Beruflich Dokumente

Kultur Dokumente

Chapter 1

Hochgeladen von

seventhhemanthCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chapter 1

Hochgeladen von

seventhhemanthCopyright:

Verfügbare Formate

Chapter 1

So You ve Got Questions ...

CHAPTER 1: So You ve Got Questions

What s in this Manual?

Welcome

Welcome to the Poly3D Tutorial-Based Users Manual. If 3D modeling and numerical modeling is completely new to you, fear not. This manual was written so even the beginner can understand and use Poly3D. For those of you who are numerical modeling gurus, this manual will be an easy jump-start into using Poly3D. This manual includes: Comparison of different numerical models Basics of Poly3D (with tutorials) Viewing Poly3D input and output files with IRIS Explorer*

For More Information

This is not the first usersmanual written for this program. In June 1993, Andrew Lyle Thomas wrote his Master of Science thesis as a usersmanual and explanation of his program Poly3D. In his thesis, he describes all the mathematical assumptions, equations, and calculations that he used to write the code. The manual you are reading now is a simplified version of his usersmanual with tutorials added throughout for ease in learning the program. It is not a substitute for his thesis, but only a starting point for learning Poly3D. Detailed mathematical explanations are left to Thomas. Once a general understanding is gained, the more complicated concepts can be understood by reading his thesis:

Thomas, A.L., 1993, Poly3D: A Three-Dimensional, Polygonal Element, Displacement Discontinuity Boundary Element Computer Program with Applications to Fractures, Faults, and Cavities in the Earth s Crust: M.S. Thesis, Stanford University, CA.

Citing Your Work

In his thesis, Thomas asks that you cite his thesis as shown above if you use Poly3D to produce results for a report or publication. He also asks that you send one reprint of each report or publication to Prof. David D. Pollard at: Rock Fracture Project ATTN: Poly3D Department of Geological & Environmental Sciences Stanford University Stanford, CA 94305-2115 USA

* While this introductory manual was being written, Juliet Crider (Rock Fracture Project, Stanford University) completed a manual for viewing Poly3D input and output files with IRIS Explorer. For the convenience of the user, her manual has been included as Chapter 4 of this manual.

A Tutorial-Based UsersManual for Poly3D

CHAPTER 1: So You ve Got Questions

Whom Should I Call?

This manual contains a lot of information. If you should have a problem, make sure you are contacting the correct person to prevent getting the run-around:

Problems with this Manual:

This manual was written by Kate Griffin, an undergraduate at the University of Wisconsin, as an internship project for her technical communications certificate. The computer copy is now maintained and distributed by the Rock Fracture Project at Stanford University. For problems with this manual, contact: Rock Fracture Project ATTN: Poly3D Tutorial-Based UsersManual Department of Geological & Environmental Sciences Stanford University Stanford, CA 94305-2115 USA or contact Prof. David D. Pollard at:

dpollard@pangea.stanford.edu

Problems with Poly3D:

Poly3D is a C language computer program written by Andrew L. Thomas as part of an M.S. thesis in the Department of Geology at Stanford University. The program will be updated and maintained by the Rock Fracture Project at Stanford University. Rock Fracture Project ATTN: Poly3D Department of Geological & Environmental Sciences Stanford University Stanford, CA 94305-2115 USA or contact Prof. David D. Pollard at:

dpollard@pangea.stanford.edu

Problems with IRIS Explorer:

IRIS Explorer was originally developed by Silicon Graphics, Inc. and was licensed to Numerical Algorithims Group (NAG) in 1992. For questions or concerns regarding this program, contact: IRIS Explorer Center (North America) 1400 Opus Place, Suite 200 Downers Grove, IL 60515-5702 USA Tel: (630) 971-2367 Fax: (630) 971-2346 E-mail: explorer@nag.com Internet: http://www.nag.com/IEC A Tutorial-Based UsersManual for Poly3D 4

CHAPTER 1: So You ve Got Questions

What Are Numerical Modeling Tools?

