Beruflich Dokumente

Kultur Dokumente

04-2-TS vOL-II, Sec-IV, FQP R1 PDF

Hochgeladen von

sanjeevchhabraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

04-2-TS vOL-II, Sec-IV, FQP R1 PDF

Hochgeladen von

sanjeevchhabraCopyright:

Verfügbare Formate

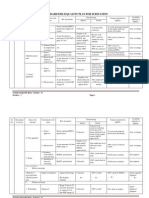

APPENDIX-II FIELD QUALITY PLAN FOR TRANSMISSION LINES

REVISED STANDARD FIELD QUALITY PLAN FOR TRANSMISSION LINES

POWERGRID Document No. C/QA&I/SFQP/TL/030, Rev. 01

S. No. Description of Activity Items to be Checked Tests/Checks to be done Ref. documents Agency Check/Testing Extent Counter Check/Test by OWNER Accepting authority in OWNER 1. Detailed Survey on rerouted portion c. Tower spotting datas given by Engg. b. Route profiling & tower spotting. 1. Ground clearance. 2. Cold wt. Span 3. Hot wt. Span 4. Sum of Adj. Span (wind span) 5. Angle of Devn. 2. Check Survey Tower Location & Final Length i) Alignment ii) Final Length a. Route alignment b. Tower Schedule c. Profile -doContractor -do-do100% at Field -do-doi) All angle towers in plains and 50% in hilly terrains. ii) Final length to be checked on 100% basis based on records/documents 3. Detailed Soil Investigation a. Borelog 1. Depth of bore log 2. SPT Test 3. Collection of samples As per OWNER Specification Contractor 100% at Field To witness 20% at Field Section incharge Section Incharge b. Tower Spotting data c. Route alignment a. Sag template Contractor -do-do-do100% at Field -do-do-do100% based on record documents -do-doLine incharge a. Route alignment Optimisation of route length b. Topographical map a. Preliminary survey. Contractor 100% at Field 100% based on record documents Project incharge

S. No.

Description of Activity

Items to be Checked

Tests/Checks to be done

Ref. documents Agency

Check/Testing Extent

Counter Check/Test by OWNER

Accepting authority in OWNER

b. Tests on samples

As per tech. Specs.

As per OWNER Specification

Lab appd. By OWNER

100% by testing lab

Review of lab test results

Line incharge based on the report review by CC Engg.

4.

Tower Foundation A. Materials 1. Cement 1. Source approval Source meeting OWNER Specification/Approved vendor 2. Physical tests As per document at Annexure-I of this FQP at Pg. 12, 13 & 14. 3. Chemical Tests Chemical composition of Cement 2. Reinforcement Steel 2. Physical and Chemical analysis test 1. Source approval To be procured from main producers only. As per annexure-2 of this FQP at pg. 15 Contractor to submit MTC All MTCs Contractor As proposed by Contractor To review the proposal based on the documents. 100% review of MTC Line Incharge Line incharge. -doSamples to be taken jointly with OWNER and tested at OWNER approved lab Contractor to submit MTC Review of all MTCs and one sample for every 500 MT 100%% review of MTC by Contractor 100% review of MTC Line Incharge 100% review of lab test results Line incharge Contractor As proposed by Contractor To verify the proposal based on the supply made and factory test results. Line incharge

S. No.

Description of Activity

Items to be Checked

Tests/Checks to be done

Ref. documents Agency

Check/Testing Extent

Counter Check/Test by OWNER

Accepting authority in OWNER

3. Coarse Aggregates

1. Source approval

Source meeting OWNER Specification

Contractor

Proposed by the Contractor, indicating the location of the quarry and based on the test results of Joint samples tested in OWNER approved lab

To review the proposal based on the documents

Line Incharge

2. Physical tests

As per document at Annexure-3 of this FQP at page 16

Samples to be taken jointly and tested in OWNER approved lab Contractor

One sample per lot of 200 cum or part thereof

100% review of lab test results

Line Incharge

4. Fine aggregate

1. Source approval

Source meeting OWNER Specification

Proposed by the Contractor, indicating the location of the quarry and based on the results of Joint samples tested in OWNER approved lab.

To review the proposal based on the documents.

Line Incharge

2. Physical test

As per Annexure-4 of this FQP at page 17

Samples to be taken jointly and tested in OWNER approved lab

One sample per lot of 200 cum or part thereof

100% review of lab test results

Line Incharge

5. Water

1. Cleaniness (Water shall be fresh and clean)

OWNER Specification

Contractor

100% visual check at Field

Verification at random

Site Engineer

S. No.

Description of Activity

Items to be Checked

Tests/Checks to be done

Ref. documents Agency

Check/Testing Extent

Counter Check/Test by OWNER

Accepting authority in OWNER

2. Suitability of water for concreting B. Classification 1. Visual observation of soil strata 2. Ground water level 3. History of water table in adj. Area/surface water 4. Soil Investigation wherever required C. Concrete Works a. Before concreting 1. Bottom of excavated earth 2. Stub setting 1) Centre Line 2) Diagonals 3) Level of stubs 3. Reinforcement steel b. During concreting Placement Depth of foundation

OWNER Specification

Contractor

100% Visual Check at Field

Verification at random

Site Engineer

OWNER Specification

Contractor

100% at Field

100% at Field

a. incharge b.

