Beruflich Dokumente

Kultur Dokumente

I C Engine

Hochgeladen von

AMIT PRAJAPATIOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

I C Engine

Hochgeladen von

AMIT PRAJAPATICopyright:

Verfügbare Formate

Experiment No.

6 Combustion parameter study of a single cylinder four stroke diesel engine

Objectives: 1. To understand the different instrumentation used to study the combustion behavior of a single cylinder four stroke diesel engine. 2. To understand the basic calculations to obtain different combustion parameters from in-cylinder pressure data. Experimental Procedure: Experiment would be conducted for three load conditions (no load, 2 kW and 4 kW) at a constant speed of 1350 rpm Draw a neat sketch with all major dimensions of the test rig. Measurement of rpm, load and fuel consumption. Measurement of manometer reading to calculate air flow rates. Measurement of temperatures.(inlet, exhaust, cylinder wall and lub oil) Measurement of in-cylinder pressure date from the acquisition system.

Analysis of the results and report submission:

Each report should include the following 1 Neat sketch of the experimental test rig.

2 Calculate the start of combustion and plot the same with respect to load. 3 Calculate the pressure rise rate(PRR) and heat release rate (HRR) from pressure data. 4 Plot the followings for three different load conditions: a) Crank angle vs pressure b) Crank angle vs HRR c) Crank angle vs PRR 5 Identify the crank angle at which peak pressure, peak PRR, peak HRR and SOC occurs. (for all 3 loads) 6 Make a plot of these four parameters (as in sl. No. 5) with their corresponding angle of occurrences. (for all three loads)

Observation table

Sl . n o

RP M

Fuel Cons. Mai(ml/ min)

Load Curr. (Amp ) Vol. (v)

Mano Readi ng (mm)

T (C) Intak e

T (C) exhau st

T (C) Lub oil

T (C) Cyl. Wall temp.

CO (%)

CO (%)

HC (pp m)

O (%)

NO (ppm )

Smoke (opacity )

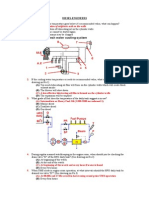

NI Acquisition System Computer Fuel tan k Charge Amplifier

Air Drum

1

P Pr e ss

Dynam o

Engine

Loading Panel

meter

Encoder

Gas Analyzer

P Pr e ss

1. Pressure

Transducer

2. Fuel Injector

3. Thermo-couple

Figure: Schematic diagram of experimental test rig. Type of engine Bore(mm) Stroke(mm) Length of connecting rod(mm) Compression ratio Maximum power

N.B. for calculations and analysis

Kirlosker single Cylinder 4-Stroke Diesel engine 102 116 230 17.5:1 7.4kW@1500 rpm

Table 1: detailed specifications of the engine

The heat release rate is usually calculated by the following formula. [ Ref. J.B.Heywood]

Where=Rate of change of heat release w.r.t. crank angle,

-crank angle in radian,

= Rate of change of pressure w.r.t. crank angle,

=,

V=Volume of cylinder at any position of crank angle,

Instantaneous volume (V) is given as,

Where,= clearance volume, B=Bore, l=Length of connecting rod, a= crank radius, =S/2 , s= stroke length

Air flow rate calculation:

a= aircdA (2ghw w /air) air=P/(RT).............................(4) Where, a=mass flow rate of air in kg/sec air=density of air at room temperature in kg/m3 P=atmospheric pressure in N/m2 R= specific gas constant in J/kg.K T=absolute temperature

cd=coefficient of discharge of orifice (take 0.62 ) A=area of orifice in m2 (take 20 mm as diameter) hw= meno metric head in meter w=density of liquid used in U-tube manometer in kg/m3 Fuel properties: Density of diesel is 0.832 kg/ltr, CV of diesel is 43 MJ/kg Density of petrol is 0.720 kg/ltr, CV of petrol is 46 MJ/kg Take the value of as 1.32 for the calculation of HRR

Das könnte Ihnen auch gefallen

- Gas-And Dual-Fuel: The New Engine BookDokument8 SeitenGas-And Dual-Fuel: The New Engine BookRoni EnjelaniNoch keine Bewertungen

- Heat Balance and Load Tests on Diesel EnginesDokument6 SeitenHeat Balance and Load Tests on Diesel EnginesMathew John0% (2)

- ALL Questions and Answers ATPLDokument59 SeitenALL Questions and Answers ATPLAlbert Aguilera91% (11)

- Otto Diesel Dual Ideal Cycle - PPT (Compatibility Mode)Dokument16 SeitenOtto Diesel Dual Ideal Cycle - PPT (Compatibility Mode)Danang Wahdiat Aulia Ishaq0% (1)

