Beruflich Dokumente

Kultur Dokumente

24334619

Hochgeladen von

cajunhillbillyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

24334619

Hochgeladen von

cajunhillbillyCopyright:

Verfügbare Formate

Paragraphs 46-47

INTERNATIONAL HARVESTER

Main metering screw & needle Nozzle and gasket Zenith Series 100 gasoline *Float setting Basic repair kit Gasket set Inlet needle & seat Idle jet Discharge nozzle Well vent jet 159-144S 12-366S Series 240 gasoline Float setting Basic repair kit Gasket set Inlet needle and seat Idle jet Main jet or needle., Discharge nozzle Well vent jet 68X7 12285 1 5/32 (in.) K12285 C181-329 C81-17-35 C55-22-11 C52-7-21 C66-114-50 C77-18-23

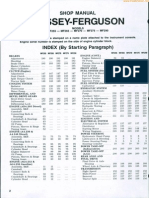

CARBURETOR (GASOLINE)

46. Tractors are equipped with either Carter, Zenith or Marvel Schebler carburetors. Their applications and specifications are as follows: Carter Series 100 gasoline UT2222S Float setting 17/64 (in,) Gasket set 207 Inlet needle & seat 25-33S Main metering jet 224-24S Nozzle bleed screw plug llB-320 Low speed jet llB-2085 Idle needle 30A-37 Main metering screw & needle ,224-30S Nozzle and gasket 12-348S Series 200 gasoline UT771SB Float setting 17/64 (in.) Gasket set 207 Inlet needle & seat 25-33S Main metering jet 224-25S Nozzle bleed screw plug llB-243 Low speed jet 11-208S Idle needle 30A-37 Nozzle and gasket 12-336S Series 100-130-140-200-230-240 Kero. & Dist UT925SA Float setting 17/64 (in.) Gasket set 207 Inlet needle & seat 25-33S Nozzle bleed screw plug llB-235 Low speed jet 11-208S Idle needle 30A-37

67X7 11704 1 5/32 (in.) K11704 C181-314 C81-17-35 C55-22-18 C66-90-55-19 .C77-18-26

Series 130-140 gasoline.. 68X7 12122A *Float setting 1 5/32 (in.) Basic repair kit .K12122A Gasket set C181-329 Inlet needle & seat C81-17-35 Idle jet C55-22-11 Main jet or needle C52-6-1-23 Discharge nozzle C66-114-38 Well vent jet C77-18-20 Series 200 gasoline Float setting Basic repair kit Gasket set Inlet needle and seat Idle jet Main jet or needle Discharge nozzle Well vent jet Series 230 gasoline *Float setting Basic repair kit Gasket set Inlet needle and seat Idle jet Main jet or needle Discharge nozzle Well vent jet 67X7 11115 1 5/32 (in.) K790 C181-314 C81-17-35 C55-22-18 C66-90-20 C66-90-20-55 C77-18-29 68X7 12115 1 5/32 (in.) K12115 C181-329 C81-17-35 C55-22-11 C52-6-21 C66-114-50 C77-18-23

Series 100-130-140-200-230-240 kerosene and distillate. .67X7 11340 *Float setting 1 5/32 (in.) Basic repair kit K790 Gasket set C181-314 Inlet needle anci seat C81-17-35 Idle jet C55-22-18 Discharge nozzle C66-90-50-18 Well vent jet C77-18-18 Series 404-2404 gasoline.68X7-12225C *Float setting 1 ^ (in.) Basic repair kit ..K12225 Gasket set C181-329 Inlet needle and seat C81-66-35 Idle jet C55-22-11 Discharge nozzle C66-114-50 Well vent jet C77-18-25 *Float setting is measured from furthest face of float to gasket surface of bowl cover. Marvel-Schebler Series 404-2404 gasoline Float setting Basic ijepair kit Gasket set Inlet needle and seat Idle jet Discharge nozzle TSX748 ^4 (in.) 286-1245 16-61S 233-536 49-101-L 47-490

LP.GAS SYSTEM

Series 404 and 2404 tractors are available with LP-Gas equipment manufactured by Ensign. Carburetor is a model Mg 1 and regulator is a model W. As with other LP-Gas systems, these systems are designed to operate with the fuel tank no more than 80% filled. It is important when starting these tractors, to open the vapor valve on the supply tank slowly; if opened too last, the fuel supply to the regulator will be automatically shut off.