Section

In case of

WBC/SFR/FS acceptance Line Incharge c. For Spl. fdns. by by

Fdns./pile Acceptance

Project In-charge

Appd. Drgs.

Contractor

100% at Field

100% check by OWNER

Jr. Engr./Engr.

-do-

-do-

-do-

-do-

-do-

Bar bending schedule

-do-

-do-

-do-

-do-

S. No.

Description of Activity

Items to be Checked

Tests/Checks to be done

Ref. documents Agency

Check/Testing Extent

Counter Check/Test by OWNER

Accepting authority in OWNER

1. Workability

Slump test

Range 25 mm to 55 mm refer document at Annexure-5 of this FQP at Pg. 18

Contractor

100% at field

20% check at random

Jr. Engr../Engr.

2. Concrete Strength

Cubes Comp Strength

CPWD SPEC as referred in document at annexure-5 of this page at 18

Casting of cubes at site. Cubes to be tested at OWNER appd. Lab for 28 days strength

One sample of 3 cubes in each tower locations

100% review of lab test results. Cubes at 20% location are to be taken in presence of OWNER officials

Section Incharge

5.

Pile foundations

1. All materials like cement, steel Coarse/fine aggregate, water 2. Before concreting 1. Check for center line of each pile 2. Check for dia/verticality of each pile 3. Check for depth of each pile 3. During Concreting a. Workability 1. Slump test -do-do-

To be tested as per procedure enumerated in the respective columns above

Appd. Drawings

Contractor

100%

100%

Site Engr.

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

100-150 mm as per OWNER Specn.

Contractor

Every one hour. For each pile

100% at field

Site Engr.

S. No.

Description of Activity

Items to be Checked

Tests/Checks to be done

Ref. documents Agency

Check/Testing Extent

Counter Check/Test by OWNER

Accepting authority in OWNER

b. Concrete strength

2. Cubes compressive strength

As per OWNER Specn.

Contractor. One set of cubes (Min. 6 nos.) to be taken and tested for 7&28 days strength at OWNER appd. Lab.

One set for each pile. For Pile caps, beams, Chimney, one sample for every 20 Cu.m. or part thereof for each day of concreting. 100% at stores

100% cubes for piles, 20% Pile caps, beams, chimney etc. to be taken in presence of OWNER officials. 100% review of test results.

Section Incharge.

6.

Tower Erection

1. Materials a. Tower member/bolts & nuts/washers/acces sories 2. Erection of Super-structure

Visual checking for 1. Stacking 2. Cleanliness 3. Galvanizing 4. Damages 1. Sequence of erection

Appd. Drgs./BOM

Contractor

100% verification of records

Site Engineer

As per Appd. Drgs./OWNER specification

Contractor

100% at field

100% check

Site Engineer

2. Check for completeness 3. Tightening of nuts and bolts 4. Check for verticality

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

S. No.

Description of Activity

Items to be Checked

Tests/Checks to be done

Ref. documents Agency

Check/Testing Extent

Counter Check/Test by OWNER

Accepting authority in OWNER

5. Tack welding for bolts & nuts 3. Tower footing resistance (TFR) TFR at locations before and after earthing. 7. Stringing 1. Materials a. Insulators 1. Visual check for cleanliness/glazing/ cracks/and white spots. 2. IR Value

OWNER Specification

Contractor

100% at Field

100% Check

Site Engineer

OWNER Specification

Contractor

100% at Field

20% locations to be verified

Line Incharge

OWNER Specification

Contractor

100% at Field

100% verification of records and to carry random checks 10%

Site Engineer

(min. 50M Ohms)

-do-

One test per sample size of 20 for every lot of 10,000

To verify Contractors records 100% and joint check 20% of total tests Collection of samples, sealing them and handing over by OWNER to Insulator supplier

-do-

3. E&M test

Insulator supplier

a. 20 per 10,000 for discs b. 3 per 1500 for long rod

Tests to be witnessed/ Appd. by QA&I at Manufacturers works

4. Traceability (Make/batch No./Locations where installed)

Packing list/CIP

Contractor

100% at field

100% Review of records

Site Engineer

S. No.

Description of Activity

Items to be Checked

Tests/Checks to be done

Ref. documents Agency

Check/Testing Extent

Counter Check/Test by OWNER

Accepting authority in OWNER

b. Conductor

On receipt, 1. Visual check of drum. 2. Check for seals at both ends, and OWNER sticker on outer end 3. Check depth from top of flange to the top of the outer most layer

Packing list

Contractor

100% at stores

20% check

Site Engineer

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

c. Earthwire

Check for seals at both ends

Packing list

Contractor

100% at stores

20% check

-do-

2. Field activity a. Before Stringing Readiness for stringing Stringing procedures as per OWNER specification b. During stringing (Conductor/Earthwrie) Contractor Readiness certificate to be submitted by the Contractor Review of Certificate Line Incharge

S. No.

Description of Activity

Items to be Checked

Tests/Checks to be done

Ref. documents Agency

Check/Testing Extent

Counter Check/Test by OWNER

Accepting authority in OWNER

1. Scratch/cut check (Visual) 2. Repair sleeve 3. Mid span Joints 4. Guying (in case of towers not designed for one side stringing) c. After stringing Check for, 1. Sag/Tension

Appd. Drawings/ OWNER Specn. -do-doAppd. Guying arrangement/OWNER specn.

