Beruflich Dokumente

Kultur Dokumente

Saddle 1

Hochgeladen von

RUDHRA DHANASEKARCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Saddle 1

Hochgeladen von

RUDHRA DHANASEKARCopyright:

Verfügbare Formate

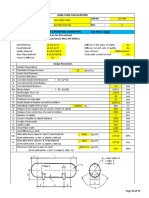

Page

L4

L1

a

tr H1 H Ws L3

x

tw

y x Wb

tb H3

H2

ts

L4

(Typ.)

L2

B Lb

Vessel Outside Diameter Wrapper Plate Thickness Saddle Included Angle Wrapper Plate Included Angle Wrapper Plate Width Height from Saddle base to Vessel CL Saddle Stiffener Thickness Web Plate Thickness Saddle Width Base Plate Width Distance from Saddle CL to outer Anchor Bolt CL Base Plate Thickness Base Plate Length Distance from Outer Stiffener CL to Vessel CL Distance from CL of web to CL of Anchor Bolt Distance from edge of Web to edge of Base

Do tr 2 a 2 (g + a) Wr H ts tw Ws Wb B tb Lb L2 L3 L4

= = = = = = = = = = = = = = = =

1219 9.53 120 132 250 1390 9 9 150 250 450 15.875 1125 350 60 25

mm mm Deg Deg mm mm mm mm mm mm mm mm mm mm mm mm

(A 516M Gr.485)

(A 36M OR EQ.) (A 36M OR EQ.)

(A 36M OR EQ.)

Height from Saddle base to outer stiffener H - ((Do/2) + tr)) x Cos Outer Stiffener Height H - ((Do/2 + tr)^2 - L2^2)^0.5 - tb Inner Stiffener Height H - (Do/2 + tr) - tb Overall Length of Saddle 2 x Sin a x (Do /2 + tw) Cross Sectional Area of a Saddle Stiffeners 3 x (ts x (Ws-tw) + (tw x L1) Minimum Saddle Section Modulus (3 x ts x (Ws^2/6)) + (Lb - (3 x ts x (tw^2/6)) Minimum Saddle Section Modulus (tw x (Lb^2/6)) + (5 x (Ws - tw)/L x (tw^2/6)) Base Plate Section Modulus Wb x tb^2/6

H1

1080

mm

H2

864

mm

H3

755

mm

L1

1072

mm

As

#REF!

mm^2

Zxx

#REF!

mm^3

Zyy

#REF!

mm^3

Zb

10501

mm^3

Page

STRESSES IN SADDLE WRAPPER PLATE Ref BS5276 Pt 2 Wrapper Plate Inside Radius Angle b 180 - a Maximum Reaction Load at Saddle (FPSO Motion) Consider a 1mm wide strip of Wrapper Plate Load/unit Width R/Rr x (1 + Cosb P )/(( 3.14159 b) + (b Cos )b x ( Sin )) q = #REF! N/mm^2 = #REF! N/mm width Rr b = = 609.53 120 mm Deg = 2.094 Rads

#REF!

Load per unit area of Wrapper Plate P/Wr Ref Roark & Young Table 26 Case 9a for

a b a/b b1 fbr

= = = = =

341.0 70.5 4.837 0.718 #REF!

mm mm

Maximum Bending Stress in Wrapper Plate b1 x q x b^2/tr^2 Shear Stress in Saddle Wrapper Plate P/(2 x tr) Bearing Stress in Wrapper Plate P/tw STRESSES IN BASE PLATE (Compressive Loading)

N/mm^2

#REF!

fsr

#REF!

N/mm^2

#REF!

fpr

#REF!

N/mm^2

#REF!

Assume that the saddle is sufficiently rigid to distribute the compressive load uniformly over the total base plate area. Consider a 1mm wide strip of Base Plate Load per unit width of Base Plate R/L Load per unit area P/Wb Ref Roark & Young Table 26 Case 10a for P = #REF! N/mm width

#REF!