Generally, analytical solutions to engineering or geology problems are limited to simple geometries. For example, analytical solutions are available to solve for stresses around a hole in a plate. For 3-D non-planar faults, however, there is no analytical aloution available. To solve these more complex problems, mathematicians and engineers have developed computer-aided numerical methods that are more powerful. These methods allow us to solve problems with complicated initial conditions, such as the 3-Dimensional deformation that occurs between two offset faults. Numerical methods can take these initial conditions and use them to predict distortions and derive the stress and strain experienced by a body or its parts. It can also be used to determine natural frequency, mode shapes of components, and buckling loads of structures. There are two main types of numerical methods: differential methods and integral methods. The Finite Element Method (FEM) is a differential method that was developed in the 1950 s and is one of the most common numerical methods in use today. Since its development, other differential methods, including the Boundary Element Method (BEM), have been developed to solve different types of problems. The most important concept to understand when considering numerical methods is that of discretization. Discretization refers to the breaking-up of a field into a finite number of elements. Drawing a free body diagram to solve a problem allows us to determine the stress and strain along the outside edges of the body by summing the forces in each di r ect i on ( Fx=0, Fy=0, Fz=0) and the moment about any point (Mo=0). To find the forces inside the body, you have to break-up that body into smaller free body diagrams. When you discretize a body for use in a modeling program, you create many smaller free body diagrams that are all adjacent. By breaking the body into these smaller parts, the numerical code can determine stresses and strains throughout the entire body.

A Tutorial-Based UsersManual for Poly3D

CHAPTER 1: So You ve Got Questions

Why Should I Use Poly3D?

The main difference between FEM and BEM is that FEM requires the entire body be discretized into elements, while BEM, as suggested by its name, uses only elements on the boundary of the body. This means that if you have a three-dimensional object, FEM will use 3-D elements and BEM will use 2-D elements. If your object is a surface, you will need to create 2-D elements for FEM and 1-D elements for BEM. Why is this important? Less complex elements means a smaller system of simultaneous equations to solve, and ultimately, less computation time. Figure 1 shows the way FEM and BEM discretizes the same body.

Figure 1: The basic difference between the Finite Element Method (FEM) and the Boundary Element Method (BEM) is the way it discretizes its elements. Finite Element Method (FEM) uses nodal points and elements to approximate differential equations. The solution requires continuity and equilibrium across the elements. Boundary Element Method (BEM) uses numerical integration over the boundary (surface) of the object which is subdivided into small segments.

Poly3D is a BEM, so let s look at some of the other characteristics of BEMs: Because BEM reduces every problem by one dimension, it is not appropriate for one-dimensional problems such as 1-D water flow. The BEM can assume boundaries at infinity, but the FEM cannot. In FEM programs, you must create an artificial boundary. This may require special efforts in order to minimize errors due to approximations. Because it only discretizes the boundaries, errors due to discretization and numerical approximations arise only on the boundaries. Because no approximations were made on interior areas, you can obtain values of variables at any specific interior point with very high resolution. It is necessary to specify only the bounding conditions, so it takes less time to prepare the data for input. With all these advantages, BEM is well suited for modeling fractures (joints, faults, bedding planes, etc.), which, by their nature, are two-dimensional in a three-dimensional body. A Tutorial-Based UsersManual for Poly3D 6

CHAPTER 1: So You ve Got Questions Numerical Modeling of Fractures

Previously, I said that the BEM is well-suited for modeling fractures. Let s look at an example to see why. Suppose you are looking at a vertical cross-section of the earth that crosses a fault as shown in Figure 2. With a BEM program, you can use an infinite boundary, so you only have to discretize the fault. If you are modeling fault propagation, you need only to add an element to the tip of the fault.

Figure 2: Modeling a fault with BEM, you can specify infinite boundaries and discretize only the fault. As the fault grows, you only need to add an element to the end of the fault.

Initial Fault

Growing Fault

With FEM, you have to define an artificial boundary and discretize the entire area inside this boundary. As the fault grows, the area will have to be rediscretized.

If you are working with the FEM, you have to define an artificial boundary which could reduce the accuracy of your results. You also need to discretize the entire area inside your artificial boundary, which might be time consuming for you or the computer. If you are modeling fault propagation, you need to re-discretize the entire area as the fault grows.

A Tutorial-Based UsersManual for Poly3D

CHAPTER 1: So You ve Got Questions

The polygonal elements in Poly3D are also well-suited for modeling complex surfaces with curving boundaries because: s Fault surfaces which change in both strike and dip can be meshed without creating gaps.

s Polygonal elements easily replicate the irregular boundary of a hydraulic fracture.

s A spherical void can be modeled by assembling hexagonal and pentagonal elements in the manner of a soccer ball.

These kinds of problems would be difficult or impossible to attempt using rectangular elements alone. For this reason, Poly3D represents a significant improvement over exiting rectangular element boundary element codes such as Dis3D.

A Tutorial-Based UsersManual for Poly3D

CHAPTER 1: So You ve Got Questions

What BEM Programs are Available?