Contractor

100% at Field

100% record & Field check 20%

Site Engineer

-do-do-do-

-do-do-do-

-do-do100%

-do-doSection Incharge

Sag tension chart/tower Spotting data

-do-

-do-

100% record & Field check 20%

Site Engr.

2. Electrical clearances

As per appd. Drgs./OWNER specifications

-do-

-do-

-do-

-do-

i) Ground clearance ii) Live metal clearance etc. 3. Jumpering

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

-do-

S. No.

Description of Activity

Items to be Checked

Tests/Checks to be done

Ref. documents Agency

Check/Testing Extent

Counter Check/Test by OWNER

Accepting authority in OWNER

4. Copper bond

As per Appd. Drgns./OWNER Specification

Contractor

100% at Field

100% record & Field Check 20%

Site Engineer

5. Placement of spacer/damper 8. Final Testing a. Precommissioni ng of lines a. Readiness of lines for precommissioning 1. Completeness of line. 2. Meggar test of line b. Commissioning of line Readiness of lines for commissioning 2. Digital photograph of each tower to ascertain the completeness of tower.

As per Specn./drgs/ placement chart

-do-

-do-

-do-

-do-

OWNER latest precommissioning procedures (Doc. No. D-2-01-70-01-00) a. OWNER latest precommissioning procedures (Doc. No. D-2-01-70-0100) b. Precommissioning Report c. CEA clearance

Contractor

100%

100% joint checking

Project Incharge

-do-

-do-

-do-

-do-

10

S. No.

Description of Activity

Items to be Checked

Tests/Checks to be done

Ref. documents Agency

Check/Testing Extent

Counter Check/Test by OWNER

Accepting authority in OWNER

3. Electrical Inspectors clearance from CEA.

-do-

-do-

-do-

-do-

11

Annex-1

ACCEPTANCE CRITERIA AND PERMISSIBLE LIMITS FOR CEMENT

ORDINARY PORTLAND CEMENT S. No. a) (i) Name of the test Ordinary Portland Cement 33 grade as per IS 269 Ordinary Portland Cement 43 grade as per IS 8112 Ordinary Portland Cement 53 grade as per IS 12269 Remarks To be conducted in apprd. Lab Specific surface area shall not be less than 225 sq.m. per Kg. or 2250 Cm2/gm. 72+/- 1 hour : Not less than 16 Mpa (16 N/mm2) 168+/-2 hour : Not less than 22 Mpa (22 N/mm2) 672+/-4 hour : Not less than 33 Mpa (33 N/mm2) (iii) Initial & setting time Final Initial setting time : Not less than 30 minutes Final setting time : Not more than 600 minutes (iv) Soundness Unaerated cement shall not have an expansion of more than 10mm when tested by Le chatlier and 0.8% Autoclave test. Specific surface area shall not be less than 225 sq.m. per Kg or 2250 Cm2/gm. 72+/- 1 hour : Not less than 27 Mpa (27 N/mm2) 168+/-2 hour : Not less than 37 Mpa (37 N/mm2) 672+/-4 hour : Not less than 53 Mpa (53 N/mm2) Initial setting time : Not less than 30 minutes Final setting time : Not more than 600 minutes Unaerated cement shall not have an expansion of more than 10mm when tested by Le chatlier and 0.8% Autoclave test Specific surface area shall not be less than 225 sq.m. per Kg or 2250 Cm2/gm. 72+/- 1 hour : Not less than 23 Mpa (23 n/mm2) 168+/-1 hour : Not less than 33 Mpa (33 N/mm2) 672+/-1 hour : Not less than 43 Mpa (43 N/mm2) Initial setting time : Not less than 30 minutes Final setting time : Not more than 600 minutes Unaerated cement shall not have an expansion of more than 10mm when tested by Le chatlier and 0.8% Autoclave test. As per IS 4031 (Part-5) -doLe chatlier and Autoclave test as per IS 4031 (Part-3) Blaines air permeability method as per IS 4031 (Part-2) As per IS 4031 (Part-6)

Physical tests Fineness

(ii)

Compressive strength

12

S. No. b)

Name of the test

Ordinary Portland Cement 33 grade as per IS 269

Ordinary Portland Cement 43 grade as per IS 8112

Ordinary Portland Cement 53 grade as per IS 12269

Remarks Review of MTCC only

Chemical composition tests a) Ratio of percentage of lime to percentage of silica, alumina & iron oxide 0.66 to 1.02 Ratio of percentage of alumina to that of iron oxide Minimum 0.66% Insoluble residue, percentage by mass Max. 4.00% Magnesia percentage by mass Max. 6% Total sulphur content calculated as sulphuric anhydride (SO3), percentage by mass Not more than 2.5 and 3.0 when tri-calcium aluminate percent by mass is 5 or less and greater than 5 respectively. a) Ratio of percentage of lime to percentage of silica, alumina % iron oxide 0.66 to 1.02 Ratio of percentage of alumina to that of iron oxide Minimum 0.66 Insoluble residue, percentage by mass Max. 4.00% Magnesia percentage by mass Max. 6% Total sulphur content calculated as sulpuric anhydride (SO3), percentage by mass Not more than 2.5 and 3.0 when tri-calcium aluminate percent by mass is 5 or less and greater than 5 respectively. a) Ratio of percentage of lime to percentage of silica, alumina % iron oxide 0.66 to 1.02% Ratio of percentage of alumina to that of iron oxide Minimum 0.66% Insoluble residue, percentage by mass Max. 4.00% Magnesia percentage mass Max. 6% by

b)

a)

a)

c)

c)

c)

d) e)

d) e)

d) e)