- 12-2103471 Heat Transfer in EngineDokument12 Seiten12-2103471 Heat Transfer in EngineRamasamikannan RamasamikannanNoch keine Bewertungen

- Section I - Theory of Gas Turbines EnginesDokument8 SeitenSection I - Theory of Gas Turbines EnginesYoshua GaloenkNoch keine Bewertungen

- c1 1Dokument301 Seitenc1 1Liza Cabalquinto LorejoNoch keine Bewertungen

- Dual fuel engine performance and emissions testingDokument1 SeiteDual fuel engine performance and emissions testingAMIT PRAJAPATINoch keine Bewertungen

- MANUAL OF I C ENGINES LAB EMISSION TESTDokument23 SeitenMANUAL OF I C ENGINES LAB EMISSION TESTjee antidoteNoch keine Bewertungen

- Experiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineDokument2 SeitenExperiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineM RoyNoch keine Bewertungen

- Experiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineDokument2 SeitenExperiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineMuket AgmasNoch keine Bewertungen

- Internal Combustion Engine Lab/heat Engine Lab ExperimentsDokument19 SeitenInternal Combustion Engine Lab/heat Engine Lab ExperimentsMathew John0% (2)

- 261 Spring 2008 PDFDokument378 Seiten261 Spring 2008 PDFcombatps1Noch keine Bewertungen

- Heat Balance Diesel Rope Brake-6Dokument3 SeitenHeat Balance Diesel Rope Brake-6Arup NaskarNoch keine Bewertungen

- MEEG 346 Thermal Laboratory: Experiment #4: The Four-Stroke Combustion EngineDokument9 SeitenMEEG 346 Thermal Laboratory: Experiment #4: The Four-Stroke Combustion EnginepsunmoorthyNoch keine Bewertungen

- Knock Characteristics of Dual-Fuel Combustion in Diesel Engines Using Natural Gas As Primary FuelDokument8 SeitenKnock Characteristics of Dual-Fuel Combustion in Diesel Engines Using Natural Gas As Primary FuelMohammad SafreedNoch keine Bewertungen

- A. B. C. D. E.: Where R (D + D) /2 or (D + T) /2 M, and W (Load) (S - S) KGDokument5 SeitenA. B. C. D. E.: Where R (D + D) /2 or (D + T) /2 M, and W (Load) (S - S) KGal hasan kanonNoch keine Bewertungen

- The Effects of Two Shaft Gas Turbine Operating Conditions On The Overall PerformanceDokument16 SeitenThe Effects of Two Shaft Gas Turbine Operating Conditions On The Overall PerformanceAhmad Mohammad Abdul-Aziz100% (1)

- Experimental Test Rig Development and MethodologyDokument16 SeitenExperimental Test Rig Development and MethodologyKonem SolutionsNoch keine Bewertungen

- FORMULAS FOR PREDICTING VGF-GL/GLD/GSID BHP and Intake Manifold PressureDokument19 SeitenFORMULAS FOR PREDICTING VGF-GL/GLD/GSID BHP and Intake Manifold PressureClemente Rafael Marval Escalona100% (1)

- Maximizing Efficiency in IC Engines and Gas TurbinesDokument15 SeitenMaximizing Efficiency in IC Engines and Gas TurbinesVishnu DasNoch keine Bewertungen

- Assignment No. 1 (Summer 2022) Subject: Adv. I. C. Engines Course Coordinator: Dr. J. G. Suryawanshi Last Date of Submission: 04/02/2022Dokument1 SeiteAssignment No. 1 (Summer 2022) Subject: Adv. I. C. Engines Course Coordinator: Dr. J. G. Suryawanshi Last Date of Submission: 04/02/2022DeepanshuKaduNoch keine Bewertungen

- Trial On Reciprocating.Dokument12 SeitenTrial On Reciprocating.zen tenNoch keine Bewertungen

- Combustion in IC EngineDokument32 SeitenCombustion in IC EngineVinodDahiyaNoch keine Bewertungen

- 1 - Lab - ICE - Engine Energy BalanceDokument7 Seiten1 - Lab - ICE - Engine Energy BalanceAcfMacNoch keine Bewertungen

- Increase of Thermal Efficiency and Reduction of Nox Emissions in Di Diesel EnginesDokument5 SeitenIncrease of Thermal Efficiency and Reduction of Nox Emissions in Di Diesel EnginesShreepal ChilaNoch keine Bewertungen