ADJUST SYSTEM Series 404-2404 47. The LP-Gas system has four adjustments; three are located on the carburetor and one on the regulator. Adjustments located on the carburetor are main fuel (load) adjustment, starting fuel adjustment and the throttle idle stop screw. The idle mixture adjusting screw is located on top side of regulator. The adjustments are pre-set at the factory and normally do not need readjustment; however, if adjustments have been disturbed, or any of the components serviced, readjust system as follows: Loosen lock nuts on starting fuel adjustment and main fuel adjustment on carburetor. Turn both of these adjustment screws and the idle

CAUTION: Before disconnecting fuel lines or removing any of the system components, close both fuel tank withdrawal valves and run engine until all fuel is exhausted from the fuel lines and components and engine stops.

mixture adjusting screw on the regulator all the way in; then make the following initial adjustments. Starting adjustment screw IVA turns open. Main fuel adjustment screw IVz turns open. Idle mixture adjustment screw (on regulator) l^t turns open. Start engine and bring to operating temperature, then place throttle control lever in low idle position. Adjust throttle stop screw to obtain an engine low idle speed of approximately 425 rpm, then turn the idle mixture needle on the regulator in or out as required to obtain the highest and smoothest engine operation. Readjust throttle stop screw, if necessary. Place hand throttle in the high idle position and turn the main fuel (load) adjustment screw in or out as required until the smoothest engine (deration is obtained.

Das könnte Ihnen auch gefallen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- STC Oil Control Valve Mechanical 006 007 K38 K50Dokument18 SeitenSTC Oil Control Valve Mechanical 006 007 K38 K50SpectrumRaijin100% (10)

- Engine Mechanical: Go To Table of Contents Go To Quick Reference IndexDokument75 SeitenEngine Mechanical: Go To Table of Contents Go To Quick Reference IndexOmar RodriguezNoch keine Bewertungen

- A32 emDokument75 SeitenA32 emLevin Tan HtNoch keine Bewertungen

- Torques PDFDokument1 SeiteTorques PDFluisNoch keine Bewertungen

- Oil Pump: Removal ProcedureDokument40 SeitenOil Pump: Removal Proceduremiguelx69Noch keine Bewertungen

- StartDokument600 SeitenStartBrent NicholsNoch keine Bewertungen

- 11528918-Ford Tw10 Tw20 Tw30 Workshop ManualDokument111 Seiten11528918-Ford Tw10 Tw20 Tw30 Workshop Manualmrbazha80% (15)

- SECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyDokument35 SeitenSECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyHassan Vela VenegasNoch keine Bewertungen

- 6-03A Engine CoolingDokument57 Seiten6-03A Engine CoolingPavel AlvarezNoch keine Bewertungen

- 93 15Dokument4 Seiten93 15sharawy12Noch keine Bewertungen

- 1995 Ford Escort 1Dokument11 Seiten1995 Ford Escort 1Francisco SanchezNoch keine Bewertungen

- MYCOM VR Series Screw Compressor Overhaul ManualDokument51 SeitenMYCOM VR Series Screw Compressor Overhaul ManualWai LaiNoch keine Bewertungen

- Clio Sport Manual 3286aDokument149 SeitenClio Sport Manual 3286aOctavio LópezNoch keine Bewertungen

- Toyota 5l Engine-Turbo Kit Fitting InstructionsDokument9 SeitenToyota 5l Engine-Turbo Kit Fitting Instructionsaqilhad100% (2)

- Clio 2 Factory Repair ManualDokument212 SeitenClio 2 Factory Repair Manualagrandi12100% (3)

- TT CapriDokument12 SeitenTT CapriLuis A. Rivera LópezNoch keine Bewertungen

- Application Note Cummins PT Fuel SystemsDokument10 SeitenApplication Note Cummins PT Fuel Systemsref.mtu.533Noch keine Bewertungen

- Volkswagen Passat GLX STEERING SYSTEMDokument5 SeitenVolkswagen Passat GLX STEERING SYSTEMNPNoch keine Bewertungen

- Catalog gaps page numbers RV electric generatorDokument50 SeitenCatalog gaps page numbers RV electric generatorbatlabs100% (1)

- Manual TransmissionDokument19 SeitenManual TransmissionPaklong Azham100% (1)

- Explorer 2013 General RepairDokument86 SeitenExplorer 2013 General RepairAngel Artigas De LeonNoch keine Bewertungen

- Manual Reparación Turbo GARRETDokument24 SeitenManual Reparación Turbo GARRETFelipe Lepe MattaNoch keine Bewertungen