Total sulphur content calculated as sulpuric anhydride (SO3), percentage by mass Not more than 2.5 and 3.0 when tri-calcium aluminate percent by mass is 5 or less and greater than 5 respectively.

c)

Total loss on Ignition

Not more than 5 percent

Not more than 5 percent

Not more than 5 percent

13

S. No. 2. a)

Name of the test

Remarks

POZZOLANA PORTLAND CEMENT AS PER IS 1489 Physical tests i) ii) Fineness Compressive strength Specific surface area shall not be less than 300 sq.m. per Kg. or 3000 Cm2/gm 168+/- 2 hour : Not less than 22 Mpa (22 N/mm2) 672+/- 2 hour : Not less than 33 Mpa (33 N/mm2) iii) Initial & Final setting time Initial setting time : Not less than 30 minutes Final setting time : Not more than 600 minutes iv) Soundness Unaerated cement shall not have an expansion of more than 10mm Le chatlier and Autoclave test as per IS 4031 (Part-3)

b)

Chemical composition tests a) b) c) Magnesia percentage by mass Max. 6% Insoluble material, percentage by mass x + 2 (100-x)/100 where x is the declared % of pozzolana in the PPC Total sulphur content calculated as sulpuric anhydride (SO3), percentage by mass Not more than 2.75 and 3.0 when tri-calcium aluminate percent by mass is 7 or less and greater than 7 respectively. Review of MTCC only -do-do-

c)

Total loss on Ignition

Not more than 5 percent

14

Annex-2

ACCEPTANCE CRITERIA AND PERMISSIBLE LIMITS FOR REINFORCEMENT STEEL

S. No. i) Name of the test Chemical analysis test Mild and medium tensile steel as per IS 432 Carbon (For 20 mm dia and below) 0.23% Max. Carbon (For over 20 mm dia) 0.25% Sulpher Phosphorus 0.055% 0.055% Carbon Sulpher Phosphorus Sulpher & Phosphorus ii) Physical tests a) Ultimate Tensile stress For all dia bars 410 N/Sq.mm. (min.) a) 0.30% Max 0.060% 0.060% 0.11% Testing in approved lab Cold twisted Deformed bars Fe 415 as per IS 1786 Remarks

Ultimate Tensile stress 10% more than actual 0.2% proof stress but not less than 485 N/Sq.mm.)

b)

Yield stress (N/Sq.mm) min. 250 240

b)

For bars upto 20 mm dia For bars above 20 mm dia c) iii) Bend & Rebend tests

0.2% of proof stress/Yield stress (N/Sq.mm) min. 415 Percentage of elongation 14.5% (min.) Pass

Testing in approved lab

For bars upto 20 mm dia c)

Percentage of elongation 23% Pass

Testing in approved lab

15

Annex-3

ACCEPTANCE CRITERIA AND PERMISSIBLE LIMITS FOR COARSE AGGREGATES AS PER IS 383

3. i) Coarse Aggregates Physical Tests a) Determination of particles size a. IS Sieve Designation %age passing for Single-Sized Aggregate of nominal size 40 mm 63 mm 40 mm 20 mm 16 mm 12.5 mm 10 mm 4.75 mm 2.36 mm b. c. d. e. Flakiness index Crushing Value Presence of deletrious material Soundness test (for concrete work subject to frost action) 100 85 to 100 0 to 20 0 to 5 20 mm 100 85 to 100 0 to 20 0 to 5 16 mm 100 85 to 100 0 to 30 0 to 5 12.5 mm 100 85 to 100 0 to 45 0 to 10 10 mm 100 85 to 100 0 to 20 0 to 5 Percentage Passing for grades Aggregate of nominal size 40 mm 95 to 100 30 to 70 10 to 35 0 to 5 20 mm 100 95 to 100 25 to 35 0 to 10 16 mm 100 90-100 30 to 70 0 to 10 12.5 mm 100 90 to 100 40 to 85 0 to 10 -

Not to exceed 25% Not to exceed 45% Total presence of deleterious materials not to exceed 5% 12% when tested with sodium sulphate and 18% when tested with magnesium sulphate

16

Annex-4

ACCEPTANCE CRITERIA AND PERMISSIBLE LIMITS FOR FINE AGGREGATES AS PER IS 383

4. i) Fine aggregates Physical Tests IS Sieve Designation a) Determination of particle size 10 mm 4.75 mm 2.36 mm 1.18 mm 600 microns 12.5 mm 300 microns 150 microns b) c) d) Silt content Presence of deleterious material Soundness Applicable to concrete work subject to frost action F.A. Zone I 100 90-100 60-95 30-70 15-34 5 to 20 0-10 Not to exceed 8% F.A. Zone II 100 90-100 75-100 55-90 35-59 8 to 30 0-10 Not to exceed 8% F.A. Zone III 100 90-100 85-100 75-100 60-79 12 to 40 01-0 Not to exceed 8% Percentage passing for graded aggregate of nominal size

Total presence of deleterious materials shall not exceed 5% 12% when tested with sodium sulphate and 15% when tested with magnesium sulphate

17

Annex-5

ACCEPTANCE CRITERIA AND PERMISSIBLE LIMITS FOR CONCRETE WORK

1) Concrete a) Workability b) Compressive strength Slump shall be recorded by slump cone method and it shall between 25-55 mm. Three samples of 15 cm cube for 28 days compressive strength for all concrete works except pile foundation work shall be taken. For pile foundation works, six cubes, three for 7 days testing and balance three for 28 days testing shall be taken.