MPa

a b a/b b1 fbb

= = = = =

341.0 70.5 4.837 2.105 #REF!

mm mm

Maximum Bending Stress in Base Plate b1 x q x b^2/tb^2 Shear Stress in Saddle Base Plate P/(2 x tb) Bearing Stress in Base Plate P/tw

N/mm^2

#REF!

fsr

#REF!

N/mm^2

#REF!

fpr

#REF!

N/mm^2

#REF!

Page

Lateral Tensile Stress in Saddle Horizontal Load in Saddle is given by Saddle Included Angle Hence Therefore Maximum Saddle Height that can resist Fh Do/6 Actual Height used for calculation of Tensile Stress Min. of H4 or H3-tb Area resisting Fh H5 x tw +Wr x tr Tensile Stress in Saddle Fh/Ash Fh 2 a K9 Fh H4 = = = = = W x K9 120 0.88 #REF! 203 Deg (Ref BS5500 App G.3.3.2.6) N

H5

203

Ash

1829

mm^2

fts

#REF!

N/mm^2

#REF!

WEB PLATE Maximum Height of Web and Outer Stiffeners Ref. BS 449 Clause 27f for Grade 43 steel Minimum permissible thickness of Web H1//180 tw(min) = 5.91 mm OK H1 = 1065 mm

Note : A 516M Gr.485 Min. Yield Stress Min. Allowable Stress Allowable Bending Stress Allowable Compressive Stress Allowable Shear Stress Allowable Bearing Stress Allowable Tensile Stress Sy Sa = = 262.00 137.89 172.92 157.20 110.31 220.62 157.20 N/mm^2 N/mm^2 N/mm^2 N/mm^2 N/mm^2 N/mm^2 N/mm^2 A 36M OR EQ. 248.22 114.46 163.83 148.93 91.57 183.13 148.93 N/mm^2 N/mm^2 N/mm^2 N/mm^2 N/mm^2 N/mm^2 N/mm^2

Sb = Sc = Ss = Sbr = St =

Das könnte Ihnen auch gefallen

- Pressure Vessel SupportDokument36 SeitenPressure Vessel SupportAndreea Luca80% (5)

- Zick Analysis For Saddle SupportDokument8 SeitenZick Analysis For Saddle Supportfuransu777100% (1)

- Welcome To Presentation On: Pipe Support Systems & Piping FlexibilityDokument67 SeitenWelcome To Presentation On: Pipe Support Systems & Piping Flexibilitysids8292% (24)

- Section VIII CalDokument19 SeitenSection VIII CalPradeep Kothapalli100% (1)

- Anchor Bolt DesignDokument2 SeitenAnchor Bolt Designmail2meanwar7865Noch keine Bewertungen

- Pinned and fixed base plate design calculations for I-section and tube columnsDokument7 SeitenPinned and fixed base plate design calculations for I-section and tube columnsabdul karee100% (6)

- Dubbel-Handbook of Mechanical EngineeringDokument918 SeitenDubbel-Handbook of Mechanical EngineeringJuan Manuel Domínguez93% (27)

- Saddle v1-10: Fixed Saddle Sliding SaddleDokument30 SeitenSaddle v1-10: Fixed Saddle Sliding SaddleidiazgNoch keine Bewertungen

- Saddle CalculationDokument7 SeitenSaddle CalculationMichael HaiseNoch keine Bewertungen

- End Plate ConnectionDokument10 SeitenEnd Plate ConnectionMohamed Tahar Allagui100% (1)

- StaircaseDokument8 SeitenStaircaseVenkat BalajiNoch keine Bewertungen

- How To Calculate Flat Plate Thickness of Flat Bottom Storage TankDokument3 SeitenHow To Calculate Flat Plate Thickness of Flat Bottom Storage TankSiva baalanNoch keine Bewertungen

- Base Plate Design Is 800-2007Dokument6 SeitenBase Plate Design Is 800-2007Suneesh P91% (11)

- 3-Leg Calculation for Vertical Vessel SupportDokument21 Seiten3-Leg Calculation for Vertical Vessel SupportBahtiar Anak LaNangNoch keine Bewertungen

