Beruflich Dokumente

Kultur Dokumente

Fracture Formation Evaluation of Reinforced Concrete Beam Subjected To Cycle Loading Using Acoustic Emission Technique

Hochgeladen von

Amin MojiriOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fracture Formation Evaluation of Reinforced Concrete Beam Subjected To Cycle Loading Using Acoustic Emission Technique

Hochgeladen von

Amin MojiriCopyright:

Verfügbare Formate

International Journal of Scientific Research in Knowledge (IJSRK), 1(4), pp. 51-59, 2013 Available online at http://www.ijsrpub.

com/ijsrk ISSN: 2322-4541, 2013 IJSRPUB

Full Length Research Paper Fracture Formation Evaluation of Reinforced Concrete Beam Subjected to Cycle Loading Using Acoustic Emission Technique

Alireza Panjsetooni1,2*, Norazura Muhamad Bunnori2

2

Islamic Azad University, Abdanan Branch School of Civil Engineering, Engineering Campus, Universiti Sains Malaysia (USM), Seri Ampangan, Seberang Perai Selatan, 14300 Nibong Tebal, Pulau Pinang, Malaysia *Corresponding Author: E-mail: Alireza5civil@yahoo.com

Received 26 February 2013; Accepted 19 March 2013

Abstract. Acoustic emission (AE) technique is one of the non-destructive evaluation (NDE) techniques that have been considered as the prime candidate for structural health and damage monitoring in loaded structures. In present study, AE technique with a new approach was employed to investigate the process of fracture formation in reinforced concrete (RC) structure. Thirty RC beam specimens with continuous and non-continuous longitudinal rebar were prepared. The RC beams were tested under loading cycle and were simultaneously monitored using AE. The AE test data was analyzed using Relaxation, Load and Calm ratio. The trend of these methods during loading and unloading was compared with behaviour of each type of specimens. The trend of Relaxation ratio and Calm and Load ratio method during loading and unloading showed that these methods are strongly sensitive with cracks growth in RC beam specimens and were able to indicate the levels of damage. Also, results showed that AE can be considered as a viable method to predict the remaining service life of reinforced concrete. In addition, with respects to the results obtained from Relaxation, Load and Calm ratio indicated, a new chart is proposed. Key words: Reinforced concrete beam; Acoustic emission; Relaxation ratio; Calm and Load ratio; nondestructive evaluation technique

1. INTRODUCTION Acoustic emission (AE) technique is one of the nondestructive evaluation (NDE) techniques that have been considered as the prime candidate for structural health and damage monitoring in loaded structures (Surgeon and Wevers, 1999). The main goal of the monitoring of AE phenomena is to provide a series of useful information by the correlation of AE signals with growing fracture process (Romaniv et al., 1987). AE technique is used to evaluate of concrete structures damage intensity in real time. The primary sources of acoustic emission in concrete structures are numerous and include cracking of the concrete, rubbing of crack surfaces during crack closure, debonding of the reinforcing steel from the surrounding concrete (Pollock, 1981) . AE data can be evaluated by means of several methods. Relaxation ratio and Calm and load ratio which are derived from events during unloading and loading are reasonable methods for evaluation structure under cyclic load. A few works were found that Relaxation ratio has been used for evaluation of concrete structure such as Colombo et al. (2005), Liu and Ziehl (2009) and Proverbio (2011). In addition, several works was found that Calm and Load ratio has been used for evaluation of concrete structure such as

Ohtsu et al. (2002), Luo et al. (2004), Colombo et al. (2005), Lovejoy (2008), Liu and Ziehl (2009), Proverbio (2011) and Vidya Sagar et al. (2012). In main objective of this current study was to evaluate damage assessment of RC beam using Relaxation and Calm and Load ratio. Commonly, previous works has been evaluated for RC beams in flexural mode. In this research RC beam in two modes failure (flexural and shear) and failure due to slippage of reinforcement in concrete were considered. Also, a new chart for evaluation of the RC beam using Relaxation and Calm and Load ratio was suggested. The ultimate goal of this current study is the possibility in implementing for a remote monitoring procedure of concrete structures using AE. 2. FUNDAMENTAL THEORETICAL 2.1. Relaxation Ratio Commonly, the load pattern of AE test is load cycles which consist of two phase: a loading and an unloading phase. AE activity during unloading is an indication of structural instability (Ohtsu et al., 2002). In respect to the AE activity during loading and unloading, quantification of Relaxation Ratio was proposed by Colombo et al. (2005). In previous

