Beruflich Dokumente

Kultur Dokumente

Aero Dynamic Wind Mill Reverse Charge Protection

Hochgeladen von

GANGYA442Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Aero Dynamic Wind Mill Reverse Charge Protection

Hochgeladen von

GANGYA442Copyright:

Verfügbare Formate

Aero Dynamic Wind Mill with Reverse Charge Protection

AERO DYNAMIC WIND MIL WITH REVERSE CHARGE PROTECTION

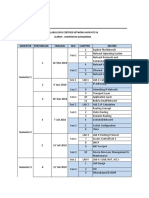

1.1 BLOCK DIAGRAM

Power Supply Unit Aero dynamic wind blade arrangemen t

Contras t

16X2 LCD

Geared DC motor

AT89S52

AC ripple neutralizer

Unidirectio nal Current Controller

Voltage Sampler

ADC

Rechargea ble Battery

Inverter

ON/ OFF control switch

Fig: 1.1 Block Diagram

1

AC 230V Load

Aero Dynamic Wind Mill with Reverse Charge Protection

2. EMBEDDED SYSTEMS

An embedded system is a system which is going to do a predefined specified task is the embedded system and is even defined as combination of both software and hardware. A generalpurpose definition of embedded systems is that they are devices used to control, monitor or assist the operation of equipment, machinery or plant. "Embedded" reflects the fact that they are an integral part of the system. At the other extreme a general-purpose computer may be used to control the operation of a large complex processing plant, and its presence will be obvious. All embedded systems are including computers or microprocessors. Some of these computers are however very simple systems as compared with a personal computer. The very simplest embedded systems are capable of performing only a single function or set of functions to meet a single predetermined purpose. In more complex systems an application program that enables the embedded system to be used for a particular purpose in a specific application determines the functioning of the embedded system. The ability to have programs means that the same embedded system can be used for a variety of different purposes. In some cases a microprocessor may be designed in such a way that application software for a particular purpose can be added to the basic software in a second process, after which it is not possible to make further changes. The applications software on such processors is sometimes referred to as firmware.

The simplest devices consist of a single microprocessor (often called a "chip), which may itself be packaged with other chips in a hybrid system or Application Specific Integrated Circuit (ASIC). Its input comes from a detector or sensor and its output goes to a switch or activator which (for example) may start or stop the operation of a machine or, by operating a valve, may control the flow of fuel to an engine. As the embedded system is the combination of both software and hardware

Aero Dynamic Wind Mill with Reverse Charge Protection

Embedded System

Software

Hardware

ALP C VB Etc.,

Processor Peripherals memory

Figure: 2 Block diagram of Embedded System Software deals with the languages like ALP, C, and VB etc., and Hardware deals with Processors, Peripherals, and Memory.

Memory: It is used to store data or address. Peripherals: These are the external devices connected Processor: It is an IC which is used to perform some task Applications of embedded systems

Manufacturing and process control

Construction industry Transport Buildings and premises Domestic service Communications Office systems and mobile equipment

3

Aero Dynamic Wind Mill with Reverse Charge Protection

Banking, finance and commercial Medical diagnostics, monitoring and life support Testing, monitoring and diagnostic systems

Processors are classified into four types like:

Micro Processor (p) Micro controller (c) Digital Signal Processor (DSP) Application Specific Integrated Circuits (ASIC)

Micro Processor (p):

A silicon chip that contains a CPU. In the world of personal computers, the terms microprocessor and CPU are used interchangeably. At the heart of all personal computers and most workstations sits a microprocessor. Microprocessors also control the logic of almost all digital devices, from clock radios to fuel-injection systems for automobiles.

Three basic characteristics differentiate microprocessors:

Instruction set: The set of instructions that the microprocessor can execute. Bandwidth : The number of bits processed in a single instruction. Clock speed : Given in megahertz (MHz), the clock speed determines how many instructions per second the processor can execute. In both cases, the higher the value, the more powerful the CPU. For example, a 32-bit microprocessor that runs at 50MHz is more powerful than a 16-bit microprocessor that runs at 25MHz. In addition to bandwidth and clock speed, microprocessors are classified as being either RISC (reduced instruction set computer) or CISC (complex instruction set computer). A microprocessor has three basic elements, as shown above. The ALU performs all arithmetic computations, such as addition, subtraction and logic operations (AND, OR, etc). It is controlled by the Control Unit and receives its data from the Register Array. The Register Array is a set of registers used for storing data. These registers can be accessed by the ALU very quickly. Some registers have specific functions - we will deal with these later. The Control Unit controls the entire process. It provides the timing and a control signal for getting data into and out of the

4

Aero Dynamic Wind Mill with Reverse Charge Protection

registers and the ALU and it synchronizes the execution of instructions (we will deal with instruction execution at a later date).

Micro Controller (c):

A microcontroller is a small computer on a single integrated circuit containing a processor core, memory, and programmable input/output peripherals. Program memory in the form of NOR flash or OTP ROM is also often included on chip, as well as a typically small amount of RAM. Microcontrollers are designed for embedded applications, in contrast to the microprocessors used in personal computers or other general purpose applications.

ALU CU

Timer, Counter, y serial communication ROM, ADC, DAC, Timers, USART, Oscillators

Memor

Figure: 2 Block Diagram Etc., of Micro Controller (c)

Digital Signal Processors (DSPs):

Digital Signal Processors is one which performs scientific and mathematical operation. Digital Signal Processor chips - specialized microprocessors with architectures designed specifically for the types of operations required in digital signal processing. Like a general-purpose microprocessor, a DSP is a programmable device, with its own native instruction code. DSP chips are capable of carrying out millions of floating point operations per second, and like their betterknown general-purpose cousins, faster and more powerful versions are continually being introduced. DSPs can also be embedded within complex "system-on-chip" devices, often containing both analog and digital circuitry.

5

Aero Dynamic Wind Mill with Reverse Charge Protection

Application Specific Integrated Circuit (ASIC):

ASIC is a combination of digital and analog circuits packed into an IC to achieve the desired control/computation function

ASIC typically contains

CPU cores for computation and control Peripherals to control timing critical functions Memories to store data and program Analog circuits to provide clocks and interface to the real world which is analog in nature I/Os to connect to external components like LEDs, memories, monitors etc.

Computer Instruction Set

There are two different types of computer instruction set there are: 1. RISC (Reduced Instruction Set Computer) and 2. CISC (Complex Instruction Set computer)

Reduced Instruction Set Computer (RISC)

A RISC (reduced instruction set computer) is a microprocessor that is designed to perform a smaller number of types of computer instruction so that it can operate at a higher speed (perform more million instructions per second, or millions of instructions per second). Since each instruction type that a computer must perform requires additional transistors and circuitry, a larger list or set of computer instructions tends to make the microprocessor more complicated and slower in operation. Besides performance improvement, some advantages of RISC and related design improvements are: A new microprocessor can be developed and tested more quickly if one of its aims is to be less complicated. Operating system and application programmers who use the microprocessor's instructions will find it easier to develop code with a smaller instruction set. The simplicity of RISC allows more freedom to choose how to use the space on a microprocessor.

6

Aero Dynamic Wind Mill with Reverse Charge Protection

Higher-level language compilers produce more efficient code than formerly because they have always tended to use the smaller set of instructions to be found in a RISC computer.

RISC characteristics:

Simple instruction set:

In a RISC machine, the instruction set contains simple, basic instructions, from which more complex instructions can be composed.

Same length instructions.

Each instruction is the same length, so that it may be fetched in a single operation.

1 machine-cycle instructions.

Most instructions complete in one machine cycle, which allows the processor to handle several instructions at the same time. This pipelining is a key technique used to speed up RISC machines.

