Beruflich Dokumente

Kultur Dokumente

North Star Plant Painting Specification

Hochgeladen von

aanouar77Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

North Star Plant Painting Specification

Hochgeladen von

aanouar77Copyright:

Verfügbare Formate

North Star Plant Specification for painting and protective coating

Mott MacDonald & Co. LLC Oman Gas Co.(S.A.O.G)

NORTH STAR PLANT SPECIFICATION FOR PAINTING AND PROTECTIVE COATING

Revision O

abc

Company:

Oman Gas Company S.A.O.C P.O. Box: 799, Postal Code 133, Muscat, Sultanate of Oman Tel +968 2468 1600 Fax +968 2468 1678

P:\Muscat Ansari\ong\Projects\246471OM01- OGC-FEED North Star Plant\Piping\Painting specification

Engineering Consultant:

Mott MacDonald & Co. LLC P.O. Box 587, Ruwi Postal Code 112 Sultanate of Oman Tel +968 2485 2000 Fax +968 2481 5850

North Star Plant Specification for painting and protective coating

Mott MacDonald & Co. LLC Oman Gas Co.(S.A.O.G)

NORTH STAR PLANT

SPECIFICATION FOR PAINTING AND PROTECTIVE COATING

Project Contract No. MMC Job No. Document No.

North Star Plant OGC-01TD 246471OM01 246471OM01-PIP-007

Issue and Revision Record

Rev 0

Date 11/03/09

Originator KUS

Checker SSM

Approver CSN

Description Issued for Tender

Client Authorization

This document has been prepared for the titled project or named part thereof and should not be relied upon or used for any other project without an independent check being carried out as to its suitability and prior written authority of Mott MacDonald being obtained. Mott MacDonald accepts no responsibility or liability for the consequence of this document being used for a purpose other than the purposes for which it was commissioned. Any person using or relying on the document for such other purpose agrees, and will by such use or reliance be taken to confirm his agreement to indemnify Mott MacDonald for all loss or damage resulting there from. Mott MacDonald accepts no responsibility or liability for this document to any party other than the person by whom it was commissioned. To the extent that this report is based on information supplied by other parties, Mott MacDonald accepts no liability for any loss or damage suffered by the client, whether contractual or tortuous, stemming from any conclusions based on data supplied by parties other than Mott MacDonald and used by Mott MacDonald in preparing this report.

P:\Muscat Ansari\ong\Projects\246471OM01- OGC-FEED North Star Plant\Piping\Painting specification

North Star Plant Specification for painting and protective coating

Mott MacDonald & Co. LLC Oman Gas Co.(S.A.O.G)

Table of Contents

1 2 3 Scope Codes, Regulations and Standards General 3.1 Workmanship 3.2 Marking conditions 4 Materials 4.1 Storage of Materials 4.2 Manufacturer's Recommendations 5 Extent of Painting 5.1 Surfaces to be Painted 5.2 Surfaces not to be Painted 5.3 Stainless Steel Piping 6 Ambient Limitations 6.1 Surface Preparation and Material Application 6.2 Ventilation 7 Surface Preparation 7.1 General 7.2 Abrasive Blast Cleaning 8 Priming and Finishing 8.1 Manufacturer's Recommendations 8.2 Application Procedures 9 10 Quality Assurance and Inspection Requirements Guarantee Project Site Information Table Of Compliance

Page

4 4 4 4 4 5 5 5 5 5 5 6 6 6 6 6 6 6 6 6 6 6 7 A-1 B-1

Appendix A: Appendix B:

P:\Muscat Ansari\ong\Projects\246471OM01- OGC-FEED North Star Plant\Piping\Painting specification

North Star Plant Specification for painting and protective coating

Mott MacDonald & Co. LLC Oman Gas Co.(S.A.O.G)

SCOPE

This specification covers the selection of materials and procedures to be followed in the course of surface preparation and the application of protective paint and primer to above-ground piping, whether they are prepared and protected in the shop or field.