Notes : 1) 2) a) b) For nominal (volumetric) concrete mixes, compressive strength for 1:1.5:3 (Sand : Fine aggreagates : Coarse aggregates) concrete shall be 265 kg/Sq.cm. for 28 days and for 1:2:4 nominal mix, it shall be 210 kg/Sq.cm. ACCEPTANCE CRITERIA BASED ON 28 DAYS COMPRESSIVE STRENGTHS FOR NOMINAL MIX CONCRETE : the average of the strength of three specimen be accepted as the compressive strength of the concrete, provided the strength of any individual cube shall neither be less than 70% nor higher than 130% of the specified strength. If the actual average strength of accepted sample exceeds specified strength by more than 30%, the Engineer-in-charge, if he so desires, may further investigate the matter. However, if the strength of any individual cube exceeds more than 30% of the specified strength, it will be restructed to 30% only for computation of strength. If the actual average strength of accepted sample is equal to or higher than specified upto 30%, the strength of the concrete shall be considered in order and the concrete shall be accepted at full rates. If the actual average strength of accepted sample is less than specified strength but not less than 70% of the specified strength, the concrete may be accepted at reduced rate at the discretion of Engineer-in-charge. If the actual average strength of accepted sample is less than 70% of specified strength, the Engineer-in-charge shall reject the defective portion of work represent by sample and nothing shall be paid for the rejected work. Remedial measures necessary to

c) d) e)

18

retain the structure shall taken at the risk and cost of contractor. If, however, the Engineer-in-charge so desires, he may order additional tests to be carried out to ascertain if the structure can be retained. All the charges in connection with these additional tests shall be borne by the Contractor. General Notes : 1) 2) 3) 4) 5) 6) 7) 8) This standard Field Quality Plan is not to limit the supervisory checks which are otherwise required to be carried out during execution of work as per drawings/Technical specifications etc. All materials should have Cat-A CIP before they are erected. Contractor shall be responsible for implementing/documenting the SFQP. Documents shall be handed over by the contractor to OWNER after the completion of the work. Project incharge means over all incharge of work. Line Incharge means incharge of the line. Section in-charge means incharge of the section. In case of deviation the approving authority will be one step above the officer designated for acceptance in this quality plan subject to minimum level of Line incharge. Acceptance criteria and permissible limits for tests are indicated in the Annexures. However for further details/tests OWNER specification and relevant Indian standards shall be referred. Tests as mentioned in this FQP shall generally be followed. However E.I.C. reserves the right to order additional tests wherever required necessary at the cost of the agency. All counter checks/tests by OWNER shall be carried out by OWNERs officials.

19

Das könnte Ihnen auch gefallen

- 8 Field Quality PlanDokument18 Seiten8 Field Quality Plangeorge_hem100% (1)

- Const - of Water TankDokument6 SeitenConst - of Water TankHiren ThakkarNoch keine Bewertungen

- Typical QAPDokument4 SeitenTypical QAPhemantmech09Noch keine Bewertungen

- SP Question BankDokument2 SeitenSP Question BankAbhishek GhoshNoch keine Bewertungen

- Speed Control System With Rfid Equipped VehicleDokument27 SeitenSpeed Control System With Rfid Equipped VehicleAnonymous L9fB0XUNoch keine Bewertungen

- List of Is StandardsDokument4 SeitenList of Is StandardsAnantha NarayananNoch keine Bewertungen

- Field Quality Plan For LgfsDokument7 SeitenField Quality Plan For LgfsUday PratapNoch keine Bewertungen

- Field Quality Plan - Civil - Rev 1 - 24 (1) .04.09Dokument13 SeitenField Quality Plan - Civil - Rev 1 - 24 (1) .04.09Sandeep JoshiNoch keine Bewertungen

- Sample Manufacturing Quality Plan Format: (Logo of Manufacturer)Dokument12 SeitenSample Manufacturing Quality Plan Format: (Logo of Manufacturer)P.Manna100% (1)

- Best Practices in Quality Assurance & Inspection IN NTPCDokument39 SeitenBest Practices in Quality Assurance & Inspection IN NTPCPrincy SinghNoch keine Bewertungen

- Carpet Floorring-Method StatementDokument6 SeitenCarpet Floorring-Method StatementMuhib sadeddeinNoch keine Bewertungen

- Checklist For Wall Panels InstallationDokument2 SeitenChecklist For Wall Panels InstallationChristos LoutrakisNoch keine Bewertungen

- RFI TempleteDokument6 SeitenRFI TempleteAshadi Amir100% (1)