51

Panjsetooni and Bunnori Fracture Formation Evaluation of Reinforced Concrete Beam Subjected to Cycle Loading Using Acoustic Emission Technique

experiments, the AE energy has been used to descript of Relaxation ratio. In these study the AE signal strength was used which shown the most effective parameter in damage evaluation. The relaxation ratio

is expressed in terms of signals strength and defined as:

2.2. Calm and Load ratio One of the important damage assessment methods is based on two parameters: calm and load ratio. Three levels of concrete damage (heavy, moderate and low) using cross plotting these two ratios can be identified. Calm ratio is based on relation AE activity during

loading and unloading (Colombo et al., 2005). The Load ratio is based on the concept of Kaiser Effect and is defined as the ratio between the load at the onset of AE activity under repeated loading and previous load (Proverbio, 2011). However, according to Gross and Ohtsu (2008), calm and load ratio was defined as:

3. METHODOLOGY 3.1. Material details The specimens used in this study were reinforced concrete (RC) beam. The dimensions of the RC beams were 1500 mm in length with a 250x250 mm crocs section. RC beam specimens were reinforced with four 10 or 12 mm diameter deformed steel bars and

with stirrups of 6mm diameter at 200 mm center to center spacing. A total of thirty reinforced concrete beams specimens in ten types were cast. Figure 1 shows the dimension of all types of the RC beam specimens. The water to cement ratio was 0.5 and the material proportions were 1:2:2.5:0.5 by weight of cement, sand, aggregate and water respectively. The average compressive strength of concrete at 28 days was 25Mpa.

(a) (b) . Fig. 1: Dimension of all types of the RC beam specimens

52

International Journal of Scientific Research in Knowledge (IJSRK), 1(4), pp. 51-59, 2013

3.2. Cyclic loading test monitoring using AE technique A total of thirty RC beam specimens described earlier were tested under loading cycle. In order to perform acoustic emission monitoring, an eight channel AE system (DISP-8PCI) manufactured by Physical Acoustics Corporation (PAC) was employed. Four R6I sensors with the resonance frequency of approximately 60 kHz were used. The AE systems hardware was set up for threshold level of 45dB for all channels in order to avoid the possibility of noise effect. The load was applied at the mid span of the RC beam specimens. The load was applied in 10kN steps at mid span of RC beam. The load was going up from o.5kN to maximum of each loading cycle and held constant for one minute. Then, the load was removed down from maximum of each loading cycle to 0.5kN and was held for 2 minutes. The test was monitored by AE throughout the test. The measurement including load, mid span deflection and AE data were recorded continuously during the three point bending test. 4. RESULTS AND DISCUSSIONS 4.1. Overall responses of test RC beam to cyclic loading The RC beams were tested in three point bending test according to described previously. A summary of

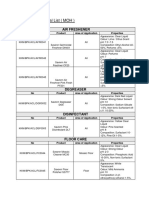

three-point bending results as shown in Table 1. In addition, Figure 2 shows the behavior of RC beam specimens under loading cycle. The behavior RC beam specimens under load can be divided into six stages of failure namely: (I) Micro-cracking (II) Initial flexural cracks visible, (III) Distributed flexural cracks, (IV) Mixed flexural and shear cracks, (V) Localized crack propagation and (V) Failure. With respect to the behavior of the RC beam specimens under loading cycle, specimens can be divided in three types: A, B and C. The specimens of type A include RCBLC1, RCBLC2, RCBLC6 and RCBLC7 which the longitudinal overlap length was not enough and were failed due to slippage of reinforcement in concrete. The load failure for all type A specimens were between 60kN to 70kN and location was at the connection zone. The specimens of type B include RCBLC3, RCBLC4 and RCBLC5 that were failed in flexural mode. The specimens of type C include RCBLC8, RCBLC9 and RCBLC10 that were failed in shear mode. In addition, the load failure for all specimens of type B and C were between 90kN to 100kN and location was outside of the connection zone.