2

2.1

CODES, REGULATIONS AND STANDARDS

External painting and protective coating shall meet or exceed the requirements of the latest edition of the following codes, regulations and standards, except as superseded herein. In cases where more than one code, regulation or standard apply to the same condition, the most stringent shall be followed. In the event of a conflict between this specification and other specifications or correspondence, a ruling, in writing, shall be obtained before any work is started. RAL German Institute for Quality Assurance and Certification - RAL Colors The Steel Structures Painting Council Manual: - SSPC SP1, Solvent - SSPC SP2, Hand Tool Cleaning SP-1246: Specification for Painting and Coating of Oil and Gas production facilities

Part 1: Technical requirements for coating systems Part 2: New construction coating systems. Part 3: Maintenance of Coating systems Part 4: Surface preparation, application and inspection of coating systems. Part 5: Approved coating systems 2.2 SP-1166: Specification for identification of on-plot pipe work. DEP 30.48.00.31: Painting & coating of new equipment DEP 31.38.01.11: Piping-General requirements. DEP 30.48.40.31: Thermal Sprayed Aluminum Coatings BS381C: Colors for identification, coding and special purposes.

Any deviation from this specification must be approved, in writing. Such written approval must be obtained prior to the commencement of any work which would constitute such a deviation.

3

3.1

GENERAL

Workmanship

Work shall be done by qualified and competent craftsmen, in a neat and workmanlike manner, conforming to code requirements and industry standards. 3.2 Marking Conditions

Where elevated structures require marking for safety consideration, they shall be marked in accordance with the requirements or the Authority having jurisdiction.

P:\Muscat Ansari\ong\Projects\246471OM01- OGC-FEED North Star Plant\Piping\Painting specification

North Star Plant Specification for painting and protective coating

Mott MacDonald & Co. LLC Oman Gas Co.(S.A.O.G)

4

4.1

MATERIALS

Storage of Materials

Materials shall be stored in Manufacturer's containers, clearly marked with Manufacturer's labels, under Manufacturer's specified storage condition. 4.2 Manufacturer's Recommendations

Materials shall be used and applied in accordance with Manufacturer's recommendations, which shall take precedence over this specification.

5

5.1 i)

EXTENT OF PAINTING

Surfaces to be painted All surfaces subject to weathering, rusting or corrosion by exposure to the elements shall be painted. All carbon steel surfaces shall be painted.

ii) Carbon steel surfaces having an operating temperature lower than 230F, which are insulated or fireproofed, shall, as a minimum, be coated with primer. 5.2 i) Surfaces NOT to be painted The following are not to be painted and must be protected from painting: a) Porcelain b) Gauge glasses c) Meter faces d) Valve stem and threads, safety valve tags e) Working surfaces of equipment or equipment interior, unless designated for corrosion protection f) Nameplates g) Aluminum,, DSS, non ferrous material, plastic and fibreglass h) Insulation jacketing or fireproofing i) j) l) Galvanized surfaces unless designated or OSHA required Concrete, transit, masonry, stucco, etc., unless designated Factory finished instrument cases and meters

k) Factory finished control panels m) Factory finished equipment, including compressors, pumps, control valves, etc. n) Factory finished buildings o) Light fixtures, unit heaters and fans ii) Masking or compounds used to protect non-painted surface must be removed prior to completion of the job.

P:\Muscat Ansari\ong\Projects\246471OM01- OGC-FEED North Star Plant\Piping\Painting specification

North Star Plant Specification for painting and protective coating

Mott MacDonald & Co. LLC Oman Gas Co.(S.A.O.G)

5.3

Stainless steel piping

Due to Marine exposure, all stainless steel piping shall be coated as per DEP 30.48.40.31 Thermal sprayed aluminium coatings.

6

6.1 i)

AMBIENT LIMITATIONS

Surface Preparation and Material Application No surface preparation or application of material shall take place under the following conditions Temperature under 50F, or not less than manufacturer published or written recommendations for the application. Wet or damp atmosphere Noticeable wind Atmosphere contaminated by dirt, dust, oil, product or any other pollutant

6.2

Ventilation

During all stages of surface preparation and application of material, adequate ventilation must be assured.