- Nozzle Reinf Calc (Rough)Dokument12 SeitenNozzle Reinf Calc (Rough)Sajal Kulshrestha100% (1)

- Bridge Bearing Main - 2 Design Calculation (R-0)Dokument27 SeitenBridge Bearing Main - 2 Design Calculation (R-0)mohan1441Noch keine Bewertungen

- Saddle CalcDokument26 SeitenSaddle CalcVamsi S100% (2)

- Column Base Plate DesignDokument5 SeitenColumn Base Plate Design_jessecaNoch keine Bewertungen

- Lifting Lug Calc - VerticalDokument7 SeitenLifting Lug Calc - Verticaljahiranazri100% (1)

- Saddle Support Calculation PD 5500,2000 Annex.G)Dokument26 SeitenSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Saddle Design at Operating ConditionDokument17 SeitenSaddle Design at Operating ConditionGanesh Bhardwaj100% (2)

- Design Calculation Sheet: H2So4 Neutralization TankDokument43 SeitenDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNoch keine Bewertungen

- Storage Tank Design Calculations for Hydrogen PeroxideDokument12 SeitenStorage Tank Design Calculations for Hydrogen Peroxidechompink6900Noch keine Bewertungen

- Nozzle Loads WRC 107 Ver 1.1Dokument5 SeitenNozzle Loads WRC 107 Ver 1.1Honey Tiwari75% (4)

- Hvac Formulas PDFDokument25 SeitenHvac Formulas PDFSaraswatapalit0% (1)

- Project Name DOC. No.: Tank Name Rev No.: Item No.Dokument4 SeitenProject Name DOC. No.: Tank Name Rev No.: Item No.AnggaNoch keine Bewertungen

- HVAC Ducting - Principles and FundamentalsDokument56 SeitenHVAC Ducting - Principles and FundamentalsRiddhi Patel100% (1)

- Anchor Chair Design CheckDokument5 SeitenAnchor Chair Design CheckManish542Noch keine Bewertungen

- Design of Tail LugDokument34 SeitenDesign of Tail LugPrajwal Shetty100% (1)

- Design of Saddle Support For VesselDokument5 SeitenDesign of Saddle Support For Vesseltvmehta01Noch keine Bewertungen

- Calculating saddle dimensions for pipesDokument2 SeitenCalculating saddle dimensions for pipesrinabiswas50% (2)

- Crane Load-Chemical Storage ShelterDokument44 SeitenCrane Load-Chemical Storage ShelterAndreas HendiNoch keine Bewertungen

- End Plate DesignDokument4 SeitenEnd Plate DesignAgnon Fung100% (4)

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Dokument32 SeitenPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNoch keine Bewertungen

- Reinforcement Pad DesignDokument3 SeitenReinforcement Pad DesignAkshat JainNoch keine Bewertungen

- Three Saddle Supports For Horizontal VesselDokument7 SeitenThree Saddle Supports For Horizontal VesselhuangjlNoch keine Bewertungen

- Strength of Materials - Torsion of Circular Cross Section - Hani Aziz AmeenDokument31 SeitenStrength of Materials - Torsion of Circular Cross Section - Hani Aziz AmeenHani Aziz Ameen80% (15)

- Horizontal Vessel Stress AnalysisDokument12 SeitenHorizontal Vessel Stress AnalysissridharNoch keine Bewertungen

- Parents' Handbook of Careers After SchoolDokument32 SeitenParents' Handbook of Careers After Schoolraj50% (4)

- PFS FWKO Tank EvaluationDokument12 SeitenPFS FWKO Tank EvaluationkoyahassanNoch keine Bewertungen

- Vessel support designDokument5 SeitenVessel support designAzwa Onexox75% (4)

- Science 6 1st Quarter TestDokument4 SeitenScience 6 1st Quarter TestkentNoch keine Bewertungen

- Stiffness Coefficients For Nozzles in API 650 Tanks PDFDokument8 SeitenStiffness Coefficients For Nozzles in API 650 Tanks PDFvijay10484100% (1)