Type A A B B B A A C C C

Specimen RCBLC1 RCBLC2 RCBLC3 RCBLC4 RCBLC5 RCBLC6 RCBLC7 RCBLC8 RCBLC9 RCBLC10

Table 1: Summary of three-point bending test L- bar size Overlap length Failure load (mm) (mm) (kN) 100 150 52 100 250 65 100 350 90 100 450 94 100 90 120 150 53 120 250 67 120 350 90 120 450 100 120 98

Failure mode Flexural Flexural Flexural Flexural Flexural Flexural Flexural Shear Shear Shear

Failure zone Connection Connection Connection Connection -

4.2. Relaxation ratio analysis The AE data obtained in test were analysed in order to carry out a relaxation ratio analysis. The Relaxation .

ratios in term of signal strength during loading and unloading phase for all channels were calculated. Figure 3 shows the trend of Relaxation ratio for all RC beam specimens.

53

Panjsetooni and Bunnori Fracture Formation Evaluation of Reinforced Concrete Beam Subjected to Cycle Loading Using Acoustic Emission Technique

Fig. 2: The behaviour RC beam specimens under loading cycle

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

(j) Fig. 3: Relaxation ratio for all RC beam specimens

54

International Journal of Scientific Research in Knowledge (IJSRK), 1(4), pp. 51-59, 2013

Figure 3(a) (b) (c) (d) shows the trend of Relaxation ratio for all RC beam specimens of Type A. Data points show that during cycle 1 to 3 (10kN to 30kN) Relaxation ratios is less than one. Also, from loading cycle 4 (40kN) when the flexural cracks were observed until specimen failure, Relaxation ratio is greater than one. Figure 3 (e) (f) (g) shows the trend of Relaxation ratio for all RC beam specimens of Type B. Data points show that during cycle 1 to 4 (10kN to 40kN) relaxation ratios is less than one. Also, from loading cycle 5 (50kN) until specimen failed in flexural mode, Relaxation ratio is greater than one. Figure 3(h) (i) (j) shows the trend of Relaxation ratio for all RC beam specimens of Type C. Data points show that during cycle 1 to 5 (10kN to 50kN) Relaxation ratios is less than one. Also, from loading cycle 6 (60kN) until specimen failed in flexural mode, Relaxation ratio is greater than one. Relaxation ratio is based on comparison of AE activity during loading and unloading phase. Relaxation radio less than one shows that AE events in loading phase are dominant. Also the relaxation radio greater than one shows that AE events in unloading phase are dominant. The results of this research shown that for specimens of Type A which had a overlap length of 150mm or 250mm and were failed at connection zone due to slippage of the reinforcement in concrete, an inversion of trend in Relaxation ratio occurs when load is approaching to 40kN. Also, for all specimens of Type B that were failed in flexural mode, an inversion of trend in load ratio occurs when load is approaching to 50kN. In addition, for Type C that was failure in sheer mode, an inversion of trend in load ratio occurs when load was approaching to 60kN. Commonly, fracture mode of cracking with the progress of fracture in concrete structure is changing from the tensile type of fracture to the shear type of fracture. Crack opening is a principal motion when tensile fracture cracks are nucleated, while sliding on an existing crack is a major motion to generate the shear fracture cracks (McCabe et al., 1976). In early stages, tensile fracture cracks are primary source of AE activities. As approaching to the final failure, the shear fracture cracks are primary source of AE activities. AE activity as the shear fracture cracks could be generated during unloading (Grosse and Ohtsu, 2008). In addition, in loading phase the cracks are the predominant source of AE activity whiles in the unloading phase the friction are sources prevail of AE activity (Colombo et al., 2005b). Therefore, it could be said that in the early stages, I and II, the tensile cracks are the primary source of AE activity. Thus,