- QC Example Resume.01Dokument4 SeitenQC Example Resume.01Guru SankarNoch keine Bewertungen

- MQAP - Long Rod InsulatorDokument8 SeitenMQAP - Long Rod InsulatorRajitha BoppaNoch keine Bewertungen

- A Qac Pro 000 38951Dokument30 SeitenA Qac Pro 000 38951Amin GNoch keine Bewertungen

- CHECKLIST For Installation of MICC CableDokument2 SeitenCHECKLIST For Installation of MICC CableTHEOPHILUS ATO FLETCHERNoch keine Bewertungen

- ITP - Fiber Optic CableDokument2 SeitenITP - Fiber Optic CableRamy AiadNoch keine Bewertungen

- QAP Solar InverterDokument4 SeitenQAP Solar Inverterzaheeruddin_mohdNoch keine Bewertungen

- ITP Work DownDokument5 SeitenITP Work DownMuralimohan Pandian100% (1)

- Construction of Acid Proof LiningDokument4 SeitenConstruction of Acid Proof LiningHiren ThakkarNoch keine Bewertungen

- QAP CivilDokument249 SeitenQAP CivilGoanengineerNoch keine Bewertungen

- Project Internal Audit Procedure: SheetalkumarDokument4 SeitenProject Internal Audit Procedure: SheetalkumarTwin BullsNoch keine Bewertungen

- DWST-MTHL-QP009 Non-Conforming Item Control ProcedureDokument15 SeitenDWST-MTHL-QP009 Non-Conforming Item Control ProcedureDeepak UpadhayayNoch keine Bewertungen

- Dokgoro K1785 Method StatementDokument6 SeitenDokgoro K1785 Method StatementJackie van SchalkwykNoch keine Bewertungen

- LPS-01-HTI-MST-EL-009 - Light FixturesDokument18 SeitenLPS-01-HTI-MST-EL-009 - Light FixturesJomy JohnyNoch keine Bewertungen

- Saudi Aramco Pre-Commissioning Form: Outdoor SubstationsDokument2 SeitenSaudi Aramco Pre-Commissioning Form: Outdoor SubstationsHaleem Ur Rashid BangashNoch keine Bewertungen

- Plant Visit ChecklistDokument3 SeitenPlant Visit ChecklistSamiul IslamNoch keine Bewertungen

- Method Statement For Re-Testing of LED Strip LightsDokument2 SeitenMethod Statement For Re-Testing of LED Strip LightsRyn Rcio100% (1)

- Inspection Test Plan For Fabrication PDF FreeDokument4 SeitenInspection Test Plan For Fabrication PDF Freesam paulNoch keine Bewertungen

- HT Performa UpdatedDokument180 SeitenHT Performa UpdatedsajuNoch keine Bewertungen

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDokument9 SeitenRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanNoch keine Bewertungen

- Work Procedure - of Plant BuildingsDokument7 SeitenWork Procedure - of Plant BuildingsHiren ThakkarNoch keine Bewertungen

- J910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)Dokument13 SeitenJ910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)rudi sarifudinNoch keine Bewertungen

- LineDokument4 SeitenLineShaharyar WaliullahNoch keine Bewertungen

- Sop of StringingDokument7 SeitenSop of Stringingshubham shindeNoch keine Bewertungen

- Quality Control Procedure For HVDokument9 SeitenQuality Control Procedure For HVVIKRAM DESAINoch keine Bewertungen

- Geo InstallationDokument78 SeitenGeo InstallationUdin DzonoNoch keine Bewertungen

- Itp For Building MaterialsDokument38 SeitenItp For Building MaterialsNavneet YaduvanshiNoch keine Bewertungen

- RFI Checklist Site BELOPARANG (Infill - SSul37)Dokument5 SeitenRFI Checklist Site BELOPARANG (Infill - SSul37)Adhyatma RaufNoch keine Bewertungen

- 16950s01 HV Testing ProceduresDokument1 Seite16950s01 HV Testing ProceduresVICTOR JOSE VILORIANoch keine Bewertungen

- Method Statement For Test and Inspection of An Existing Lightning Protection/Earthing SystemDokument4 SeitenMethod Statement For Test and Inspection of An Existing Lightning Protection/Earthing Systemdangtuan27Noch keine Bewertungen

- Q A P (Qap) - PV C: Uality Ssurance LAN ELLDokument5 SeitenQ A P (Qap) - PV C: Uality Ssurance LAN ELLsasikumarNoch keine Bewertungen

- Inspection & Testing Plan For AggregatesDokument2 SeitenInspection & Testing Plan For Aggregatesjerin sam kurian100% (1)

- EDO-PLN-QAC-GNR-INT-XXX-013-110-111-Rev-A.SAMPLE PROJECT QUALITY MANAGEMENT FOR STORAGE TANK PDFDokument31 SeitenEDO-PLN-QAC-GNR-INT-XXX-013-110-111-Rev-A.SAMPLE PROJECT QUALITY MANAGEMENT FOR STORAGE TANK PDFErol DAĞNoch keine Bewertungen

- BK-HH-QAC-MS-0017 - Foundation of Central Control Room & Switch Gear BuildingDokument12 SeitenBK-HH-QAC-MS-0017 - Foundation of Central Control Room & Switch Gear BuildingSyed Abbas AliNoch keine Bewertungen

