Beruflich Dokumente

Kultur Dokumente

Current Carrying Caopacity of Electrical Conductors

Hochgeladen von

Phani Kumar0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

214 Ansichten1 SeiteThe document discusses the factors that determine the current carrying capacity of copper conductors, including conductor size, ambient temperature, number of conductors bundled together, and installation method. Larger conductor size, lower ambient temperature, fewer bundled conductors, and installation in open air rather than an enclosed space allow conductors to carry more current before exceeding safe temperature limits. Tables provide derating factors for bundled conductors and guidelines for maximum current based on conductor size and insulation material/temperature.

Originalbeschreibung:

Current carrying capacity of various conductors

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document discusses the factors that determine the current carrying capacity of copper conductors, including conductor size, ambient temperature, number of conductors bundled together, and installation method. Larger conductor size, lower ambient temperature, fewer bundled conductors, and installation in open air rather than an enclosed space allow conductors to carry more current before exceeding safe temperature limits. Tables provide derating factors for bundled conductors and guidelines for maximum current based on conductor size and insulation material/temperature.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

214 Ansichten1 SeiteCurrent Carrying Caopacity of Electrical Conductors

Hochgeladen von

Phani KumarThe document discusses the factors that determine the current carrying capacity of copper conductors, including conductor size, ambient temperature, number of conductors bundled together, and installation method. Larger conductor size, lower ambient temperature, fewer bundled conductors, and installation in open air rather than an enclosed space allow conductors to carry more current before exceeding safe temperature limits. Tables provide derating factors for bundled conductors and guidelines for maximum current based on conductor size and insulation material/temperature.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

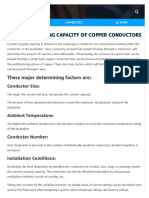

TECHNICAL DATA

CURRENT CARRYING CAPACITY OF COPPER CONDUCTORS

Current carrying capacity is defined as the amperage a conductor can carry before melting either the conductor or the insulation. Heat, caused by an electrical current flowing through the conductor, will determine the amount of current a wire will handle. Theoretically, the amount of current that can be passed through a single bare copper wire can be increased until the heat generated reaches the melting temperature of the copper. There are many factors which will limit the amount of current that can be passed through a wire. These major determining factors are: Conductor Size: The larger the circular mil area, the greater the current carrying capacity. The amount of heat generated should never exceed the maximum temperature rating of the insulation. Ambient Temperature: The higher the ambient temperature, the less heat required to reach the maximum temperature rating of the insulation. Conductor Number: Heat dissipation is lessened as the number of individually insulated conductors, bundled together, is increased. Installation Conductors: Restricting the heat dissipation by installing the conductors in conduit, duct, trays or raceways lessens the current carrying capacity. This restriction can be alleviated somewhat by using proper ventilation methods, forced air cooling, etc. Taking into account all the variables involved, no simple chart of current ratings can be developed and used as the final word when designing a system where amperage ratings can become critical. The chart shows the current required to raise the temperatures of single insulated conductor in free air (30C ambient) to the limits of various insulation types. The following table gives a derating factor to be used when the conductors are bundled. These charts should only be used as a guide when attempting to establish current ratings on conductor and cable.

DERATING FACTORS FOR BUNDLED CONDUCTORS BUNDLE # 2-5 6-15 16-30 DERATING FACTOR (X AMPS) 0.8 0.7 0.5

383

CURRENT CARRYING CAPACITY OF COPPER CONDUCTORS (Measured in Amperes)