AE activity during loading phase is dominant. As approaching the final failure, shear cracks and friction between cracks are the primary source of AE activity. Thus, AE activity during un- loading phase is dominant. Therefore, for specimens of types of B and C, it could be said that in the early stages stage (I and II), the tensile cracks are primary source of AE activity. Thus, AE activity during loading phase is dominant. Also, as approaching to the final failure, shear cracks and friction between cracks are the primary source of the AE activity. Thus , AE activity during un-loading phase is dominant. In addition for types of A samples, at the early stage of loading,the tensile cracks are primary source of AE activity. Thus, AE activity during loading phase is dominant. Also, in this stage the behvour of specimens is similar to specimens of type B and C . As approching the final failure, the behavour of specimens of type A is not similar to type B and C. In this stage, the specimens of type A of specimens due to slippage of reinforcement in concrete were failed and the slippage of reinforcement in concrete is the primary source of AE activity. However, the results show that in the stage of micro cracks and initial crack propagation, Relaxation ratio is less than one. Also, in stage of the cracks distribution until specimen failure relaxation ratio is more than one. In addition, the results show that when load is greater than 45%, 55% and 65% of the ultimate bending load for type A, B and C respectively, Relaxation ratio is more than one. A few works could be found in which AE activity was considered using relaxation ratio Such as Colombo et al.(2005) and Liu and Ziehl (2009). Colombo et al. (2005) investigated the number of RC beam under cyclic load using Relaxation ratio analysis. They found that Relaxation ratio is more than one when load is greater than approximately 45% of the ultimate bending load. Also, Liu and Ziehl (2009) found that Relaxation ratio increased with load to yield load and this measure was relatively stable and was not well-suited to post-yield load evaluation because the ratio often decreased significantly after yield load. Also, no clear trend was observed for the shear specimens. 4.3. Calm ratio The AE data were processed in order to carry out a Calm ratio analysis. The Calm ratios in terms of signal strength during loading and unloading phase for all channels were calculated. Figure 4 shows the trend of Calm ratio for all RC beam specimens.

55

Panjsetooni and Bunnori Fracture Formation Evaluation of Reinforced Concrete Beam Subjected to Cycle Loading Using Acoustic Emission Technique

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

(j) Fig. 4: Calm ratio for all RC beam specimens Figure 4 (a) (b) (c) (d) shows the trend of Calm ratio for all RC beam specimens of type A. Data points show that during cycle 1 to 3 (10kN to 30kN) when the behaviour of RC beam specimens is in stage of micro-cracking, Calm ratio is low level and less than 0.05. Also, from loading cycle 4 (40kN) when the flexural cracks were observed, Calm ratio is increased to 0.25. Figure 4 (e) (f) (g) (h) (i) (j) shows the trend of Calm ratio for all RC beam specimens of type B. Data points show that during loading cycle 1 to 2 when the behaviour of RC beam specimens was in stage of micro-cracking and during loading cycle 3 to 4 in stage of observation of first cracks, Calm ratio is low level and less than 0.05. Also, from loading cycle 5 (40kN) when the flexural cracks were distributed, Calm ratio is increased to 0.25. Figure 4 (h) (i) (j) shows the trend of Calm ratio for all RC beam specimens of type C. Data points show that during loading cycle 1 to 2, when the behaviour of RC beam specimens is in stage of micro-cracking and during loading cycle 3 to 4 in stage of observation of first cracks, Calm ratio is low lever and less than 0.05. In addition, from loading cycle 5 (40kN) when the flexural cracks were distributed, Calm ratio is increased to 0.25. Several works were found that Calm ratio has been used for evaluation of RC structure such as Ohtsu et al. (2002), Luo et al. (2004) , Colombo et al. (2005) , Lovejoy (2008), Liu and Ziehl (2009) and Proverbio (2011) . They found that for failure in flexural mode, Calm ratio was relatively stable and increased with load sets up to yield. It was not well-suited to postyield evaluation because the ratio often decreased significantly after yield. The results obtained in this study for failure in flexural mode are similar to previously works. 4.4. Load ratio The Load ratio for all RC beams was calculated. Figure 5 shows the trend of Load ratio versus cycle number for each sample of each type. The results

