Beruflich Dokumente

Kultur Dokumente

FL - Hvac Instrumentation and Controls

Hochgeladen von

cytech6619Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

FL - Hvac Instrumentation and Controls

Hochgeladen von

cytech6619Copyright:

Verfügbare Formate

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING SECTION 230900

WBA PROJECT NUMBER 1104024.000

HVAC INSTRUMENTATION AND CONTROLS PART 1 - GENERAL 1.1 A. RELATED DOCUMENTS Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 1 Specification Sections, apply to this Section. SUMMARY This Section includes control equipment for HVAC systems and components, including control components for terminal heating and cooling units not supplied with factorywired controls. Related Sections include the following: 1. Section of these specifications covering "Meters and Gages" for measuring equipment that relates to this Section.

1.2 A.

B.

1.3 A. B. C. D. E. F. G. 1.4 A.

DEFINITIONS DDC: Direct digital control. I/O: Input/output. LonWorks: A control network technology platform for designing and implementing interoperable control devices and networks. MS/TP: Master slave/token passing. PC: Personal computer. PID: Proportional plus integral plus derivative. RTD: Resistance temperature detector. SYSTEM PERFORMANCE Comply with the following performance requirements: 1. Graphic Display: Display graphic with minimum 20 dynamic points with current data within 10 seconds.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 1

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 2. 3. 4. 5. 6. 7. 8.

WBA PROJECT NUMBER 1104024.000

Graphic Refresh: Update graphic with minimum 20 dynamic points with current data within 8 seconds. Object Command: Reaction time of less than two seconds between operator command of a binary object and device reaction. Object Scan: Transmit change of state and change of analog values to control units or workstation within six seconds. Alarm Response Time: Annunciate alarm at workstation within 45 seconds. Multiple workstations must receive alarms within five seconds of each other. Program Execution Frequency: Run capability of applications as often as five seconds, but selected consistent with mechanical process under control. Performance: Programmable controllers shall execute DDC PID control loops, and scan and update process values and outputs at least once per second. Reporting Accuracy and Stability of Control: Report values and maintain measured variables within tolerances as follows: a. b. c. d. e. f. g. h. i. j. k. l. m. n. o. p. Water Temperature: Plus or minus 1 deg F. Water Flow: Plus or minus 5 percent of full scale. Water Pressure: Plus or minus 2 percent of full scale. Space Temperature: Plus or minus 1 deg F. Ducted Air Temperature: Plus or minus 1 deg F. Outside Air Temperature: Plus or minus 2 deg F. Dew Point Temperature: Plus or minus 3 deg F. Temperature Differential: Plus or minus 0.25 deg F. Relative Humidity: Plus or minus 5 percent. Airflow (Pressurized Spaces): Plus or minus 3 percent of full scale. Airflow (Measuring Stations): Plus or minus 5 percent of full scale. Airflow (Terminal): Plus or minus 10 percent of full scale. Air Pressure (Space): Plus or minus 0.01-inch wg. Air Pressure (Ducts): Plus or minus 0.1-inch wg. Carbon Dioxide: Plus or minus 50 ppm. Electrical: Plus or minus 5 percent of reading.

1.5 1.6 A.

SEQUENCE OF OPERATION SUBMITTALS Product Data: Include manufacturer's technical literature for each control device. Indicate dimensions, capacities, performance characteristics, electrical characteristics, finishes for materials, and installation and startup instructions for each type of product indicated. 1. DDC System Hardware: Bill of materials of equipment indicating quantity, manufacturer, and model number. Include technical data for operator workstation equipment, interface equipment, control units, transducers/transmitters, sensors, actuators, valves, relays/switches, control panels, and operator interface equipment. Control System Software: Include technical data for operating system software, operator interface, color graphics, and other third-party applications.

2.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 2

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 3.

WBA PROJECT NUMBER 1104024.000

Controlled Systems: Instrumentation list with element name, type of device, manufacturer, model number, and product data. Include written description of sequence of operation including schematic diagram.

B.

Shop Drawings: Detail equipment assemblies and indicate dimensions, weights, loads, required clearances, method of field assembly, components, and location and size of each field connection. 1. 2. 3. 4. 5. 6. 7. 8. Bill of materials of equipment indicating quantity, manufacturer, and model number. Schematic flow diagrams showing fans, pumps, coils, dampers, valves, and control devices. Wiring Diagrams: Power, signal, and control wiring. Details of control panel faces, including controls, instruments, and labeling. Written description of sequence of operation. Schedule of dampers including size, leakage, and flow characteristics. Schedule of valves including flow characteristics. DDC System Hardware: a. b. c. Wiring diagrams for control units with termination numbers. Schematic diagrams and floor plans for field sensors and control hardware. Schematic diagrams for control, communication, and power wiring, showing trunk data conductors and wiring between operator workstation and control unit locations.

9.

10.

Control System Software: List of color graphics indicating monitored systems, data (connected and calculated) point addresses, output schedule, and operator notations. Controlled Systems: a. b. c. d. Schematic diagrams of each controlled system with control points labeled and control elements graphically shown, with wiring. Scaled drawings showing mounting, routing, and wiring of elements including bases and special construction. Written description of sequence of operation including schematic diagram. Points list.

C. D. E. F. G.

Data Communications Protocol Certificates: Certify that each proposed DDC system component complies with ASHRAE 135. Data Communications Protocol Certificates: Certify that each proposed DDC system component complies with LonWorks. Samples for Initial Selection: For each color required, of each type of thermostat or sensor cover with factory-applied color finishes. Samples for Verification: sensor] cover. For each color required, of each type of thermostat[ or

Software and Firmware Operational Documentation: Include the following:

HVAC INSTRUMENTATION AND CONTROLS

230900 - 3

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 1. 2. 3. 4. 5. H. I. J. K.

WBA PROJECT NUMBER 1104024.000

Software operating and upgrade manuals. Program Software Backup: On a magnetic media or compact disc, complete with data files. Device address list. Printout of software application and graphic screens. Software license required by and installed for DDC workstations and control systems.

Software Upgrade Kit: For Owner to use in modifying software to suit future systems revisions or monitoring and control revisions. Qualification Data: For Installer and manufacturer. Field quality-control test reports. Operation and Maintenance Data: For HVAC instrumentation and control system to include in emergency, operation, and maintenance manuals. Include the following: 1. 2. 3. 4. 5. Maintenance instructions and lists of spare parts for each type of control device and compressed-air station. Interconnection wiring diagrams with identified and numbered system components and devices. Keyboard illustrations and step-by-step procedures indexed for each operator function. Inspection period, cleaning methods, cleaning materials recommended, and calibration tolerances. Calibration records and list of set points.

1.7 A.

QUALITY ASSURANCE Installer Qualifications: Automatic control system manufacturer's authorized representative who is trained and approved for installation of system components required for this Project. Electrical Components, Devices, and Accessories: Listed and labeled as defined in NFPA 70, Article 100, by a testing agency acceptable to authorities having jurisdiction, and marked for intended use. Comply with ASHRAE 135 for DDC system components. DELIVERY, STORAGE, AND HANDLING Factory-Mounted Components: Where control devices specified in this Section are indicated to be factory mounted on equipment, arrange for shipping of control devices to equipment manufacturer. System Software: Update to latest version of software at Project completion.

B.

C. 1.8 A.

B.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 4

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 1.9 A. B. C. D. E. F. G. H. I. COORDINATION

WBA PROJECT NUMBER 1104024.000

Coordinate location of thermostats, humidistats, and other exposed control sensors with plans and room details before installation. Coordinate equipment with other sections of these specifications that cover "Security Access" to achieve compatibility with equipment that interfaces with that system. Coordinate equipment with other sections of these specifications that cover "Lighting Controls" to achieve compatibility with equipment that interfaces with that system. Coordinate equipment with other sections of these specifications that cover "Fire Alarm" to achieve compatibility with equipment that interfaces with that system. Coordinate supply of conditioned electrical branch circuits for control units and operator workstation. Coordinate equipment with other sections of these specifications that cover "Electrical Power Monitoring and Control" to achieve compatibility of communication interfaces. Coordinate equipment with other sections of these specifications that cover "Panelboards" to achieve compatibility with starter coils and annunciation devices. Coordinate equipment with other sections of these specifications that cover "MotorControl Centers" to achieve compatibility with motor starters and annunciation devices. Coordinate size and location of concrete bases. Cast anchor-bolt inserts into bases. Concrete, reinforcement, and formwork requirements are specified in other sections of these specifications covering "Cast-in-Place Concrete."