So if BEM is so great, why wouldn t you use it all the time? Finite Element Modeling has been around for much longer than Boundary Element Modeling, so current FEM codes can incorporate material differences and non-linear rheologies. It is possible to incorporate these characterisitics into BEM, but no BEM programs have been written with this capability yet. The BEM codes that have been written are variable in their capabilities. Some of the 2-D and 3-D codes allow you to incorporate infinite boundaries and frictional elements, some can model fault propagation, and others vary in the shape of the faults. A few of the BEM codes that have been written are listed in Table 1 with their current capabilities. Capabilities of BEM Codes

Dimensions Infinite Boundaries Fracture Propagation Frictional Elements Fracture Shape

Table 2: BEM codes have different capabilities including incorporating infinite boundaries, fault propagation, friction, and fault shape.

Frac2D Fric2D Dis3D

2-D 2-D 3-D 3-D

X X X

X X

Rectangular Polygonal

Poly3D

Thomas, A.L. & Pollard, D.D. (1993). The geometry of echelon fractures in rock: implications from laboratory and numerical experiments. Journal of Structural Geology 15, 323-334. Cooke, M. (1996). Frictional slip and fractures associated with faults and folds. Unpublished PhD thesis, Stanford University. (Includes opening-mode fracture propagation and opening-mode fracture initiation along frictional interfaces away from the tips). Erickson, L.L. (1986). A three-dimensional dislocation program with application so faulting in the earth. Unpublished M.S. thesis, Stanford University.

What Can t Poly3D Do?

Currently, Poly3D cannot model: fracture propagation frictional slip along interfaces elements with more than 40 sides material differences or layered materials non-linear rheologies variable remote boundary conditions Perhaps future generations of BEM will incorporate these capabilities. A Tutorial-Based UsersManual for Poly3D 9

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Case Study 1Dokument2 SeitenCase Study 1asad ee100% (1)

- FBL ManualDokument12 SeitenFBL Manualaurumstar2000Noch keine Bewertungen

- Actvty Transact On Descr PT On I I I I IDokument1 SeiteActvty Transact On Descr PT On I I I I IseventhhemanthNoch keine Bewertungen

- TASD41Dokument124 SeitenTASD41scorpion.0411100% (2)

- Senior Design Fixture AnalysisDokument19 SeitenSenior Design Fixture AnalysisseventhhemanthNoch keine Bewertungen

- Student Projects SldwrksDokument6 SeitenStudent Projects SldwrksPrithvi Harve100% (1)

- Lan Gender Fer Honors PresentationDokument33 SeitenLan Gender Fer Honors PresentationseventhhemanthNoch keine Bewertungen

- Nascar Analysis Sp03Dokument27 SeitenNascar Analysis Sp03seventhhemanthNoch keine Bewertungen

- PPME450BMeyer JSimpsonDokument28 SeitenPPME450BMeyer JSimpsonseventhhemanthNoch keine Bewertungen

- Drafting Projects: Estimated Time To Complete This Course: 1 - 2 HoursDokument33 SeitenDrafting Projects: Estimated Time To Complete This Course: 1 - 2 HoursseventhhemanthNoch keine Bewertungen

- Bishop Steering ProjectDokument13 SeitenBishop Steering ProjectseventhhemanthNoch keine Bewertungen

- 40H Project Best Access SystemsDokument12 Seiten40H Project Best Access SystemsseventhhemanthNoch keine Bewertungen

- Wing Design Level3Dokument2 SeitenWing Design Level3seventhhemanthNoch keine Bewertungen

- Moon Buggy Rear SuspensionDokument23 SeitenMoon Buggy Rear SuspensionseventhhemanthNoch keine Bewertungen

- WCSDokument15 SeitenWCSseventhhemanthNoch keine Bewertungen

- Muffler Deformation Due To Thermal LoadsDokument15 SeitenMuffler Deformation Due To Thermal LoadsseventhhemanthNoch keine Bewertungen

- Assembly Projects: Locating The PartsDokument18 SeitenAssembly Projects: Locating The PartsseventhhemanthNoch keine Bewertungen

- c01 Proe WF 3 EvalDokument44 Seitenc01 Proe WF 3 EvalseventhhemanthNoch keine Bewertungen

- IUPUI Moonbuggy Design and Race ProjectDokument18 SeitenIUPUI Moonbuggy Design and Race ProjectseventhhemanthNoch keine Bewertungen

- GB Programme Chart: A B C D J IDokument2 SeitenGB Programme Chart: A B C D J IRyan MeltonNoch keine Bewertungen

- Sample Deed of DonationDokument2 SeitenSample Deed of DonationMenchie Ann Sabandal Salinas100% (1)

