treybal (Ref. 2) presented adsorption data which are correlated well

by

where T is absolute bed temperature and is relative humidity. As is seen in Figure 4, this gives

a good fit of the data, with a relatively small scatter band.

Fig. 1: Comparison of Drying Curves for Lignite

and PRB Coals for a 66C Drying Temperature

Fig. 2: Drying Rate as a Function of

Superficial Air Velocity and Particle Size

Fig. 3: Comparison of Drying Rates for Lignite Fig. 4: Equilibrium Relative Humidity of

and PRB. Effect of Bed and Inlet Air Temperature Air Versus Moisture Content of Lignite

) ( f log T

4

Air

Air

2

1

The equilibrium moisture content-relative humidity relationship, described in Figure 4

was used, along with the equations of conservation of mass and energy, to develop a first

principle model of the drying process. The model assumes at any instant of time, the particles

and air in the bed are at the same temperature and the gas and particle properties do not vary with

vertical distance in the bed. Thus for the batch bed drying process illustrated in Figure 5,

conservation of mass and energy can be written:

( )

i 2

DC

a

m

m

dt

d

&

Eq. 1

( ) ( )

( ) [ ]

1 1 2 2 1 2 pa a

1 2

DC

a

L

2

L C DC LOSS TUBES

hg hg T T C m

m

m

u

dt

dT

C C m Q Q

+ +

1

]

1

,

_

+ +

&

&

& &

Eq. 2

Specific humidity, , can be related to relative humidity and air temperature T, by

( )

( ) T P P

T P 622 . 0

sat

sat

Eq. 3

while the relative humidity is an empirical function of coal moisture (Figure 4).

In addition, the tube bundle heat transfer rate is

( )

BED TUBE TUBE

T T UA Q

&

Eq. 4

and the parameters P

sat

and hg are functions of air temperature.

Fig. 5: Sketch of Dryer Model

Equations 1 to 4 form a system of ordinary differential equations for coal moisture and

bed temperature T

2

as functions of t. This was treated as an initial value problem and solved by a

Runge Kutta numerical integration scheme.

Figures 6-9 show a comparison of the model with one set of drying data. The degree of

agreement shown here is typical of the agreement obtained for the experiments with other bed

operating conditions. The model is an equilibrium model and does not utilize information on bed

5

TEST #36 - COAL MOISTURE CONTENT

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0 10 20 30 40 50 60 70

Time (min)

C

o

a

l

M

o

i

s

t

u

r

e

C

o

n

t

e

n

t

Test L36

Uo = 1.15m/s

Tair,in = 150F

ho = 0.39m

2D spacing

TEST #36 - EXIT AIR SPECIFIC HUMIDITY

0.002

0.006

0.010

0.014

0.018

0.022

0.026

0.030

0 10 20 30 40 50 60 70

Time (min)

E

x

i

t

A

i

r

S

p

e

c

i

f

i

c

H

u

m

i

d

i

t

y

Test L36

Uo= 1.15m/s

Tair,in = 150F

ho = 0.39m

2D spacing

TEST #36 - EXIT AIR TEMPERATURE

70

80

90

100

110

120

130

140

150

160

0 10 20 30 40 50 60 70

Time (min)

E

x

i

t

A

i

r

T

e

m

p

e

r

a

t

u

r

e

(

F

)

Test L36

Uo = 1.15m/s

T

air,in

= 150F

Uo = 0.39m

2D spacing

TEST #36 - EXIT AIR RELATIVE HUMIDITY

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0 10 20 30 40 50 60 70

Time (min)

E

x

i

t

A

i

r

R

e

l

a

t

i

v

e

H

u

m

i

d

i

t

y

Test L36

Uo = 1.15m/s

Tair,in = 150F

ho = 0.39m

2D spacing

bubbling behavior, particle- gas contacting nor mass transfer within the particle pores. For the

range of fluidization conditions encountered in this process, a simple equilibrium model works

very nicely.