PART 2 - PRODUCTS 2.1 A. MANUFACTURERS In other Part 2 articles where titles below introduce lists, the following requirements apply to product selection: 1. Available Manufacturers: Manufacturer that is incorporated into the Work is limited to the following specified. No other substitution is permitted

2.2 A.

CONTROL SYSTEM Manufacturers: 1. Andover Controls Corporation.

B.

Control system shall consist of sensors, indicators, actuators, final control elements, interface equipment, other apparatus, and accessories to control mechanical systems.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 5

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING C.

WBA PROJECT NUMBER 1104024.000

Control system shall consist of sensors, indicators, actuators, final control elements, interface equipment, other apparatus, accessories, and software connected to distributed controllers operating in multiuser, multitasking environment on tokenpassing network and programmed to control mechanical systems. An operator workstation permits interface with the network via dynamic color graphics with each mechanical system, building floor plan, and control device depicted by point-and-click graphics. DDC EQUIPMENT Operator Workstation: One PC-based microcomputer(s) with minimum configuration as follows: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Motherboard: With 8 integrated USB 2.0 ports, integrated Intel Pro 10/100 (Ethernet), integrated audio, bios, and hardware monitoring. Processor. Random-Access Memory. Graphics: Video adapter. Monitor, LCD color. Keyboard: QWERTY, 105 keys in ergonomic shape. Hard-Disk Drive. CD-ROM Read/Write Drive. Mouse: Three button, optical. Uninterruptible Power Supply. Operating System: Microsoft Windows XP Professional with high-speed Internet access. a. ASHRAE 135 Compliance: Workstation shall use ASHRAE 135 protocol and communicate using ISO 8802-3 (Ethernet) datalink/physical layer protocol. LonWorks Compliance: Control units shall use LonTalk protocol and communicate using EIA/CEA 709.1 datalink/physical layer protocol.

2.3 A.

b. 12.

Printer: Color, ink-jet type as follows: a. b. c. Print Head: 4800 x 1200 dpi optimized color resolution. Paper Handling: Minimum of 100 sheets. Print Speed: Minimum of 17 ppm in black and 12 ppm in color.

13.

Application Software: a. b. c. d. e. f. g. I/O capability from operator station. System security for each operator via software password and access levels. Automatic system diagnostics; monitor system and report failures. Database creation and support. Automatic and manual database save and restore. Dynamic color graphic displays with up to 10 screen displays at once. Custom graphics generation and graphics library of HVAC equipment and symbols.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 6

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING h. i. j. k. l. m.

WBA PROJECT NUMBER 1104024.000

Alarm processing, messages, and reactions. Trend logs retrievable in spreadsheets and database programs. Alarm and event processing. Object and property status and control. Automatic restart of field equipment on restoration of power. Data collection, reports, and logs. Include standard reports for the following: 1) 2) 3) 4) 5) Current values of all objects. Current alarm summary. Disabled objects. Alarm lockout objects. Logs.

n. o. p. q. r. 14.

Custom report development. Utility and weather reports. ASHRAE Guideline 3 report. Workstation application editors for controllers and schedules. Maintenance management.

Custom Application Software: a. b. c. d. e. f. English language oriented. Full-screen character editor/programming environment. Allow development of independently executing program modules with debugging/simulation capability. Support conditional statements. Support floating-point arithmetic with mathematic functions. Contains predefined time variables.

B.

Diagnostic Terminal Unit: Portable notebook-style, PC-based microcomputer terminal capable of accessing system data by connecting to system network with minimum configuration as follows: 1. 2. 3. 4. 5. 6. 7. 8. 9. System: With one integrated USB 2.0 port, integrated Intel Pro 10/100 (Ethernet), integrated audio, bios, and hardware monitoring. Processor: Intel Pentium 4 MHz. Random-Access Memory. Graphics: Video adapter. Monitor: LCD color. Keyboard: QWERTY 105 keys in ergonomic shape. Hard-Disk Drive. CD-ROM Read/Write Drive. Pointing Device: Touch pad or other internal device.

C.

Control Units: Modular, comprising processor board with programmable, nonvolatile, random-access memory; local operator access and display panel; integral interface equipment; and backup power source.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 7

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 1.

WBA PROJECT NUMBER 1104024.000

2.

Units monitor or control each I/O point; process information; execute commands from other control units, devices, and operator stations; and download from or upload to operator workstation or diagnostic terminal unit. Stand-alone mode control functions operate regardless of network status. Functions include the following: a. b. c. d. e. Global communications. Discrete/digital, analog, and pulse I/O. Monitoring, controlling, or addressing data points. Software applications, scheduling, and alarm processing. Testing and developing control algorithms without disrupting field hardware and controlled environment.

3.

Standard Application Programs: a. Electric Control Programs: Demand limiting, duty cycling, automatic time scheduling, start/stop time optimization, night setback/setup, on-off control with differential sequencing, staggered start, antishort cycling, PID control, DDC with fine tuning, and trend logging. HVAC Control Programs: Optimal run time, supply-air reset, and enthalpy switchover. Chiller Control Programs: Control function of chilled-water reset, and equipment sequencing. Programming Application Features: Include trend point; alarm processing and messaging; weekly, monthly, and annual scheduling; energy calculations; run-time totalization; and security access. Remote communications. Maintenance management. Units of Measure: Inch-pound and SI (metric).

b. c. d.

e. f. g. 4. 5. 6. D.

Local operator interface provides for download from or upload to operator workstation or diagnostic terminal unit. ASHRAE 135 Compliance: Control units shall use ASHRAE 135 protocol and communicate using ISO 8802-3 (Ethernet) datalink/physical layer protocol. LonWorks Compliance: Control units shall use LonTalk protocol and communicate using EIA/CEA 709.1 datalink/physical layer protocol.

Local Control Units: Modular, comprising processor board with electronically programmable, nonvolatile, read-only memory; and backup power source. 1. 2. Units monitor or control each I/O point, process information, and download from or upload to operator workstation or diagnostic terminal unit. Stand-alone mode control functions operate regardless of network status. Functions include the following: a. b. c. 3. Global communications. Discrete/digital, analog, and pulse I/O. Monitoring, controlling, or addressing data points.

Local operator interface provides for download from or upload to operator workstation or diagnostic terminal unit.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 8

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 4. 5. E.

WBA PROJECT NUMBER 1104024.000

ASHRAE 135 Compliance: Control units shall use ASHRAE 135 protocol and communicate using ISO 8802-3 (Ethernet) datalink/physical layer protocol. LonWorks Compliance: Control units shall use LonTalk protocol and communicate using EIA/CEA 709.1 datalink/physical layer protocol.

I/O Interface: Hardwired inputs and outputs may tie into system through controllers. Protect points so that shorting will cause no damage to controllers. 1. 2. 3. 4. 5. 6. 7. Binary Inputs: Allow monitoring of on-off signals without external power. Pulse Accumulation Inputs: Accept up to 10 pulses per second. Analog Inputs: Allow monitoring of low-voltage (0- to 10-V dc), current (4 to 20 mA), or resistance signals. Binary Outputs: Provide on-off or pulsed low-voltage signal, selectable for normally open or normally closed operation. Analog Outputs: Provide modulating signal, either low voltage (0- to 10-V dc) or current (4 to 20 mA). Tri-State Outputs: Provide two coordinated binary outputs for control of threepoint, floating-type electronic actuators. Universal I/Os: Provide software selectable binary or analog outputs.

F.

Power Supplies: Transformers with Class 2 current-limiting type or overcurrent protection; limit connected loads to 80 percent of rated capacity. DC power supply shall match output current and voltage requirements and be full-wave rectifier type with the following: 1. 2. 3. Output ripple of 5.0 mV maximum peak to peak. Combined 1 percent line and load regulation with 100-mic.sec. response time for 50 percent load changes. Built-in overvoltage and overcurrent protection and be able to withstand 150 percent overload for at least 3 seconds without failure.

G.

Power Line Filtering: Internal or external transient voltage and surge suppression for workstations or controllers with the following: 1. 2. 3. 4. Minimum dielectric strength of 1000 V. Maximum response time of 10 nanoseconds. Minimum transverse-mode noise attenuation of 65 dB. Minimum common-mode noise attenuation of 150 dB at 40 to 100 Hz.

2.4 A.

UNITARY CONTROLLERS Unitized, capable of stand-alone operation with sufficient memory to support its operating system, database, and programming requirements, and with sufficient I/O capacity for the application. 1. Configuration: Local keypad and display; diagnostic LEDs for power, communication, and processor; wiring termination to terminal strip or card connected with ribbon cable; memory with bios; and battery backup.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 9

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 2.