- Vol 17 No 3 and No 4 Fort Laramie and The Sioux War of 1876Dokument19 SeitenVol 17 No 3 and No 4 Fort Laramie and The Sioux War of 1876Лазар СрећковићNoch keine Bewertungen

- Taxicab Operators V BOTDokument2 SeitenTaxicab Operators V BOTHazel P.Noch keine Bewertungen

- BF2207 Exercise 6 - Dorchester LimitedDokument2 SeitenBF2207 Exercise 6 - Dorchester LimitedEvelyn TeoNoch keine Bewertungen

- RMU With Eco-Efficient Gas Mixture-Evaluation After Three Years of Field ExperienceDokument5 SeitenRMU With Eco-Efficient Gas Mixture-Evaluation After Three Years of Field ExperienceZineddine BENOUADAHNoch keine Bewertungen

- Notes in Judicial AffidavitDokument11 SeitenNotes in Judicial AffidavitguibonganNoch keine Bewertungen

- Lean ManufacturingDokument61 SeitenLean ManufacturingWasiYamanChoudhuryNoch keine Bewertungen

- Presentation - 02 Reliability in Computer SystemsDokument24 SeitenPresentation - 02 Reliability in Computer Systemsvictorwu.ukNoch keine Bewertungen

- Micro Economics SummaryDokument62 SeitenMicro Economics SummaryEVS PRADEEPNoch keine Bewertungen

- Claims Reserving With R: Chainladder-0.2.10 Package VignetteDokument60 SeitenClaims Reserving With R: Chainladder-0.2.10 Package Vignetteenrique gonzalez duranNoch keine Bewertungen

- Questionnaire On EthnocentrismDokument14 SeitenQuestionnaire On Ethnocentrismkalpa vrikshaNoch keine Bewertungen

- International Advertising: Definition of International MarketingDokument2 SeitenInternational Advertising: Definition of International MarketingAfad KhanNoch keine Bewertungen

- Trail Beaver Valley Edition of May 29, 2012 PennywiseDokument56 SeitenTrail Beaver Valley Edition of May 29, 2012 PennywisePennywise PublishingNoch keine Bewertungen

- GSP Product Info 092711Dokument19 SeitenGSP Product Info 092711Joao SilvaNoch keine Bewertungen

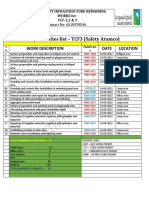

- Daily Activities List - TCF3 (Safety Aramco) : Work Description Date LocationDokument2 SeitenDaily Activities List - TCF3 (Safety Aramco) : Work Description Date LocationSheri DiĺlNoch keine Bewertungen

- HP Training Diagnostics 75 Usage and AdministrationDokument2 SeitenHP Training Diagnostics 75 Usage and AdministrationraviskskskNoch keine Bewertungen

- Quick Commerce:: The Real Last MileDokument9 SeitenQuick Commerce:: The Real Last MileChhavi KhandujaNoch keine Bewertungen

- Pulido VsDokument14 SeitenPulido Vsroyel arabejoNoch keine Bewertungen

- Sustainability and Economy - A Paradigm For Managing Entrepreneurship Towards Sustainable DevelopmentFDokument21 SeitenSustainability and Economy - A Paradigm For Managing Entrepreneurship Towards Sustainable DevelopmentFArmando Tarupí MontenegroNoch keine Bewertungen

- Etpm Mód 3 Assignment 2.1 Grammar and Use of English SkillsDokument3 SeitenEtpm Mód 3 Assignment 2.1 Grammar and Use of English SkillsLourdes LimaNoch keine Bewertungen

- Lezione Argiolu - Master Roma3!3!12-2010 - Test Di Application SecurityDokument26 SeitenLezione Argiolu - Master Roma3!3!12-2010 - Test Di Application SecurityWB_YeatsNoch keine Bewertungen

- Best of SEO#1 SEO Training & Content Marketing Course 2022Dokument2 SeitenBest of SEO#1 SEO Training & Content Marketing Course 2022Oscar MascarenoNoch keine Bewertungen

- Sample Lesson Plan Baking Tools and EquipmentDokument3 SeitenSample Lesson Plan Baking Tools and EquipmentJoenel PabloNoch keine Bewertungen

- NAA CHALDA LYRICS - Amar Sehmbi, Gurlez AkhtarDokument1 SeiteNAA CHALDA LYRICS - Amar Sehmbi, Gurlez Akhtarannpurna pathakNoch keine Bewertungen

- SIConitDokument2 SeitenSIConitJosueNoch keine Bewertungen

- Aling MODEDokument29 SeitenAling MODEBojan PetronijevicNoch keine Bewertungen