7

7.1

SURFACE PREPARATION

General

The type of surface preparation shall be in accordance with the SHELL SPs & DEPs 7.2 Abrasive Blast Cleaning

Blast cleaning shall be done as specified in the SP 1246-4, clause 5.4.

8

8.1

PRIMING AND FINISHING

Manufacturer's Recommendations

The finish and primer paint Manufacturer's recommendations on application and surface preparation are to take precedence over these general specifications. 8.2 Application Procedures

Application techniques shall be done as specified in the SP-1246-4, clause 6.2.

QUALITY ASSURANCE AND INSPECTION REQUIREMENTS

The Vendor shall establish, implement and maintain the Quality Management System in line with the following specifications to assure the quality of the product / service:

P:\Muscat Ansari\ong\Projects\246471OM01- OGC-FEED North Star Plant\Piping\Painting specification

North Star Plant Specification for painting and protective coating

Mott MacDonald & Co. LLC Oman Gas Co.(S.A.O.G)

SP-1171 Specification for Quality Assurance of Design, Construction and Engineering works, SP-1122 Specifications for Design QA Plans, DEP 82.00.10.10 - Project Quality Assurance, ISO 9001:2000 Quality Management System Requirements. The Vendor shall select the sub-vendors from the OGC Approved Vendors List only. All sub-vendors shall establish, implement and maintain the Quality Management System in line with SP-1171, SP-1122, DEP 82.00.10.10 and ISO 9001:2000. 9.1 9.2 9.3 Access to all work while being performed and sufficient notification to complete all required inspections shall be given. All prepared surfaces shall be subject to inspection and approval before primer is applied. Measurement of paint dry film thickness will be made with a Mikrotest or post test dry film thickness gauges or similar approved gauge. Failure to meet specified thickness requirement shall cause work to be rejected. Paint shall not be thinned beyond Manufacturer's recommendation and if requires, a viscosity check shall be made. Work will be rejected because of poor workmanship. Poor workmanship is defined as inadequate drying or curing, dirt and dust inclusions, overspray, pin-holes, runs and sags, or inadequate film build. Acceptable finish work must be free of abrasions and must be uniform in color and appearance. Inspection and testing shall be as per DEP 30.48.00.31 para 6.

9.4 9.5

9.6 9.7

10

10.1

GUARANTEE

Satisfactory application of the paint shall be guaranteed. Neither conditions in the shop nor the laboratory acceptance of the paint shall relieve the applicators of responsibility for providing a satisfactory product. If rusting occurs or the paint coat lifts, blisters, wrinkles, or shows evidence of having been applied under unfavorable conditions, or if the workmanship is poor, or if impure or unauthorized paint has been used, or if for any other reason the painting is unsatisfactory, the effected paint shall be removed and the metal thoroughly cleaned and repainted. Guarantee painting against poor workmanship and improper application. This guarantee shall remain in effect for eighteen months from the date painting is completed or one year from the time the equipment is placed in regular operation. Repair any defects noted during the guarantee period, with no further charges to the Company.

10.2

P:\Muscat Ansari\ong\Projects\246471OM01- OGC-FEED North Star Plant\Piping\Painting specification

North Star Plant Specification for painting and protective coating

Mott MacDonald & Co. LLC Oman Gas Co.(S.A.O.G)

Appendix A:

Project Site Information

Environmental Conditions and Geographic Data Location Field : : Musandam Peninsula West Bukha

Environmental / Meteorological Data

Ambient Air Temperature Air Temp shade (Summer Max) Summer Average Winter Minimum Winter Average Maximum black bulb temperature Maximum daily variation in temperature Notes 1 and 2 50 C 30C 5C 15C 82C 25C

Ground Temperature

Max 35C @ 800 mm (Summer) Min (Winter) 20 C @ l000 mm

Relative Humidity

Max Min

98% 30%

Soil Data Average Soil Thermal Resistivity 240 cmC/W

Barometric Pressure

Average

95.7 to 98.9 kPa(a)