WBA PROJECT NUMBER 1104024.000

3.

4. 5. 6. 2.5 A.

Operating System: Manage I/O communication to allow distributed controllers to share real and virtual object information and allow central monitoring and alarms. Perform automatic system diagnostics; monitor system and report failures. ASHRAE 135 Compliance: Communicate using read (execute and initiate) and write (execute and initiate) property services defined in ASHRAE 135. Reside on network using MS/TP datalink/physical layer protocol and have service communication port for connection to diagnostic terminal unit. LonWorks Compliance: Communicate using EIA/CEA 709.1 datalink/physical layer protocol using LonTalk protocol. Enclosure: Dustproof rated for operation at 32 to 120 deg F. Enclosure: Waterproof rated for operation at 40 to 150 deg F.

ALARM PANELS Unitized cabinet with suitable brackets for wall or floor mounting. Fabricate of 0.06inch- thick, furniture-quality steel or extruded-aluminum alloy, totally enclosed, with hinged doors and keyed lock and with manufacturer's standard shop-painted finish. Provide common keying for all panels. Indicating light for each alarm point, single horn, acknowledge switch, and test switch, mounted on hinged cover. 1. 2. 3. 4. 5. Alarm Condition: Indicating light flashes and horn sounds. Acknowledge Switch: Horn is silent and indicating light is steady. Second Alarm: Horn sounds and indicating light is steady. Alarm Condition Cleared: System is reset and indicating light is extinguished. Contacts in alarm panel allow remote monitoring by independent alarm company.

B.

2.6 A. B.

ANALOG CONTROLLERS Step Controllers: 6- or 10-stage type, with heavy-duty switching rated to handle loads and operated by electric motor. Electric, Outdoor-Reset Controllers: Remote-bulb or bimetal rod-and-tube type, proportioning action with adjustable throttling range, adjustable set point, scale range minus 10 to plus 70 deg F, and single- or double-pole contacts. Electronic Controllers: Wheatstone-bridge-amplifier type, in steel enclosure with provision for remote-resistance readjustment. Identify adjustments on controllers, including proportional band and authority. 1. Single controllers can be integral with control motor if provided with accessible control readjustment potentiometer.

C.

2.7 A.

ELECTRONIC SENSORS Description: Vibration and corrosion resistant; for wall, immersion, or duct mounting as required.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 10

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING B. Thermistor Temperature Sensors and Transmitters: 1. Available Manufacturers: a. b. c. d. e. f. 2. 3. 4. 5. 6. 7. BEC Controls Corporation. Ebtron, Inc. Heat-Timer Corporation. I.T.M. Instruments Inc. MAMAC Systems, Inc. RDF Corporation.

WBA PROJECT NUMBER 1104024.000

Accuracy: Plus or minus 0.5 deg F at calibration point. Wire: Twisted, shielded-pair cable. Insertion Elements in Ducts: Single point, 18 inches long; use where not affected by temperature stratification or where ducts are smaller than 9 sq. ft. Averaging Elements in Ducts: 72 inches long, flexible; use where prone to temperature stratification or where ducts are larger than 10 sq. ft. Insertion Elements for Liquids: Brass or stainless-steel socket with minimum insertion length of 2-1/2 inches. Room Sensor Cover Construction: Manufacturer's standard locking covers. a. b. c. d. e. Set-Point Adjustment: None for common area, Exposed elsewhere. Set-Point Indication: None for common area, Exposed elesewhere. Thermometer: Exposed Red-reading glass. Color: Manufacturers standard color. Orientation: Vertical.

8. 9. C.

Outside-Air Sensors: Watertight inlet fitting, shielded from direct sunlight. Room Security Sensors: Stainless-steel cover plate with insulated back and security screws.

RTDs and Transmitters: 1. Available Manufacturers: a. b. c. 2. 3. 4. 5. BEC Controls Corporation. MAMAC Systems, Inc. RDF Corporation.

6. 7.

Accuracy: Plus or minus 0.2 percent at calibration point. Wire: Twisted, shielded-pair cable. Insertion Elements in Ducts: Single point, 18 inches long; use where not affected by temperature stratification or where ducts are smaller than 9 sq. ft.. Averaging Elements in Ducts: 24 feet long, flexible; use where prone to temperature stratification or where ducts are larger than 9 sq. ft.; length as required. Insertion Elements for Liquids: Brass socket with minimum insertion length of 21/2 inches. Room Sensor Cover Construction: Manufacturer's standard locking covers. a. Set-Point Adjustment: None for common area, Exposed elsewhere.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 11

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING b. c. d. e. 8. 9. D.

WBA PROJECT NUMBER 1104024.000

Set-Point Indication: None for common area, Exposed elsewhere. Thermometer: Exposed Red-reading glass. Color: Manufacturers standard color. Orientation: Vertical.

Outside-Air Sensors: Watertight inlet fitting, shielded from direct sunlight. Room Security Sensors: Stainless-steel cover plate with insulated back and security screws.

Humidity Sensors: Bulk polymer sensor element. 1. Available Manufacturers: a. b. c. d. e. f. 2. 3. 4. 5. BEC Controls Corporation. General Eastern Instruments. MAMAC Systems, Inc. ROTRONIC Instrument Corp. TCS/Basys Controls. Vaisala.

Accuracy: 2 percent full range with linear output. Duct Sensor: 20 to 80 percent relative humidity range with element guard and mounting plate. Outside-Air Sensor: 20 to 80 percent relative humidity range with mounting enclosure, suitable for operation at outdoor temperatures of 32 to 120 deg F . Duct and Sensors: With element guard and mounting plate, range of 0 to 100 percent relative humidity.

E.

Pressure Transmitters/Transducers: 1. Available Manufacturers: a. b. c. d. e. f. 2. BEC Controls Corporation. General Eastern Instruments. MAMAC Systems, Inc. ROTRONIC Instrument Corp. TCS/Basys Controls. Vaisala.

Static-Pressure Transmitter: Nondirectional sensor with suitable range for expected input, and temperature compensated. a. b. c. Accuracy: 2 percent of full scale with repeatability of 0.5 percent. Output: 4 to 20 mA. Duct Static-Pressure Range: 0- to 5-inch wg.

3.

Water Pressure Transducers: Stainless-steel diaphragm construction, suitable for service; minimum 150-psig operating pressure; linear output 4 to 20 mA.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 12

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 4.

WBA PROJECT NUMBER 1104024.000

5. 6. F.

Water Differential-Pressure Transducers: Stainless-steel diaphragm construction, suitable for service; minimum 150-psig operating pressure and tested to 300-psig; linear output 4 to 20 mA. Differential-Pressure Switch (Air or Water): Snap acting, with pilot-duty rating and with suitable scale range and differential. Pressure Transmitters: Direct acting for gas, liquid, or steam service; range suitable for system; linear output 4 to 20 mA.

Room Sensor Cover Construction: Manufacturer's standard locking covers. 1. 2. 3. 4. 5. Set-Point Adjustment: None for common area, Exposed elswhere. Set-Point Indication: None for common area, Exposed elswhere. Thermometer: Exposed Red-reading glass. Color: Manufacturers standard color. Orientation: Vertical.

G.

Room sensor accessories include the following: 1. Insulating Bases: For sensors located on exterior walls.

2.8 A. B. C.

STATUS SENSORS Status Inputs for Fans: Differential-pressure switch with pilot-duty rating and with adjustable range of 0- to 5-inch wg. Status Inputs for Pumps: Differential-pressure switch with pilot-duty rating and with adjustable pressure-differential range of 8 to 60 psig, piped across pump. Status Inputs for Electric Motors: Comply with ISA 50.00.01, current-sensing fixed- or split-core transformers with self-powered transmitter, adjustable and suitable for 175 percent of rated motor current. Voltage Transmitter (100- to 600-V ac): Comply with ISA 50.00.01, single-loop, selfpowered transmitter, adjustable, with suitable range and 1 percent full-scale accuracy. Power Monitor: 3-phase type with disconnect/shorting switch assembly, listed voltage and current transformers, with pulse kilowatt hour output and 4- to 20-mA kW output, with maximum 2 percent error at 1.0 power factor and 2.5 percent error at 0.5 power factor. Current Switches: Self-powered, solid-state with adjustable trip current, selected to match current and system output requirements. Electronic Valve/Damper Position Indicator: Visual scale indicating percent of travel and 2- to 10-V dc, feedback signal. Water-Flow Switches: Bellows-actuated mercury or snap-acting type with pilot-duty rating, stainless-steel or bronze paddle, with appropriate range and differential adjustment, in NEMA 250, Type 1 enclosure.