- AE 431 Analysis of Turbojet Engine - EditedDokument6 SeitenAE 431 Analysis of Turbojet Engine - EditedGaurav VaibhavNoch keine Bewertungen

- Effect of coolant temperature on SI engine performanceDokument7 SeitenEffect of coolant temperature on SI engine performanceM Hidayatullah NurNoch keine Bewertungen

- Data Analysis and Performance Model Calibration of A Small Turbojet EngineDokument24 SeitenData Analysis and Performance Model Calibration of A Small Turbojet EngineFathima J100% (1)

- Analysis of Turbojet Engine - FinalDokument6 SeitenAnalysis of Turbojet Engine - FinalRoy VaughnNoch keine Bewertungen

- ME6404 Thermal EngineeringDokument21 SeitenME6404 Thermal EngineeringAnonymous mRBbdopMKfNoch keine Bewertungen

- Min Zar TarDokument247 SeitenMin Zar Tarjohndmariner123100% (12)

- VCR EngineDokument6 SeitenVCR EngineAbNoch keine Bewertungen

- Load Test On Single Cylinder 4s Diesel EngineDokument8 SeitenLoad Test On Single Cylinder 4s Diesel EngineMathew JohnNoch keine Bewertungen

- Thermodynamic Analysis of Internal Combustion EnginesDokument26 SeitenThermodynamic Analysis of Internal Combustion EnginesKatu2010Noch keine Bewertungen

- Diesel CycleDokument20 SeitenDiesel CycleShafiq ShapianNoch keine Bewertungen

- Combustion Part IIB LT 2005: Dr. Clemens KaminskiDokument38 SeitenCombustion Part IIB LT 2005: Dr. Clemens KaminskiHotib PerwiraNoch keine Bewertungen

- Unit 2 IC Engine CyclesDokument12 SeitenUnit 2 IC Engine CyclesFrezer BelayNoch keine Bewertungen

- Exp 2 Performance Parameter of Diesel EngineDokument7 SeitenExp 2 Performance Parameter of Diesel EngineShashwat JainNoch keine Bewertungen

- MEE2003 Thermal Engineering Systems Lab Test QuestionsDokument4 SeitenMEE2003 Thermal Engineering Systems Lab Test QuestionsKartik ChaturvediNoch keine Bewertungen

- Internal Combustion Engine ProblemsDokument7 SeitenInternal Combustion Engine ProblemsGeetha Krishna ChallaNoch keine Bewertungen

- Internal CombusionDokument9 SeitenInternal Combusioneyad mohamadNoch keine Bewertungen

- Performace Test On Otto Engine With Premium and Pertamax FuelDokument12 SeitenPerformace Test On Otto Engine With Premium and Pertamax FuelRifanni JuliantiNoch keine Bewertungen

- Exp#4-Gas TurbineDokument9 SeitenExp#4-Gas TurbineLilo17xiNoch keine Bewertungen

- Experimental Test RigDokument31 SeitenExperimental Test RigNarasimhaPrasadNoch keine Bewertungen

- IC Engine Lab ManualDokument11 SeitenIC Engine Lab ManualVyankat Dev Singh100% (1)

- Lab Report Internal Combustion Engine: Group MembersDokument3 SeitenLab Report Internal Combustion Engine: Group MembersHassan SamiNoch keine Bewertungen

- Modeling and Energy Analysis of A Diesel and Biodiesel Fuelled EngineDokument5 SeitenModeling and Energy Analysis of A Diesel and Biodiesel Fuelled EngineMikael Bezerra Cotias Dos SantosNoch keine Bewertungen

- Mechanical Engineering Thermodynamics II - Lecture 03 - 27 SepDokument25 SeitenMechanical Engineering Thermodynamics II - Lecture 03 - 27 SepThineshraaj Naidu Jaya RamanNoch keine Bewertungen

- Technical Note A FORTRAN Program For Calculating The Evaporation Rates in Diesel Engine Fuel SpraysDokument5 SeitenTechnical Note A FORTRAN Program For Calculating The Evaporation Rates in Diesel Engine Fuel Spraysim19rahulNoch keine Bewertungen

- Internal Combustion Engine Performance Testing MAE 408Dokument19 SeitenInternal Combustion Engine Performance Testing MAE 408Tim WongNoch keine Bewertungen

- Air Standard CyclesDokument28 SeitenAir Standard CyclesAditya Krishnakumar100% (1)

- UNIT I Gas Power Cycles FinalDokument75 SeitenUNIT I Gas Power Cycles FinalMAYUR BHOSALENoch keine Bewertungen