Rainfall (Note 3) Design Rainfall in 1 hour Design Rainfall average Wind: Prevailing wind directions

P:\Muscat Ansari\ong\Projects\246471OM01- OGC-FEED North Star Plant\Piping\Painting specification A-1

25mm Nil

North Star Plant Specification for painting and protective coating

Mott MacDonald & Co. LLC Oman Gas Co.(S.A.O.G)

For six months For three months For one month Rest of the months

North west to South east From South to North From West to east varies

Design Wind Speed Max Hourly 3 Sec. Gusts 80km/h 168km/h

Solar Radiation Solar Radiation 120mW/cm2

Sea Temperature

Winter Summer

15 C 30 C

Notes:

1. The ambient temperature may rise up to 60C for short periods but, as this temperature occurs for short periods only, equipment shall be designed to achieve its rated capacity with a shade temperature of 50C. 2. The outdoor electrical equipment (Switchgear, Transformer, motors etc) shall be designed for 55C ambient temperature. Indoor equipment shall be designed for 40C ambient temperature. 3. Rainfall is infrequent, but when rainfall occurs, it is often combined with severe sand storms. 4. Sandstorms: These are both frequent and severe; they can last for days. The atmosphere is heavily laden with dust particles as small as 2 microns, as stated in the Tender document No OGC/--/207 November 2006.

Design Life

All equipment, facilities and pipelines shall be designed for a minimum operational life of minimum 30 years.

Seismic Load

For Seismic load details, No 246471OM01-CIV-013. please refer Feed stage Civil Design Basis Document

P:\Muscat Ansari\ong\Projects\246471OM01- OGC-FEED North Star Plant\Piping\Painting specification

A-2

North Star Plant Specification for painting and protective coating

Mott MacDonald & Co. LLC Oman Gas Co.(S.A.O.G)

Appendix B:

Spec. Clause No.

TABLE OF COMPLIANCE

Conforms Yes/No Alternative Yes/No Noted Yes/No Clarification

1 2 2.1 2.2 3 3.1 3.2 4 4.1 4.2 5 5.1 5.2 5.3 6 6.1 6.2 7 7.1 7.2 8 8.1 8.2 9 9.1 9.2 9.3 9.4 9.5 9.6 9.7 10 10.1 10.2 Appendix-A

P:\Muscat Ansari\ong\Projects\246471OM01- OGC-FEED North Star Plant\Piping\Painting specification

B-1

Das könnte Ihnen auch gefallen

- Painting SpecificationDokument23 SeitenPainting SpecificationPrashant Malve100% (1)

- COM-SU-5191 Chevron Onshore Painting Specification PDFDokument157 SeitenCOM-SU-5191 Chevron Onshore Painting Specification PDFKhepa Baba100% (1)

- SP-1246 Part-5Dokument27 SeitenSP-1246 Part-5Rajkumar A50% (2)

- YKP External Coating SpecificationDokument34 SeitenYKP External Coating SpecificationAnonymous jLVLP4w3m100% (2)

- Installation of Flexible, Removable Reusable Insulation Covers For Hot Insulation ServiceDokument22 SeitenInstallation of Flexible, Removable Reusable Insulation Covers For Hot Insulation ServiceAkram DriraNoch keine Bewertungen

- Statoil Epoxy Coating SpecificationDokument11 SeitenStatoil Epoxy Coating SpecificationSkazemi7100% (2)

- ACI 222.2R-01 - Corrosion of Prestressing SteelsDokument43 SeitenACI 222.2R-01 - Corrosion of Prestressing Steelsmekgeo1Noch keine Bewertungen

- Painting Specification For Storage TanksDokument27 SeitenPainting Specification For Storage TanksRohmat Benny IsmantoNoch keine Bewertungen

- AC-036915-001 Fireproofing For Column and Vessel SkirtsDokument1 SeiteAC-036915-001 Fireproofing For Column and Vessel Skirtsnarutothunderjet216100% (1)