INSULATION MATERIALS AT GIVEN TEMPERATURES

POLYETHYLENE NEOPRENE POLYURETHANE POLYVINYLCHLORIDE (SEMI-RIGID) AT 80C 2 3 4 6 8 10 15 19 27 36 47 65 95 125 170 POLYPROPYLENE POLYETHYLENE (HIGH DENSITY) AT 90C 3 4 5 7 9 12 17 22 30 40 55 70 100 135 180 POLYVINYLCHLORIDE PVC (IRRADIATED) NYLON AT 105C 3 4 5 7 10 13 18 24 33 45 58 75 105 145 200 KYNAR POLYETHYLENE (CROSSLINKED) THERMOPLASTIC ELASTOMERS AT 125C 3 5 6 8 11 14 20 26 40 50 70 90 125 170 225 KAPTON TEFLON SILICONE AT 200C 4 6 7 10 13 17 24 32 45 55 75 100 135 180 240

CONDUCTOR SIZE 30 AWG 28 AWG 26 AWG 24 AWG 22 AWG 20 AWG 18 AWG 16 AWG 14 AWG 12 AWG 10 AWG 8 AWG 6 AWG 4 AWG 2 AWG

Single Conductor in Free Air 30C Ambient Temp.

Web Site: www.alphawire.com Email: info@alphawire.com

Toll Free: 1-800-52 ALPHA Telephone: 908-925-8000 Fax: 908-925-6923 Europe/UK Telephone: +44 (0) 1932 772422 Europe/UK Fax: +44 (0) 1932 772433

Das könnte Ihnen auch gefallen

- Midterm Test Wk3Dokument13 SeitenMidterm Test Wk3Phani Kumar71% (24)

- Sizing CircuitsDokument130 SeitenSizing Circuitsinhenyeronerb100% (17)

- Advanced Structural Analysis Prof. Devdas Menon Department of Civil Engineering Indian Institute of Technology, MadrasDokument45 SeitenAdvanced Structural Analysis Prof. Devdas Menon Department of Civil Engineering Indian Institute of Technology, MadrasAshutosh Yadav0% (1)

- CCCof CCDokument1 SeiteCCCof CCDamodharan ChandranNoch keine Bewertungen

- DSP DS1104 Electric Drives - LabDokument2 SeitenDSP DS1104 Electric Drives - LabrocaoNoch keine Bewertungen

- Current Carying Capacity of CopperDokument2 SeitenCurrent Carying Capacity of Coppereng_hosNoch keine Bewertungen

- Capacity of Copper Conductors by MahmudDokument2 SeitenCapacity of Copper Conductors by MahmudMahmudNoch keine Bewertungen

- Capacity of Copper ConductorsDokument2 SeitenCapacity of Copper ConductorsMahmudNoch keine Bewertungen

- Section NexansDokument112 SeitenSection NexansRudanekNoch keine Bewertungen

- pp3-2 WiringDokument17 Seitenpp3-2 WiringMahbubul IslamNoch keine Bewertungen

- 1.2.5 Precision Temperature Sensing Resistor PRC100: Length: 13.5mm (Excl. Leads) Diameter: 5mm RS Stock NumberDokument12 Seiten1.2.5 Precision Temperature Sensing Resistor PRC100: Length: 13.5mm (Excl. Leads) Diameter: 5mm RS Stock NumberEng Bashar MufidNoch keine Bewertungen

- The Basic of Electric Process HeatingDokument8 SeitenThe Basic of Electric Process HeatingAmir AmkaNoch keine Bewertungen

- Electrical Wiring Theory Wiring PracticesDokument2 SeitenElectrical Wiring Theory Wiring Practicesdejanbog66100% (1)

- CableDokument13 SeitenCablejugnudubeyNoch keine Bewertungen

- Measuring Temperature Withthermistors - A Tutorial: National InstrumentsDokument8 SeitenMeasuring Temperature Withthermistors - A Tutorial: National InstrumentsPuerco AstralNoch keine Bewertungen

- NTC Thermistors:: Type CLDokument3 SeitenNTC Thermistors:: Type CLErnesto Moya-AlborNoch keine Bewertungen

- TafirifezaDokument2 SeitenTafirifezazafrikhan875Noch keine Bewertungen

- Temperature Measurements With Thermistors: How-To Guide: 1. Thermistor OverviewDokument3 SeitenTemperature Measurements With Thermistors: How-To Guide: 1. Thermistor OverviewalidabirniaNoch keine Bewertungen