Complex Instruction Set Computer (CISC)

CISC, which stands for Complex Instruction Set Computer, is a philosophy for designing chips that are easy to program and which make efficient use of memory. Each instruction in a CISC instruction set might perform a series of operations inside the processor. This reduces the number of instructions required to implement a given program, and allows the programmer to learn a small but flexible set of instructions.

The advantages of CISC

At the time of their initial development, CISC machines used available technologies to optimize computer performance. Microprogramming is as easy as assembly language to implement, and much less expensive than hardwiring a control unit. The ease of micro-coding new instructions allowed designers to make CISC machines upwardly compatible: a new computer could run the same programs as earlier computers because the new computer would contain a superset of the instructions of the earlier computers.

Aero Dynamic Wind Mill with Reverse Charge Protection

As each instruction became more capable, fewer instructions could be used to implement a given task. This made more efficient use of the relatively slow main memory. Because micro program instruction sets can be written to match the constructs of high-level languages, the compiler does not have to be as complicated.

The disadvantages of CISC:

Still, designers soon realized that the CISC philosophy had its own problems, including: Earlier generations of a processor family generally were contained as a subset in every new version --- so instruction set & chip hardware become more complex with each generation of computers. So that as many instructions as possible could be stored in memory with the least possible wasted space, individual instructions could be of almost any length---this means that different instructions will take different amounts of clock time to execute, slowing down the overall performance of the machine. Many specialized instructions aren't used frequently enough to justify their existence --approximately 20% of the available instructions are used in a typical program. CISC instructions typically set the condition codes as a side effect of the instruction. Not only does setting the condition codes take time, but programmers have to remember to examine the condition code bits before a subsequent instruction changes them.

Memory Architecture

There two different types memory architectures there are: Harvard Architecture Von-Neumann Architecture

Harvard Architecture

Aero Dynamic Wind Mill with Reverse Charge Protection

Computers have separate memory areas for program instructions and data. There are two or more internal data buses, which allow simultaneous access to both instructions and data. The CPU fetches program instructions on the program memory bus. The Harvard architecture is a computer architecture with physically separate storage and signal pathways for instructions and data. The term originated from the Harvard Mark I relay-based computer, which stored instructions on punched tape (24 bits wide) and data in electro-mechanical counters. These early machines had limited data storage, entirely contained within the central processing unit, and provided no access to the instruction storage as data. Programs needed to be loaded by an operator, the processor could not boot itself.

Figure: 2 Harvard Architecture

Modern uses of the Harvard architecture

The principal advantage of the pure Harvard architecture - simultaneous access to more than one memory system - has been reduced by modified Harvard processors using modern CPU cache systems. Relatively pure Harvard architecture machines are used mostly in applications where tradeoffs, such as the cost and power savings from omitting caches, outweigh the programming penalties from having distinct code and data address spaces. Digital signal processors (DSPs) generally execute small, highly-optimized audio or video processing algorithms. They avoid caches because their behavior must be extremely reproducible. The difficulties of coping with multiple address spaces are of secondary concern to speed of execution. As a result, some DSPs have multiple data memories in distinct address spaces to

9

Aero Dynamic Wind Mill with Reverse Charge Protection

facilitate SIMD and VLIW processing. Texas Instruments TMS320 C55x processors, as one example, have multiple parallel data busses (two write, three read) and one instruction bus. Microcontrollers are characterized by having small amounts of program (flash memory) and data (SRAM) memory, with no cache, and take advantage of the Harvard architecture to speed processing by concurrent instruction and data access. The separate storage means the program and data memories can have different bit depths, for example using 16-bit wide instructions and 8-bit wide data. They also mean that instruction pre-fetch can be performed in parallel with other activities. Examples include, the AVR by Atmel Corp, the PIC by Microchip Technology, Inc. and the ARM Cortex-M3 processor (not all ARM chips have Harvard architecture).

Von-Neumann Architecture

A computer has a single, common memory space in which both program instructions and data are stored. There is a single internal data bus that fetches both instructions and data. They cannot be performed at the same time The Von Neumann architecture is a design model for a stored-program digital computer that uses a central processing unit (CPU) and a single separate storage structure ("memory") to hold both instructions and data. It is named after the mathematician and early computer scientist John von Neumann. Such computers implement a universal Turing machine and have a sequential architecture. A stored-program digital computer is one that keeps its programmed instructions, as well as its data, in read-write, random-access memory (RAM). Stored-program computers were advancement over the program-controlled computers of the 1940s, such as the Colossus and the ENIAC, which were programmed by setting switches and inserting patch leads to route data and to control signals between various functional units. In the vast majority of modern computers, the same memory is used for both data and program instructions. The mechanisms for transferring the data and instructions between the CPU and memory are, however, considerably more complex than the original von Neumann architecture. The terms "von Neumann architecture" and "stored-program computer" are generally used interchangeably, and that usage is followed in this article.

10

Aero Dynamic Wind Mill with Reverse Charge Protection

Figure: 2 Schematic of the Von-Neumann Architecture.

11

Aero Dynamic Wind Mill with Reverse Charge Protection

Basic Difference between Harvard and Von-Neumann Architecture

The primary difference between Harvard architecture and the Von Neumann architecture is in the Von Neumann architecture data and programs are stored in the same memory and managed by the same information handling system. Whereas the Harvard architecture stores data and programs in separate memory devices and they are handled by different subsystems. In a computer using the Von-Neumann architecture without cache; the central processing unit (CPU) can either be reading and instruction or writing/reading data to/from the memory. Both of these operations cannot occur simultaneously as the data and instructions use the same system bus. In a computer using the Harvard architecture the CPU can both read an instruction and access data memory at the same time without cache. This means that a computer with Harvard architecture can potentially be faster for a given circuit complexity because data access and instruction fetches do not contend for use of a single memory pathway. Today, the vast majority of computers are designed and built using the Von Neumann architecture template primarily because of the dynamic capabilities and efficiencies gained in designing, implementing, operating one memory system as opposed to two. Von Neumann architecture may be somewhat slower than the contrasting Harvard Architecture for certain specific tasks, but it is much more flexible and allows for many concepts unavailable to Harvard architecture such as self programming, word processing and so on. Harvard architectures are typically only used in either specialized systems or for very specific uses. It is used in specialized digital signal processing (DSP), typically for video and audio processing products. It is also used in many small microcontrollers used in electronics applications such as Advanced RISK Machine (ARM) based products for many vendors.

12

Aero Dynamic Wind Mill with Reverse Charge Protection

3. BLOCK DESCRIPTION

3.1 POWER SUPPLY:

The input to the circuit is applied from the regulated power supply. The a.c. input i.e., 230V from the mains supply is step down by the transformer to 12V and is fed to a rectifier. The output obtained from the rectifier is a pulsating d.c voltage. So in order to get a pure d.c voltage, the output voltage from the rectifier is fed to a filter to remove any a.c components present even after rectification. Now, this voltage is given to a voltage regulator to obtain a pure constant dc voltage.

230V AC 50Hz

D.C Output

Step down transformer

Bridge Rectifier

FILTER

Regulator

Fig 3.1: Power supply

Transformer:

13

Aero Dynamic Wind Mill with Reverse Charge Protection

Usually, DC voltages are required to operate various electronic equipment and these voltages are 5V, 9V or 12V. But these voltages cannot be obtained directly. Thus the a.c input available at the mains supply i.e., 230V is to be brought down to the required voltage level. This is done by a transformer. Thus, a step down transformer is employed to decrease the voltage to a required level.

Fig 3.1: Transformer

Rectifier:

The output from the transformer is fed to the rectifier. It converts A.C. into pulsating D.C. The rectifier may be a half wave or a full wave rectifier. In this project, a bridge rectifier is used because of its merits like good stability and full wave rectification.