- Chevron Specification for Fusion Bonded Epoxy Pipeline CoatingDokument15 SeitenChevron Specification for Fusion Bonded Epoxy Pipeline CoatingChozha RajanNoch keine Bewertungen

- Saes H 204Dokument34 SeitenSaes H 204heartbreakkid132Noch keine Bewertungen

- Pip PNSM0105Dokument6 SeitenPip PNSM0105romerobernaNoch keine Bewertungen

- Standard Specification FOR Shop AND Field PaintingDokument5 SeitenStandard Specification FOR Shop AND Field PaintingRanjan KumarNoch keine Bewertungen

- MineralWoolInsulation Data SheetDokument18 SeitenMineralWoolInsulation Data SheetAnonymous MB5YbaLrBENoch keine Bewertungen

- JPCL Transpipe EbookDokument82 SeitenJPCL Transpipe Ebookvincent.w.stone6724Noch keine Bewertungen

- 29001E00Dokument61 Seiten29001E00Mohamed GhonaimNoch keine Bewertungen

- Technical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoDokument27 SeitenTechnical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoIdung ChristopherNoch keine Bewertungen

- Coating Standards PDFDokument5 SeitenCoating Standards PDFHanuman RaoNoch keine Bewertungen

- Saes H 204Dokument33 SeitenSaes H 204Rei Lizardo100% (1)

- Eil Painting Tech Spec Vol IIDokument44 SeitenEil Painting Tech Spec Vol IIMl Jain82% (11)

- CP Painting Revised SpecsDokument57 SeitenCP Painting Revised SpecsanilnwaychalNoch keine Bewertungen

- HSS (Heat-Shrinkable Sleeve) Installation ProcedureDokument60 SeitenHSS (Heat-Shrinkable Sleeve) Installation ProcedureIntegrity EngineerNoch keine Bewertungen

- 6-Blasting and Painting Procedure - BP006Dokument14 Seiten6-Blasting and Painting Procedure - BP006mohd as shahiddin jafriNoch keine Bewertungen

- Laser Cladding Metal BondingDokument4 SeitenLaser Cladding Metal Bondingcal2_uniNoch keine Bewertungen

- Engineering Encyclopedia: Maintenance Paint and Protective Coating SurveysDokument24 SeitenEngineering Encyclopedia: Maintenance Paint and Protective Coating Surveyscvg ertdNoch keine Bewertungen

- 18B. Protegol UR 32.55R Data SheetDokument3 Seiten18B. Protegol UR 32.55R Data SheetClarkFedele27Noch keine Bewertungen

- Pipeline Internal CoatingDokument14 SeitenPipeline Internal CoatingMostafa Sharaf100% (1)

- Pip Insc2000-1999Dokument15 SeitenPip Insc2000-1999antonio diaz100% (3)

- 09 Job Procedure For Fire ProofingDokument4 Seiten09 Job Procedure For Fire ProofingAlvin Smith100% (2)

- PIP INEG1000 Insulation Design and Type Codes 1999-04Dokument35 SeitenPIP INEG1000 Insulation Design and Type Codes 1999-04asvasan5554Noch keine Bewertungen

- Technical Data & CalculationsDokument13 SeitenTechnical Data & Calculationsmaxwell marshall100% (1)

- Method Statements of Surface Treatment and Painting For Valves Nh3 ProjectDokument5 SeitenMethod Statements of Surface Treatment and Painting For Valves Nh3 ProjectDuongthithuydung0% (1)

- Industrial Coating ApplicationDokument22 SeitenIndustrial Coating ApplicationaamirsaddiqNoch keine Bewertungen

- VAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev ADokument8 SeitenVAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev AAdvis100% (1)

- AV650 Petrochemical Fireproofing Application MethodDokument4 SeitenAV650 Petrochemical Fireproofing Application MethodNizarHamrouniNoch keine Bewertungen

- Standard Specification FOR Pipeline Internal CoatingDokument2 SeitenStandard Specification FOR Pipeline Internal CoatingRanjan KumarNoch keine Bewertungen