56

International Journal of Scientific Research in Knowledge (IJSRK), 1(4), pp. 51-59, 2013

show that load ratio decreases with increasing load. Also, the results indicated in stage of micro cracks, load ratios is more than one and then an inversion of trend in Load ratio occurs and the Load ratio is less than one. This change occurs when the cracks were observed. Load ratio is based on the concept of Kaiser

Effect and a load ratio which is more than 1, is a criterion of a structure in good condition (Colombo et al. 2005). The results of Load ratio analysis shows that initial cracks associated with an inversion of trend in Load ratio from more than that one to less than one.

Fig. 5: Load ratio for all RC beam specimens Several works was found that Load ratio has been used for evaluation of RC be concrete structure such as Ohtsu et al. (2002), Luo et al. (2004) , Colombo et al., (2005) , Lovejoy (2008), Liu and Ziehl (2009) and Proverbio (2011) . They found that Load ratio was increased associated levels of Damage. The results obtained in this study show that Load ratio was increased associated levels of damage and initial cracks, Load ratio is less than one. 4.5. Calm and Load ratio chart According to NDIS 2421, damage assessment could be evaluated by using two ratios: Load and Calm Ratios (Colombo et al., 2005). Calm and Load ratio chart is divided in three level of damage: low, moderate and high. Load ratio more than 1 is a criterion of a structure in good condition (Colombo et al. 2005). Thus, an appropriate limit value for Load ratio can be 1.0. In the relaxation ratio chart for RC beam, points move from a loading dominant to a relaxation dominant condition from loading cycle 4, 5 and 6 for specimens of type A, B and C. With respect to the results of Relaxation ratio, an appropriate limit value for Calm ratio can be identified as any justification 5%.Calm and load ratio chart was plotted with considering two limit values as shown in Figure 6.

Fig. 6: Calm and load ratio chart 5. CONCLUSIONS This paper provides the results from tests on RC beam under loading cycle and was monitored by AE throughout the test. On the basis of AE activities, the analysis of signal characteristics using ratios of Relaxation, Load and Calm and with regard to damage levels, the conclusions are presented below: 1. Three levels of damage in concrete structure can be identified using this chart by cross plotting Relaxation ratio and Calm and Load ratio. 2. The relaxation ratio was dominated with approaching load to 40 to 60% of the ultimate load for three types of RC beam specimens. 3. The trend of Relaxation ratio and Calm and Load ratio method during loading and unloading showed that these methods are strongly sensitive

57

Panjsetooni and Bunnori Fracture Formation Evaluation of Reinforced Concrete Beam Subjected to Cycle Loading Using Acoustic Emission Technique

with cracks growth in RC beam specimen and were able to indicate the levels of damage. 4. Results showed that AE can be considered as a viable method to predict the remaining service life of reinforced concrete. Acknowledgment The authors would like to thank Universiti Sains Malaysia (USM) for providing support through the short term Grant [304/PAWAM/6039047] REFERENCES Colombo S, Forde M, Main I, Halliday J, Shigeishi M (2005a). AE energy analysis on concrete bridge beams. Materials and structures, 38: 851-856. Colombo S, Forde M, Main I, Shigeishi M (2005b). Predicting the ultimate bending capacity of concrete beams from the relaxation ratio analysis of AE signals. Construction and Building Materials, 19: 746-754. Grosse CU, Ohtsu M (2008). Acoustic emission testing, Springer. Liu Z, Ziehl PH (2009). Evaluation of reinforced concrete beam specimens with acoustic emission and cyclic load test methods. ACI Structural Journal, 106. Lovejoy SC (2008). Acoustic emission testing of beams to simulate SHM of vintage reinforced concrete deck girder highway bridges. Structural Health Monitoring, 7: 329-346.