- B13. Compressor Oil System - Kenco Klce Oil Level ControllersDokument7 SeitenB13. Compressor Oil System - Kenco Klce Oil Level ControllersKleiber OrtegaNoch keine Bewertungen

- Ford Edge 2008-2009 PDFDokument462 SeitenFord Edge 2008-2009 PDFEnedine RamirezNoch keine Bewertungen

- Tool List & Tightening TorqueDokument21 SeitenTool List & Tightening TorqueShivamGarg63% (8)

- Self-Study Programme 246 - Variable Valve TimingDokument30 SeitenSelf-Study Programme 246 - Variable Valve TimingTombalicious100% (1)

- 5120NG 50166-104 Feb08 PDFDokument32 Seiten5120NG 50166-104 Feb08 PDFCesar SenisseNoch keine Bewertungen

- Pruebas Yu AjustesDokument15 SeitenPruebas Yu AjustesFbrzo Di GvargasNoch keine Bewertungen

- Yamaha DS7 (72) RD250 (73) R5C (72) RD350Dokument113 SeitenYamaha DS7 (72) RD250 (73) R5C (72) RD350Igor Majksner100% (5)

- QSK 45GDokument25 SeitenQSK 45Gvassindou67% (3)

- CATERPILLAR ENGINE PARTS GUIDEDokument80 SeitenCATERPILLAR ENGINE PARTS GUIDEALEXNoch keine Bewertungen

- Exhaust System - Catalytic Converter-1.6L Duratorq-TDCi (74kW-100PS 81kW-110PS) - DV 110 PSDokument12 SeitenExhaust System - Catalytic Converter-1.6L Duratorq-TDCi (74kW-100PS 81kW-110PS) - DV 110 PSaalin14Noch keine Bewertungen

- CAT 3412 Fuel System IdentificationDokument17 SeitenCAT 3412 Fuel System IdentificationCEVegaO100% (5)

- Flat Head 6Dokument5 SeitenFlat Head 6Griffin WilliamsonNoch keine Bewertungen

- MF 200-Series Workshop Sec WatDokument0 SeitenMF 200-Series Workshop Sec WatSelmirije2Noch keine Bewertungen

- Engine Fuel System Troubleshooting GuideDokument19 SeitenEngine Fuel System Troubleshooting GuidePablo Rojas Valenzuela100% (1)

- 2009 3560ton Lowboys Web PDFDokument55 Seiten2009 3560ton Lowboys Web PDFFelipe Pan Iturra Ramirez100% (2)

- Kenco KlceDokument6 SeitenKenco KlcenelsonNoch keine Bewertungen

- 2012 5.7 Hemi Cylinder Head InstallationDokument6 Seiten2012 5.7 Hemi Cylinder Head InstallationzackNoch keine Bewertungen

- 89-93 4G63 Engine ManualDokument108 Seiten89-93 4G63 Engine ManualSonny Vicente88% (26)

- Special Features of The Twingo Fitted With The D7F EngineDokument314 SeitenSpecial Features of The Twingo Fitted With The D7F EngineGyula75% (4)

- 2GR FE CoolingDokument36 Seiten2GR FE CoolingLuks FernandezNoch keine Bewertungen

- Tech Tip: Si CarburettorDokument2 SeitenTech Tip: Si CarburettorcesarecontoNoch keine Bewertungen

- Jin Bei ManualDokument300 SeitenJin Bei Manualrjan7pe100% (5)

- Testing and Adjusting Cat 3412 SN 3fzDokument21 SeitenTesting and Adjusting Cat 3412 SN 3fzEd Calhe100% (11)

- Navistart TSI 00-12-02Dokument4 SeitenNavistart TSI 00-12-02huskerchampsNoch keine Bewertungen

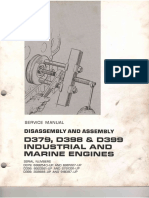

- Desmontaje y Montaje D 379398 y 399Dokument137 SeitenDesmontaje y Montaje D 379398 y 399Yuriy Senyk100% (6)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingVon EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingBewertung: 5 von 5 Sternen5/5 (1)

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SVon EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNoch keine Bewertungen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesVon EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNoch keine Bewertungen

- Construction and Manufacture of AutomobilesVon EverandConstruction and Manufacture of AutomobilesBewertung: 5 von 5 Sternen5/5 (1)

- Survival GunsDokument22 SeitenSurvival GunsChristiana McLeanNoch keine Bewertungen