- 835a) Method Statement For Ceramic Tile Marble Works - R0-SignedDokument23 Seiten835a) Method Statement For Ceramic Tile Marble Works - R0-Signedwaseq911Noch keine Bewertungen

- QM Plan ProcedureDokument13 SeitenQM Plan ProcedureHans JonesNoch keine Bewertungen

- PMPT Itp 010Dokument3 SeitenPMPT Itp 010hz135874Noch keine Bewertungen

- Inspection and Test Plan Suspension ClampsDokument2 SeitenInspection and Test Plan Suspension ClampsAvinash Lal0% (1)

- QCS 2010 Section 5 Part 2 AggregatesDokument9 SeitenQCS 2010 Section 5 Part 2 Aggregatesbryanpastor106Noch keine Bewertungen

- QA&QC-DT-FRMC-014 Mouting Structure Material RecordDokument1 SeiteQA&QC-DT-FRMC-014 Mouting Structure Material RecordTariq Ali SialNoch keine Bewertungen

- Inspected by QCP Approval 1-APC 1-Employer (APC) 2 - DAR 2 - Engineer (DAR) 3 - Contractor (NEGEMCO) 4 - Vendor 5 - Third PartyDokument6 SeitenInspected by QCP Approval 1-APC 1-Employer (APC) 2 - DAR 2 - Engineer (DAR) 3 - Contractor (NEGEMCO) 4 - Vendor 5 - Third PartyAhmad DagamsehNoch keine Bewertungen

- QA&QC-DT-FRMC-020 Foundation Work of Transmission LineDokument2 SeitenQA&QC-DT-FRMC-020 Foundation Work of Transmission LineTariq Ali SialNoch keine Bewertungen

- Inspection Test Plan For Civil Works: Rev - A 28.05.2022Dokument17 SeitenInspection Test Plan For Civil Works: Rev - A 28.05.2022Suraj ShettyNoch keine Bewertungen

- MS For The Audio Intercom SystemDokument11 SeitenMS For The Audio Intercom Systemwaaji snapNoch keine Bewertungen

- Request For Inspection (Rfi) : Project TitleDokument2 SeitenRequest For Inspection (Rfi) : Project TitleJing Wei Fong100% (1)

- Const Sup 03 May NR II 2009 10s41standardised Field Quality PlanDokument31 SeitenConst Sup 03 May NR II 2009 10s41standardised Field Quality PlanKurapati SiddarthNoch keine Bewertungen

- Ref FQP ErectionDokument12 SeitenRef FQP ErectionSaurabh HimkarNoch keine Bewertungen

- Coal FeederDokument8 SeitenCoal FeedersanjeevchhabraNoch keine Bewertungen

- Damage To Bottom Ash Handling SysDokument6 SeitenDamage To Bottom Ash Handling SyssanjeevchhabraNoch keine Bewertungen

- Format For Feeder Cable 48 - 42Dokument1 SeiteFormat For Feeder Cable 48 - 42sanjeevchhabraNoch keine Bewertungen

- Format For Feeder Cable 48 - 42Dokument1 SeiteFormat For Feeder Cable 48 - 42sanjeevchhabraNoch keine Bewertungen

- D1300009 Sheet 1Dokument1 SeiteD1300009 Sheet 1sanjeevchhabraNoch keine Bewertungen

- Aux Steam SystemDokument14 SeitenAux Steam Systemsanjeevchhabra100% (1)

- Gas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFDokument4 SeitenGas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFsanjeevchhabraNoch keine Bewertungen

- Gas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFDokument4 SeitenGas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFsanjeevchhabraNoch keine Bewertungen

- High Axial Shift in Turbine, 210 MW Unit, 02-03 PDFDokument1 SeiteHigh Axial Shift in Turbine, 210 MW Unit, 02-03 PDFsanjeevchhabra100% (1)

- Failure of Rotary Flow Divider PDFDokument8 SeitenFailure of Rotary Flow Divider PDFsanjeevchhabraNoch keine Bewertungen

- X79 PDFDokument2 SeitenX79 PDFsanjeevchhabraNoch keine Bewertungen

- Maintenance PlanDokument35 SeitenMaintenance PlansanjeevchhabraNoch keine Bewertungen

- Heavy Deposit in Raidant Roof Tube PDFDokument5 SeitenHeavy Deposit in Raidant Roof Tube PDFsanjeevchhabraNoch keine Bewertungen

- Design of Iec 61850 Based Substation Automation SystemsDokument8 SeitenDesign of Iec 61850 Based Substation Automation Systemsİsmail KayahanNoch keine Bewertungen

- Sample Construction Methodology For Civil WorksDokument6 SeitenSample Construction Methodology For Civil WorksRotsen Kho YuteNoch keine Bewertungen

- Frequent Tripping of VFD On BUSHOG - JUN10 PDFDokument2 SeitenFrequent Tripping of VFD On BUSHOG - JUN10 PDFsanjeevchhabraNoch keine Bewertungen

- Develop Project Charter CaseDokument25 SeitenDevelop Project Charter Casesanjeevchhabra100% (1)

- Substation SpecDokument143 SeitenSubstation Specsanjeevchhabra100% (2)