- AutoPipe Vessel PresentationDokument32 SeitenAutoPipe Vessel PresentationRUDHRA DHANASEKARNoch keine Bewertungen

- Api 610Dokument11 SeitenApi 610prakasharmyNoch keine Bewertungen

- Scantling Calculation Design CheckDokument6 SeitenScantling Calculation Design CheckShyamshesha GiriNoch keine Bewertungen

- Column Base Plate DesignDokument4 SeitenColumn Base Plate Design_jessecaNoch keine Bewertungen

- Skirt Support TrialDokument11 SeitenSkirt Support TrialAbhishek Nag0% (1)

- Davit CalcDokument6 SeitenDavit Calcrustamriyadi100% (1)

- FIRE WATER TANK-API-650-Calculation-Report - RVDDokument42 SeitenFIRE WATER TANK-API-650-Calculation-Report - RVDahmed aboyosefNoch keine Bewertungen

- Single Shear Steel ConnectionDokument36 SeitenSingle Shear Steel ConnectionNatalie WestNoch keine Bewertungen

- Design and Study of Floating Roof For Oil Storage TanksDokument20 SeitenDesign and Study of Floating Roof For Oil Storage TanksswaminathanNoch keine Bewertungen

- Lug SupportDokument2 SeitenLug SupportSachin5586Noch keine Bewertungen

- Saddle Road Transportation Analysis 1Dokument2 SeitenSaddle Road Transportation Analysis 1vpjagannaathNoch keine Bewertungen

- Camera CalibrationDokument39 SeitenCamera CalibrationyokeshNoch keine Bewertungen

- Total Middle East New Bitumen Terminal in TlbuDokument25 SeitenTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Base Ring Fillet Size CalculationDokument4 SeitenBase Ring Fillet Size Calculationmiteshpatel191Noch keine Bewertungen

- Saddle Calc PD5500Dokument4 SeitenSaddle Calc PD5500rsubramaniNoch keine Bewertungen

- Saddle CalculationDokument10 SeitenSaddle Calculationpharis_chrisNoch keine Bewertungen

- Man Crane Cages Check Sheet GuideDokument1 SeiteMan Crane Cages Check Sheet GuideRUDHRA DHANASEKAR100% (1)

- Longitudinal Bending Stress: M1 Allowable Limit RemarkDokument16 SeitenLongitudinal Bending Stress: M1 Allowable Limit RemarkSandal JepitNoch keine Bewertungen

- Introduction to Slag Fundamentals Under 40 CharactersDokument38 SeitenIntroduction to Slag Fundamentals Under 40 CharactersNicole Altamirano Catalán100% (1)

- Wind Seismic Calculation DataDokument8 SeitenWind Seismic Calculation Dataaknauriyal2013Noch keine Bewertungen

- Scantling Calculation 1031Dokument9 SeitenScantling Calculation 1031ShifatMahmudRumman100% (5)

- Nozzle Load AnalysisDokument2 SeitenNozzle Load Analysisvm153748763Noch keine Bewertungen

- NozzleDokument11 SeitenNozzleharyfadlyNoch keine Bewertungen

- Tailing Lug - 173004-05Dokument1 SeiteTailing Lug - 173004-05shazan100% (1)

- Calculation of left and right saddle supports for offshore tankerDokument12 SeitenCalculation of left and right saddle supports for offshore tankerrustamriyadiNoch keine Bewertungen

- Calculation LugDokument20 SeitenCalculation LugKartika ZuhraNoch keine Bewertungen

- Tappi 550Dokument8 SeitenTappi 550Alberto Koji TakakuraNoch keine Bewertungen

- Saddle 3Dokument3 SeitenSaddle 3RUDHRA DHANASEKAR100% (1)

- ANCHOR BOLT DESIGN - Gulf Publishing - Pressure Vessel Design Manual 3rd Edition 195Dokument1 SeiteANCHOR BOLT DESIGN - Gulf Publishing - Pressure Vessel Design Manual 3rd Edition 195Alessio BarboneNoch keine Bewertungen