- Capacitors For Power Electronics: Westcode Semiconductors LTD Issue 4 - August 2004Dokument38 SeitenCapacitors For Power Electronics: Westcode Semiconductors LTD Issue 4 - August 2004Sunil GeorgeNoch keine Bewertungen

- Alcan Cable: A Growing TrendDokument3 SeitenAlcan Cable: A Growing TrendCarlos Lino Rojas AgüeroNoch keine Bewertungen

- HV Cable SizingDokument11 SeitenHV Cable SizingPallab MukherjeeNoch keine Bewertungen

- Fuseology: Dual-Element Fuse BenefitsDokument2 SeitenFuseology: Dual-Element Fuse BenefitsdipenkhandhediyaNoch keine Bewertungen

- Wiring Amperage and CapacityiesDokument3 SeitenWiring Amperage and CapacityiesAden RimbeyNoch keine Bewertungen

- 14F3099X00 Ampacity Wire WisdomDokument2 Seiten14F3099X00 Ampacity Wire WisdomAnonymous IvZSKJCNoch keine Bewertungen

- Electronics Cooling SuperDokument33 SeitenElectronics Cooling SuperSaravanagsNoch keine Bewertungen

- Heat Tracing InsulationDokument8 SeitenHeat Tracing InsulationJessie PimentelNoch keine Bewertungen

- 3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFDokument11 Seiten3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFManoj Balla100% (1)

- Conductor Size, General: Table C-2 NEC References For Conductor SizingDokument4 SeitenConductor Size, General: Table C-2 NEC References For Conductor SizingYashwanth NNoch keine Bewertungen

- Sizing of Power Cables For Circuit Breaker Controlled FeedersDokument25 SeitenSizing of Power Cables For Circuit Breaker Controlled Feedersakash_ing7683100% (1)

- Thermister TrainingDokument6 SeitenThermister TrainingkazishahNoch keine Bewertungen

- Duct Heat LossDokument5 SeitenDuct Heat Losser_ranga1523Noch keine Bewertungen

- Sizing of Power Cables For Circuit Breaker Controlled FeedersDokument15 SeitenSizing of Power Cables For Circuit Breaker Controlled FeedersAlmir Mahmutovic100% (1)

- Current Calculation For BusbarsDokument41 SeitenCurrent Calculation For Busbarsraghuveeranush0% (1)

- Busbar Size CalculationDokument5 SeitenBusbar Size Calculationdermasdemo100% (6)

- Heat SinkDokument15 SeitenHeat Sinknitin chauhanNoch keine Bewertungen

- HVT 5 Applications of Insulating Materials, 3Dokument6 SeitenHVT 5 Applications of Insulating Materials, 3sahiiiiNoch keine Bewertungen

- DLMS Spec For Bulk MetersDokument36 SeitenDLMS Spec For Bulk MetersSuresh UmadiNoch keine Bewertungen

- NTC Inrush Current Limiter: Thermometrics ThermistorsDokument4 SeitenNTC Inrush Current Limiter: Thermometrics ThermistorsPham LongNoch keine Bewertungen

- General Guidelines On Installation of ThermocouplesDokument15 SeitenGeneral Guidelines On Installation of ThermocouplesCharu ChhabraNoch keine Bewertungen

- Sizing of Power Cables For Circuit Breaker Controlled Feeders Part 2Dokument8 SeitenSizing of Power Cables For Circuit Breaker Controlled Feeders Part 2bpsrichardNoch keine Bewertungen

- I Need A Formula or Framework To Calculate Heat Dissipation of WiresDokument10 SeitenI Need A Formula or Framework To Calculate Heat Dissipation of WiresnemascribdNoch keine Bewertungen

- RTD Questions and AnswersDokument19 SeitenRTD Questions and AnswersJêmš NavikNoch keine Bewertungen