Fig. 6: Lignite Drying Curve for Test 36 Fig. 7: Exit Air Temperature for Test 36

Comparison Between Theory and Experiment Comparison Between Theory and Experiment

Fig. 8: Exit Air Specific Humidity for Fig. 9: Exit Air Relative Humidity for Test 36

Test 36 Comparison Between Theory and Comparison Between Theory and Experiment

Experiment

IV. CONCLUSIONS

Laboratory experiments were performed on crushed high moisture coal to determine the

effects of fluidization velocity, particle size, bed temperature and coal rank on rate of drying.

The data show that drying rates do not depend on fluidized bed bubble behavior or on particle-

gas contact, but instead are controlled by in-bed heat transfer, flow rate, moisture content and

temperature of the feed air, and the equilibrium moisture content of the coal. The theoretical

model of the drying process described in this paper is in excellent agreement with the laboratory

6

data. The model assumes the bed is well- mixed, with the air and coal particles being at the same

temperature. The model also assumes the air-water vapor mixture leaving the free surface of the

bed is in equilibrium with the local values of particle moisture.

V. ACKNOWLEDGEMENTS

This conference paper was prepared with the support of the U.S. Department of Energy,

under Award No. DE-FC26-03NT41729. However, any opinions, findings, conclusions, or

recommendations expressed herein are those of the author(s) and do not necessarily reflect the

views of the DOE. The authors are also grateful to Great River Energy for providing partial

funding for the project.

VI. NOMENCLATURE

C

c

Specific Heat of Coal

C

L

Specific Heat of Coal Moisture

C

pair

Specific Heat of Air

d

p

Particle Size

hg Enthalpy of Saturated H

2

O Vapor

a

m

&

Flow Rate of Dry Air

P Absolute Pressure

P

sat

Vapor Pressure of H

2

O

LOSS

Q

&

Rate of Heat Loss to Surroundings

TUBES

Q

&

Rate of Heat Transfer in Tube Bundle

T

1

Air Inlet Temperature

T

2

Bed Temperature

u

L

Internal Energy of Coal Moisture

U

o

Superficial Air Velocity

Relative Humidity

Coal Moisture

,

_

coal dry kg

O H kg

2

&

Drying Rate =

dt

d

Specific Humidity of Air

Das könnte Ihnen auch gefallen

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringVon EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNoch keine Bewertungen

- Combustion of Spanish Coals Under Simulated Pressurized - Uidized-Bed-Combustion ConditionsDokument6 SeitenCombustion of Spanish Coals Under Simulated Pressurized - Uidized-Bed-Combustion Conditionsphemt84Noch keine Bewertungen

- Heat Transfer in Polymer Composite Materials: Forming ProcessesVon EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNoch keine Bewertungen

- Experimental Study On Super-Heated Steam Drying of LigniteDokument7 SeitenExperimental Study On Super-Heated Steam Drying of LignitevhendrayawanNoch keine Bewertungen

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsVon EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilNoch keine Bewertungen

- Conversion of Coal Particles in Pyrolysis and Gasification: Comparison of Conversions in A Pilot-Scale Gasifier and Bench-Scale Test EquipmentDokument10 SeitenConversion of Coal Particles in Pyrolysis and Gasification: Comparison of Conversions in A Pilot-Scale Gasifier and Bench-Scale Test EquipmentRoberto Macias NNoch keine Bewertungen

- Application of COMSOL in Chemical EngineeringDokument11 SeitenApplication of COMSOL in Chemical Engineeringjoseferrehigieneuru100% (1)

- The Effect of Air Preheating On The Combustion of Solid Fuels On A GrateDokument9 SeitenThe Effect of Air Preheating On The Combustion of Solid Fuels On A Gratewindtalkers49Noch keine Bewertungen

- 42 PDFDokument6 Seiten42 PDFbrenbraNoch keine Bewertungen

- Heat Capacity, Entropy, and Free Energy of Rubber HydrocarbonDokument13 SeitenHeat Capacity, Entropy, and Free Energy of Rubber HydrocarbonrifikoNoch keine Bewertungen