D. E.

F. G. H.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 13

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 1. Available Manufacturers: a. b. 2.9 A. BEC Controls Corporation. I.T.M. Instruments Inc.

WBA PROJECT NUMBER 1104024.000

GAS DETECTION EQUIPMENT Available Manufacturers: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. B. W. Technologies. CEA Instruments, Inc. Ebtron, Inc. Gems Sensors Inc. Greystone Energy Systems Inc. Honeywell International Inc.; Home & Building Control. INTEC Controls, Inc. I.T.M. Instruments Inc. MSA Canada Inc. QEL/Quatrosense Environmental Limited. Sauter Controls Corporation. Sensidyne, Inc. TSI Incorporated. Vaisala. Vulcain Inc.

B.

Carbon Dioxide Sensor and Transmitter: Single detectors using solid-state infrared sensors; suitable over a temperature range of 23 to 130 deg F and calibrated for 0 to 2 percent, with continuous or averaged reading, 4- to 20-mA output;, for wall mounting. Occupancy Sensor: Passive infrared, with time delay, daylight sensor lockout, sensitivity control, and 180-degree field of view with vertical sensing adjustment; for flush mounting. FLOW MEASURING STATIONS Duct Airflow Station: Combination of air straightener and multiport, self-averaging pitot tube station. 1. Available Manufacturers: a. b. c. 2. 3. 4. Air Monitor Corporation. Wetmaster Co., Ltd. Ebtron

C.

2.10 A.

Casing: Galvanized-steel frame. Flow Straightener: Aluminum honeycomb, 3/4-inch parallel cell, 3 inches deep. Sensing Manifold: Copper manifold with bullet-nosed static pressure sensors positioned on equal area basis.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 14

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 2.11 A. THERMOSTATS Available Manufacturers: 1. 2. 3. 4. 5. 6. B.

WBA PROJECT NUMBER 1104024.000

Erie Controls. Danfoss Inc.; Air-Conditioning and Refrigeration Div. Heat-Timer Corporation. Sauter Controls Corporation. tekmar Control Systems, Inc. Theben AG - Lumilite Control Technology, Inc.

Combination Thermostat and Fan Switches: Line-voltage thermostat with push-button or lever-operated fan switch. 1. 2. Label switches "FAN ON-OFF". Mount on single electric switch box.

C.

Electric, solid-state, microcomputer-based room thermostat with remote sensor. 1. 2. 3. 4. 5. 6. 7. 8. 9. Automatic switching from heating to cooling. Preferential rate control to minimize overshoot and deviation from set point. Set up for four separate temperatures per day. Instant override of set point for continuous or timed period from 1 hour to 31 days. Short-cycle protection. Programming based on weekday, Saturday, and Sunday. Selection features include degree F or degree C display, 12- or 24-hour clock, keyboard disable, remote sensor, and fan on-auto. Battery replacement without program loss. Thermostat display features include the following: a. b. c. d. e. f. g. Time of day. Actual room temperature. Programmed temperature. Programmed time. Duration of timed override. Day of week. System mode indications include "heating," "off," "fan auto," and "fan on."

D.

Low-Voltage, On-Off Thermostats: NEMA DC 3, 24-V, bimetal-operated, mercuryswitch type, with adjustable or fixed anticipation heater, concealed set-point adjustment, 55 to 85 deg F set-point range, and 2 deg F maximum differential. Line-Voltage, On-Off Thermostats: Bimetal-actuated, open contact or bellowsactuated, enclosed, snap-switch or equivalent solid-state type, with heat anticipator; listed for electrical rating; with concealed set-point adjustment, 55 to 85 deg F set-point range, and 2 deg F maximum differential. 1. 2. Electric Heating Thermostats: Equip with off position on dial wired to break ungrounded conductors. Selector Switch: Integral, manual on-off-auto.

E.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 15

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING F.

WBA PROJECT NUMBER 1104024.000

Remote-Bulb Thermostats: On-off or modulating type, liquid filled to compensate for changes in ambient temperature; with copper capillary and bulb, unless otherwise indicated. 1. 2. 3. 4. 5. 6. Bulbs in water lines with separate wells of same material as bulb. Bulbs in air ducts with flanges and shields. Averaging Elements: Copper tubing with either single- or multiple-unit elements, extended to cover full width of duct or unit; adequately supported. Scale settings and differential settings are clearly visible and adjustable from front of instrument. On-Off Thermostat: With precision snap switches and with electrical ratings required by application. Modulating Thermostats: Construct so complete potentiometer coil and wiper assembly is removable for inspection or replacement without disturbing calibration of instrument.

G. H.

Immersion Thermostat: Remote-bulb or bimetal rod-and-tube type, proportioning action with adjustable throttling range and adjustable set point. Airstream Thermostats: Two-pipe, fully proportional, single-temperature type; with adjustable set point in middle of range, adjustable throttling range, plug-in test fitting or permanent pressure gage, remote bulb, bimetal rod and tube, or averaging element. Electric, Low-Limit Duct Thermostat: Snap-acting, single-pole, single-throw, manualreset switch that trips if temperature sensed across any 12 inches of bulb length is equal to or below set point. 1. 2. Bulb Length: Minimum 20 feet. Quantity: One thermostat for every 20 sq. ft.of coil surface.

I.

J.

Electric, High-Limit Duct Thermostat: Snap-acting, single-pole, single-throw, manualreset switch that trips if temperature sensed across any 12 inches of bulb length is equal to or above set point. 1. 2. Bulb Length: Minimum 20 feet. Quantity: One thermostat for every 20 sq. ft. of coil surface.

2.12 A.

HUMIDISTATS Available Manufacturers: 1. 2. MAMAC Systems, Inc. ROTRONIC Instrument Corp.

B.

Duct-Mounting Humidistats: Electric insertion, 2-position type with adjustable, 2 percent throttling range, 20 to 80 percent operating range, and single- or double-pole contacts.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 16

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 2.13 A. ACTUATORS

WBA PROJECT NUMBER 1104024.000

Electric Motors: Size to operate with sufficient reserve power to provide smooth modulating action or two-position action. 1. Permanent Split-Capacitor or Shaded-Pole Type: Gear trains completely oil immersed and sealed. Equip spring-return motors with integral spiral-spring mechanism in housings designed for easy removal for service or adjustment of limit switches, auxiliary switches, or feedback potentiometer. Nonspring-Return Motors for Valves Larger Than NPS 2-1/2: Size for running torque of 150 in. x lbf and breakaway torque of 300 in. x lbf. Spring-Return Motors for Valves Larger Than NPS 2-1/2: Size for running and breakaway torque of 150 in. x lbf. Nonspring-Return Motors for Dampers Larger Than 25 Sq. Ft.: Size for running torque of 150 in. x lbf and breakaway torque of 300 in. x lbf . Spring-Return Motors for Dampers Larger Than 25 Sq. Ft.: Size for running and breakaway torque of 150 in. x lbf .

2. 3. 4. 5. B.

Electronic Actuators: Direct-coupled type designed for minimum 60,000 full-stroke cycles at rated torque. 1. Available Manufacturers: a. 2. 3. Belimo Aircontrols (USA), Inc.

Valves: Size for torque required for valve close off at maximum pump differential pressure. Dampers: Size for running torque calculated as follows: a. b. c. d. e. f. Parallel-Blade Damper with Edge Seals: 7 inch-lb/sq. ft. of damper. Opposed-Blade Damper with Edge Seals: 5 inch-lb/sq. ft. of damper. Parallel-Blade Damper without Edge Seals: 4 inch-lb/sq. ft of damper. Opposed-Blade Damper without Edge Seals: 3 inch-lb/sq. ft. of damper. Dampers with 2- to 3-Inch wg of Pressure Drop or Face Velocities of 1000 to 2500 fpm: Increase running torque by 1.5. Dampers with 3- to 4-Inch wg of Pressure Drop or Face Velocities of 2500 to 3000 fpm: Increase running torque by 2.0.

4. 5. 6. 7. 8. 9. 10. 11.

Coupling: V-bolt and V-shaped, toothed cradle. Overload Protection: Electronic overload or digital rotation-sensing circuitry. Fail-Safe Operation: Mechanical, spring-return mechanism. Provide external, manual gear release on nonspring-return actuators. Power Requirements (Two-Position Spring Return): 24Vac. Power Requirements (Modulating): Maximum 10 VA at 24-V ac or 8 W at 24-V dc. Proportional Signal: 2- to 10-V dc or 4 to 20 mA, and 2- to 10-V dc position feedback signal. Temperature Rating: Minus 22 to plus 122 deg F . Run Time: 12 seconds open, 5 seconds closed.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 17

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 2.14 A. CONTROL VALVES Available Manufacturers: 1. 2. 3. 4. 5. 6. 7. 8. B.