- Knots (Notes)Dokument22 SeitenKnots (Notes)OPSS NPCC91% (11)

- Art of SurvivalDokument14 SeitenArt of SurvivalFreakbizarroNoch keine Bewertungen

- You Might Be A Survivalist IfDokument3 SeitenYou Might Be A Survivalist Ifbuckonbeach100% (1)

- Husqvarna Service ManualDokument125 SeitenHusqvarna Service ManualGavin Hackett60% (5)

- 288XP/XP Lite: Operator's Manual (EPA)Dokument36 Seiten288XP/XP Lite: Operator's Manual (EPA)cajunhillbilly100% (1)

- Husqvarna 50, 50 Special, 51, and 55 Workshop ManualDokument58 SeitenHusqvarna 50, 50 Special, 51, and 55 Workshop ManualcajunhillbillyNoch keine Bewertungen

- Tuff Stuff: February 2008 Subscribe and Receive Our 6-Sport Price Guide Annual. Call 1-877-300-0255 and Mention Offer Code ABBF4ADokument3 SeitenTuff Stuff: February 2008 Subscribe and Receive Our 6-Sport Price Guide Annual. Call 1-877-300-0255 and Mention Offer Code ABBF4AcajunhillbillyNoch keine Bewertungen

- Homelite C5Dokument6 SeitenHomelite C5cajunhillbillyNoch keine Bewertungen

- PartyPoker Starting HandsDokument1 SeitePartyPoker Starting HandscajunhillbillyNoch keine Bewertungen

- Tuff Stuff: February 2008 Subscribe and Receive Our 6-Sport Price Guide Annual. Call 1-877-300-0255 and Mention Offer Code ABBF4ADokument3 SeitenTuff Stuff: February 2008 Subscribe and Receive Our 6-Sport Price Guide Annual. Call 1-877-300-0255 and Mention Offer Code ABBF4AcajunhillbillyNoch keine Bewertungen

- Barnett Quad 300Dokument16 SeitenBarnett Quad 300cajunhillbilly0% (1)

- Tree FellingDokument58 SeitenTree FellingcajunhillbillyNoch keine Bewertungen

- Real Estate LicenseDokument1 SeiteReal Estate LicensecajunhillbillyNoch keine Bewertungen

- Part One - Basic DimentionsDokument5 SeitenPart One - Basic Dimentionseu1mister6002Noch keine Bewertungen

- Sept RF News NCMDokument9 SeitenSept RF News NCMcajunhillbillyNoch keine Bewertungen

- Part One - Basic DimentionsDokument5 SeitenPart One - Basic Dimentionseu1mister6002Noch keine Bewertungen

- Stihl Saw Chain IDDokument2 SeitenStihl Saw Chain IDcajunhillbilly67% (3)

- Tanning Hide PDFDokument8 SeitenTanning Hide PDFRon LongNoch keine Bewertungen

- Einstein LectureDokument9 SeitenEinstein Lecturealiuddin1Noch keine Bewertungen

- Carburetor Repair ManualDokument65 SeitenCarburetor Repair Manualcajunhillbilly89% (9)

- Craftsman DLT2000 ManualDokument64 SeitenCraftsman DLT2000 Manualcajunhillbilly100% (2)

- 0es4csDokument36 Seiten0es4cscajunhillbillyNoch keine Bewertungen

- 460 IplDokument46 Seiten460 IplClifford HubbardNoch keine Bewertungen

- Homelite - Owners Manual XL-12 & SXLAODokument40 SeitenHomelite - Owners Manual XL-12 & SXLAOcajunhillbilly67% (3)

- ScanCat Lite PlusDokument2 SeitenScanCat Lite PluscajunhillbillyNoch keine Bewertungen

- Fine Woodworking - Gluing and Clamping StrategiesDokument7 SeitenFine Woodworking - Gluing and Clamping Strategiescajunhillbilly100% (1)

- Build A Brick BarbecueDokument4 SeitenBuild A Brick Barbecuebotezatu_adrianNoch keine Bewertungen

- Shell Donax TA Transmission Fluid TDS PDFDokument1 SeiteShell Donax TA Transmission Fluid TDS PDFirwanbahrudin117134Noch keine Bewertungen

- A Review of Solar Parabolic Trough CollectorDokument7 SeitenA Review of Solar Parabolic Trough Collectoraxel_oscNoch keine Bewertungen