- Astm D-3840 - 01Dokument9 SeitenAstm D-3840 - 01Bipin SasikumarNoch keine Bewertungen

- Hempadur 45070 Product Data SheetDokument3 SeitenHempadur 45070 Product Data Sheetarjunmohanan50% (2)

- Coating Personnel Id FormatDokument1 SeiteCoating Personnel Id FormatShabbar Abbas MalikNoch keine Bewertungen

- PIP INIC1000 (2012) - Cold Insulation Installation DetailsDokument25 SeitenPIP INIC1000 (2012) - Cold Insulation Installation DetailsAbimelech Salas100% (3)

- Chevron Pre-Inspection ChecklistDokument2 SeitenChevron Pre-Inspection ChecklistosersNoch keine Bewertungen

- 10080-1-SS-PP-014 - Painting Shop FloorDokument57 Seiten10080-1-SS-PP-014 - Painting Shop FloorselvakumarNoch keine Bewertungen

- HSS80 Heat Shrink Sleeve: Features & BenefitsDokument2 SeitenHSS80 Heat Shrink Sleeve: Features & BenefitsAnonymous eEJDOR2100% (1)

- 01 Samss 042Dokument38 Seiten01 Samss 042বিপ্লব পালNoch keine Bewertungen

- Dfy - Coating Quality Key PointsDokument1 SeiteDfy - Coating Quality Key PointsMohammed SadiqNoch keine Bewertungen

- Nozzle Allowable LoadsDokument9 SeitenNozzle Allowable LoadsRajaramNoch keine Bewertungen

- Field Applied External Coatings For Nuayyim Piping and Steel StructuresDokument2 SeitenField Applied External Coatings For Nuayyim Piping and Steel Structuresishaq_khanNoch keine Bewertungen

- Com Su 4042 IDokument38 SeitenCom Su 4042 Iolalekan100% (1)

- Standard Colour List PDFDokument1 SeiteStandard Colour List PDFKumarNoch keine Bewertungen

- Saep 1200Dokument9 SeitenSaep 1200Anonymous 4IpmN7On100% (1)

- Com Su 6095 PDFDokument33 SeitenCom Su 6095 PDFresp-ect100% (1)

- Aramco Painting SpecificationDokument6 SeitenAramco Painting Specificationvicky100% (1)

- Project Standard and Specifications Painting Specifications Rev01webDokument6 SeitenProject Standard and Specifications Painting Specifications Rev01webhiyeonNoch keine Bewertungen

- Painting SpecDokument54 SeitenPainting Specashim_scribd100% (4)

- 022 Painting Spec (A)Dokument8 Seiten022 Painting Spec (A)sravan_kits929Noch keine Bewertungen

- 3PS Gaw 005 - 06Dokument46 Seiten3PS Gaw 005 - 06Viveck VivekNoch keine Bewertungen

- Coating Application & Inspection Procedure-Rev 0Dokument27 SeitenCoating Application & Inspection Procedure-Rev 0tinphat100% (1)

- Appendix D - Specification For Coating & Wrapping of Underground PipiDokument13 SeitenAppendix D - Specification For Coating & Wrapping of Underground PipivgestantyoNoch keine Bewertungen

- Sheet Membrance Water ProofingDokument6 SeitenSheet Membrance Water ProofingphilipyapNoch keine Bewertungen

- Design Guidelines for Surface Mount TechnologyVon EverandDesign Guidelines for Surface Mount TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Resend Due To The Wrong Attachment, Sorry For The Inconvenience, Best RegardsDokument1 SeiteResend Due To The Wrong Attachment, Sorry For The Inconvenience, Best Regardsaanouar77Noch keine Bewertungen

- Resend Due To The Wrong Attachment, Sorry For The Inconvenience, Best RegardsDokument1 SeiteResend Due To The Wrong Attachment, Sorry For The Inconvenience, Best Regardsaanouar77Noch keine Bewertungen