WBA PROJECT NUMBER 1104024.000

Danfoss Inc.; Air Conditioning & Refrigeration Div. Erie Controls. Hayward Industrial Products, Inc. Magnatrol Valve Corporation. Neles-Jamesbury. Parker Hannifin Corporation; Skinner Valve Division. Sauter Controls Corporation. Belimo

Control Valves: Factory fabricated, of type, body material, and pressure class based on maximum pressure and temperature rating of piping system, unless otherwise indicated. Hydronic system globe valves shall have the following characteristics: 1. NPS 2 and Smaller: Class 125 bronze body, bronze trim, rising stem, renewable composition disc, and screwed ends with backseating capacity repackable under pressure. NPS 2-1/2 and Larger: Class 125 iron body, bronze trim, rising stem, plug-type disc, flanged ends, and renewable seat and disc. Internal Construction: Replaceable plugs and stainless-steel or brass seats. a. b. 4. Single-Seated Valves: Cage trim provides seating and guiding surfaces for plug on top and bottom. Double-Seated Valves: Balanced plug; cage trim provides seating and guiding surfaces for plugs on top and bottom.

C.

2. 3.

Sizing: 3-psig maximum pressure drop at design flow rate or the following: a. Two-Way Modulating: Either the value specified above or twice the load pressure drop, whichever is more.

5. 6.

Flow Characteristics: Two-way valves shall have equal percentage characteristics. Close-Off (Differential) Pressure Rating: Combination of actuator and trim shall provide minimum close-off pressure rating of 150 percent of total system (pump) head for two-way valves and 100 percent of pressure differential across valve or 100 percent of total system (pump) head.

D.

Butterfly Valves: 200-psig maximum pressure differential, ASTM A 126 cast-iron or ASTM A 536 ductile-iron body and bonnet, extended neck, stainless-steel stem, fieldreplaceable EPDM or Buna N sleeve and stem seals. 1. 2. 3. Body Style: Wafer. Disc Type: Nickel-plated ductile iron. Sizing: 1-psig maximum pressure drop at design flow rate.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 18

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 2.15 A. DAMPERS Available Manufacturers: 1. 2. 3. 4. 5. 6. B. Air Balance Inc. Don Park Inc.; Autodamp Div. TAMCO (T. A. Morrison & Co. Inc.). United Enertech Corp. Vent Products Company, Inc. Ruskin

WBA PROJECT NUMBER 1104024.000

Dampers: AMCA-rated, parallel or opposed-blade design; 0.108-inch minimum thick, galvanized-steel or 0.125-inch minimum thick, extruded-aluminum frames with holes for duct mounting; damper blades shall not be less than 0.064-inch thick galvanized steel with maximum blade width of 8 inches and length of 48 inches. 1. Secure blades to 1/2-inch-diameter, zinc-plated axles using zinc-plated hardware, with oil-impregnated sintered bronze or nylon blade bearings, bladelinkage hardware of zinc-plated steel and brass, ends sealed against springstainless-steel blade bearings, and thrust bearings at each end of every blade. Operating Temperature Range: From minus 40 to plus 200 deg F. Edge Seals, Standard Pressure Applications: Closed-cell neoprene. Edge Seals, Low-Leakage Applications: Use inflatable blade edging or replaceable rubber blade seals and spring-loaded stainless-steel side seals, rated for leakage at less than 10 cfm per sq. ft. of damper area, at differential pressure of 4-inch wg when damper is held by torque of 50 in. x lbf ; when tested according to AMCA 500D.

2. 3. 4.

2.16 A. B.

CONTROL CABLE Electronic cables for control wiring are specified in other sections of these specifications covering Voice and Data Communication Cabling. Plenum rated cable for control wiring in concealed, accessible locations is acceptable.

PART 3 - EXECUTION 3.1 A. B. EXAMINATION Verify that conditioned power supply is available to control units and operator workstation. Verify that duct-, pipe, and equipment-mounted devices are installed before proceeding with installation.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 19

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 3.2 A. B. C. INSTALLATION

WBA PROJECT NUMBER 1104024.000

Install software in control units and operator workstation(s). Implement all features of programs to specified requirements and as appropriate to sequence of operation. Connect and configure equipment and software to achieve sequence of operation specified. Verify location of thermostats, humidistats, and other exposed control sensors with Drawings and room details before installation. Install devices 48 inches above the floor. 1. Install averaging elements in ducts and plenums in crossing or zigzag pattern.

D. E. F. G. H. I.

Install automatic dampers according to other sections of these specifications covering "Duct Accessories." Install damper motors on outside of duct in warm areas, not in locations exposed to outdoor temperatures. Install labels and nameplates to identify control components according to other sections of these specifications covering "Mechanical Identification." Install hydronic instrument wells, valves, and other accessories according to other section of these specifications covering "Hydronic Piping." Install duct volume-control dampers. Install electronic and fiber-optic cables according to other sections of these specifications covering Voice and Data Communication Cabling. ELECTRICAL WIRING AND CONNECTION INSTALLATION Install raceways, boxes, and cabinets according to other sections of these specifications covering Raceways and Boxes. Install building wire and cable according to other sections of these specifications covering Conductors and Cables. Install signal and communication cable according to other sections of these specifications covering Voice and Data Communication Cabling. 1. 2. 3. 4. 5. Conceal cable, except in mechanical rooms and areas where other conduit and piping are exposed. Install exposed cable in raceway. Install concealed cable in raceway. Bundle and harness multiconductor instrument cable in place of single cables where several cables follow a common path. Fasten flexible conductors, bridging cabinets and doors, along hinge side; protect against abrasion. Tie and support conductors.

3.3 A. B. C.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 20

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 6. 7. D. E.

WBA PROJECT NUMBER 1104024.000

Number-code or color-code conductors for future identification and service of control system, except local individual room control cables. Install wire and cable with sufficient slack and flexible connections to allow for vibration of piping and equipment.

Connect manual-reset limit controls independent of manual-control switch positions. Automatic duct heater resets may be connected in interlock circuit of power controllers. Connect hand-off-auto selector switches to override automatic interlock controls when switch is in hand position. FIELD QUALITY CONTROL Manufacturer's Field Service: Engage a factory-authorized service representative to inspect, test, and adjust components and equipment installation, including connections, and to assist in field testing. Report results in writing. Perform the following field tests and inspections and prepare test reports: 1. Operational Test: After electrical circuitry has been energized, start units to confirm proper unit operation. Remove and replace malfunctioning units and retest. Test and adjust controls and safeties. Leak Test: After installation, charge system and test for leaks. Repair leaks and retest until no leaks exist. Test calibration of electronic controllers by disconnecting input sensors and stimulating operation with compatible signal generator. Test each point through its full operating range to verify that safety and operating control set points are as required. Test each control loop to verify stable mode of operation and compliance with sequence of operation. Adjust PID actions. Test each system for compliance with sequence of operation. Test software and hardware interlocks.

3.4 A.

B.

2. 3. 4. 5. 6. 7. 8. C.

DDC Verification: 1. 2. 3. 4. 5. 6. 7. 8. 9. Verify that instruments are installed before calibration and testing. Check instruments for proper location and accessibility. Check instrument installation for direction of flow, elevation, orientation, insertion depth, and other applicable considerations. Check instrument tubing for proper fittings, slope, material, and support. Check flow instruments. Inspect tag number and line and bore size, and verify that inlet side is identified and that meters are installed correctly. Check pressure instruments, piping slope, installation of valve manifold, and selfcontained pressure regulators. Check temperature instruments and material and length of sensing elements. Check control valves. Verify that they are in correct direction. Check DDC system as follows:

HVAC INSTRUMENTATION AND CONTROLS

230900 - 21

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING a. b. c. D.

WBA PROJECT NUMBER 1104024.000

Verify that wires at control panels are tagged with their service designation and approved tagging system. Verify that spare I/O capacity has been provided. Verify that DDC controllers are protected from power supply surges.