- All Unit UnitwiseDokument17 SeitenAll Unit UnitwisebalajigandhirajanNoch keine Bewertungen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentVon EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNoch keine Bewertungen

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasVon EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNoch keine Bewertungen

- Southern Marine Engineering Desk Reference: Second Edition Volume IiVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNoch keine Bewertungen

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferVon EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferBewertung: 5 von 5 Sternen5/5 (2)

- Adv. Turbo - SyllDokument1 SeiteAdv. Turbo - SyllAMIT PRAJAPATINoch keine Bewertungen

- UNIT 3 Gas TurbineDokument2 SeitenUNIT 3 Gas TurbineAMIT PRAJAPATINoch keine Bewertungen

- Mechanical Engineering DepartmentDokument1 SeiteMechanical Engineering DepartmentAMIT PRAJAPATINoch keine Bewertungen

- MECHANICAL ENGINEERING ASSIGNMENT ON CARNOT CYCLE, REGENERATION, RANKINE CYCLEDokument1 SeiteMECHANICAL ENGINEERING ASSIGNMENT ON CARNOT CYCLE, REGENERATION, RANKINE CYCLEAMIT PRAJAPATINoch keine Bewertungen

- EC-II - Assign. 1Dokument1 SeiteEC-II - Assign. 1AMIT PRAJAPATINoch keine Bewertungen

- Scheme BTech AEDokument1 SeiteScheme BTech AEAMIT PRAJAPATINoch keine Bewertungen

- MTech ADV TURBODokument2 SeitenMTech ADV TURBOAMIT PRAJAPATINoch keine Bewertungen

- Syllabus-Refrigeration & Air Conditioning (T) - ME3CO16 (T)Dokument2 SeitenSyllabus-Refrigeration & Air Conditioning (T) - ME3CO16 (T)AMIT PRAJAPATINoch keine Bewertungen

- EC-II - Assign. 2Dokument1 SeiteEC-II - Assign. 2AMIT PRAJAPATINoch keine Bewertungen

- Mechanical Engineering Department: DATE: 19.2.19 Assignment No.1Dokument1 SeiteMechanical Engineering Department: DATE: 19.2.19 Assignment No.1AMIT PRAJAPATINoch keine Bewertungen

- Medi-Caps University, Indore Department of Mechanical EngineeringDokument1 SeiteMedi-Caps University, Indore Department of Mechanical EngineeringAMIT PRAJAPATINoch keine Bewertungen

- Medi-Caps University, Indore Department of Mechanical EngineeringDokument1 SeiteMedi-Caps University, Indore Department of Mechanical EngineeringAMIT PRAJAPATINoch keine Bewertungen

- AU III Sem AE SyllabusDokument2 SeitenAU III Sem AE SyllabusAMIT PRAJAPATINoch keine Bewertungen

- Mechanical Engineering Department: and After Last Date No Assignment Will Be TakenDokument1 SeiteMechanical Engineering Department: and After Last Date No Assignment Will Be TakenAMIT PRAJAPATINoch keine Bewertungen

- Handmade Shoe Project ProfileDokument2 SeitenHandmade Shoe Project ProfileAMIT PRAJAPATINoch keine Bewertungen

- Bio DieselDokument1 SeiteBio DieselSandeep PnsNoch keine Bewertungen

- R e G PDFDokument1 SeiteR e G PDFAMIT PRAJAPATINoch keine Bewertungen

- Pithampur Industries ListDokument1 SeitePithampur Industries ListAMIT PRAJAPATINoch keine Bewertungen

- R e G PDFDokument1 SeiteR e G PDFAMIT PRAJAPATINoch keine Bewertungen

- Noodle AgraDokument11 SeitenNoodle Agrarecio_seth09Noch keine Bewertungen

- Plastic cluster CFC proposalDokument21 SeitenPlastic cluster CFC proposalmeenakshi_ludNoch keine Bewertungen

- Cannedjackfruitgoa PDFDokument9 SeitenCannedjackfruitgoa PDFAMIT PRAJAPATINoch keine Bewertungen

- Rice Mill & Poha Mill Industry Report (1) Industrial Visit ReportDokument7 SeitenRice Mill & Poha Mill Industry Report (1) Industrial Visit ReportAMIT PRAJAPATINoch keine Bewertungen

- CH 21Dokument5 SeitenCH 21ProfNDAcharyaNoch keine Bewertungen

- Plastic cluster CFC proposalDokument21 SeitenPlastic cluster CFC proposalmeenakshi_ludNoch keine Bewertungen