- FDYRTUTDokument146 SeitenFDYRTUTaanouar77Noch keine Bewertungen

- MMMMMMDokument13 SeitenMMMMMMaanouar77Noch keine Bewertungen

- SDHRTDokument2 SeitenSDHRTaanouar77Noch keine Bewertungen

- OOPJDokument14 SeitenOOPJaanouar77Noch keine Bewertungen

- OOPJDokument14 SeitenOOPJaanouar77Noch keine Bewertungen

- BoilerDokument4 SeitenBoileraanouar77Noch keine Bewertungen

- Dge Rhree HRDokument37 SeitenDge Rhree HRaanouar77Noch keine Bewertungen

- DcereDokument2 SeitenDcereaanouar77Noch keine Bewertungen

- DGHREDokument7 SeitenDGHREaanouar77Noch keine Bewertungen

- DsgfrhteyDokument2 SeitenDsgfrhteyaanouar77Noch keine Bewertungen

- FHSRTHRTDokument1 SeiteFHSRTHRTaanouar77Noch keine Bewertungen

- OOPJDokument14 SeitenOOPJaanouar77Noch keine Bewertungen

- OOPJDokument14 SeitenOOPJaanouar77Noch keine Bewertungen

- The Babcock & Wilcox Company: Section IV - Environmental ProtectionDokument1 SeiteThe Babcock & Wilcox Company: Section IV - Environmental Protectionaanouar77Noch keine Bewertungen

- SDCDCDDokument1 SeiteSDCDCDaanouar77Noch keine Bewertungen

- BoilerDokument4 SeitenBoileraanouar77Noch keine Bewertungen

- IOHIOHOHDokument1 SeiteIOHIOHOHaanouar77Noch keine Bewertungen

- LDokument1 SeiteLaanouar77Noch keine Bewertungen

- FDGRTDokument1 SeiteFDGRTaanouar77Noch keine Bewertungen

- OJOJJDokument1 SeiteOJOJJaanouar77Noch keine Bewertungen

- DutiesDokument1 SeiteDutiesaanouar77Noch keine Bewertungen

- 4444Dokument1 Seite4444aanouar77Noch keine Bewertungen

- Process Control FundamentalsDokument59 SeitenProcess Control Fundamentalsaanouar77Noch keine Bewertungen

- Level MeasurementDokument14 SeitenLevel Measurementaanouar77Noch keine Bewertungen

- IVT BlueSoleil 8.0.356.0 ReleaseNoteDokument6 SeitenIVT BlueSoleil 8.0.356.0 ReleaseNoteLuciano Cipriani100% (1)

- SP-00-J-0002 Rev 0Dokument42 SeitenSP-00-J-0002 Rev 0aanouar77Noch keine Bewertungen

- 1861B 3342002Dokument1 Seite1861B 3342002cherif yahyaouiNoch keine Bewertungen

- 7SA513 CatalogueDokument16 Seiten7SA513 Catalogueaanouar77Noch keine Bewertungen

- 6ac 14mac ReadingDokument40 Seiten6ac 14mac Readingnoreen diorNoch keine Bewertungen

- Lrfdcons 3 I3Dokument29 SeitenLrfdcons 3 I3RAIMUNDO SUHERDINNoch keine Bewertungen

- A320 Prepared LandingDokument5 SeitenA320 Prepared Landingme2 koreancosmeticNoch keine Bewertungen

- United States Bankruptcy Court District of Colorado Voluntary PetitionDokument64 SeitenUnited States Bankruptcy Court District of Colorado Voluntary Petitionspacecat007Noch keine Bewertungen

- Employment Law Handbook for Non-LawyersDokument30 SeitenEmployment Law Handbook for Non-LawyersBobo SweNoch keine Bewertungen

- Vedic Mantras An Influential Factor For Spiritual HealthDokument7 SeitenVedic Mantras An Influential Factor For Spiritual Healthbanny 123Noch keine Bewertungen

- BS BuzzDokument6 SeitenBS BuzzBS Central, Inc. "The Buzz"Noch keine Bewertungen