Replace damaged or malfunctioning controls and equipment and repeat testing procedures. ADJUSTING Calibrating and Adjusting: 1. 2. 3. Calibrate instruments. Make three-point calibration test for both linearity and accuracy for each analog instrument. Calibrate equipment and procedures using manufacturer's written recommendations and instruction manuals. Use test equipment with accuracy at least double that of instrument being calibrated. Control System Inputs and Outputs: a. b. c. d. e. 5. Flow: a. b. 6. Set differential pressure flow transmitters for 0 and 100 percent values with 3-point calibration accomplished at 50, 90, and 100 percent of span. Manually operate flow switches to verify that they make or break contact. Check analog inputs at 0, 50, and 100 percent of span. Check analog outputs using milliampere meter at 0, 50, and 100 percent output. Check digital inputs using jumper wire. Check digital outputs using ohmmeter to test for contact making or breaking. Check resistance temperature inputs at 0, 50, and 100 percent of span using a precision-resistant source.

3.5 A.

4.

Pressure: a. b. Calibrate pressure transmitters at 0, 50, and 100 percent of span. Calibrate pressure switches to make or break contacts, with adjustable differential set at minimum.

7.

Temperature: a. b. Calibrate resistance temperature transmitters at 0, 50, and 100 percent of span using a precision-resistance source. Calibrate temperature switches to make or break contacts.

8.

Stroke and adjust control valves and dampers without positioners, following the manufacturer's recommended procedure, so that valve or damper is 100 percent open and closed.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 22

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 9.

WBA PROJECT NUMBER 1104024.000

10. 11.

Stroke and adjust control valves and dampers with positioners, following manufacturer's recommended procedure, so that valve and damper is 0, 50, and 100 percent closed. Provide diagnostic and test instruments for calibration and adjustment of system. Provide written description of procedures and equipment for calibrating each type of instrument. Submit procedures review and approval before initiating startup procedures.

B. C.

Adjust initial temperature and humidity set points. Occupancy Adjustments: When requested within 12 months of date of Substantial Completion, provide on-site assistance in adjusting system to suit actual occupied conditions. Provide up to three visits to Project during other than normal occupancy hours for this purpose. DEMONSTRATION Engage a factory-authorized service representative to train Owner's maintenance personnel to adjust, operate, and maintain HVAC instrumentation and controls.

3.6 A.

PART 4 - SEQUENCE OF OPERATIONS 4.1 AIR COOLED CHILLER(S) SYSTEM CONTROL A. General - The microprocessor based chiller control panel shall monitor and control the chiller(s) or as directed by the chiller sequencing software. The chiller sequencing software shall perform the following control strategies, provide the points as listed on the chiller point list and support their specified monitoring and diagnostics. B. System Scheduling - The chiller sequencing software shall start the chiller system based upon an 8 day (7 + Holiday) time of day schedule. The system shall also start in response to the optimum start, night setback or timed override operation of any system air handler. C. Chiller Sequencing - The chiller sequencing software shall start and stop system water pumps and chillers based upon system load. 1. When the chilled water system is enabled the chiller system control shall: a. b. c. Start the system chilled water pump. Start the lead chiller chilled water pump and prove flow through the evaporator. Start the lead chiller after chilled water is proven.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 23

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 2.

WBA PROJECT NUMBER 1104024.000

The chiller sequencing software shall consider starting another chiller whenever there is deficit flow in the primary - secondary decoupler (bypass) pipe. The chiller sequencing software shall determine when there is deficit flow by measuring the system and chiller return water and decoupler water temperatures. Mixing equations shall then be used to calculate the deficit flow volume. When deficit flow exists continuously for an operator - specified length of time, the chiller sequencing software shall initiate the start of the next chiller in the sequence. a. b. c. Lag chillers shall start in a similar manner to the lead chiller start sequence. The chiller sequencing software will unload operating chillers prior to starting a lag chiller. The BAS shall control each chillers' setpoint t equalize the chiller unloading and meet system demands as the system load varies.

3.

The chiller sequencing software shall consider stopping another chiller whenever the excess flow in the decoupler (bypass) pipe exceeds 120 percent of the next off chiller's flow. The chiller sequencing software shall determine the quantity of excess flow by measuring the system and chiller supply and return water and decoupler water temperatures. Mixing equations shall then be used to calculate the deficit flow volume. When the calculated excess flow exceeds 120 percent (adjustable) of the next off chiller's flow continuously for 15 minutes (adjustable), the chiller sequencing software shall initiate the shutdown of the next chiller in the sequence. The excess flow setpoint and duration shall be easily modifiable by the chiller systems operator. a. The chiller sequencing software shall not shutdown the chiller pump until it has confirmed that the chiller compressor has shutdown.

4.

The chiller sequencing software shall control individual chiller setpoints to the system supply water temperature setpoint. The system setpoint shall be 44.0 degrees F and editable by the operator. Chilled water reset shall not be used because of its affect on secondary chilled water pumping power. Prior to the start of another chiller all operating chillers shall be unloaded. This is done to prevent flow disturbances caused by the starting of another pump from affecting chiller operation. Following confirmation of the additional chiller operation all chillers shall be allowed to reload.

5.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 24

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING 6.

WBA PROJECT NUMBER 1104024.000

Upon sensing a chiller failure the chiller sequencing software shall lockout that chiller and pump and immediately initiate the start of the next chiller in the rotation sequence. Automatic rotation of chiller operation will equalize chiller run time. a. b. Rotation shall be initiated based on an operator entered day interval or by the cycling of a binary point. The method of sequence shall be operator selectable. Chillers maybe forced into a new rotation sequence by cycling chillers at the time of initiation. Alternatively chiller cycling caused by normal system load fluctuations shall cause the chillers to change rotation sequence therefore eliminating unnecessarily chiller cycling.

7.

D.

Chiller Soft Start - The chiller sequencing software will provide a user adjustable loading time at system start-up. This prevent the unnecessary operation of chillers and limits system electrical demand during chilled water loop pulldown. Chiller Status Report - Provide an operating status report for each chiller. The report(s) shall provide the present status of all binary information and for analog information present value, today's average, and the month to date average for the following information to provide the operator with critical chiller operating data. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Compressor On/Off Status. Compressor Starts/Run Hours - Compressor A, B Phase 1/2/3 Percent RLA - Compressor A, B Active Chiller Diagnostics or Alarms Leaving Chilled Water Temperature Entering Chilled Water Temperature Chilled Water Setpoint. Condenser Fan Percent Airflow - Circuit 1, 2 Refrigerant Temperature Evaporator/Condenser - Circuit 1, 2 Operating Mode Chiller Model and Serial Number Percent RLA/Percent Current Limit Outside Air Temperature

E.

F.

SECONDARY CHILED WATER PUMP CONTROL: 1. Start/Stop: The DDC system shall enable the secondary chilled water pump when a chiller status is on. The chilled water pump start/stop relays shall utilize normally open contacts so upon failure of the relay or DDC controller the pump will fail off. Lead / Standby Control: Current status switches, either integral to the VFD and/or discreet devices, shall prove lead and standby pump operation. If the lead pump is called to run and the current status switch indicates that the lead pump is not operating for 30 seconds (adj.), an alarm shall be sent to the operator interface and the DDC system shall start the standby pump. Upon sensing a failed pump is again operating, the standby pump shall be stopped and the normal sequence shall automatically resume. The DDC system shall index the lead pump through weekly

2.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 25

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING

WBA PROJECT NUMBER 1104024.000

scheduling feature of the building automation system or manually as determined by the chiller plant operator.

3.

System Differential Pressure Control: The lead secondary chilled water pump shall be started and shall be modulated to maintain a differential pressure setpoint at the lowest reading differential pressure sensor at AHU-3. Final setpoint shall be optimized by the Balancing Contractor. The DDC system shall maintain a differential pressure setpoint as described below. Constant Differential Pressure Setpoint Control: The operating pump VFD shall be modulated to maintain a constant setpoint of 10 psig (adj.) at the differential pressure sensor. Final setpoint shall be optimized by the Balancing Contractor.

4.