- ReprocessingDokument10 SeitenReprocessingAMIT PRAJAPATINoch keine Bewertungen

- ch8 Elastic Tape PDFDokument4 Seitench8 Elastic Tape PDFAMIT PRAJAPATINoch keine Bewertungen

- Project Profile On G. P. Bucket: Dcdi-Mzfpur - Dcmsme@gov - in WWW - Msmedimzfpur.bih - Nic.inDokument8 SeitenProject Profile On G. P. Bucket: Dcdi-Mzfpur - Dcmsme@gov - in WWW - Msmedimzfpur.bih - Nic.inAMIT PRAJAPATINoch keine Bewertungen

- 11 PohaDokument8 Seiten11 PohapritamrbhadadeNoch keine Bewertungen

- A-619 136699 PDFDokument25 SeitenA-619 136699 PDFAMIT PRAJAPATINoch keine Bewertungen

- (##) Gaskit For Two WheelerDokument69 Seiten(##) Gaskit For Two WheelerRobin ShaNoch keine Bewertungen

- SM 02 ADokument36 SeitenSM 02 AMark OreschnickNoch keine Bewertungen

- 4D56 Service PointsDokument28 Seiten4D56 Service PointsJancel Castro100% (1)

- Turbo SuperchargerDokument42 SeitenTurbo SuperchargerMahendhar ReddyNoch keine Bewertungen

- Applsci-12-06818-V2 JURNAL TERMODokument19 SeitenApplsci-12-06818-V2 JURNAL TERMORIZAL MUXNoch keine Bewertungen

- MST-Manual 19121735 PDFDokument101 SeitenMST-Manual 19121735 PDFKároly VighNoch keine Bewertungen

- Sec6 6HK1Dokument336 SeitenSec6 6HK1Brett M100% (2)

- 1006tag2 PDFDokument6 Seiten1006tag2 PDFMuhammad Ahmad100% (4)

- 2020catalogue Gasoline GeneratorDokument26 Seiten2020catalogue Gasoline GeneratorRavikant SainiNoch keine Bewertungen

- Book 04 AGK3 Engines PDFDokument479 SeitenBook 04 AGK3 Engines PDFTempNoch keine Bewertungen

- Sogav™ Solenoid Operated Gas Admission ValveDokument4 SeitenSogav™ Solenoid Operated Gas Admission Valvemilagros castañeda zuni100% (1)

- Ch2Dokument34 SeitenCh2papipapiiNoch keine Bewertungen

- AttachmentDokument13 SeitenAttachmentGURMEET SAGINoch keine Bewertungen

- Diesel Engines Fourth Edition PDFDokument97 SeitenDiesel Engines Fourth Edition PDFAndres RvNoch keine Bewertungen

- Wiseco PS Cat2018Dokument253 SeitenWiseco PS Cat2018cafematicaNoch keine Bewertungen

- Guidebook To Trade Test For Vehicle Mechanics: Vocational Training Council Automobile Training BoardDokument19 SeitenGuidebook To Trade Test For Vehicle Mechanics: Vocational Training Council Automobile Training BoardDesireNoch keine Bewertungen

- Lecture 3-IC Engines-Cycles PDFDokument38 SeitenLecture 3-IC Engines-Cycles PDFFelipe Barsanufio Pereira100% (2)

- Ans Key 1 InternalDokument8 SeitenAns Key 1 InternalRavichandran GNoch keine Bewertungen

- Diesel EngineersDokument18 SeitenDiesel EngineerslalindaNoch keine Bewertungen

- Lexus NX 200tDokument28 SeitenLexus NX 200tSopheak LimNoch keine Bewertungen

- MTZ-2011-11 - New Two-Stroke Marine Diesel Engines From WärtsiläDokument8 SeitenMTZ-2011-11 - New Two-Stroke Marine Diesel Engines From WärtsiläDmitrii PustoshkinNoch keine Bewertungen

- Morooka MST500 Service ManualDokument101 SeitenMorooka MST500 Service Manualabdullah.rahmat93Noch keine Bewertungen

- Marine Diesel Engine Gme Competence 6Dokument121 SeitenMarine Diesel Engine Gme Competence 6yuvarajs_91221100% (1)

- Automobile Engineering R19 - UNIT-1Dokument28 SeitenAutomobile Engineering R19 - UNIT-1Rajesh MurkurNoch keine Bewertungen

- Over View On 5 S TechnicDokument14 SeitenOver View On 5 S TechnicSachleen Singh BajwaNoch keine Bewertungen

- Birla Institute of Technology and Science, PilaniDokument2 SeitenBirla Institute of Technology and Science, Pilanip vsNoch keine Bewertungen