Fig 3.1: Rectifier The Bridge rectifier is a circuit, which converts an ac voltage to dc voltage using both half cycles of the input ac voltage. The Bridge rectifier circuit is shown in the figure. The circuit has four diodes connected to form a bridge. The ac input voltage is applied to the diagonally opposite ends of the bridge. The load resistance is connected between the other two ends of the bridge.

14

Aero Dynamic Wind Mill with Reverse Charge Protection

For the positive half cycle of the input ac voltage, diodes D1 and D3 conduct, whereas diodes D2 and D4 remain in the OFF state. The conducting diodes will be in series with the load resistance RL and hence the load current flows through RL. For the negative half cycle of the input ac voltage, diodes D2 and D4 conduct whereas, D1 and D3 remain OFF. The conducting diodes D2 and D4 will be in series with the load resistance RL and hence the current flows through RL in the same direction as in the previous half cycle. Thus a bi-directional wave is converted into a unidirectional wave.

Fig: 3.1 Bridge rectifier

Filter:

Capacitive filter is used in this project. It removes the ripples from the output of rectifier and smoothens the D.C. Output received from this filter is constant until the mains voltage and load is

15

Aero Dynamic Wind Mill with Reverse Charge Protection

maintained constant. However, if either of the two is varied, D.C. voltage received at this point changes. Therefore a regulator is applied at the output stage.

Fig: 3.1 Capacitor Filter

Voltage regulator:

As the name itself implies, it regulates the input applied to it. A voltage regulator is an electrical regulator designed to automatically maintain a constant voltage level. In this project, power supply of 5V and 12V are required. In order to obtain these voltage levels, 7805 and 7812 voltage regulators are to be used. The first number 78 represents positive supply and the numbers 05, 12 represent the required output voltage levels. The L78xx series of three-terminal positive regulators is available in TO-220, TO-220FP, TO-3, D2PAK and DPAK packages and several fixed output voltages, making it useful in a wide range of applications. These regulators can provide local on-card regulation, eliminating the distribution problems associated with single point regulation. Each type employs internal current limiting, thermal shut-down and safe area protection, making it essentially indestructible. If adequate heat sinking is provided, they can deliver over 1 A output current. Although designed primarily as fixed voltage regulators, these devices can be used with external components to obtain adjustable voltage and currents.

16

Aero Dynamic Wind Mill with Reverse Charge Protection

Fig: 3.1 voltage regulator

3.2 AERO DYNAMIC WIND BLADE

Wind turbine blades are shaped to generate the maximum power from the wind at the minimum cost. Primarily the design is driven by the aerodynamic requirements, but economics mean that the blade shape is a compromise to keep the cost of construction reasonable. In particular, the blade tends to be thicker than the aerodynamic optimum close to the root, where the stresses due to bending are greatest. The blade design process starts with a best guess compromise between aerodynamic and structural efficiency. The choice of materials and manufacturing process will also have an influence on how thin (hence aerodynamically ideal) the blade can be built. For instance, prepreg carbon fibre is stiffer and stronger than infused glass fibre. The chosen aerodynamic shape gives rise to loads, which are fed into the structural design. Problems identified at this stage can then be used to modify the shape if necessary and recalculate the aerodynamic performance.

Fig: 3.2 Aero Wind Blade

The Wind:

It might seem obvious, but an understanding of the wind is fundamental to wind turbine design. The power available from the wind varies as the cube of the wind speed, so twice the wind speed means eight times the power. This is why sites have to be selected carefully: below about 5m/s (0mph) wind speed there is not sufficient power in the wind to be useful. Conversely, strong gusts provide extremely high levels of power, but it is not economically viable to build machines to be able to make the most of the power peaks as their capacity would be wasted most of

17

Aero Dynamic Wind Mill with Reverse Charge Protection

the time. So the ideal is a site with steady winds and a machine that is able to make the most of the lighter winds whilst surviving the strongest gusts. As well as varying day-to-day, the wind varies every second due to turbulence caused by land features, thermals and weather. It also blows more strongly higher above the ground than closer to it, due to surface friction. All these effects lead to varying loads on the blades of a turbine as they rotate, and mean that the aerodynamic and structural design needs to cope with conditions that are rarely optimal. By extracting power, the turbine itself has an effect on the wind: downwind of the turbine the air moves more slowly than upwind. The wind starts to slow down even before it reaches the blades, reducing the wind speed through the disc (the imaginary circle formed by the blade tips, also called the swept area) and hence reducing the available power. Some of the wind that was heading for the disc diverts around the slower-moving air and misses the blades entirely. So there is an optimum amount of power to extract from a given disc diameter: try to take too much and the wind will slow down too much, reducing the available power. In fact the ideal is to reduce the wind speed by about two thirds downwind of the turbine, though even then the wind just before the turbine will have lost about a third of its speed. This allows a theoretical maximum of 59% of the winds power to be captured (this is called Betzs limit). In practice only 40-50% is achieved by current designs.

Number of blades:

The limitation on the available power in the wind means that the more blades there are the less power each can extract. A consequence of this is that each blade must also be narrower to maintain aerodynamic efficiency. The total blade area as a fraction of the total swept disc area is called the solidity, and aerodynamically there is an optimum solidity for a given tip speed; the higher the number of blades, the narrower each one must be. In practice the optimum solidity is low (only a few percent) which means that even with only three blades, each one must be very narrow. To slip through the air easily the blades must be thin relative to their width, so the limited solidity also limits the thickness of the blades. Furthermore, it becomes difficult to build the blades strong enough if they are too thin or the cost per blade increases significantly as more expensive materials are required. For this reason, most large machines do not have more than three blades. The other

18

Aero Dynamic Wind Mill with Reverse Charge Protection

factor influencing the number of blades is aesthetics: it is generally accepted that three-bladed turbines are less visually disturbing than one- or two-bladed designs.

How blades capture wind power:

Just like an aeroplane wing, wind turbine blades work by generating lift due to their shape. The more curved side generates low air pressures while high pressure air pushes on the other side of the aerofoil. The net result is a lift force perpendicular to the direction of flow of the air. The lift force increases as the blade is turned to present itself at a greater angle to the wind. This is called the angle of attack. At very large angles of attack the blade stalls and the lift decreases again. So there is an optimum angle of attack to generate the maximum l if .Lift & drag vectors. There is, unfortunately, also a retarding force on the blade: the drag. This is the force parallel to the wind flow, and also increases with angle of attack. If the aerofoil shape is good, the lift force is much bigger than the drag, but at very high angles of attack, especially when the blade stalls, the drag increases dramatically. So at an angle slightly less than the maximum lift angle, the blade reaches its maximum lift/drag ratio. The best operating point will be between these two angles. Since the drag is in the downwind direction, it may seem that it wouldnt matter for a wind turbine as the drag would be parallel to the turbine axis, so wouldnt slow the rotor down. It would just create thrust, the force that acts parallel to the turbine axis hence has no tendency to speed up or slow down the rotor. When the rotor is stationary (e.g. just before start-up), this is indeed the case. However the blades own movement through the air means that, as far as the blade is concerned, the wind is blowing from a different angle. This is called apparent wind. The apparent wind is stronger than the true wind but its angle is less it rotates the angles of the lift and drag to reduce the effect of lift force pulling the blade round and increase the effect of drag slowing it down. It also means that the lift force contributes to the thrust on the rotor. The result of this is that, to maintain a good angle of attack, the blade must be turned further from the true wind angle.

19

Aero Dynamic Wind Mill with Reverse Charge Protection

Fig: 3.2 Angle of attack of wind

Fig: 3.2 angle of wind blow

20

Aero Dynamic Wind Mill with Reverse Charge Protection

Fig: 3.2 contact of wind on wind mill

Apparent wind angles

The closer to the tip of the blade you get, the faster the blade is moving through the air and so the greater the apparent wind angle is. Thus the blade needs to be turned further at the tips than at the root, in other words it must be built with a twist along its length. Typically the twist is around 0-20 from root to tip. The requirement to twist the blade has implications on the ease of manufacture.