Luo X, Haya H, Inaba T, Shiotani T, Nakanishi Y (2004). Damage evaluation of railway structures by using train-induced AE. Construction and Building Materials, 18: 215223. Mccabe WM, Koerner RM, Lord AE (1976). Acoustic emission behavior of concrete laboratory specimens. Journal of the American Concrete Institute, 73: 367-71. Ohtsu M, Uchida M, Okamoto T, Yuyama S (2002). Damage assessment of reinforced concrete beams qualified by acoustic emission. ACI Structural Journal, 99. Pollock A (1981). Acoustic emission amplitude distributions. International Advances in Nondestructive Testing., 7: 215-239. Proverbio E (2011). Evaluation of deterioration in reinforced concrete structures by AE technique. Materials and corrosion, 62: 161-169. Romaniv O, Kirillov K, Zima YV, Nikiforchin G (1987). Relationship of acoustic emission to the kinetics and micromechanism of fatigue failure of high-strength steel with a martensitic structure. Materials Science, 23: 156-160. Surgeon M, Wevers M (1999). Modal analysis of acoustic emission signals from CFRP laminates. NDT & E International, 32: 311-322. Vidya Sagar R, Raghu Prasad BK (2012). Damage limit states of reinforced concrete beams subjected to incremental cyclic loading using relaxation ratio analysis of AE parameters. Construction and Building Materials, 35: 139148.

58

International Journal of Scientific Research in Knowledge (IJSRK), 1(4), pp. 51-59, 2013

Alireza Panjsetooni was born in Western area of Iran on 2rd January 1976. His first degree at University Tabriz in Bach of Civil Eng(Hons) 2000. Then he continued deeply in Master of earthquake Engineering (M.Struct) at Universiti Tehran in 2008 and currently his pursuing in PhD level at Universiti Sains Malaysia in Structural Health Monitoring.

Norazura Muhamad Bunnori (PhD) has been involved in Acoustic Emission (AE) technique since 2004 while she was pursuing her PhD study at Cardiff University, Wales, UK. She was graduated from Cardiff University in 2008 and continues with the AE research area in Universiti Sains Malaysia (USM), Malaysia. Currently she is working as a Senior Lecturer at School of Civil Engineering, Universiti Sains Malaysia (USM) since 2009. The research covered several topics of AE applications and analysis (quantitative and qualitive). The aim is to continue the AE study especially in Structural Health Monitoring (SHM) research area and to discover more in this potential area. The passion towards AE is deep and she believes that there are a great number of information can be studied and discovered with this tool.

59

Das könnte Ihnen auch gefallen

- Effect of Millimeter Waves With Low Intensity On Peroxidase Total Activity and Isoenzyme Composition in Cells of Wheat Seedling ShootsDokument7 SeitenEffect of Millimeter Waves With Low Intensity On Peroxidase Total Activity and Isoenzyme Composition in Cells of Wheat Seedling ShootsAmin MojiriNoch keine Bewertungen

- Comparison of The Physical Characteristics and GC/MS of The Essential Oils of Ocimum Basilicum and Ocimum SanctumDokument10 SeitenComparison of The Physical Characteristics and GC/MS of The Essential Oils of Ocimum Basilicum and Ocimum SanctumAmin MojiriNoch keine Bewertungen

- Effect of Processing Variables On Compaction and Relaxation Ratio of Water Hyacinth BriquettesDokument9 SeitenEffect of Processing Variables On Compaction and Relaxation Ratio of Water Hyacinth BriquettesAmin MojiriNoch keine Bewertungen

- Full Length Research Paper: ISSN: 2322-4541 ©2013 IJSRPUBDokument7 SeitenFull Length Research Paper: ISSN: 2322-4541 ©2013 IJSRPUBAmin MojiriNoch keine Bewertungen

- Factors Influencing Anemia and Night Blindness Among Children Less Than Five Years Old (0 - 4.11 Years) in Khartoum State, SudanDokument13 SeitenFactors Influencing Anemia and Night Blindness Among Children Less Than Five Years Old (0 - 4.11 Years) in Khartoum State, SudanAmin MojiriNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Approved Chemical ListDokument2 SeitenApproved Chemical ListSyed Mansur Alyahya100% (1)