- An Experimental Study On Gasification of Colombian Coal in Fluidised BedDokument4 SeitenAn Experimental Study On Gasification of Colombian Coal in Fluidised BedAhmed Al SayedNoch keine Bewertungen

- Advanced 3D Modelling For Anode Baking FurnaceDokument6 SeitenAdvanced 3D Modelling For Anode Baking Furnacefariza_yunitaNoch keine Bewertungen

- Drying Kinetics Lignite, Subbituminous Coals, and High-Volatile Bituminous CoalsDokument5 SeitenDrying Kinetics Lignite, Subbituminous Coals, and High-Volatile Bituminous CoalsyemresimsekNoch keine Bewertungen

- Grigorean Stefan ACMEDokument9 SeitenGrigorean Stefan ACMEStefan GrigoreanNoch keine Bewertungen

- Laminar Flame Speeds of Ethanol, N-Heptane, IsooctaneDokument8 SeitenLaminar Flame Speeds of Ethanol, N-Heptane, IsooctaneanilkoleNoch keine Bewertungen

- CFD Analysis of A 210 MW Tangential Fired BoilerDokument6 SeitenCFD Analysis of A 210 MW Tangential Fired BoilerInnovative Research PublicationsNoch keine Bewertungen

- 09 Combustion (Burners, Combustion Systems)Dokument1 Seite09 Combustion (Burners, Combustion Systems)ahmed1581973Noch keine Bewertungen

- P01 19 PDFDokument0 SeitenP01 19 PDFgarridolopezNoch keine Bewertungen

- Energy Efficiency in Building Using Co2 Heat Pump Water HeatingDokument7 SeitenEnergy Efficiency in Building Using Co2 Heat Pump Water HeatingMarclauryn AdewaleNoch keine Bewertungen

- Radical Evidence For ImprovedDokument8 SeitenRadical Evidence For ImprovedtorillazNoch keine Bewertungen

- Effect of MoistureDokument10 SeitenEffect of Moisturemukesh vikramNoch keine Bewertungen

- Mohammad Zadeh 2002Dokument9 SeitenMohammad Zadeh 2002Reza RhiNoch keine Bewertungen

- THE EFFECT OF FOAMY SLAG IN THE ELECTRIC ARC FURNACES ON ELECTRIC Energy Consumption PDFDokument10 SeitenTHE EFFECT OF FOAMY SLAG IN THE ELECTRIC ARC FURNACES ON ELECTRIC Energy Consumption PDFManojlovic VasoNoch keine Bewertungen

- Methodology: Table 3.1. Enthalpy and Entropy of Magnesium, Calcium and Iron (II) CarbonatesDokument8 SeitenMethodology: Table 3.1. Enthalpy and Entropy of Magnesium, Calcium and Iron (II) Carbonatesnomore891Noch keine Bewertungen

- Simulation of Non-Premixed Natural Gas FlameDokument4 SeitenSimulation of Non-Premixed Natural Gas FlameArul RizkiNoch keine Bewertungen

- (Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Dokument11 Seiten(Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Siraj AL sharifNoch keine Bewertungen

- Void Reduction in Autoclave Processing of Thermoset CompositesDokument5 SeitenVoid Reduction in Autoclave Processing of Thermoset CompositesAbd BaghadNoch keine Bewertungen

- Burner ModellingDokument7 SeitenBurner Modellingkhurram482Noch keine Bewertungen

- Propane Combustion Reaction MechanismDokument11 SeitenPropane Combustion Reaction MechanismAzharuddin Ehtesham FarooquiNoch keine Bewertungen

- Experimental Study of The Dynamic Behavior of A Flame in A 1 m3 Under-Ventilated Compartment: Application To Fire SafetyDokument7 SeitenExperimental Study of The Dynamic Behavior of A Flame in A 1 m3 Under-Ventilated Compartment: Application To Fire SafetyDanny MartinezNoch keine Bewertungen

- High-Pressure Co-Gasification of Coal and Biomass in A Fluidized BedDokument12 SeitenHigh-Pressure Co-Gasification of Coal and Biomass in A Fluidized BedHocine SerNoch keine Bewertungen