Blade section shape

Apart from the twist, wind turbine blades have similar requirements to aeroplane wings, so their cross-sections are usually based on a similar family of shapes. In general the best lift/drag characteristics are obtained by an aerofoil that is fairly thin: its thickness might be only 0-5% of its chord length (the length across the blade, in the direction of the wind flow).

21

Aero Dynamic Wind Mill with Reverse Charge Protection

Blade twist:

If there were no structural requirements, this is how a wind turbine blade would be proportioned, but of course the blade needs to support the lift, drag and gravitational forces acting on it. These structural requirements generally mean the aerofoil needs to be thicker than the aerodynamic optimum, especially at locations towards the root (where the blade attaches to the hub) where the bending forces are greatest. Fortunately that is also where the apparent wind is moving more slowly and the blade has the least leverage over the hub, so some aerodynamic inefficiency at that point is less serious than it would be closer to the tip. Having said this, the section cant get too thick for its chord length or the air flow will separate from the back of the blade similar to what happens when it stalls and the drag will increase dramatically.

Fig: 3.2 Blade Twist on Wind Mill To increase thickness near the root without creating a very short, fat, aerofoil section, some designs use a flat back section. This is either a standard section thickened up to a square trailing (back) edge, or a longer aerofoil shape that has been truncated. This reduces the drag compared to a rounder section, but can generate more noise so its suitability depends on the wind farm site. There is a trade-off to be made between aerodynamic efficiency and structural efficiency even if a thin blade can be made strong and stiff enough by using lots of reinforcement inside, it might still be better to make the blade a bit thicker (hence less aerodynamically efficient) if it saves so much cost of material that the overall cost of electricity is reduced. The wind is free after all; its

22

Aero Dynamic Wind Mill with Reverse Charge Protection

only the machine that we have to pay for. So there is inevitably some iteration in the design process to find the optimum thickness for the blade.

Blade platform shape:

The platform shape is chosen to give the blade an approximately constant slowing effect on the wind over the whole rotor disc (i.e. the tip slows the wind to the same degree as the centre or root of the blade). This ensures that none of the air leaves the turbine too slowly (causing turbulence), yet none is allowed to pass through too fast (which would represent wasted energy). Remembering Betzs limit discussed above, this results in the maximum power extraction. Because the tip of the blade is moving faster than the root, it passes through more volume of air, hence must generate a greater lift force to slow that air down enough. Fortunately, lift increases with the square of speed so its greater speed more than allows for that. In reality the blade can be narrower close to the tip than near the root and still generate enough lift. The optimum tapering of the blade platforms as it goes outboard can be calculated; roughly speaking the chord should be inverse to the radius. So if the chord was 2m at 10m radius, it should be 10m at 1m radius. This relationship breaks down close to the root and tip, where the optimum shape changes to account for tip losses. In reality a fairly linear taper is sufficiently close to the optimum for most designs, structurally superior and easier to build than the optimum shape.

Fig: 3.2 Plane Shape of Blade

Rotational speed:

23

Aero Dynamic Wind Mill with Reverse Charge Protection

The speed at which the turbine rotates is a fundamental choice in the design, and is defined in terms of the speed of the blade tips relative to the free wind speed (i.e. Before the wind is slowed down by the turbine). This is called the tip speed ratio. High tip speed ratio means the aerodynamic force on the blades (due to lift and drag) is almost parallel to the rotor axis, so relies on a good lift/drag ratio. The lift/drag ratio can be affected severely by dirt or roughness on the blades. Low tip speed ratio would seem like a better choice but unfortunately results in lower aerodynamic efficiency, due to two effects. Because the lift force on the blades generates torque, it has an equal but opposite effect on the wind, tending to push it around tangentially in the other direction. The result is that the air downwind of the turbine has swirl, i.e. it spins in the opposite direction to the blades. That swirl represents lost power so reduces the available power that can be extracted from the wind. Lower rotational speed requires higher torque for the same power output, so lower tip speed results in higher wake swirl losses.

Fig: 3.2 Rotational Speed The other reduction in efficiency at low tip speed ratio comes from tip losses, where highpressure air from the upwind side of the blade escapes around the blade tip to the low pressure side, thereby wasting energy. Since power = force x speed, at slower rotational speed the blades need to generate more lift force to achieve the same power. To generate more lift for a given length the

24

Aero Dynamic Wind Mill with Reverse Charge Protection

blade has to be wider, which means that, geometrically speaking, a greater proportion of the blades length can be considered to be close to the tip. Thus more of the air contributes to tip losses and the efficiency decreases. Various techniques can be used to limit tip losses such as winglets (commonly seen on airliners) but few are employed in practice owing to their additional cost. The higher lift force on a wider blade also translates to higher loads on the other components such as the hub and bearings, so low tip speed ratio will increase the cost of these items. On the other hand the wide blade is better able to carry the lift force (as discussed previously), so the blade itself may be cheaper. All this means that turbine designers typically compromise on tip speed ratios in the region of -0, so at design wind speed (usually 2-5 meters per second) the blade tip can be moving at around 20 m/s (approximately 20 miles per hour). There are practical limits on the absolute tip speed too: at these speeds, bird impacts and rain erosion start to become a problem for the longevity of the blades and noise increases dramatically with tip speed.

Power and pitch control

For an economical design, the maximum performance of the generator and gearbox need to be limited to an appropriate level for the turbines operating environment. The ideal situation is for the turbine to be able to extract as much power as possible from the wind up to the rated power of the generator, then limit the power extraction at that level as the wind increases further. Turbine Power Curve WE Handbook- 2- Aerodynamics and Loads 9 If the blades angle is kept constant, the turbine is unable to respond to changes in wind speed. Not only does this make it impossible to maintain an optimum angle of attack to generate the maximum power at varying wind speeds, the only way to depower the machine in high wind speeds is by relying on the blades to stall (known as passive stall control). This doesnt give the perfectly flat power curve above the rated wind speed shown in the graph above, so to limit the maximum power, a passive stall-controlled turbine will usually be operating somewhat below its maximum potential. If instead the blades are attached via a bearing that allows the angle of attack to be varied (active pitch control), the blades can be angled to maintain optimum efficiency right up to the design wind speed (at which the generator is producing itsratedoutput). Above that wind speed they can be feathered, i.e. rotated in pitch to decrease their angle of attack and hence their lift, so controlling the power. In survival conditions, the turbine can be stopped altogether and the blades feathered to produce no turning force at all.

25

Aero Dynamic Wind Mill with Reverse Charge Protection

An alternative to decreasing the angle of attack above the design wind speed is deliberately to increase it to the point where the blade stalls (active stall control). This decreases lift and increases drag, so has the desired slowing effect on blade rotation. It is also less sensitive to gusts of wind than feathering: by decreasing the apparent wind angle, gusts increase the angle of attack so tend to make the blade stall more. Therefore controlling blade speed by stall rather than feathering can be beneficial in gusty conditions. Both methods are used by different designs.

3.3 DC MOTOR:

In any electric motor, operation is based on simple electromagnetism. A currentcarrying conductor generates a magnetic field; when this is then placed in an external magnetic field, it will experience a force proportional to the current in the conductor, and to the strength of the external magnetic field. As you are well aware of from playing with magnets as a kid, opposite (North and South) polarities attract, while like polarities (North and North, South and South) repel. The internal configuration of a DC motor is designed to harness the magnetic interaction between a current-carrying conductor and an external magnetic field to generate rotational motion.

Fig: 3.3 DC Motor Let's start by looking at a simple 2-pole DC electric motor (here red represents a magnet or winding with a "North" polarization, while green represents a magnet or winding with a "South" polarization).