- Deed of Sale Cavite LandDokument4 SeitenDeed of Sale Cavite LandolangNoch keine Bewertungen

- Rev DDokument21 SeitenRev Dpsn1234567890Noch keine Bewertungen

- Avi Volunteer GuidebookDokument44 SeitenAvi Volunteer GuidebookReuben Henry HartNoch keine Bewertungen

- Series F DelVal Oilfield Ball ValveDokument6 SeitenSeries F DelVal Oilfield Ball ValveProcess Controls & ServicesNoch keine Bewertungen

- 2017, 9999, N/a-N/a 9999 : Icole Odriguez Egan Evesque Ictoria Ohrs AND Essica IemeierDokument16 Seiten2017, 9999, N/a-N/a 9999 : Icole Odriguez Egan Evesque Ictoria Ohrs AND Essica IemeierAndré Luíz FerreiraNoch keine Bewertungen

- Ess 6Dokument6 SeitenEss 6api-582020074Noch keine Bewertungen

- Case Study Chapter 30Dokument2 SeitenCase Study Chapter 30Hannah Angelu CabadingNoch keine Bewertungen

- M1 Seminar Report 1Dokument26 SeitenM1 Seminar Report 1naithivka rsNoch keine Bewertungen

- Leica M822 Ameliyat MikroskopuDokument12 SeitenLeica M822 Ameliyat Mikroskopuderya papuçNoch keine Bewertungen

- Bi Substrate ReactionsDokument14 SeitenBi Substrate ReactionsIda Nancy KNoch keine Bewertungen

- CH 31 - Assessment and Management of Patients With Vascular Disorders and Problems of PeripheralDokument16 SeitenCH 31 - Assessment and Management of Patients With Vascular Disorders and Problems of PeripheralPye Antwan DelvaNoch keine Bewertungen

- MS50 ManualDokument16 SeitenMS50 ManualROGELIO QUIJANONoch keine Bewertungen

- Breaker UL1066PrintDokument362 SeitenBreaker UL1066PrintGaurav MaithilNoch keine Bewertungen

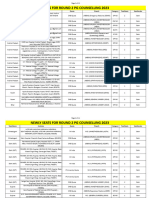

- Newly Seats For Round 2 PG Counselling 2023Dokument11 SeitenNewly Seats For Round 2 PG Counselling 2023Manoj KumarNoch keine Bewertungen

- (USCG Cert) 162.060.7.1 - Techcross - Aprill30 - 2019Dokument2 Seiten(USCG Cert) 162.060.7.1 - Techcross - Aprill30 - 2019peter1070811Noch keine Bewertungen

- BBB Vs AAA. GR 193225 February 9, 2015docxDokument4 SeitenBBB Vs AAA. GR 193225 February 9, 2015docxJoeyBoyCruzNoch keine Bewertungen

- ArresterWorks Facts-001 Arrester Lead LengthDokument11 SeitenArresterWorks Facts-001 Arrester Lead Lengthnshj196Noch keine Bewertungen

- Oil Drilling Operation. Pre-DiggingDokument5 SeitenOil Drilling Operation. Pre-DiggingКаролина ЛемешеваNoch keine Bewertungen

- Governmentality and risk in the new NHSDokument21 SeitenGovernmentality and risk in the new NHSS A SouravNoch keine Bewertungen

- Lactogrow VS Lactogen 2Dokument3 SeitenLactogrow VS Lactogen 2Mardan Love SunnahNoch keine Bewertungen

- Manual Tester 38XR-B PDFDokument4 SeitenManual Tester 38XR-B PDFSantiago Fabián BuesoNoch keine Bewertungen

- Written Works Mapeh 7&9 2ndDokument8 SeitenWritten Works Mapeh 7&9 2ndNas LeeNoch keine Bewertungen

- GEOTHERMAL POWER (Aashutosh Tiwari)Dokument17 SeitenGEOTHERMAL POWER (Aashutosh Tiwari)Aashutosh TiwariNoch keine Bewertungen