- Production of Synthesis Gas: Caalysis Today, 18 (1993) 305-324Dokument20 SeitenProduction of Synthesis Gas: Caalysis Today, 18 (1993) 305-324ainmnrhNoch keine Bewertungen

- Monitoring and Modelling Gas Side Fouling Biomass BoilerDokument7 SeitenMonitoring and Modelling Gas Side Fouling Biomass BoilermsoyoralNoch keine Bewertungen

- Mayank Ate PaperDokument19 SeitenMayank Ate PaperAbhishekSinghNoch keine Bewertungen

- Mast or AkosDokument22 SeitenMast or AkosMohammed Shafi AhmedNoch keine Bewertungen

- Simulation of Secondary Reformer in Industrial Ammonia PlantDokument8 SeitenSimulation of Secondary Reformer in Industrial Ammonia PlantGiang Nguyễn TrườngNoch keine Bewertungen

- Effects of Calcination Conditions On The Properties of LimeDokument15 SeitenEffects of Calcination Conditions On The Properties of Limealexander_suarez_19Noch keine Bewertungen

- Modeling of Propane-Air Combustion in Meso-Scale Tubes With Wire MeshDokument7 SeitenModeling of Propane-Air Combustion in Meso-Scale Tubes With Wire Meshherdi sutanto adigunaNoch keine Bewertungen

- 18 16-96 Adnan P 137-147Dokument11 Seiten18 16-96 Adnan P 137-147محمد رمضانNoch keine Bewertungen

- 2008 - SADRNEZHAAD - Mathematical Model For A Straight Grate Iron Ore Pellet Induration Process PDFDokument7 Seiten2008 - SADRNEZHAAD - Mathematical Model For A Straight Grate Iron Ore Pellet Induration Process PDFKrol Prieto100% (1)

- CFD Modeling of Spontaneous Heating in A Large-Scale Coal ChamberDokument8 SeitenCFD Modeling of Spontaneous Heating in A Large-Scale Coal ChamberdenichezNoch keine Bewertungen

- IgnitionDokument7 SeitenIgnitionfpersiancatNoch keine Bewertungen

- Artigo Do TrabalhoDokument8 SeitenArtigo Do TrabalhoRafaelTeixeiraNoch keine Bewertungen

- CFD Modeling of Spontaneous Heating in A Large-Scale Coal ChamberDokument8 SeitenCFD Modeling of Spontaneous Heating in A Large-Scale Coal Chambernay denNoch keine Bewertungen

- Sirine 3Dokument10 SeitenSirine 3Syrine BOUDEFNoch keine Bewertungen

- Heat Transfer in Rotary KilnsDokument6 SeitenHeat Transfer in Rotary KilnsRafael Curiel MedinaNoch keine Bewertungen

- Development of The "Micro Combustor"Dokument6 SeitenDevelopment of The "Micro Combustor"Haris AbdullaNoch keine Bewertungen

- Optimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073Dokument6 SeitenOptimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073fujiman35Noch keine Bewertungen

- Production of Synthesis GasDokument18 SeitenProduction of Synthesis GasGonzalo TitoNoch keine Bewertungen

- Ignition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionDokument8 SeitenIgnition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionthinhklNoch keine Bewertungen

- Problems With Identifiying A Standard Procedure For Determining Values For Flammable VaporsDokument8 SeitenProblems With Identifiying A Standard Procedure For Determining Values For Flammable VaporsSteve WanNoch keine Bewertungen

- Analysis of Sootblowing Experiments and Research oDokument7 SeitenAnalysis of Sootblowing Experiments and Research ouser_nitsNoch keine Bewertungen

- Building and Environment: Xing Jin, Xiaosong Zhang, Yajun Luo, Rongquan CaoDokument8 SeitenBuilding and Environment: Xing Jin, Xiaosong Zhang, Yajun Luo, Rongquan Caoanon_144521603Noch keine Bewertungen