26

Aero Dynamic Wind Mill with Reverse Charge Protection

Fig:3.3 Simple 2-pole dc electric motor Every DC motor has six basic parts -- axle, rotor (a.k.a., armature), stator, commutator, field magnet(s), and brushes. In most common DC motors (and all that Beamers will see), the external magnetic field is produced by high-strength permanent magnets 1. The stator is the stationary part of the motor -- this includes the motor casing, as well as two or more permanent magnet pole pieces. The rotor (together with the axle and attached commutator) rotate with respect to the stator. The rotor consists of windings (generally on a core), the windings being electrically connected to the commutator. The above diagram shows a common motor layout -- with the rotor inside the stator (field) magnets. The geometry of the brushes, commutator contacts, and rotor windings are such that when power is applied, the polarities of the energized winding and the stator magnet(s) are misaligned, and the rotor will rotate until it is almost aligned with the stator's field magnets. As the rotor reaches alignment, the brushes move to the next commutator contacts, and energize the next winding. Given our example two-pole motor, the rotation reverses the direction of current through the rotor winding, leading to a "flip" of the rotor's magnetic field, driving it to continue rotatin

Fig: 3.3 rotation of rotor in dc motor In real life, though, DC motors will always have more than two poles (three is a very common number). In particular, this avoids "dead spots" in the commutator. You can imagine how

27

Aero Dynamic Wind Mill with Reverse Charge Protection

with our example two-pole motor, if the rotor is exactly at the middle of its rotation (perfectly aligned with the field magnets); it will get "stuck" there. Meanwhile, with a two-pole motor, there is a moment where the commutator shorts out the power supply (i.e., both brushes touch both commutator contacts simultaneously). This would be bad for the power supply, waste energy, and damage motor components as well. Yet another disadvantage of such a simple motor is that it would exhibit a high amount of torque "ripple" (the amount of torque it could produce is cyclic with the position of the rotor). So since most small DC motors are of a three-pole design, let's tinker with the workings of one via an interactive animation (JavaScript required): You'll notice a few things from this -- namely, one pole is fully energized at a time (but two others are "partially" energized). As each brush transitions from one commutator contact to the next, one coil's field will rapidly collapse, as the next coil's field will rapidly charge up (this occurs within a few microsecond). We'll see more about the effects of this later, but in the meantime you can see that this is a direct result of the coil windings' series wiring:

Fig: 3.3 Placing of Commutator in DC Motor The use of an iron core armature (as in the Mabuchi, above) is quite common, and has a number of advantages. First off, the iron core provides a strong, rigid support for the windings -- a particularly important consideration for high-torque motors. The core also conducts heat away from the rotor

28

Aero Dynamic Wind Mill with Reverse Charge Protection

windings, allowing the motor to be driven harder than might otherwise be the case. Iron core construction is also relatively inexpensive compared with other construction types. But iron core construction also has several disadvantages. The iron armature has a relatively high inertia which limits motor acceleration. This construction also results in high winding inductances which limit brush and commutator life. In small motors, an alternative design is often used which features a 'coreless' armature winding. This design depends upon the coil wire itself for structural integrity. As a result, the armature is hollow, and the permanent magnet can be mounted inside the rotor coil. Coreless DC motors have much lower armature inductance than iron-core motors of comparable size, extending brush and commutator life/

Fig: 3.3 courtesy of Micromole The coreless design also allows manufacturers to build smaller motors; meanwhile, due to the lack of iron in their rotors, coreless motors are somewhat prone to overheating. As a result, this design is generally used just in small, low-power motors. Beamers will most often see coreless DC motors in the form of pager motors.

3.4 RIPPLE NUTRALIZER:

The most common meaning of ripple in electrical science, is the small unwanted residual periodic variation of the direct current (dc) output of a power supply which has been

29

Aero Dynamic Wind Mill with Reverse Charge Protection

derived from an alternating current (ac) source. This ripple is due to incomplete suppression of the alternating waveform within the power supply. As well as this time-varying phenomenon, there is a frequency domain ripple that arises in some classes of filter and other signal processing networks. In this case the periodic variation is a variation in the insertion loss of the network against increasing frequency. The variation may not be strictly linearly periodic. In this meaning also, ripple is usually to be considered an unwanted effect, its existence being a compromise between the amount of ripple and other design parameters.

TIME DOMINE RIPPLE:

Full-wave rectifier circuit with a reservoir capacitor on the output for the purpose of smoothing ripple Ripple factor () may be defined as the ratio of the root mean square (rms) value of the ripple voltage to the absolute value of the dc component of the output voltage, usually expressed as a percentage. However, ripple voltage is also commonly expressed as the peak-to-peak value. This is largely because peak-to-peak is both easier to measure on an oscilloscope and is simpler to calculate theoretically. Filter circuits intended for the reduction of ripple are usually called smoothing circuits.

Fig: 3.4 Time domine ripple The simplest scenario in ac to dc conversion is a rectifier without any smoothing circuitry at all. The ripple voltage is very large in this situation; the peak-to-peak ripple voltage is equal to the peak ac voltage. A more common arrangement is to allow the rectifier to work into a large smoothing capacitor which acts as a reservoir. After a peak in output voltage the capacitor (C) supplies the current to the load (R) and continues to do so until the capacitor voltage has fallen to the value of the now rising next half-cycle of rectified voltage. At that point the rectifiers turn on

30

Aero Dynamic Wind Mill with Reverse Charge Protection

again and deliver current to the reservoir until peak voltage is again reached. If the time constant, CR, is large in comparison to the period of the ac waveform, then a reasonable accurate approximation can be made by assuming that the capacitor voltage falls linearly. A further useful assumption can be made if the ripple is small compared to the dc voltage. In this case the phase angle through which the rectifiers conduct will be small and it can be assumed that the capacitor is discharging all the way from one peak to the next with little loss of accuracy

Fig: 3.4 Ripple wave form Ripple voltage from a full-wave rectifier, before and after the application of a smoothing capacitor With the above assumptions the peak-to-peak ripple voltage can be calculated as: For a full-wave rectifier:

For a half-wave rectification:

Where

App. is the peak-to-peak ripple voltage I is the current in the circuit f is the frequency of the ac power

31

Aero Dynamic Wind Mill with Reverse Charge Protection

C is the capacitance

For the rms value of the ripple voltage, the calculation is more involved as the shape of the ripple waveform has a bearing on the result. Assuming a saw tooth waveform is a similar assumption to the ones above and yields the result:

Where

is the ripple factor R is the resistance of the load

Another approach to reducing ripple is to use a series choke. A choke has a filtering action and consequently produces a smoother waveform with less high-order harmonics. Against this, the dc output is close to the average input voltage as opposed to the higher voltage with the reservoir capacitor which is close to the peak input voltage. With suitable approximations, the ripple factor is given by:

Where

is the angular frequency 2f L is the inductance of the choke

More complex arrangements are possible; the filter can be an LC ladder rather than a simple choke or the filter and the reservoir capacitor can both be used to gain the benefits of both. The most commonly seen of these is a low-pass -filter consisting of a reservoir capacitor followed by a series choke followed by a further shunt capacitor. However, use of chokes is deprecated in contemporary designs for economic reasons. A more common solution where good ripple rejection is required is to use a reservoir capacitor to reduce the ripple to something manageable and then pass through a voltage regulator circuit. The regulator circuit, as well as regulating the output, will

32

Aero Dynamic Wind Mill with Reverse Charge Protection

incidentally filter out nearly all of the ripple as long as the minimum level of the ripple waveform does not go below the voltage being regulated to. The majority of power supplies are now switched mode. The filtering requirements for such power supplies are much easier to meet due to the frequency of the ripple waveform being very high. In traditional power supply designs the ripple frequency is either equal to (half-wave), or twice (full-wave) the ac line frequency. With switched mode power supplies the ripple frequency is not related to the line frequency, but is instead related to the frequency of the chopper circuit. The ripple frequency and its harmonics are within the audio band and will therefore be audible on equipment such as radio receivers, equipment for playing recordings and professional studio equipment. The ripple frequency is within television video bandwidth. Analogue TV receivers will exhibit a pattern of moving wavy lines if too much ripple is present. The presence of ripple can reduce the resolution of electronic test and measurement instruments. On an oscilloscope it will manifest itself as a visible pattern on screen. Within digital circuits, it reduces the threshold, as does any form of supply rail noise, at which logic circuits give incorrect outputs and data is corrupted. High amplitude ripple currents reduce the life of electrolytic capacitors.