- 28 Roark Flat PlatesDokument14 Seiten28 Roark Flat Platesgutmont0% (1)

- WRC Check List CriteriaDokument1 SeiteWRC Check List CriteriaAlvin Smith100% (1)

- Design Parameter:-Geo-ParameterDokument50 SeitenDesign Parameter:-Geo-ParameterpandyatusharNoch keine Bewertungen

- Cygnus Surface Brochure Iss7Dokument12 SeitenCygnus Surface Brochure Iss7RUDHRA DHANASEKARNoch keine Bewertungen

- Kill Your Limiting Beliefs PDFDokument8 SeitenKill Your Limiting Beliefs PDFBhupesh PatelNoch keine Bewertungen

- PE FeestructDokument1 SeitePE FeestructRUDHRA DHANASEKARNoch keine Bewertungen

- Gc-27 (West Kuwait) : Arabi Enertech K.S.CDokument1 SeiteGc-27 (West Kuwait) : Arabi Enertech K.S.CRUDHRA DHANASEKARNoch keine Bewertungen

- Power Capacity HVAC CalculationDokument12 SeitenPower Capacity HVAC CalculationEdNoch keine Bewertungen

- M-2214 - SHT 2 PDFDokument1 SeiteM-2214 - SHT 2 PDFRUDHRA DHANASEKARNoch keine Bewertungen

- Diploma in Industrial Safety 1 Yr. HAZARDS IN WORK PLACES (DIS-1) (4031504)Dokument2 SeitenDiploma in Industrial Safety 1 Yr. HAZARDS IN WORK PLACES (DIS-1) (4031504)RUDHRA DHANASEKARNoch keine Bewertungen

- Pipe SupportDokument5 SeitenPipe SupportRUDHRA DHANASEKARNoch keine Bewertungen

- Syllabus - : Week 1 2: Simulation Tool TrainingDokument16 SeitenSyllabus - : Week 1 2: Simulation Tool TrainingRUDHRA DHANASEKARNoch keine Bewertungen

- Li Cad 10 SettingsDokument2 SeitenLi Cad 10 SettingsRUDHRA DHANASEKARNoch keine Bewertungen

- Lifting DetailDokument1 SeiteLifting DetailRUDHRA DHANASEKARNoch keine Bewertungen

- Symbols Pipe SupportDokument1 SeiteSymbols Pipe SupportRUDHRA DHANASEKARNoch keine Bewertungen

- Bottle SupportsDokument2 SeitenBottle SupportsRUDHRA DHANASEKARNoch keine Bewertungen

- Internal & DetailDokument1 SeiteInternal & DetailRUDHRA DHANASEKARNoch keine Bewertungen

- What's New - PV Elite 2018Dokument36 SeitenWhat's New - PV Elite 2018RUDHRA DHANASEKARNoch keine Bewertungen

- Trigonometry Formulas PDFDokument2 SeitenTrigonometry Formulas PDFsasi15augNoch keine Bewertungen

- Ga-Key PlanDokument1 SeiteGa-Key PlanRUDHRA DHANASEKARNoch keine Bewertungen

- Algebra Formulas Cheat SheetDokument3 SeitenAlgebra Formulas Cheat Sheetyuvarajr30Noch keine Bewertungen

- What S New - PV Elite 2018Dokument5 SeitenWhat S New - PV Elite 2018NirmalNoch keine Bewertungen

- Series FormulasDokument3 SeitenSeries FormulasBachchan MishraNoch keine Bewertungen

- Reflectarray AntennaDokument27 SeitenReflectarray AntennaVISHNU UNNIKRISHNANNoch keine Bewertungen

- ASTM C 226 - 02 Standard Speci Cation For Air-Entraining Additions For Use in The Manufacture of Air-Entraining Hydraulic CementDokument4 SeitenASTM C 226 - 02 Standard Speci Cation For Air-Entraining Additions For Use in The Manufacture of Air-Entraining Hydraulic CementfilipeNoch keine Bewertungen