- (Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Dokument11 Seiten(Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Siraj AL sharifNoch keine Bewertungen

- PP 58-62 Effect of Depth Ratio On The Thermal Performance of Double Flow Packed Bed Solar Air Heater SatendraDokument5 SeitenPP 58-62 Effect of Depth Ratio On The Thermal Performance of Double Flow Packed Bed Solar Air Heater SatendraEditorijset IjsetNoch keine Bewertungen

- Rotary Cement Kiln Coating Estimator: Integrated Modelling of Kiln With Shell Temperature MeasurementDokument10 SeitenRotary Cement Kiln Coating Estimator: Integrated Modelling of Kiln With Shell Temperature MeasurementDiego MorenoNoch keine Bewertungen

- 1 s2.0 S1540748912002702 Main - Cetane - NumberDokument7 Seiten1 s2.0 S1540748912002702 Main - Cetane - NumberEverton Luiz Dias da SilvaNoch keine Bewertungen

- Tyre PyrolysisDokument6 SeitenTyre PyrolysisHande CambazNoch keine Bewertungen

- Oxidation Mechanism of C in MgO-C Refractory BricksDokument1 SeiteOxidation Mechanism of C in MgO-C Refractory BricksGisele SilNoch keine Bewertungen

- Improving The Heat Transfer of Nano Fluids and Nano Lubricants With Carbon NanotubesDokument12 SeitenImproving The Heat Transfer of Nano Fluids and Nano Lubricants With Carbon Nanotubeszahidanwar446100% (1)

- 2020 (Plasma) Comparision of Gliding Arc and Micorwave PlasmaDokument25 Seiten2020 (Plasma) Comparision of Gliding Arc and Micorwave PlasmaKin Wai CheahNoch keine Bewertungen

- 2020 (Reaction Mechanism) H2S Decomposition With MoS3 & WS3Dokument9 Seiten2020 (Reaction Mechanism) H2S Decomposition With MoS3 & WS3Kin Wai CheahNoch keine Bewertungen

- 2012 (Process) Packed Bed Coaxial Dielectric Barrier DischargeDokument6 Seiten2012 (Process) Packed Bed Coaxial Dielectric Barrier DischargeKin Wai CheahNoch keine Bewertungen

- 2019 (Cat) NP Dielectric Barrier Discharge With NiMo Sulfide SemiConductorDokument13 Seiten2019 (Cat) NP Dielectric Barrier Discharge With NiMo Sulfide SemiConductorKin Wai CheahNoch keine Bewertungen

- 2019 (Process) Dielectric Barrier DischargeDokument8 Seiten2019 (Process) Dielectric Barrier DischargeKin Wai CheahNoch keine Bewertungen

- NP Coaxial Pulsed Corona DischargeDokument5 SeitenNP Coaxial Pulsed Corona DischargeKin Wai CheahNoch keine Bewertungen

- 2019 (Cat) Decomposition of H2S Over Ceria Supported Transition MetalDokument10 Seiten2019 (Cat) Decomposition of H2S Over Ceria Supported Transition MetalKin Wai CheahNoch keine Bewertungen

- 2007 (Process) NP Pulsed Corona Discharge ReactorDokument12 Seiten2007 (Process) NP Pulsed Corona Discharge ReactorKin Wai CheahNoch keine Bewertungen

- Lu2019 Article AReviewOnApplicationOfDielectrDokument19 SeitenLu2019 Article AReviewOnApplicationOfDielectrKin Wai CheahNoch keine Bewertungen

- 2013 (Process) NP Dielectric Barrier DischargeDokument5 Seiten2013 (Process) NP Dielectric Barrier DischargeKin Wai CheahNoch keine Bewertungen

- (Teaching) Form 1 Maths NotesDokument10 Seiten(Teaching) Form 1 Maths NotesKin Wai Cheah100% (1)

- Iron Phase TransformationDokument25 SeitenIron Phase TransformationKin Wai Cheah100% (1)