- Auto Transformerr4 PDFDokument54 SeitenAuto Transformerr4 PDFsanjeevchhabraNoch keine Bewertungen

- ProceduresDokument104 SeitenProceduressanjeevchhabraNoch keine Bewertungen

- Guaranteed Technical Parameters:: Inhibited Insulating OilDokument2 SeitenGuaranteed Technical Parameters:: Inhibited Insulating Oilsanjeevchhabra100% (1)

- 02 ACSR ZEBRA ConductorDokument37 Seiten02 ACSR ZEBRA Conductorsanjeevchhabra100% (2)

- 03 1 TS (vOL II) Sec IIISurvey (Part I)Dokument39 Seiten03 1 TS (vOL II) Sec IIISurvey (Part I)sanjeevchhabraNoch keine Bewertungen

- Architect Operation Manual PDFDokument2.770 SeitenArchitect Operation Manual PDFJithin Babu100% (19)

- Guide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodsDokument24 SeitenGuide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodsPushkar NathNoch keine Bewertungen

- Welding Inspection and TestingDokument14 SeitenWelding Inspection and TestingMyst VernNoch keine Bewertungen

- TS - For Road Works RevisedDokument310 SeitenTS - For Road Works RevisedFrancisca RosetaNoch keine Bewertungen

- DPP Installation of 02 Nos Deep Tube Well P&DDokument27 SeitenDPP Installation of 02 Nos Deep Tube Well P&DMahfuzur RahmanNoch keine Bewertungen

- NMEA Parser DesignDokument4 SeitenNMEA Parser DesignpriyosantosaNoch keine Bewertungen

- Toolbox4Planning - Activities and Logical Sequence For Electrical and Instrumentation EngineeringDokument1 SeiteToolbox4Planning - Activities and Logical Sequence For Electrical and Instrumentation EngineeringMuslimNoch keine Bewertungen

- HSE Manual PDFDokument30 SeitenHSE Manual PDFRanjan Kumar75% (4)

- Spesifikasi Kabel Sling PDFDokument36 SeitenSpesifikasi Kabel Sling PDFDedeNoch keine Bewertungen

- Company XYZ Test Strategy Sample Ver 1Dokument28 SeitenCompany XYZ Test Strategy Sample Ver 1StevenBurryNoch keine Bewertungen

- Maestro UMDokument98 SeitenMaestro UMIonNoch keine Bewertungen

- A Summmer Internship Projuct Report: " On Effective Way To Do Recruitment Process"Dokument56 SeitenA Summmer Internship Projuct Report: " On Effective Way To Do Recruitment Process"Sakshi GuptaNoch keine Bewertungen

- Astm D4024 2000 PDFDokument6 SeitenAstm D4024 2000 PDFmohammed siddiqNoch keine Bewertungen

- C 59 - C 59m - 95 - Qzu5l0m1ou0tukveDokument3 SeitenC 59 - C 59m - 95 - Qzu5l0m1ou0tukve2010civ164Noch keine Bewertungen

- Best Practices Mobile Application DevelopmentDokument63 SeitenBest Practices Mobile Application DevelopmentivahdamNoch keine Bewertungen

- What Is A Table of Specifications 2Dokument4 SeitenWhat Is A Table of Specifications 2CherryLee AnnNoch keine Bewertungen

- BSH - CQP and Isir TraningDokument46 SeitenBSH - CQP and Isir TraningAtakan TunaliNoch keine Bewertungen

- Preengineer Building SpecsDokument35 SeitenPreengineer Building SpecstOMNoch keine Bewertungen

- Astm A673Dokument4 SeitenAstm A673gustavo aguilarNoch keine Bewertungen

- MBD 2013 RCD Govt of BiharDokument350 SeitenMBD 2013 RCD Govt of BiharGobinder SinghNoch keine Bewertungen

- TD.57 v30.03Dokument274 SeitenTD.57 v30.03Jhon Albert TorresNoch keine Bewertungen

- PV System Design NC IIIDokument68 SeitenPV System Design NC IIIAngelo MichaelsNoch keine Bewertungen

- ARINC Standards Document ListDokument45 SeitenARINC Standards Document Listindra_wirasendjajaNoch keine Bewertungen

- Specification 302 Earthworks PDFDokument50 SeitenSpecification 302 Earthworks PDFalejandraoy9Noch keine Bewertungen

- Calipers (New Standard ISO-ASME)Dokument8 SeitenCalipers (New Standard ISO-ASME)Hernando Sanchez100% (4)

- Struct RefData Overview SM3DDokument294 SeitenStruct RefData Overview SM3DrmnrajanNoch keine Bewertungen

- ASTM D 5888-19 Disposición GCL PDFDokument3 SeitenASTM D 5888-19 Disposición GCL PDFLuis Mauricio AstudilloNoch keine Bewertungen

- BASTA Passive Antenna Whitepaper V11.1Dokument167 SeitenBASTA Passive Antenna Whitepaper V11.1ayyappanNoch keine Bewertungen

- Level-II MasonryDokument55 SeitenLevel-II Masonryhabtie kebede91% (11)

- Defining and Assessing Software Quality by Quality Models Klaus LochmannDokument173 SeitenDefining and Assessing Software Quality by Quality Models Klaus LochmannLiz MoldovanNoch keine Bewertungen