- Limit Test of Arsenic and Lead: - Tashi (91901263048)Dokument17 SeitenLimit Test of Arsenic and Lead: - Tashi (91901263048)Tshering Yangzom NamdaNoch keine Bewertungen

- Behavior of Steel Under TensionDokument6 SeitenBehavior of Steel Under TensionAshNoch keine Bewertungen

- Coefficient Estimation in The Dynamic Equations of Motion of An AUVDokument4 SeitenCoefficient Estimation in The Dynamic Equations of Motion of An AUVanitapinkyNoch keine Bewertungen

- Introduction and Basic Concepts: (Iii) Classification of Optimization ProblemsDokument19 SeitenIntroduction and Basic Concepts: (Iii) Classification of Optimization Problemsaviraj2006Noch keine Bewertungen

- Meteoric Water Mobility ProcedureDokument6 SeitenMeteoric Water Mobility ProcedureJose ValdesNoch keine Bewertungen

- Humanoid RobotsDokument17 SeitenHumanoid RobotsPaul JacksonNoch keine Bewertungen

- The Relation Between Expressions for Time-Dependent Electromagnetic Fields Given by Jefimenko and Panofsky and PhillipsDokument8 SeitenThe Relation Between Expressions for Time-Dependent Electromagnetic Fields Given by Jefimenko and Panofsky and PhillipsCarolina BouvierNoch keine Bewertungen

- Numerical Scheme To Modeling Open Channels-5 PDFDokument10 SeitenNumerical Scheme To Modeling Open Channels-5 PDFOdalis MatuteNoch keine Bewertungen

- Cantilever Discussion and ResultDokument12 SeitenCantilever Discussion and ResultYewHang SooNoch keine Bewertungen

- ASTM Standard For Metallic Bone PlateDokument7 SeitenASTM Standard For Metallic Bone PlatedoctorniravNoch keine Bewertungen

- Physics 1401 - Exam 1 Review - Chapter 1,2Dokument23 SeitenPhysics 1401 - Exam 1 Review - Chapter 1,2shoaibNoch keine Bewertungen

- 7 4 Inverse of MatrixDokument13 Seiten7 4 Inverse of MatrixEbookcrazeNoch keine Bewertungen

- PCA Gen ManualDokument11 SeitenPCA Gen ManualElia CFNoch keine Bewertungen

- Viscoelastic Modeling of Flexible Pavement With Abaqus PDFDokument143 SeitenViscoelastic Modeling of Flexible Pavement With Abaqus PDFcabrel TokamNoch keine Bewertungen

- Bsen 3310 Lab ReportDokument5 SeitenBsen 3310 Lab Reportapi-271759053Noch keine Bewertungen

- Qualification of Innovative Floating Substructures For 10MW Wind Turbines and Water Depths Greater Than 50mDokument41 SeitenQualification of Innovative Floating Substructures For 10MW Wind Turbines and Water Depths Greater Than 50mjuho jungNoch keine Bewertungen

- Review Problems: Ppendix GDokument22 SeitenReview Problems: Ppendix Givan ivanaNoch keine Bewertungen

- Finite Element Primer for Solving Diffusion ProblemsDokument26 SeitenFinite Element Primer for Solving Diffusion Problemsted_kordNoch keine Bewertungen

- Harmonising Rock Engineering and The Environment - Qihu - QianDokument823 SeitenHarmonising Rock Engineering and The Environment - Qihu - Qianhidrogeolo_29Noch keine Bewertungen

- 2064-2110 - Magnetic Iron Oxide Nanoparticles - Synthesis, Stabilization, Vectorization, PDFDokument48 Seiten2064-2110 - Magnetic Iron Oxide Nanoparticles - Synthesis, Stabilization, Vectorization, PDFRoxana Cristina PopescuNoch keine Bewertungen

- Fatigue and Fracture PDFDokument31 SeitenFatigue and Fracture PDFpericharla ravivarmaNoch keine Bewertungen

- 1.5 Feynman Diagrams WorksheetDokument4 Seiten1.5 Feynman Diagrams WorksheetVishnu Kaushik100% (2)