- Form 4 Chapter 1: Introduction To Chemistry: The Meaning of ChemistryDokument1 SeiteForm 4 Chapter 1: Introduction To Chemistry: The Meaning of ChemistryKin Wai CheahNoch keine Bewertungen

- BAPC2019jULY PDFDokument1 SeiteBAPC2019jULY PDFKin Wai CheahNoch keine Bewertungen

- Catalytic Transfer Hydrogenation of Cooking Oil, and Fatty Acid Content of The Hydrogenated Cooking OilDokument4 SeitenCatalytic Transfer Hydrogenation of Cooking Oil, and Fatty Acid Content of The Hydrogenated Cooking OilKin Wai CheahNoch keine Bewertungen

- Transfer Hydrogenation of Olive Oil: Winthrop University Organic Chemistry Lab Department of Chemistry CHEM 303Dokument3 SeitenTransfer Hydrogenation of Olive Oil: Winthrop University Organic Chemistry Lab Department of Chemistry CHEM 303Kin Wai CheahNoch keine Bewertungen

- 2019 SPM Chemistry Paper 2 - Modul Test 1: SECTION A Answer All The Questions in This SectionDokument18 Seiten2019 SPM Chemistry Paper 2 - Modul Test 1: SECTION A Answer All The Questions in This SectionKin Wai CheahNoch keine Bewertungen

- BAPC2019jULY PDFDokument1 SeiteBAPC2019jULY PDFKin Wai CheahNoch keine Bewertungen

- SPM Examination Paper 2016Dokument26 SeitenSPM Examination Paper 2016Kin Wai CheahNoch keine Bewertungen

- Mod. 1 Basic ElectricalDokument21 SeitenMod. 1 Basic Electricalderping lemon100% (1)

- B Tech ECE Courses NBADokument4 SeitenB Tech ECE Courses NBAPratyush ChauhanNoch keine Bewertungen

- The Andromedan Compendium - 7bDokument10 SeitenThe Andromedan Compendium - 7bAnonymous XSNBQQ4yNoch keine Bewertungen

- Algebra2 Glenco EOCDokument62 SeitenAlgebra2 Glenco EOCDeborah LeeNoch keine Bewertungen

- Calculating MagnificaitonDokument3 SeitenCalculating MagnificaitonShruthi Yalamalli ArunNoch keine Bewertungen

- Document Trafag PD3.4Dokument7 SeitenDocument Trafag PD3.4Rick Van den BosNoch keine Bewertungen

- Documentazione Tubo A Raggi X Tube Documentation Documentation Du TubeDokument4 SeitenDocumentazione Tubo A Raggi X Tube Documentation Documentation Du Tubecamq827Noch keine Bewertungen

- An Elin Load Tap Changer Diagnosis by DgaDokument4 SeitenAn Elin Load Tap Changer Diagnosis by Dgamartinez_joselNoch keine Bewertungen

- Basics of Mining and Mineral ProcessingDokument179 SeitenBasics of Mining and Mineral Processingminerales&materiales100% (6)

- 03 Chapter 1Dokument45 Seiten03 Chapter 1hymerchmidt100% (1)

- Introduction To Vehicle Electronic Systems and Fault DiagnosisDokument20 SeitenIntroduction To Vehicle Electronic Systems and Fault Diagnosisyogita patil100% (1)

- Isolation and Purification of AlkaloidsDokument14 SeitenIsolation and Purification of AlkaloidsLuděk SpurnýNoch keine Bewertungen

- ECB Non Turf Cricket Wicket PDFDokument23 SeitenECB Non Turf Cricket Wicket PDFJames OttaNoch keine Bewertungen

- Abrasive SDokument3 SeitenAbrasive SmurusaNoch keine Bewertungen

- Modeling and Simulation: Qiu-Zhou Runall - Tex - 12/25/2008 3:19am Page 13Dokument51 SeitenModeling and Simulation: Qiu-Zhou Runall - Tex - 12/25/2008 3:19am Page 13Samuel ChanNoch keine Bewertungen