- 3D Technical Data Package Configuration Management, Modeling and Drawing ProcedureDokument175 Seiten3D Technical Data Package Configuration Management, Modeling and Drawing Procedurejesse_w_petersNoch keine Bewertungen

- Formulation and Evaluation of Lansoprazole Delayed Release PelletsDokument20 SeitenFormulation and Evaluation of Lansoprazole Delayed Release PelletsUmair MazharNoch keine Bewertungen

- Bid ProcessDokument85 SeitenBid ProcessRobiatol Adawiah Mohammad ShamsidiNoch keine Bewertungen

- FMVSS 139 2022-10-01Dokument7 SeitenFMVSS 139 2022-10-01skr_757Noch keine Bewertungen

- New Membership Application GemsDokument5 SeitenNew Membership Application Gemslaguila18Noch keine Bewertungen

- Synopsis Sagar Project - A Study On The Need of CRM in OrganizatonDokument3 SeitenSynopsis Sagar Project - A Study On The Need of CRM in OrganizatonViraja GuruNoch keine Bewertungen

- Porter's Five Forces: Submitted by Subham Chakraborty PGDMDokument5 SeitenPorter's Five Forces: Submitted by Subham Chakraborty PGDMSubham ChakrabortyNoch keine Bewertungen

- FormatCARS KAAUH Alqahtani 106Dokument8 SeitenFormatCARS KAAUH Alqahtani 106ZEYNONoch keine Bewertungen

- Job Order Costing ExplainedDokument43 SeitenJob Order Costing ExplainedZovia Lucio100% (1)

- Axion DatabaseDokument25 SeitenAxion Databasemacy williamsNoch keine Bewertungen

- 9608/21/M/J/15 © Ucles 2015Dokument57 Seiten9608/21/M/J/15 © Ucles 2015Asilbek AshurovNoch keine Bewertungen

- Advantages and Disadvantages of Social MediaDokument2 SeitenAdvantages and Disadvantages of Social MediaCeleste GalvanNoch keine Bewertungen

- CASE ANALYSIS: DMX Manufacturing: Property of STIDokument3 SeitenCASE ANALYSIS: DMX Manufacturing: Property of STICarmela CaloNoch keine Bewertungen

- Learn About Steganography TechniquesDokument11 SeitenLearn About Steganography TechniquesashaNoch keine Bewertungen

- What Is Creole Language - Definition & PhrasesDokument2 SeitenWhat Is Creole Language - Definition & PhrasesGabriel7496Noch keine Bewertungen

- Technical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemDokument12 SeitenTechnical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemAna RojasNoch keine Bewertungen

- Hypac C 766 C 778Dokument4 SeitenHypac C 766 C 778Dave100% (1)

- Modern Machine Shop 262180-MAR 2014Dokument228 SeitenModern Machine Shop 262180-MAR 20141mmahoneyNoch keine Bewertungen

- Vision and Mission Analysis ChapterDokument15 SeitenVision and Mission Analysis Chapterzaza bazazaNoch keine Bewertungen

- Cahyadi J Malia Tugas MID TPODokument9 SeitenCahyadi J Malia Tugas MID TPOCahyadi J MaliaNoch keine Bewertungen

- Let's Mingle Chat Invite ExamplesDokument22 SeitenLet's Mingle Chat Invite ExamplesCarmen BalbuenaNoch keine Bewertungen

- BBK SMP123HDT2 SMP124HDT2 Service ManualDokument25 SeitenBBK SMP123HDT2 SMP124HDT2 Service ManualdanielNoch keine Bewertungen

- FSR & FST First Stage Regulator: Maintenance Manual FOR Authorised TechniciansDokument23 SeitenFSR & FST First Stage Regulator: Maintenance Manual FOR Authorised TechniciansпавелNoch keine Bewertungen

- Usg Sheetrock® Brand Acoustical SealantDokument3 SeitenUsg Sheetrock® Brand Acoustical SealantHoracio PadillaNoch keine Bewertungen

- Fop 2.1Dokument11 SeitenFop 2.1Paramita HalderNoch keine Bewertungen

- #1 Introduction To C LanguageDokument6 Seiten#1 Introduction To C LanguageAtul SharmaNoch keine Bewertungen

- Adv - Student - HandbookDokument61 SeitenAdv - Student - HandbookOmkar BezzankiNoch keine Bewertungen

- 03 - Gherkin An OverviewDokument19 Seiten03 - Gherkin An OverviewArunkumar KrishnamoorthyNoch keine Bewertungen