- GearsDokument14 SeitenGearsZulhilmi Chik TakNoch keine Bewertungen

- The Training Toolbox: Forced Reps - The Real Strength SenseiDokument7 SeitenThe Training Toolbox: Forced Reps - The Real Strength SenseiSean DrewNoch keine Bewertungen

- Radio Network Parameters: Wcdma Ran W19Dokument12 SeitenRadio Network Parameters: Wcdma Ran W19Chu Quang TuanNoch keine Bewertungen

- Julie Jacko - Professor of Healthcare InformaticsDokument1 SeiteJulie Jacko - Professor of Healthcare InformaticsjuliejackoNoch keine Bewertungen

- AASW Code of Ethics-2004Dokument36 SeitenAASW Code of Ethics-2004Steven TanNoch keine Bewertungen

- Acts 1 Bible StudyDokument4 SeitenActs 1 Bible StudyPastor Jeanne100% (1)

- NCPDokument3 SeitenNCPchesca_paunganNoch keine Bewertungen

- 9m.2-L.5@i Have A Dream & Literary DevicesDokument2 Seiten9m.2-L.5@i Have A Dream & Literary DevicesMaria BuizonNoch keine Bewertungen

- Advanced Technical Analysis: - Online Live Interactive SessionDokument4 SeitenAdvanced Technical Analysis: - Online Live Interactive SessionmahendarNoch keine Bewertungen

- E TN SWD Csa A23 3 94 009 PDFDokument5 SeitenE TN SWD Csa A23 3 94 009 PDFRazvan RobertNoch keine Bewertungen

- 2023-Tutorial 02Dokument6 Seiten2023-Tutorial 02chyhyhyNoch keine Bewertungen

- Indg 264.3 w02Dokument15 SeitenIndg 264.3 w02FrauNoch keine Bewertungen

- Prepositions French Worksheet For PracticeDokument37 SeitenPrepositions French Worksheet For Practiceangelamonteiro100% (1)

- 2009 Annual Report - NSCBDokument54 Seiten2009 Annual Report - NSCBgracegganaNoch keine Bewertungen

- Research Paper 701Dokument13 SeitenResearch Paper 701api-655942045Noch keine Bewertungen

- Clinincal Decision Support SystemDokument10 SeitenClinincal Decision Support Systemم. سهير عبد داؤد عسىNoch keine Bewertungen

- Snapshot Traveller January 2022Dokument11 SeitenSnapshot Traveller January 2022api-320548675Noch keine Bewertungen

- Goats & Sheep: What You Need To KnowDokument74 SeitenGoats & Sheep: What You Need To KnowAdrian BAGAYANNoch keine Bewertungen

- ESU Mauritius Newsletter Dec 2014Dokument8 SeitenESU Mauritius Newsletter Dec 2014Ashesh RamjeeawonNoch keine Bewertungen

- MINIMENTAL, Puntos de Corte ColombianosDokument5 SeitenMINIMENTAL, Puntos de Corte ColombianosCatalina GutiérrezNoch keine Bewertungen

- Challenges For Omnichannel StoreDokument5 SeitenChallenges For Omnichannel StoreAnjali SrivastvaNoch keine Bewertungen

- Top 100 Questions On Modern India History PDFDokument16 SeitenTop 100 Questions On Modern India History PDFmohammed arsalan khan pathan100% (1)

- Accounting 110: Acc110Dokument19 SeitenAccounting 110: Acc110ahoffm05100% (1)

- Focus Group DiscussionDokument13 SeitenFocus Group DiscussionSumon ChowdhuryNoch keine Bewertungen

- Welcome LetterDokument2 SeitenWelcome Letterapi-348364586Noch keine Bewertungen

- Theater 10 Syllabus Printed PDFDokument7 SeitenTheater 10 Syllabus Printed PDFJim QuentinNoch keine Bewertungen

- Bakhtin's Chronotope On The RoadDokument17 SeitenBakhtin's Chronotope On The RoadLeandro OliveiraNoch keine Bewertungen

- Hce ReviewerDokument270 SeitenHce ReviewerRaquel MonsalveNoch keine Bewertungen