4.2

VAV AIR HANDLING UNIT(s) WITH VENTILATION RESET AND STATIC PRESSURE OPTIMIZATION A. OCCUPIED COOLING MODE When the AHU is in the Occupied Cooling Mode, the Supply Fan shall operate continuously, the Variable Frequency Drive (VFD) shall modulate to maintain the Duct Static Pressure, and the Cooling Valve shall modulate to maintain the cooling Discharge Air Temperature. The return air damper shall be open. The outdoor airflow, as measured at the mechanical room outdoor air supply duct, shall be maintained at a value equal to or higher than the minimum required outdoor airflow. B. UNOCCUPIED MODE When the AHU is in the Unoccupied Mode, the Supply Fan shall be OFF, the VFD, Outdoor Air Damper, the return air damper, and Cooling Valve will be closed. C. NIGHT SETBACK (NSB) / MORNING WARM-UP HEATING MODE (MWU) When the AHU is in the Night Setback / Morning Warm-up Heating Mode, the Supply Fan shall operate continuously, the VFD shall modulate to maintain the Duct Static Pressure, the Outdoor Air Damper and Cooling Valve will be closed, the Return Air Damper will be fully open, and the Electric Heater SCR shall modulate to maintain the maximum heating Discharge Air Temperature setpoint. All VAV Terminal Units shall disable local heat and operate in their VAV heating mode until the NSB/MWU criteria is satisfied and the AHU returns to the occupied or unoccupied mode. D. SUPPLY FAN CONTROL The Supply Fan will operate continuously whenever the AHU is in either the Occupied Cooling Mode or the Night Setback / Morning Warm-up Heating Mode.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 26

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING

WBA PROJECT NUMBER 1104024.000

The Supply Fan will be OFF whenever the AHU is in the Unoccupied Mode, the Stop / Auto interlock is open, the Mixed Air Low Limit is tripped, or the Supply Fan Status indicates a failure (after a two minute delay). The Low Limit and the Fan Failure require a manual reset. E. VARIABLE FREQUENCY DRIVE CONTROL When the Supply Fan is ON, the VFD shall slowly ramp (adjustable) up and modulate to maintain the proper Discharge Duct Static Pressure Setpoint. Determination of the Discharge Duct Static Pressure Setpoint will be per the Discharge Duct Static Pressure Setpoint section of the AHU System Level Operation section of this specification. The VFD shall turn OFF if the Supply Fan is OFF or the Duct Static Pressure Sensor fails. F. ELECTRIC HEATER CONTROL The Heater SCR shall modulate to maintain the Discharge Air Temperature at the NSB/MWU Discharge Air Heating Setpoint. The Heater shall be enabled to operate during the occupied cooling mode so it can maintain the cooling discharge air temperature setpoint as required. The Heater shall be turned Off if the Cooling Valve is open. The Heater shall be OFF if the Supply Fan is OFF. G. COOLING VALVE CONTROL The Cooling Valve shall modulate to maintain the Discharge Air Temperature at the Discharge Cooling Setpoint. The Cooling Valve shall be closed if the AHU is in the Heating mode, the Supply Fan is OFF, or the Discharge Air Sensor has failed. H. BUILDING AUTOMATION SYSTEM INTERFACE The Building Automation System (BAS) shall send the AHU a Discharge Air Temperature Setpoint, a Discharge Duct Static Pressure Setpoint and a Minimum Required Outdoor Airflow Setpoint. The BAS shall also send Start-up, Occupied, Pre-Occupancy Ventilation, Unoccupied, Morning Warm-up, Heating / Cooling, Timed Override, Startup, Coastdown, Night Setback, and Priority Shutdown commands. If communication with the BAS is lost, the AHU uses its default setpoints and operates in the Occupied Cooling mode. The last known Minimum Required Outdoor Airflow Setpoint will be maintained. I. AHU SYSTEM LEVEL OPERATION 1. DEMAND CONTROL VENTILATION

The level of CO2 concentration in the return air shall be continuously monitored during the Occupied Mode. When the return air CO2 concentration is less than 900 PPM, the mechanical room Outdoor Air Damper shall be controlled to deliver the minimum outdoor airflow to the respective air handler. The minimum outdoor airflow shall be equal to the floor exhaust air flow rate as determined by the Test HVAC INSTRUMENTATION AND CONTROLS 230900 - 27

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING

WBA PROJECT NUMBER 1104024.000

and Balance report. The actual outdoor airflow shall be sensed at the outdoor air supply duct serving the mechanical room. Upon a rise in the CO2 level beyond 1100 PPM (adjustable), the outdoor air damper shall modulate toward full open position. Upon a drop in the level of CO2 concentration below 900 PPM (adjustable), the reverse shall occur. Prior to final system acceptance, a trend log of actual air system operation over a typical forty-eight hour period will be required by the engineer and owner. System operating conditions to be logged include: system supply air flow, calculated outdoor airflow setpoint and actual measured outdoor airflow at 15 minute intervals.

2.

Discharge Duct Static Pressure Setpoint The building automation system shall continuously monitor the damper position of all VAV terminal units. The discharge duct static pressure shall be sensed 2/3 down the main supply air duct. The sensor must be mounted in a non-turbulent location. When any damper is more than 95% (adj) open, the supply fan discharge duct static pressure setpoint shall be reset upward by 5% (adj) of the maximum system static pressure setpoint at a frequency of 10 minutes (adj) until no damper is more than 95% open or the static pressure setpoint has reset upward to the system maximum setting or the VFD is at its maximum setting. When all dampers are less than 85% (adj) open, the supply fan discharge duct static pressure setpoint shall be reset downward by 5% (adj) of the maximum system static pressure setpoint at a frequency of 10 minutes (adj) until any damper is more than 85% open or the static pressure setpoint has reset downward to the system minimum setting or the VFD is at its minimum setting. The control bands, setpoint increment values, setpoint decrement values and adjustment frequencies shall be adjusted to maintain maximum static pressure optimization with stable system control and maximum comfort control.

4.3

TERMINAL UNITS- VAV A. Unit shall be controlled by a Terminal Unit Controller mounted directly to the terminal unit. The BAS system shall communicate with the Terminal Unit Controller to send setpoints and commands as required per the sequence of operations. If zone temperature is between cooling and heating setpoints (in deadband), unit will be in NEITHER heating nor cooling mode. Damper shall modulate to maintain minimum design airflow rate. Cooling Mode: If zone temperature exceeds the cooling temperature setpoint, unit will be placed in Cooling Mode. Damper shall modulate using a PI loop be-

B.

D.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 28

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING

WBA PROJECT NUMBER 1104024.000

tween scheduled maximum and minimum air flows to meet zone temperature setpoint. E. Heating Mode: If the unit damper is at minimum position and zone temperature falls below heating setpoint, unit will be placed in Heating Mode. Upon a further drop in zone temperature, the electric heater shall be staged ON to maintain space temperature. Zone Temperature Setpoints: Except for the common area, the occupant shall be able to adjust the zone cooling and heating temperature setpoints at the zone thermostat. The amount by which the occupant is able to adjust setpoints shall be 2F (adjustable). There shall be separate heating and cooling setpoints adjustable through the BAS system subject to the following limitations. There shall be a minimum differential (deadband) between heating and cooling setpoints of 3F (adjustable). If a cooling or heating setpoint input is attempted that is less than this differential, then the setpoint shall be automatically adjusted so that the minimum differential is maintained. Cooling setpoints, including any occupant adjustments at the thermostat, may not be below 72F (adjustable). Heating setpoints, including any occupant adjustments at the thermostat, may not be above 69F (adjustable).

F.

4.4

Terminal Unit VAV, Parallel Fan Powered

A.

Unit shall be controlled by a Terminal Unit Controller mounted directly to the terminal unit. The BAS system shall communicate with the Terminal Unit Controller to send setpoints and commands as required per the sequence of operations. If zone temperature is between cooling and heating setpoints (in deadband), unit will be in NEITHER heating nor cooling mode. Damper shall modulate to maintain minimum design airflow rate. Cooling Mode: If zone temperature exceeds the cooling temperature setpoint unit will be placed in Cooling Mode. Damper shall modulate using a PI loop between programmed maximum and minimum air flows to meet zone temperature setpoint. During cooling mode both electric heat and fan shall be off. Heating Mode: If the unit damper is at minimum position and zone temperature falls below heating setpoint, unit will be placed in Heating Mode. Terminal unit fan shall engage to mix plenum/ return air into the primary air stream to be discharged in to the zone. If the zone temperature continues to fall, the electric heat shall be staged to maintain zone temperature setpoint. As the zone temperature rises, the reverse order shall occur as necessary to maintain zone temperature setpoint. Zone Temperature Setpoints: Except for the common area, the occupant shall be able to adjust the zone cooling and heating temperature setpoints at the zone

B.

C.

D.

E.