Fig:3.4 Ripple on a fifth order prototype Chebyshev filter Ripple in the context of the frequency domain is referring to the periodic variation in insertion loss with frequency of a filter or some other two-port network. Not all filters exhibit ripple, some have monotonically increasing insertion loss with frequency such as the Butterworth

33

Aero Dynamic Wind Mill with Reverse Charge Protection

filter. Common classes of filter which exhibit ripple are the Chebyshev filter, inverse Chebyshev filter and the Elliptical filter. The ripple is not usually strictly linearly periodic as can be seen from the example plot. Other examples of networks exhibiting ripple are impedance matching networks that have been designed using Chebyshev polynomials. The ripple of these networks, unlike regular filters, will never reach 0dB at minimum loss if designed for optimum transmission across the pass band as a whole. The amount of ripple can be traded for other parameters in the filter design. For instance, the rate of roll-off from the pass band to the stop band can be increased at the expense of increasing the ripple without increasing the order of the filter (that is, the number of components has stayed the same). On the other hand, the ripple can be reduced by increasing the order of the filter while at the same time maintaining the same rate of roll-off.

3.5 RECHARGEBLE BATTERIES

A rechargeable battery or storage battery is a group of one or more electrochemical cells. They are known as secondary cells because their electrochemical reactions are electrically reversible. Rechargeable batteries come in many different shapes and sizes, ranging anything from a button cell to megawatt systems connected to stabilize an electrical distribution network. Several different polymer). combinations of chemicals are commonly used, including: lead-acid, nickel cadmium(NiCad), nickel metal hydride (Nigh), lithium ion (Li-ion), and lithium ion polymer (Li-ion

Fig: 3.5 Rechargeable Batteries

34

Aero Dynamic Wind Mill with Reverse Charge Protection

Rechargeable batteries have lower total cost of use and environmental impact than disposable batteries. Some rechargeable battery types are available in the same sizes as disposable types. Rechargeable batteries have higher initial cost, but can be recharged very cheaply and used many times. Rechargeable batteries are used for automobile starters, portable consumer devices, light vehicles (such as motorized wheelchairs, golf carts, electric bicycles, and electric forklifts), tools, and uninterruptible power supplies. Emerging applications in hybrid electric vehicles and electric vehicles are driving the technology to reduce cost and weight and increase lifetime. Normally, new rechargeable batteries have to be charged before use; newer low self-discharge batteries hold their charge for many months, and are supplied charged to about 70% of their rated capacity. Grid energy storage applications use rechargeable batteries for load leveling, where they store electric energy for use during peak load periods, and for renewable uses, such as storing power generated from photovoltaic arrays during the day to be used at night. By charging batteries during periods of low demand and returning energy to the grid during periods of high electrical demand, load-leveling helps eliminate the need for expensive peaking power plants and helps amortize the cost of generators over more hours of operation. The US National Electrical Manufacturers Association has estimated that U.S. demand for rechargeable batteries is growing twice as fast as demand for non -rechargeable.

CHARGING AND DISCHARGING

During charging, the positive active material is oxidized, producing electrons, and the negative material is reduced, consuming electrons. These electrons constitute the current flow in the external circuit. The electrolyte may serve as a simple buffer for ion flow between the electrodes, as in lithium-ion and nickel-cadmium cells, or it may be an active participant in the electrochemical reaction, as in lead-acid cells.

35

Aero Dynamic Wind Mill with Reverse Charge Protection

Fig: 3.5 charging of a secondary cell battery.

Fig: 3.5 Battery charger

Fig: 3.5 A solar-powered charger for rechargeable batteries The energy used to charge rechargeable batteries usually comes from a battery charger using AC mains electricity. Chargers take from a few minutes (rapid chargers) to several hours to charge a battery. Most batteries are capable of being charged far faster than simple battery chargers are capable of; there are chargers that can charge consumer sizes of NiMH batteries in 15 minutes. Fast charges must have multiple ways of detecting full charge (voltage, temperature, etc.) to stop charging before onset of harmful overcharging. Rechargeable multi-cell batteries are susceptible to cell damage due to reverse charging if they are fully discharged. Fully integrated battery chargers that optimize the charging current are available. Attempting to recharge non-rechargeable batteries with unsuitable equipment may cause battery explosion Flow batteries, used for specialised applications, are recharged by replacing the electrolyte liquid. Battery manufacturers' technical notes often refer to VPC; this is volts per cell, and refers to the individual secondary cells that make up the battery. For example, to charge a 12 V battery (containing 6 cells of 2 V each) at 2.3 VPC requires a voltage of 13.8 V across the battery's terminals.

36

Aero Dynamic Wind Mill with Reverse Charge Protection

Non-rechargeable alkaline and zinc-carbon cells output 1.5V when new, but this voltage gradually drops with use. Most NiMH AA and AAA batteries rate their cells at 1.2 V, and can usually be used in equipment designed to use alkaline batteries up to an end-point of 0.9 to 1.2V

Reverse charging:

Subjecting a discharged cell to a current in the direction which tends to discharge it further, rather than charge it, is called reverse charging; this damages cells. Reverse charging can occur under a number of circumstances, the two most common being:

When a battery or cell is connected to a charging circuit the wrong way round. When a battery made of several cells connected in series is deeply discharged.

When one cell completely discharges ahead of the rest, the live cells will apply a reverse current to the discharged cell ("cell reversal"). This can happen even to a "weak" cell that is not fully discharged. If the battery drain current is high enough, the weak cell's internal resistance can experience a reverse voltage that is greater than the cell's remaining internal forward voltage. This results in the reversal of the weak cell's polarity while the current is flowing through the cells. [3]

[4]

this can significantly shorten the life of the affected cell and therefore of the battery. The higher

the discharge rate of the battery needs to be, the better matched the cells should be, both in kind of cell and state of charge. In some extreme cases, the reversed cell can begin to emit smoke or catch fire. In critical applications using Ni-Cad batteries, such as in aircraft, each cell is individually discharged by connecting a load clip across the terminals of each cell, thereby avoiding cell reversal, then charging the cells in series.

3.6 INVERTER

An inverter is an electrical device that converts direct current (DC) to alternating current (AC); the converted AC can be at any required voltage and frequency with the use of appropriate transformers, switching, and control circuits. Solid-state inverters have no moving parts and are used in a wide range of applications, from small switching power supplies in computers, to large electric utility high-voltage direct current applications that transport bulk power. Inverters are commonly used to supply AC power from DC sources such as solar panels or batteries.

37

Aero Dynamic Wind Mill with Reverse Charge Protection

Fig: 3.6 Inverter There are two main types of inverter. The output of a modified sine wave inverter is similar to a square wave output except that the output goes to zero volts for a time before switching positive or negative. It is simple and low cost (~$0.10USD/Watt) and is compatible with most electronic devices, except for sensitive or specialized equipment, for example certain laser printers. A pure sine wave inverter produces a nearly perfect sine wave output (<3% total harmonic distortion) that is essentially the same as utility-supplied grid power. Thus it is compatible with all AC electronic devices. This is the type used in grid-tie inverters. Its design is more complex, and costs 5 or 10 times more per unit power (~$0.50 to $1.00USD/Watt). [1] The electrical inverter is a highpower electronic oscillator. It is so named because early mechanical AC to DC converters were made to work in reverse, and thus were "inverted", to convert DC to AC. The inverter performs the opposite function of a rectifier.