- LNG Receiving Terminals: BY CH - Satvika 16021A2545Dokument24 SeitenLNG Receiving Terminals: BY CH - Satvika 16021A2545Ram Charan Konidela100% (1)

- The Hubbard Coil MatrixDokument4 SeitenThe Hubbard Coil MatrixAna Luisa Lynce100% (1)

- A New Method of Grounding Grid DesignDokument5 SeitenA New Method of Grounding Grid DesignOrgil-erdene YadamsurenNoch keine Bewertungen

- Failure Modes of Bolt and Nut Assemblies Under Tensile LoadingDokument11 SeitenFailure Modes of Bolt and Nut Assemblies Under Tensile LoadingclevercogNoch keine Bewertungen

- ValveTypesSelection - ControlsWikiDokument42 SeitenValveTypesSelection - ControlsWikiMayur PatelNoch keine Bewertungen

- Centrifugal Pump Test RigDokument4 SeitenCentrifugal Pump Test RigSameer Tamboli100% (1)

- Data Sheets de Todos Cabos Da ListaDokument20 SeitenData Sheets de Todos Cabos Da ListaLaercio ChissicoNoch keine Bewertungen

- NAVIER Laboratory - UMR 8205 - DUPLA Jean-ClaudeDokument6 SeitenNAVIER Laboratory - UMR 8205 - DUPLA Jean-ClaudeSusmita PandaNoch keine Bewertungen

- Chapter Four: Fig.12.a. Flow Diagram of Simple Vapour Compression SystemDokument15 SeitenChapter Four: Fig.12.a. Flow Diagram of Simple Vapour Compression SystemAnonymous 5HYsyrddpNoch keine Bewertungen

- Shaft Locking DeviceDokument24 SeitenShaft Locking DevicechienhamthepNoch keine Bewertungen

- Gates Timing Belt Product TrainingDokument25 SeitenGates Timing Belt Product TrainingRoberto FernandesNoch keine Bewertungen

- Questions and Solutions at End of Chapter 2: Measurement and Instrumentation. © 2016 Elsevier Inc. All Rights ReservedDokument14 SeitenQuestions and Solutions at End of Chapter 2: Measurement and Instrumentation. © 2016 Elsevier Inc. All Rights ReservedKevin AzizNoch keine Bewertungen

- Stepper Motors VsServo MotorsDokument2 SeitenStepper Motors VsServo MotorsEhab MohamedNoch keine Bewertungen

- GGHHHDokument3 SeitenGGHHHjovica37Noch keine Bewertungen

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherVon EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNoch keine Bewertungen

- The Importance of Being Earnest: Classic Tales EditionVon EverandThe Importance of Being Earnest: Classic Tales EditionBewertung: 4.5 von 5 Sternen4.5/5 (44)

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedVon EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedBewertung: 4.5 von 5 Sternen4.5/5 (5)

- The Inimitable Jeeves [Classic Tales Edition]Von EverandThe Inimitable Jeeves [Classic Tales Edition]Bewertung: 5 von 5 Sternen5/5 (3)

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtVon EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtBewertung: 4 von 5 Sternen4/5 (60)

- Sex, Drugs, and Cocoa Puffs: A Low Culture ManifestoVon EverandSex, Drugs, and Cocoa Puffs: A Low Culture ManifestoBewertung: 3.5 von 5 Sternen3.5/5 (1428)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticVon EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticBewertung: 3.5 von 5 Sternen3.5/5 (10)

- The Book of Bad:: Stuff You Should Know Unless You’re a PussyVon EverandThe Book of Bad:: Stuff You Should Know Unless You’re a PussyBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Take My Advice: Letters to the Next Generation from People Who Know a Thing or TwoVon EverandTake My Advice: Letters to the Next Generation from People Who Know a Thing or TwoJames L. HarmonBewertung: 4 von 5 Sternen4/5 (5)

- The Little Book of Big F*#k Ups: 220 of History's Most-Regrettable MomentsVon EverandThe Little Book of Big F*#k Ups: 220 of History's Most-Regrettable MomentsNoch keine Bewertungen

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)