- RTDDokument4 SeitenRTDCss GaneshNoch keine Bewertungen

- Gestra NRGT 26 1 NRGT 26 1sDokument2 SeitenGestra NRGT 26 1 NRGT 26 1sVoicu StaneseNoch keine Bewertungen

- Electrician - Dictionary Hecho Por RafDokument20 SeitenElectrician - Dictionary Hecho Por RafRaul PeitzNoch keine Bewertungen

- An82f - Understanding and Applying Voltage References - Linear Technology - 1999Dokument12 SeitenAn82f - Understanding and Applying Voltage References - Linear Technology - 1999HahdNoch keine Bewertungen

- Temperature Sensor: AHS 1853 Automotive Sensor & Actuator HairulazmiDokument26 SeitenTemperature Sensor: AHS 1853 Automotive Sensor & Actuator Hairulazmiamirul lexNoch keine Bewertungen

- Introduction To Power AmplifiersDokument22 SeitenIntroduction To Power AmplifiersGaneshVenkatachalamNoch keine Bewertungen

- Salinity Alarm Equipment - 09.8.22Dokument4 SeitenSalinity Alarm Equipment - 09.8.22sridharNoch keine Bewertungen

- 12 Steps For Designing SMPS TransformersDokument11 Seiten12 Steps For Designing SMPS TransformersRnDES1 CMLNoch keine Bewertungen

- ANSI MV TechTopics85 ENDokument2 SeitenANSI MV TechTopics85 ENArunava DasguptaNoch keine Bewertungen

- RF Ceramic Chip Capacitors in High RF Power ApplicationsDokument6 SeitenRF Ceramic Chip Capacitors in High RF Power ApplicationsLuke GomezNoch keine Bewertungen

- Heat Chap15 001Dokument15 SeitenHeat Chap15 001Kerem GönceNoch keine Bewertungen

- Neher Mcgrath1 PDFDokument13 SeitenNeher Mcgrath1 PDFelmodeer9841Noch keine Bewertungen

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsVon EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsBewertung: 3 von 5 Sternen3/5 (2)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsVon EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNoch keine Bewertungen

- Emotional Intelligence Tests: Review of MSCEIT TestDokument8 SeitenEmotional Intelligence Tests: Review of MSCEIT TestPhani KumarNoch keine Bewertungen

- RelayDokument37 SeitenRelayPhani KumarNoch keine Bewertungen

- Understanding: ParanoiaDokument24 SeitenUnderstanding: ParanoiaPhani KumarNoch keine Bewertungen

- Definition of EI PDFDokument13 SeitenDefinition of EI PDFPhani KumarNoch keine Bewertungen

- Grid & Sub StationDokument39 SeitenGrid & Sub StationPhani KumarNoch keine Bewertungen

- 100KW Solar Plant in KLDokument1 Seite100KW Solar Plant in KLPhani KumarNoch keine Bewertungen

- TNERC-Tariff Order For Wind Energy-2012Dokument142 SeitenTNERC-Tariff Order For Wind Energy-2012Phani KumarNoch keine Bewertungen

- TeambuildingDokument11 SeitenTeambuildingPhani Kumar100% (1)

- Training On 5 S'Dokument23 SeitenTraining On 5 S'Phani KumarNoch keine Bewertungen

- Prof. RUCHI DASDokument4 SeitenProf. RUCHI DASGrace HoagnNoch keine Bewertungen

- CHE145 Gomez, TerradoDokument42 SeitenCHE145 Gomez, TerradoRicky JayNoch keine Bewertungen

- "Automatic Paper Punching Machine With Cam MachansmDokument31 Seiten"Automatic Paper Punching Machine With Cam Machansmsourabh palNoch keine Bewertungen

- Physics Chapter 12 Homework SolutionsDokument5 SeitenPhysics Chapter 12 Homework Solutionscffm80at100% (1)