DC power source utilization:

Inverter designed to provide 115 VAC from the 12 VDC source provided in an automobile. The unit shown provides up to 1.2 amperes of alternating current, or enough to power two sixty watt light bulbs.

38

Aero Dynamic Wind Mill with Reverse Charge Protection

Fig:3.6 Inverter snap An inverter converts the DC electricity from sources such as batteries, solar panels, or fuel cells to AC electricity. The electricity can be at any required voltage; in particular it can operate AC equipment designed for mains operation, or rectified to produce DC at any desired voltage. Grid tie inverters can feed energy back into the distribution network because they produce alternating current with the same wave shape and frequency as supplied by the distribution system. They can also switch off automatically in the event of a blackout. Micro-inverters convert direct current from individual solar panels into alternating current for the electric grid. They are grid tie designs by default.

Uninterruptible power supplies:

An uninterruptible power supply (UPS) uses batteries and an inverter to supply AC power when main power is not available. When main power is restored, a rectifier supplies DC power to recharge the batteries.

Induction heating:

Inverters convert low frequency main AC power to higher frequency for use in induction heating. To do this, AC power is first rectified to provide DC power. The inverter then changes the DC power to high frequency AC power.

HVDC power transmission:

With HVDC power transmission, AC power is rectified and high voltage DC power is transmitted to another location. At the receiving location, an inverter in a static inverter plant converts the power back to AC.

39

Aero Dynamic Wind Mill with Reverse Charge Protection

Variable-frequency drive :

A variable-frequency drive controls the operating speed of an AC motor by controlling the frequency and voltage of the power supplied to the motor. An inverter provides the controlled power. In most cases, the variable-frequency drive includes a rectifier so that DC power for the inverter can be provided from main AC power. Since an inverter is the key component, variablefrequency drives are sometimes called inverter drives or just inverters.

Electric vehicle drives:

Adjustable speed motor control inverters are currently used to power the traction motors in some electric and diesel-electric rail vehicles as well as some battery electric vehicles and electric highway vehicles such as the Toyota Pries and Frisker Karma. Various improvements in inverter technology are being developed specifically for electric vehicle applications.[2] In vehicles withregenerative braking, the inverter also takes power from the motor (now acting as a generator) and stores it in the batteries.

Air conditioning :

An air conditioner bearing the inverter tag uses a variable-frequency drive to control the speed of the motor and thus the compressor.

The general case:

A transformer allows AC power to be converted to any desired voltage, but at the same frequency. Inverters, plus rectifiers for DC, can be designed to convert from any voltage, AC or DC, to any other voltage, also AC or DC, at any desired frequency. The output power can never exceed the input power, but efficiencies can be high, with a small proportion of the power dissipated as waste heat.

Basic designs:

In one simple inverter circuit, DC power is connected to a transformer through the centre tap of the primary winding. A switch is rapidly switched back and forth to allow current to flow back to the DC source following two alternate paths through one end of the primary winding and then the other. The alternation of the direction of current in the primary winding of the transformer produces alternating current (AC) in the secondary circuit.

40

Aero Dynamic Wind Mill with Reverse Charge Protection

The electromechanical version of the switching device includes two stationary contacts and a spring supported moving contact. The spring holds the movable contact against one of the stationary contacts and an electromagnet pulls the movable contact to the opposite stationary contact. The current in the electromagnet is interrupted by the action of the switch so that the switch continually switches rapidly back and forth. This type of electromechanical inverter switch, called a vibrator or buzzer, was once used in vacuum tube automobile radios. A similar mechanism has been used in door bells, buzzers and tattoo guns. As they became available with adequate power ratings, transistors and various other types of semiconductor switches have been incorporated into inverter circuit designs.

Output waveforms:

The switch in the simple inverter described above, when not coupled to an output transformer, produces a square voltage waveform due to its simple off and on nature as opposed to the sinusoidal waveform that is the usual waveform of an AC power supply. Using Fourier analysis, periodic waveforms are represented as the sum of an infinite series of sine waves. The sine wave that has the same frequency as the original waveform is called the fundamental component. The other sine waves, called harmonics that are included in the series have frequencies that are integral multiples of the fundamental frequency. The quality of the inverter output waveform can be expressed by using the Fourier analysis data to calculate the total harmonic distortion (THD). The total harmonic distortion is the square root of the sum of the squares of the harmonic voltages divided by the fundamental voltage:

The quality of output waveform that is needed from an inverter depends on the characteristics of the connected load. Some loads need a nearly perfect sine wave voltage supply in order to work properly. Other loads may work quite well with a square wave voltage.

41

Aero Dynamic Wind Mill with Reverse Charge Protection

Advanced designs:

There are many different power circuit topologies and control strategies used in inverter designs. Different design approaches address various issues that may be more or less important depending on the way that the inverter is intended to be used.

Fig: 3.6 H-bridge inverter circuit The issue of waveform quality can be addressed in many ways. Capacitors and inductors can be used to filter the waveform. If the design includes a transformer, filtering can be applied to the primary or the secondary side of the transformer or to both sides. Low-pass filters are applied to allow the fundamental component of the waveform to pass to the output while limiting the passage of the harmonic components. If the inverter is designed to provide power at a fixed frequency, a resonant filter can be used. For an adjustable frequency inverter, the filter must be tuned to a frequency that is above the maximum fundamental frequency. Since most loads contain inductance, feedback rectifiers or antiparallel diodes are often connected across each semiconductor switch to provide a path for the peak inductive load current when the switch is turned off. The antiparallel diodes are somewhat similar to the freewheeling diodes used in AC/DC converter circuits.

signal Waveform transitions per period

harmonics harmonics

System

eliminated amplified Description

THD

42

Aero Dynamic Wind Mill with Reverse Charge Protection

2-level 2 square wave ~45%[1]

3-level 4 3, 9, 27, "modified square wave" > 23.8%[1]

5-level 8 "modified square wave" > 6.5%[1]

2-level 10 3, 5, 9, 27 7, 11, very slow PWM

3-level 12 3, 5, 9, 27 7, 11, very slow PWM

Fourier analysis reveals that a waveform, like a square wave, that is anti-symmetrical about the 180 degree point contains only odd harmonics, the 3rd, 5th, 7th, etc. Waveforms that have steps of certain widths and heights can attenuate certain lower harmonics at the expense of amplifying higher harmonics. For example, by inserting a zero-voltage step between the positive and negative sections of the square-wave, all of the harmonics that are divisible by three (3rd and 9th, etc.) can be

43

Aero Dynamic Wind Mill with Reverse Charge Protection

eliminated. That leaves only the 5th, 7th, 11th, 13th etc. The required width of the steps is one third of the period for each of the positive and negative steps and one sixth of the period for each of the zero-voltage steps. Changing the square wave as described above is an example of pulse-width modulation (PWM). Modulating, or regulating the width of a square-wave pulse is often used as a method of regulating or adjusting an inverter's output voltage. When voltage control is not required, a fixed pulse width can be selected to reduce or eliminate selected harmonics. Harmonic elimination techniques are generally applied to the lowest harmonics because filtering is much more practical at high frequencies, where the filter components can be much smaller and less expensive. Multiple pulse-width or carrier based PWM control schemes produce waveforms that are composed of many narrow pulses. The frequency represented by the number of narrow pulses per second is called the switching frequency or carrier frequency. These control schemes are often used in variablefrequency motor control inverters because they allow a wide range of output voltage and frequency adjustment while also improving the quality of the waveform. Multilevel inverters provide another approach to harmonic cancellation. Multilevel inverters provide an output waveform that exhibits multiple steps at several voltage levels. For example, it is possible to produce a more sinusoidal wave by having split-rail direct current inputs at two voltages, or positive and negative inputs with a central ground. By connecting the inverter output terminals in sequence between the positive rail and ground, the positive rail and the negative rail, the ground rail and the negative rail, then both to the ground rail, a stepped waveform is generated at the inverter output. This is an example of a three level inverter: the two voltages and ground.