HVAC INSTRUMENTATION AND CONTROLS

230900 - 29

BAPTIST MEDICAL CENTER CLAY COUNTY MEDICAL OFFICE BUILDING

WBA PROJECT NUMBER 1104024.000

thermostat. The amount by which the occupant is able to adjust setpoints shall be 2F (adjustable). There shall be separate heating and cooling setpoints adjustable through the BAS system subject to the following limitations.There shall be a minimum differential (deadband) between heating and cooling setpoints of 3F (adjustable). If a cooling or heating setpoint input is attempted that is less than this differential, then the setpoint shall be automatically adjusted so that the minimum differential is maintained. Cooling setpoints, including any occupant adjustments at the thermostat, may not be below 72F (adjustable). Heating setpoints, including any occupant adjustments at the thermostat, may not be above 69F (adjustable). END OF SECTION 230900

HVAC INSTRUMENTATION AND CONTROLS

230900 - 30

Das könnte Ihnen auch gefallen

- Hydrastep and Hydratect Water/Steam Monitoring SystemsDokument12 SeitenHydrastep and Hydratect Water/Steam Monitoring Systemscytech6619Noch keine Bewertungen

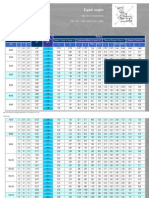

- Checkered PlatesDokument1 SeiteCheckered PlatesRamilArtatesNoch keine Bewertungen

- A08 eDokument3 SeitenA08 ecytech6619Noch keine Bewertungen

- Clamp ConnectorsDokument3 SeitenClamp Connectorscytech6619Noch keine Bewertungen

- Channels: Tis / Jis Standards (TIS 1227: 1996 / JIS G3192: 1990)Dokument2 SeitenChannels: Tis / Jis Standards (TIS 1227: 1996 / JIS G3192: 1990)cytech6619Noch keine Bewertungen

- 12 MGDP I 1150 0 (Instr Utility Air Calculation)Dokument2 Seiten12 MGDP I 1150 0 (Instr Utility Air Calculation)cytech6619Noch keine Bewertungen

- Hydrastep & Hydratect Water/steam Monitoring Systems: Solartron Mobrey LTD B246801Dokument7 SeitenHydrastep & Hydratect Water/steam Monitoring Systems: Solartron Mobrey LTD B246801cytech6619Noch keine Bewertungen

- Non-Insulated Terminals & Sleeves: For Safety UseDokument1 SeiteNon-Insulated Terminals & Sleeves: For Safety Usecytech6619Noch keine Bewertungen

- Sensepoint XCD: Flammable, Toxic and Oxygen Gas Detector For Industrial ApplicationsDokument8 SeitenSensepoint XCD: Flammable, Toxic and Oxygen Gas Detector For Industrial Applicationscytech6619Noch keine Bewertungen

- Flat BarsDokument3 SeitenFlat Barscytech6619Noch keine Bewertungen

- Hydrastep and Hydratect Water/Steam Monitoring SystemsDokument12 SeitenHydrastep and Hydratect Water/Steam Monitoring Systemscytech6619Noch keine Bewertungen

- Carbon Steel PipeDokument2 SeitenCarbon Steel PipemadooNoch keine Bewertungen

- Hydrastep WorkingDokument166 SeitenHydrastep WorkingAyan ChattarajNoch keine Bewertungen

- 2851 - MS Electrical WorksDokument16 Seiten2851 - MS Electrical WorksleoconsolacionNoch keine Bewertungen

- Equal AnglesDokument2 SeitenEqual Anglescytech6619Noch keine Bewertungen

- Deformed BarsDokument1 SeiteDeformed Barscytech6619Noch keine Bewertungen

- Dell PowerEdge 4Post and 2Post Rack Rail InstallationDokument8 SeitenDell PowerEdge 4Post and 2Post Rack Rail Installationcytech6619Noch keine Bewertungen

- Dell PowerEdge 4Post and 2Post Rack Rail InstallationDokument8 SeitenDell PowerEdge 4Post and 2Post Rack Rail Installationcytech6619Noch keine Bewertungen

- DELL PowerEdge R710 Technical GuideBookDokument63 SeitenDELL PowerEdge R710 Technical GuideBooksimon_sparks_1Noch keine Bewertungen

- Rack Guide v20Dokument37 SeitenRack Guide v20cytech6619Noch keine Bewertungen

- Checkered PlateDokument1 SeiteCheckered Platecytech6619Noch keine Bewertungen

- Sliding Rail Kit For Dell Servers: Installation Instructions P/N: 2URAIL-R7 P/N: 2UARM-R7 (Optional)Dokument4 SeitenSliding Rail Kit For Dell Servers: Installation Instructions P/N: 2URAIL-R7 P/N: 2UARM-R7 (Optional)cytech6619Noch keine Bewertungen

- Earthtags LocknutsDokument1 SeiteEarthtags Locknutscytech6619Noch keine Bewertungen

- Accessories: Nylon & Red Fibre Washers Serrated WasherDokument1 SeiteAccessories: Nylon & Red Fibre Washers Serrated Washercytech6619Noch keine Bewertungen

- Insulated Adaptors ShroudsDokument1 SeiteInsulated Adaptors Shroudscytech6619Noch keine Bewertungen

- 475 477Dokument1 Seite475 477cytech6619Noch keine Bewertungen

- Type 475 / 477 Stopping Plug InstructionsDokument1 SeiteType 475 / 477 Stopping Plug Instructionscytech6619Noch keine Bewertungen

- Thin Wall Section of Enclosure: Earth TagDokument1 SeiteThin Wall Section of Enclosure: Earth Tagcytech6619Noch keine Bewertungen

- 487 489Dokument1 Seite487 489cytech6619Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- What Is System Software and Application Software? Explain With ExampleDokument19 SeitenWhat Is System Software and Application Software? Explain With ExampleYUVRAJ SINGHNoch keine Bewertungen

- Barracuda Load Balancer FeaturesDokument3 SeitenBarracuda Load Balancer FeaturesRahul KumarNoch keine Bewertungen

- Machine-to-Machine Communications (M2M) 3GPP Interworking: Technical SpecificationDokument15 SeitenMachine-to-Machine Communications (M2M) 3GPP Interworking: Technical Specificationad444Noch keine Bewertungen

- Use Case Applying Vlan Insertion Industrial ScadaDokument7 SeitenUse Case Applying Vlan Insertion Industrial Scadaantonio hh100% (1)

- Omnipeek GettingStartedDokument85 SeitenOmnipeek GettingStartedchris100% (1)

- Open-Source Multi-Access Edge Computing For 6G Opportunities and ChallengesDokument14 SeitenOpen-Source Multi-Access Edge Computing For 6G Opportunities and ChallengeskevincosbarNoch keine Bewertungen

- 0 JDSU - W1314A - Spec - Configuration GuideDokument20 Seiten0 JDSU - W1314A - Spec - Configuration GuideSuraj JoshiNoch keine Bewertungen

- MGI The Social Economy Full ReportDokument184 SeitenMGI The Social Economy Full ReportpdfalNoch keine Bewertungen

- Exam-Part-1/ Guide-April-2019-Corrected-Flash-Cards/: A System Logs B Activity LogsDokument16 SeitenExam-Part-1/ Guide-April-2019-Corrected-Flash-Cards/: A System Logs B Activity LogsAvi SutantoNoch keine Bewertungen

- Comprehensive Medical Assisting Administrative and Clinical Competencies 6th Edition Lindh Solutions ManualDokument15 SeitenComprehensive Medical Assisting Administrative and Clinical Competencies 6th Edition Lindh Solutions Manualanthonyhollowayxqkfprdjew100% (28)

- PV Plants Connecting To NetEco 1000S Smart PV Management System Quick Guide (Inverters + SmartLogger3000 + MBUS Networking)Dokument5 SeitenPV Plants Connecting To NetEco 1000S Smart PV Management System Quick Guide (Inverters + SmartLogger3000 + MBUS Networking)Gaurav pawarNoch keine Bewertungen

- Mac OS X Security TipsDokument33 SeitenMac OS X Security TipsRafael BortolatoNoch keine Bewertungen

- 8.1.4.7 Packet Tracer - Subnetting Scenario 1Dokument5 Seiten8.1.4.7 Packet Tracer - Subnetting Scenario 1ParthPatel33% (6)

- Non-Functional Requirements ChecklistDokument18 SeitenNon-Functional Requirements ChecklistGopalakrishnan5100% (3)

- 2019 Book DataScienceAndBigDataAnalyticsDokument418 Seiten2019 Book DataScienceAndBigDataAnalyticsfrmalthus100% (6)

- Cisco 800M Series Integrated Services Routers Software Configuration GuideDokument134 SeitenCisco 800M Series Integrated Services Routers Software Configuration GuideSteven HtooNoch keine Bewertungen

- 4 Network-Building-BlocksDokument14 Seiten4 Network-Building-BlocksSalma SaleemNoch keine Bewertungen

- Silabus Training FortiGate PDFDokument15 SeitenSilabus Training FortiGate PDFhmuslimsNoch keine Bewertungen