- Dehydration PDFDokument45 SeitenDehydration PDF12mchc07Noch keine Bewertungen

- Solved - Chapter 10 Problem 28P Solution - Classical Mechanics 0th EditionDokument6 SeitenSolved - Chapter 10 Problem 28P Solution - Classical Mechanics 0th EditionRyuNoch keine Bewertungen

- FP 700 EngineeringDokument8 SeitenFP 700 EngineeringCarlos Alberto VargasNoch keine Bewertungen

- DM1 315S6 75,0kWDokument3 SeitenDM1 315S6 75,0kWJohnny Diaz VargasNoch keine Bewertungen

- BCA Circular Guide July 2019 - Guide in Format For Structural Plan SubmissionDokument23 SeitenBCA Circular Guide July 2019 - Guide in Format For Structural Plan Submissionengrfrancis052993Noch keine Bewertungen

- 2015-II. Flow SheetingDokument98 Seiten2015-II. Flow SheetinganisamaulidaaNoch keine Bewertungen

- Waves Brain MapDokument1 SeiteWaves Brain MapBala MuruganNoch keine Bewertungen

- Jet Engine IntegrationDokument8 SeitenJet Engine IntegrationZeeshan100% (1)

- Juan Pablo Physics Paper 1Dokument27 SeitenJuan Pablo Physics Paper 1juanfogedaNoch keine Bewertungen

- Insulation Condition During Transformer Manufacturing: by Study Committee A2Dokument4 SeitenInsulation Condition During Transformer Manufacturing: by Study Committee A2Pruthvi KrishnaNoch keine Bewertungen

- Japanese Porous AsphaltTechnologyDokument51 SeitenJapanese Porous AsphaltTechnologyAbdillah AhmadNoch keine Bewertungen

- Ice Plant FrickDokument16 SeitenIce Plant FrickDharani PathyNoch keine Bewertungen

- Arianespace Payload SeparationDokument9 SeitenArianespace Payload SeparationkirancallsNoch keine Bewertungen

- Transport Anurag Kanpur: TripathiDokument9 SeitenTransport Anurag Kanpur: TripathiPankaj Kumar SainiNoch keine Bewertungen

- 13 149Dokument2 Seiten13 149Frederick Jaradal PetallarNoch keine Bewertungen

- Air Cooled CondensersDokument13 SeitenAir Cooled CondensersSyed ShoebNoch keine Bewertungen

- Prelims Reviewer in VectorDokument2 SeitenPrelims Reviewer in VectorDomsNoch keine Bewertungen

- Astm D6927 22Dokument7 SeitenAstm D6927 22Okello StevenNoch keine Bewertungen

- Case Studies On Nonlinear Control Theory of The Inverted PendulumDokument28 SeitenCase Studies On Nonlinear Control Theory of The Inverted PendulumDragan ErcegNoch keine Bewertungen

- Conceptual Physics SampleDokument6 SeitenConceptual Physics SampleAhmed ElshinawyNoch keine Bewertungen

- MEEN208 - 2018 Tutorials - 2019Dokument65 SeitenMEEN208 - 2018 Tutorials - 2019Abdulmujeeb simpaNoch keine Bewertungen

- Panasonic TX L32C10P 10PS Chassis GLP24Dokument38 SeitenPanasonic TX L32C10P 10PS Chassis GLP24yacosNoch keine Bewertungen

- (DOC) EXACTLY HOW THE UNIVERSE IS CONSTRUCTED - Docx - MIKE EMERY - Academia - EduDokument3 Seiten(DOC) EXACTLY HOW THE UNIVERSE IS CONSTRUCTED - Docx - MIKE EMERY - Academia - EduStellaEstelNoch keine Bewertungen

- Rolleicord V InstructionsDokument56 SeitenRolleicord V InstructionsFranck PowellNoch keine Bewertungen

- Abaqus Tutorial 1Dokument11 SeitenAbaqus Tutorial 1Dg IRfan100% (1)