Three phase inverters:

Fig: 3.6 3-phase inverter

44

Aero Dynamic Wind Mill with Reverse Charge Protection

Three-phase inverters are used for variable-frequency drive applications and for high power applications such asHVDC power transmission. A basic three-phase inverter consists of three single-phase inverter switches each connected to one of the three load terminals. For the most basic control scheme, the operation of the three switches is coordinated so that one switch operates at each 60 degree point of the fundamental output waveform. This creates a line-to-line output waveform that has six steps. The six-step waveform has a zero-voltage step between the positive and negative sections of the square-wave such that the harmonics that are multiples of three are eliminated as described above. When carrier-based PWM techniques are applied to six-step waveforms, the basic overall shape, or envelope, of the waveform is retained so that the 3rd harmonic and its multiples are cancelled.

Fig:3.6 3-phase inverter waveform 3-phase inverter switching circuit showing 6-step switching sequence and waveform of voltage between terminals A and C To construct inverters with higher power ratings, two six-step three-phase inverters can be connected in parallel for a higher current rating or in series for a higher voltage rating. In either case, the output waveforms are phase shifted to obtain a 12-step waveform. If additional inverters are combined, an 18-step inverter is obtained with three inverters etc. Although inverters are usually combined for the purpose of achieving increased voltage or current ratings, the quality of the waveform is improved as well. Controlled rectifier inverters Since early transistors were not available with sufficient voltage and current ratings for most inverter applications, it was the 1957 introduction of the thyristor or silicon-controlled rectifier (SCR) that initiated the transition to solid state inverter circuits.

45

Aero Dynamic Wind Mill with Reverse Charge Protection

Fig: 3.6 12-pulse line-commutated inverter circuit The commutation requirements of SCRs are a key consideration in SCR circuit designs. SCRs do not turn off or commutate automatically when the gate control signal is shut off. They only turn off when the forward current is reduced to below the minimum holding current, which varies with each kind of SCR, through some external process. For SCRs connected to an AC power source, commutation occurs naturally every time the polarity of the source voltage reverses. SCRs connected to a DC power source usually require a means of forced commutation that forces the current to zero when commutation is required. The least complicated SCR circuits employ natural commutation rather than forced commutation. With the addition of forced commutation circuits, SCRs have been used in the types of inverter circuits described above. In applications where inverters transfer power from a DC power source to an AC power source, it is possible to use AC-to-DC controlled rectifier circuits operating in the inversion mode. In the inversion mode, a controlled rectifier circuit operates as a line commutated inverter. This type of operation can be used in HVDC power transmission systems and in regenerative braking operation of motor control systems. Another type of SCR inverter circuit is the current source input (CSI) inverter. A CSI inverter is the dual of a six-step voltage source inverter. With a current source inverter, the DC power supply is configured as a current source rather than a voltage source. The inverter SCRs are switched in a six-step sequence to direct the current to a three-phase AC load as a stepped current waveform. CSI inverter commutation methods include load commutation and parallel capacitor commutation. With both methods, the input current regulation assists the commutation. With load commutation, the load is a synchronous motor operated at a leading power factor.

46

Aero Dynamic Wind Mill with Reverse Charge Protection

As they have become available in higher voltage and current ratings, semiconductors such as transistors or IGBTs that can be turned off by means of control signals have become the preferred switching components for use in inverter circuits.

Rectifier and inverter pulse numbers:

Rectifier circuits are often classified by the number of current pulses that flow to the DC side of the rectifier per cycle of AC input voltage. A single-phase half-wave rectifier is a onepulse circuit and asingle-phase full-wave rectifier is a two-pulse circuit. A three-phase half-wave rectifier is a three-pulse circuit and a three-phase full-wave rectifier is a six-pulse circuit. With three-phase rectifiers, two or more rectifiers are sometimes connected in series or parallel to obtain higher voltage or current ratings. The rectifier inputs are supplied from special transformers that provide phase shifted outputs. This has the effect of phase multiplication. Six phases are obtained from two transformers, twelve phases from three transformers and so on. The associated rectifier circuits are 12-pulse rectifiers, 18-pulse rectifiers and so on. When controlled rectifier circuits are operated in the inversion mode, they would be classified by pulse number also. Rectifier circuits that have a higher pulse number have reduced harmonic content in the AC input current and reduced ripple in the DC output voltage. In the inversion mode, circuits that have a higher pulse number have lower harmonic content in the AC output voltage waveform. 3.7 SWITCHES: In electronics, a switch is an electrical component that can break an electrical circuit, interrupting the current or diverting it from one conductor to another. The most familiar form of switch is a manually operated electromechanical device with one or more sets of electrical contacts. Each set of contacts can be in one of two states: either 'closed' meaning the contacts are touching and electricity can flow between them, or 'open', meaning the contacts are separated and nonconducting.

47

Aero Dynamic Wind Mill with Reverse Charge Protection

Fig: 3.7 Switches A switch may be directly manipulated by a human as a control signal to a system, such as a computer keyboard button, or to control power flow in a circuit, such as a light switch. Automatically operated switches can be used to control the motions of machines, for example, to indicate that a garage door has reached its full open position or that a machine tool is in a position to accept another workpiece. Switches may be operated by process variables such as pressure, temperature, flow, current, voltage, and force, acting as sensors in a process and used to automatically control a system. For example, a thermostat is a temperature-operated switch used to control a heating process. A switch that is operated by another electrical circuit is called a relay. Large switches may be remotely operated by a motor drive mechanism. Some switches are used to isolate electric power from a system, providing a visible point of isolation that can be pad-locked if necessary to prevent accidental operation of a machine during maintenance, or to prevent electric shock.

3.8 LCD :( 16 * 2 ALPHANUMERIC)

Liquid crystal display is very important device in embedded system. It offers high flexibility to user as he can display the required data on it. A liquid crystal display (LCD) is a thin, flat electronic visual display that uses the light modulating properties of liquid crystals (LCs).LCs does not emit light directly. LCDs therefore need a light source and are classified as "passive" displays. This is the interfacing example for the Parallel Port LCD). Schematic

48

Aero Dynamic Wind Mill with Reverse Charge Protection

Fig: 3.8 LCD

3.9 ANALOG TO DIGITAL CONVERTER (ADC):

Analog-to-digital converters are among the most widely used devices for data acquisition. Digital systems use binary values, but in the physical world everything is continuous i.e., analog values. Temperature, pressure (wind or liquid), humidity and velocity are the physical analog quantities. These physical quantities are to be converted into digital values for further processing. One such device to convert these physical quantities into electrical signals is sensor. Sensors for temperature, pressure, humidity, light and many other natural quantities produce an output that is voltage or current. Thus, an analog-to-digital converter is needed to convert these electrical signals into digital values so that the microcontroller can read and process them. An ADC has an n-bit resolution where n can be 8,10,12,16 or even 24 bits. The higher resolution ADC provides a smaller step size, where step size is the smallest change that can be detected by an ADC. In addition to resolution, conversion time is another major factor in judging an ADC. Conversion time is defined as the time it takes the ADC to convert the analog input to a digital number.

ADC0808:

49

Aero Dynamic Wind Mill with Reverse Charge Protection